Abstract

Paper is focused on the assessment of two alternatives of family house from environmental performance. Environmental impact categories such as Global warming potential (GWP), Acidification potential (AP) and Eutrophication potential (EP) expressed as CO2eq, SO2eq and PO43−eq using the LCA assessment method are presented. Alternative solutions of building materials are also compared from phase shift of thermal oscillation. Results show that natural building materials are characterized by lower environmental impacts expressed as equivalent emissions of CO2 (6%), SO2 (24%) and PO43− (44%). The wood fiber board can store nearly 24 times more heat than the mineral wool. The wood fiber boards have a phase shift of thermal oscillation of 7–13 h, while other insulation materials only about 3–4 h.

1. Introduction

Life Cycle Assessment (LCA) as a methodology focused on evaluating the total environmental impacts should take into account all life stages of a building: planning, design, construction, use and demolition. Study [1] aims to demonstrate the feasibility of using LCA to select facilities in the construction sector, which minimize environmental and energy impacts. To facilitate the understanding of the proposed methodology, a comparative LCA was performed. Two approaches were selected to perform the comparative LCA of different material compositions for a double sheet ceramic facade. A simplified analysis was carried out in which three different compositions are studied for this facade, with identic thermal performance, proposing a totally objective comparative study and disregarding impacts associated to the use stage of the enclosures, conditioned by different factors. A complete study was aimed to demonstrate that LCA methodology application in the construction sector involves substantial improvement in energy efficiency, when compared with current existing national energy efficiency certificates. The main conclusion of the simplified LCA study is that it allows analyzing the environmental impacts and primary energy consumption on manufacturing, construction and final disposition stages of materials used in construction. The simplified LCA study allows identifying which insulating material type exhibits a better environmental and energy behavior. This study reveals that to obtain improvements in terms of energy efficiency in the construction sector, it is very important to associate energy certification procedures with LCA application. According to a study [2] a prefabricated building module causes the emission of 1.5 t of CO2eq/m2 and consumes 29.2 GJ/m2 of primary energy during its life cycle. The building achieves the Net Zero Energy Building target even if it has relevant environmental impacts in the materials production stage (72%) on average of the total impacts while the use stage reaches the 23% on average). The construction and the end-of-life stages give a marginal contribution to the total impacts, since they account for the 1% and the 3%, respectively.

2. Design of Assessed Family House

The family house assessed in this paper with a built-up area of 145 m2 is placed on a slightly sloppy terrain. It is designed as a self-standing two-storey building designed as a five-person household. In terms of the existing plot, it is oriented to the southwest side. The family house has a compact layout with minimized communication spaces. On the ground floor of the building there is bedroom, bathroom, living room with kitchen, staircase, storage room, technical room, entrance hall with wardrobe which separates a studio apartment—a workplace occasionally serving as a guest room with accessories (second bathroom and wardrobe) [3,4]. The second floor is just a childrens room. The architecture of the building is given by the design itself, by combining a vegetation roof with a flat surface and a surface finish.

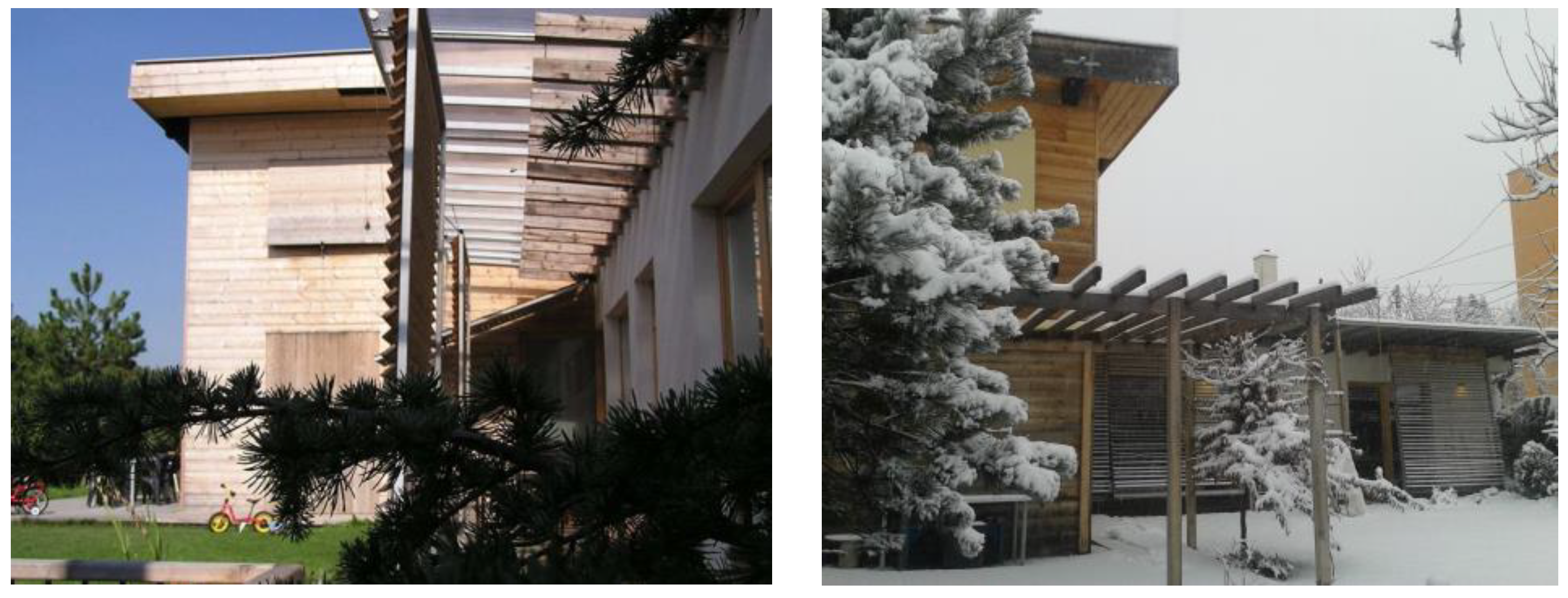

This family house won second place in the 2012 International Building Energy Efficiency Competition (BEFFA) [5]. Photos (Figure 1) were provided by owners of the family house.

Figure 1.

Family house in Rozhanovce.

Material Compositions

Structurally, it is a wooden structure with a reinforced concrete baffle wall and a bonded wood-concrete ceiling, based on plain concrete strips. The perimeter walls are made up of a supporting wooden frame, filled with thermal insulation, which is covered with wooden tiling from the outside and with plasterboards from the interior. The roofing is made by a combination of flat and vegetation roof, smoothly merging with the surrounding terrain. Ground floor consists of accumulation layer from fine sand with thickness of 300 mm.

Windows and glazed walls are wooden with triple-glass insulation [3]. All thermal insulation in the family house is made of mineral wool and EPS polystyrene. These thermal insulations are replaced in a second alternative. They were proposed from natural materials such as cellulose and fiberboard.

The heating and hot water preparation is provided by heat recovery ventilation backed up by solar panels and wood-burning stove.

Table 1, Table 2 and Table 3 summarize basic and thermo-physical parameters of building structures: thickness d [m], thermal conductivity λ [W/m·K], thermal resistance R [m2·K/W], heat transfer coefficient U [W/m2.K], specific heat capacity c [J/kg·K]. Compositions below are listed from the interior.

Table 1.

Roofs, Alternative 1—R = 9.28 m2·K/W, U = 0.11 W/m2·K, Alternative 2—R = 9.2 m2·K/W, U = 0.11 W/m2·K.

Table 2.

Waals, Alternative 1—R = 10.42 m2·K/W, U = 0.09 W/m2·K, Alternative 2—R = 10.52 m2·K/W, U = 0.09 W/m2·K.

Table 3.

Floors, Alternative 1—R = 8.65 m2·K/W, U = 0.11 W/m2·K, Alternative 2—R = 8.5 m2·K/W, U = 0.11 W/m2·K.

3. Experimental Method

The assessment of two alternatives of family house is focused on the comparison of various thermal insulations of building envelope. Environmental performance of material solutions is calculated by using the LCA assessment method according to the recommendations of EN 15804 and EN 15978. The LCA framework is interpreted in ISO series 14040-44. Emissions of CO2 (GWP), SO2 (AP) and PO43−eq represent the equivalent emissions within the LCA “cradle to grave” boundaries. This analysis investigates the role of applied green technologies for impact categories such as: global warming potential (GWP), acidification potential (AP) and eutrophication potential (EP) within “Cradle to Grave” boundary by using the LCA method. The functional unit is considered to be one square meter of gross floor area for a period of the life cycle (1 m2). Reference study period is considered to be 60 years. For the LCA analysis was used software eToolLCD which uses third party background processes aggregated as midpoint indicators and stored in a number of libraries within the software which are coupled with algorithms and user inputs to output the environmental impact assessment [6].

4. Results

The described method was used to determine the environmental impacts for family house alternatives (Table 4).

Table 4.

Characteristic impacts on m2 of the total floor area of a family house.

Table 4 shows that alternative 2 using natural building materials for building envelope is characterized by lower environmental impacts expressed for equivalent emissions of CO2 (6%), SO2 (24%) and PO43− (44%). Moreover the natural building materials are characterized by better thermo-physical properties. There are considerable differences in phase shift of thermal oscillation Ψ [h]. The wood fiber board can store nearly 24 times more heat than the mineral wool. The wood fiber boards have a phase shift of thermal oscillation of 7–13 h, while other insulation materials only about 3–4 h [7]. In the case of cooling the house, this is not necessary, which contributes to the further reduction of environmental impacts.

5. Conclusions

Traditionally the emissions embodied in construction materials have not been considered of high importance, but they are actually becoming crucial due to the short time—frame in which the emissions should be reduce. Wooden materials seem to have considerably lower impacts on the environment as aerated concrete blocks or metallic and plastic materials (although their usage cannot be avoided completely). If we are thinking about the future direction of construction, we must act responsibly.

Acknowledgments

This paper was financially supported by the Slovak Grants No. 1/0307/16 and 1/0648/17. Authors would like to thank to Ing. arch. Pavol Škombár and Ing. arch. Jana Račková for providing family house’s project documentation that has been used during the elaboration of this paper.

References

- Garcia-Ceballos, L.; de Andres-Díaz, J.R.; Contreras-Lopez, M.A. Life cycle study of different constructive solutions for building enclosures. Sci. Total Environ. 2018, 626, 1167–1174. [Google Scholar] [CrossRef] [PubMed]

- Tumminia, G.; Guarino, F.; Longo, S.; Ferraro, M.; Cellura, M. Life cycle energy performances and environmental impacts of a prefabricated building module. Renew. Sustain. Energy Rev. 2018, 92, 272–283. [Google Scholar] [CrossRef]

- Skombar, P.; Rackova, J. Family House in Rozhanove. Available online: http://www.zelenarchitektura.sk (accessed on 1 July 2012).

- Passive House. Available online: http://www.pasivnydom.tvojdom.eu/ (accessed on 2 December 2011).

- TVOJ DOM.EU: TVOJDOM je teraz aj ZDRAVYDOM.SK na Východe. Available online: http://www.tvojdom.eu/ (accessed on 1 July 2012).

- eTool. eToolLCD Software. Available online: https://etoolglobal.com/ (accessed on 1 January 2018).

- Vilcekova, S.; Culakova, M.; Kridlova Burdova, E.; Katunska, J. Energy and Environmental Evaluation of Non-Transparent Constructions of Building Envelope for Wooden Houses. Energies 2015, 8, 11047–11075. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).