Shape-Changing Carbon Fiber Composite with Tunable Frequency and Damping †

Abstract

:1. Introduction

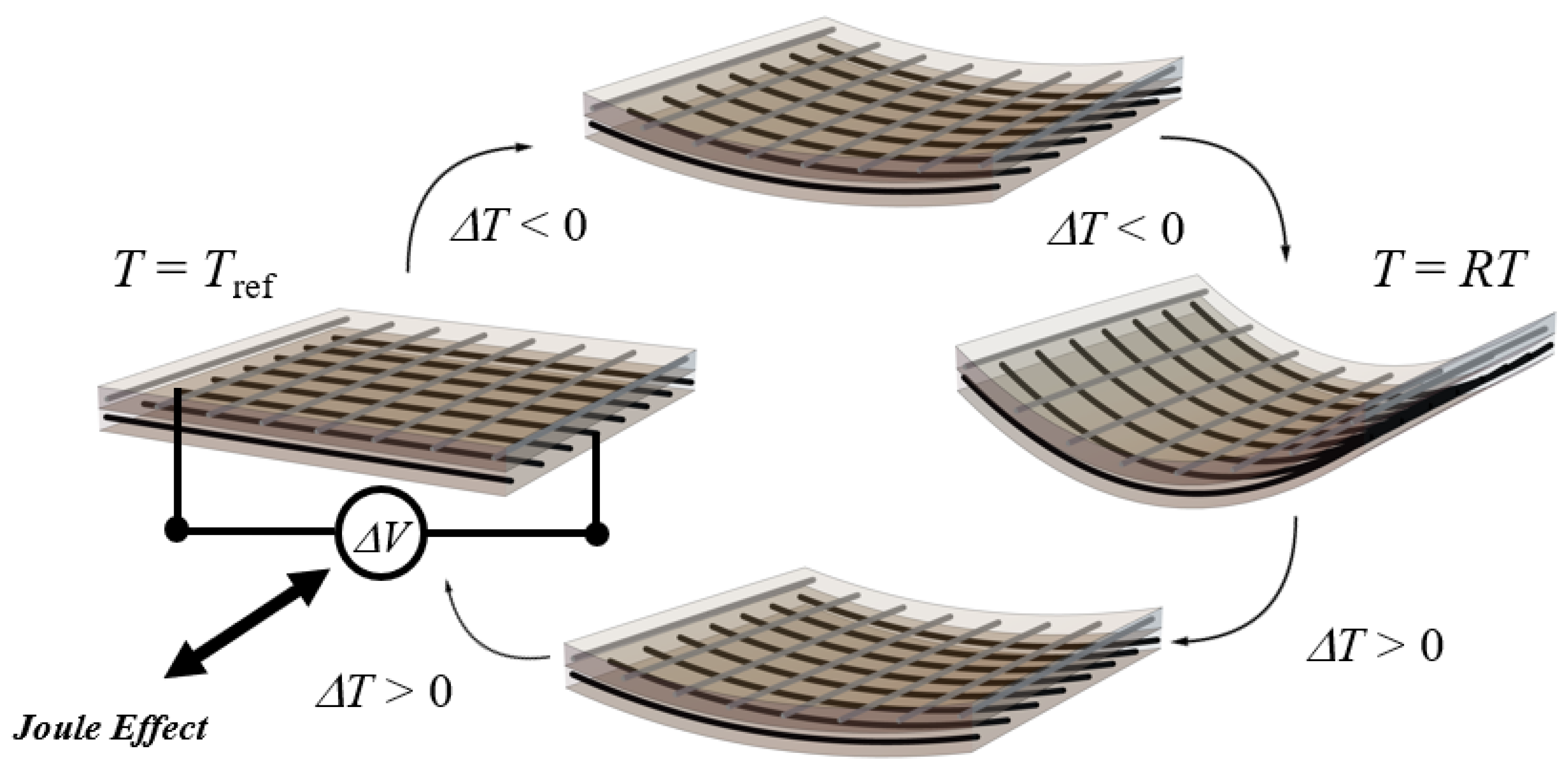

2. Material Concept

3. Results and Discussion

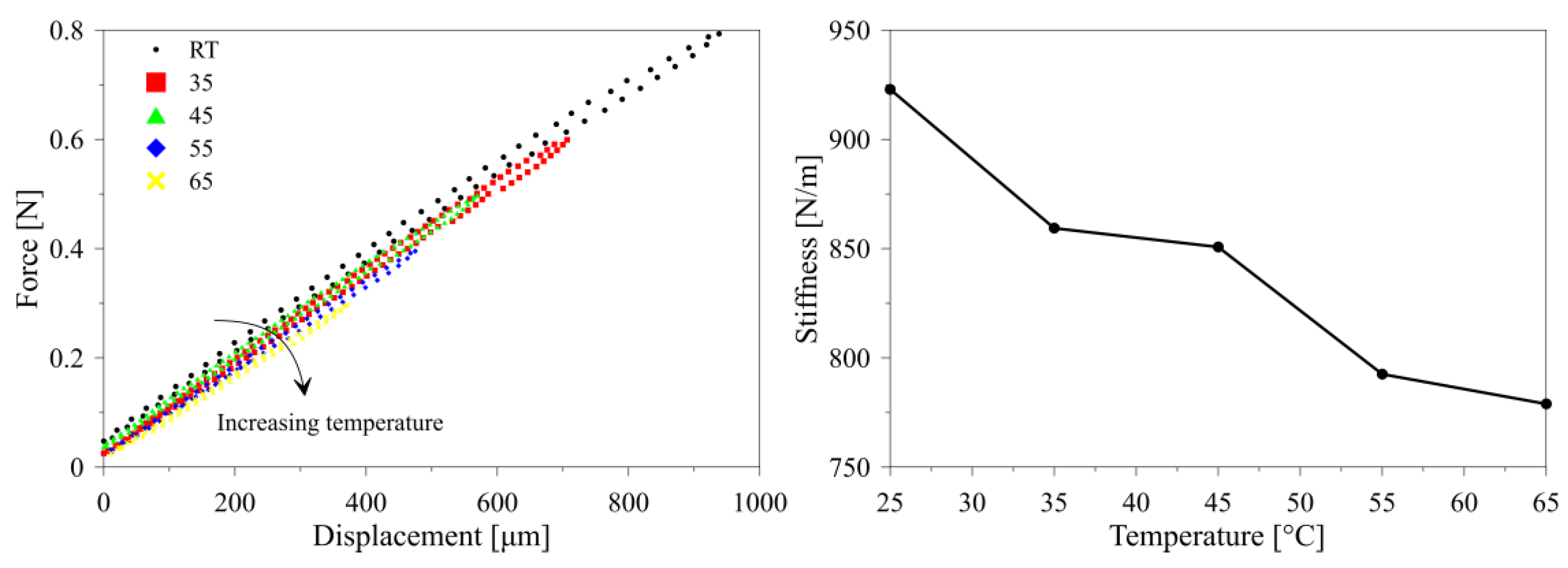

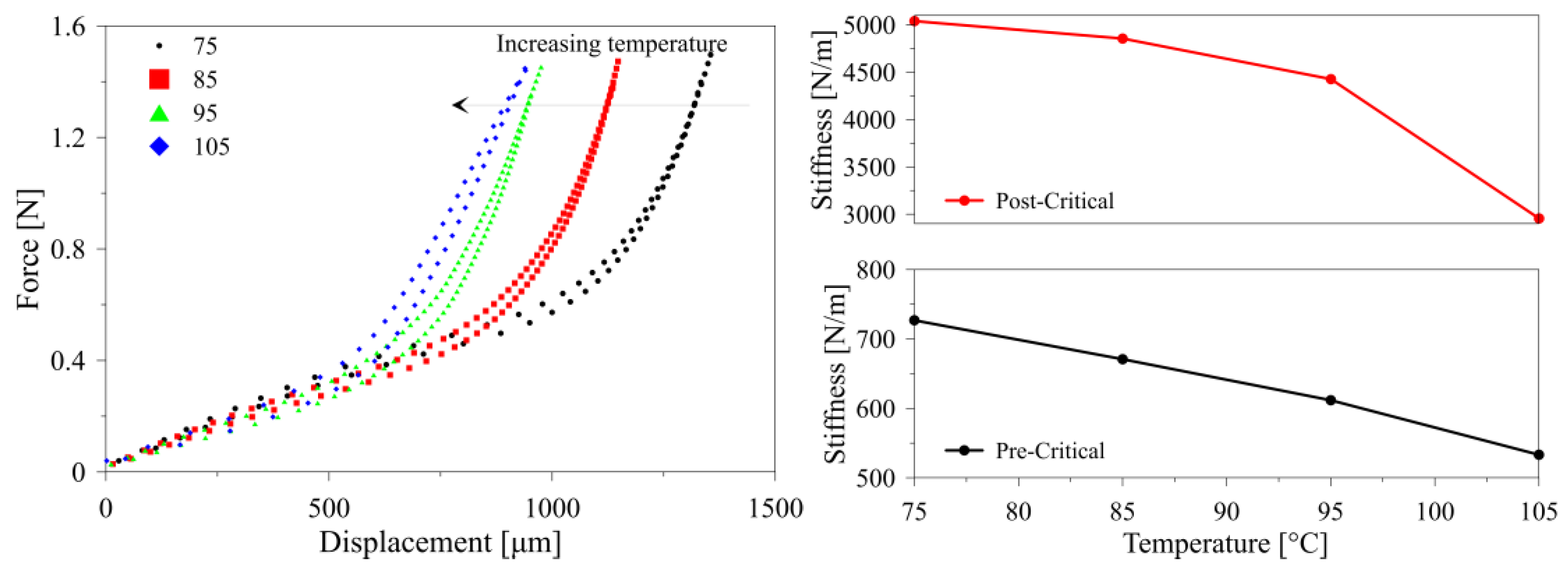

3.1. Structural Characterization

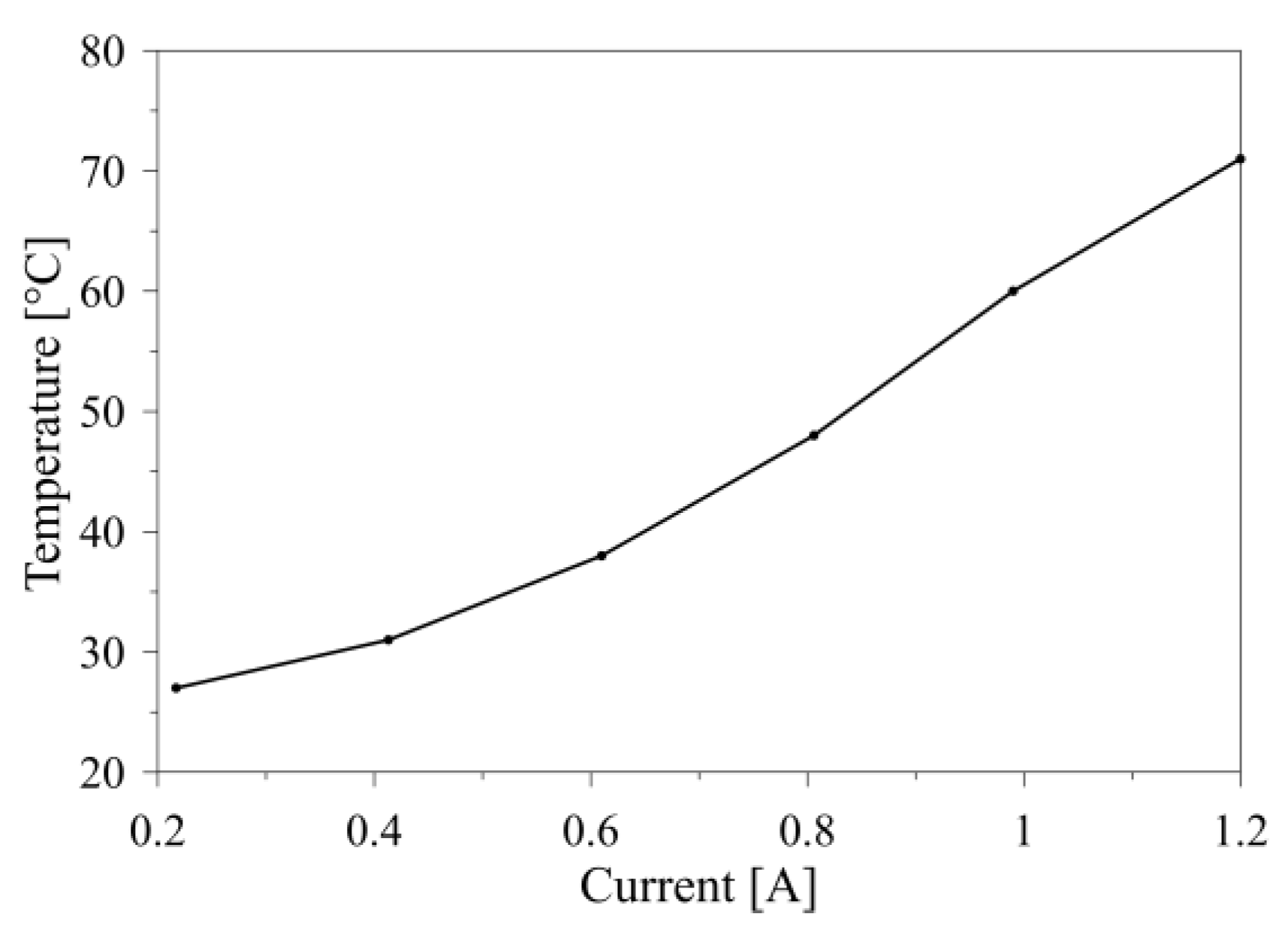

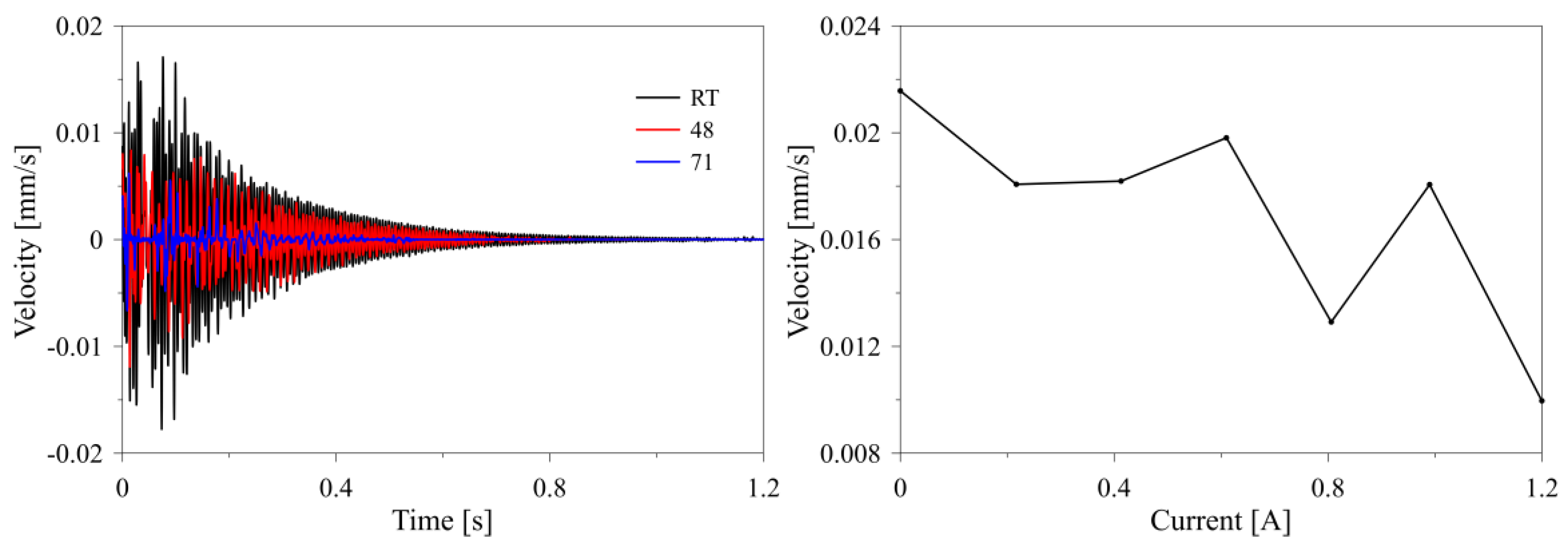

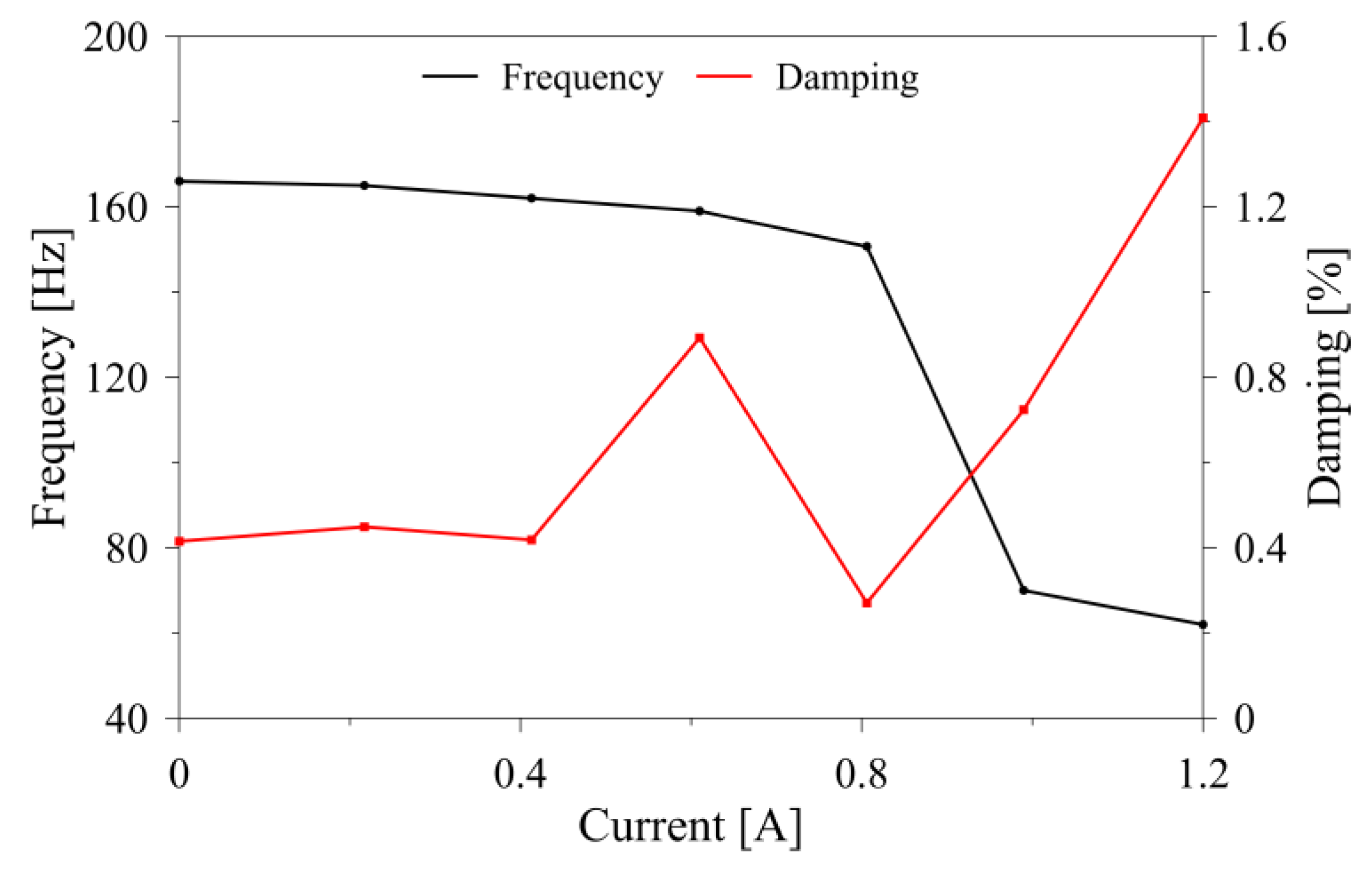

3.2. Snap-Through Oscillations

4. Conclusions

Author Contributions

Acknowledgments

References

- Tupper, M.; Munshi, N.; Beavers, F.; Gall, K.; Mikuls, M. Developments in elastic memory composite materials for spacecraft deployable structures. IEEE Proc. 2001, 5, 2541–2547. [Google Scholar]

- Hufenbach, W.; Gude, M.; Kroll, L. Design of multistable composite for application in adaptive structures. Compos. Sci. Technol. 2002, 62, 2201–2207. [Google Scholar] [CrossRef]

- Sickinger, S.; Herbeck, L.; Breitbach, E. Structural engineering on deployable CFRP booms for a solar propelled sailcraft. Acta Astronaut. 2006, 58, 185–196. [Google Scholar] [CrossRef]

- Thill, C.; Etches, J.; Bond, I.; Potter, K.; Weaver, P. Morphing skins. Aeronaut. J. 2008, 3216, 1–23. [Google Scholar] [CrossRef]

- Hyer, M.W. Calculations of the Room-Temperature Shapes of Unsymmetric Laminates; Tech. Rep.; Virginia Polytechnic Institute and State University: Blacksburg, VA, USA, 1981. [Google Scholar]

- Hyer, M.W. Stress Analysis of Fiber-Reinforced Composite Materials; McGraw Hill: New York, NY, USA, 1998. [Google Scholar]

- Jones, R.M. Mechanics of Composite Materials; Taylor & Francis: Milton Park, UK, 1999. [Google Scholar]

- Hamamoto, A.; Hyer, M.W. Nonlinear temperature-curvature relationships for unsymmetric graphite-epoxy laminates. Int. J. Solids Struct. 1987, 23, 919–935. [Google Scholar]

- Schlecht, M.; Schulte, K.; Hyer, M.W. Advanced calculations of the room-temperature shapes of thin unsymmetric composite laminates. Compos. Struct. 1995, 32, 627–633. [Google Scholar] [CrossRef]

- Gigliotti, M.; Wisnom, M.R.; Potter, K.D. Loss of bifurcation and multiple shapes of thin [0/90] unsymmetric composite plates subject to thermal stress. Compos. Sci. Technol. 2003, 64, 109–128. [Google Scholar] [CrossRef]

- Dano, M.L.; Hyer, M.W. Thermally-induced deformation behavior of unsymmetric laminates. Int. J. Solids Struct. 1998, 35, 2101–2120. [Google Scholar] [CrossRef]

- Hufenbach, W.; Gude, M. Analyisis and optimisation of multistable composite under residual stresses. Compos. Struct. 2002, 55, 319–327. [Google Scholar] [CrossRef]

- Gigliotti, M.; Wisnom, M.R.; Potter, K.D. Development of curvature during the cure of as4/8552 [0/90] unsymmetric composite plates. Compos. Sci. Technol. 2003, 63, 187–197. [Google Scholar] [CrossRef]

- Wisnom, M.R.; Gigliotti, M.; Ersoy, N.; Campbell, M.; Potter, K.D. Mechanisms generating residual stresses and distortion during manufacture of polymer matrix composite structures. Compos. Part A 2006, 37, 522–529. [Google Scholar] [CrossRef]

- Giddings, P.F.; Bowen, C.R.; Salo, A.I.T.; Kim, H.A.; Ive, A. Bistable composite laminates: Effects of laminate composition on cured shape and response to thermal load. Compos. Struct. 2010, 92, 2220–2225. [Google Scholar] [CrossRef]

- Betts, D.N.; Salo, A.I.T.; Bowen, C.R.; Kim, H.A. Characterization and modelling of the cured shapes of arbitrary layup bistable composite laminates. Compos. Struct. 2010, 92, 1694–1700. [Google Scholar] [CrossRef]

- Eckstein, E.; Pirrera, A.; Weaver, P.M. Morphing high-temperature composite plates utilizing thermal gradients. Compos. Struct. 2013, 100, 363–372. [Google Scholar] [CrossRef]

- Eckstein, E.; Pirrera, A.; Weaver, P.M. Multimode morphing using initially curved composite plates. Compos. Struct. 2014, 109, 240–245. [Google Scholar] [CrossRef]

- Zhang, Z.; Ye, G.; Wu, H.; Wu, H.; Chen, D.; Chai, G. Thermal effect and active control on bistable behaviour of anti-symmetric composite shells with temperature-dependent properties. Compos. Struct. 2015, 124, 263–271. [Google Scholar] [CrossRef]

- Tridech, C.; Maples, H.A.; Robinson, P.; Bismark, A. High performance carbon fibre reinforced epoxy composites with controllable stiffness. Compos. Sci. Technol. 2014, 105, 134–143. [Google Scholar]

- Tridech, C.; Maples, H.A.; Robinson, P.; Bismark, A. High performance composites with active stiffness control. Appl. Mater. Interfaces 2013, 5, 9111–9119. [Google Scholar] [CrossRef]

- Dano, M.L.; Hyer, M.W. Snap-through of unsymmetric fiber-reinforced composite laminates. Int. J. Solids Struct. 2002, 39, 175–198. [Google Scholar] [CrossRef]

- Cantera, M.A.; Romera, J.M.; Adarraga, I.; Mujika, F. Modelling and testing of the snap-through process of bi-stable cross-ply composites. Compos. Struct. 2015, 120, 41–52. [Google Scholar] [CrossRef]

- Dano, M.L.; Hyer, M.W. SMA-induced snap-through of unsymmetric fiber-reinforced composite laminates. Int. J. Solids Struct. 2003, 40, 5949–5972. [Google Scholar] [CrossRef]

- Schultz, M.R.; Hyer, M.W.; Williams, R.B.; Wilkie, W.K.; Inman, D.J. Snap-through of unsymmetric laminates using piezocomposite actuators. Compos. Sci. Technol. 2006, 66, 2442–2448. [Google Scholar] [CrossRef]

- Giddings, P.F.; Kim, H.A.; Salo, A.I.T.; Bowen, C.R. Modelling of piezoelectrically actuated bistable composites. Mater. Lett. 2011, 65, 1261–1263. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Casalotti, A.; Lanzara, G. Shape-Changing Carbon Fiber Composite with Tunable Frequency and Damping. Proceedings 2018, 2, 465. https://doi.org/10.3390/ICEM18-05382

Casalotti A, Lanzara G. Shape-Changing Carbon Fiber Composite with Tunable Frequency and Damping. Proceedings. 2018; 2(8):465. https://doi.org/10.3390/ICEM18-05382

Chicago/Turabian StyleCasalotti, Arnaldo, and Giulia Lanzara. 2018. "Shape-Changing Carbon Fiber Composite with Tunable Frequency and Damping" Proceedings 2, no. 8: 465. https://doi.org/10.3390/ICEM18-05382

APA StyleCasalotti, A., & Lanzara, G. (2018). Shape-Changing Carbon Fiber Composite with Tunable Frequency and Damping. Proceedings, 2(8), 465. https://doi.org/10.3390/ICEM18-05382