In-Situ SEM Deformation Testing of Ni-Based Superalloy Heated by the Joule Heat †

Abstract

:1. Introduction

2. Materials and Method

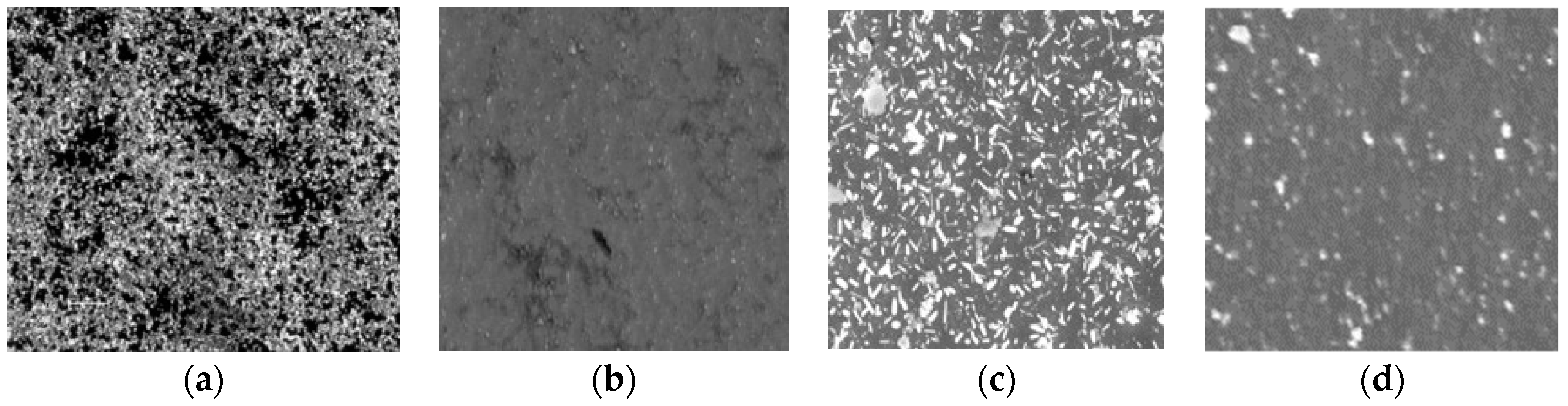

2.2. Materials

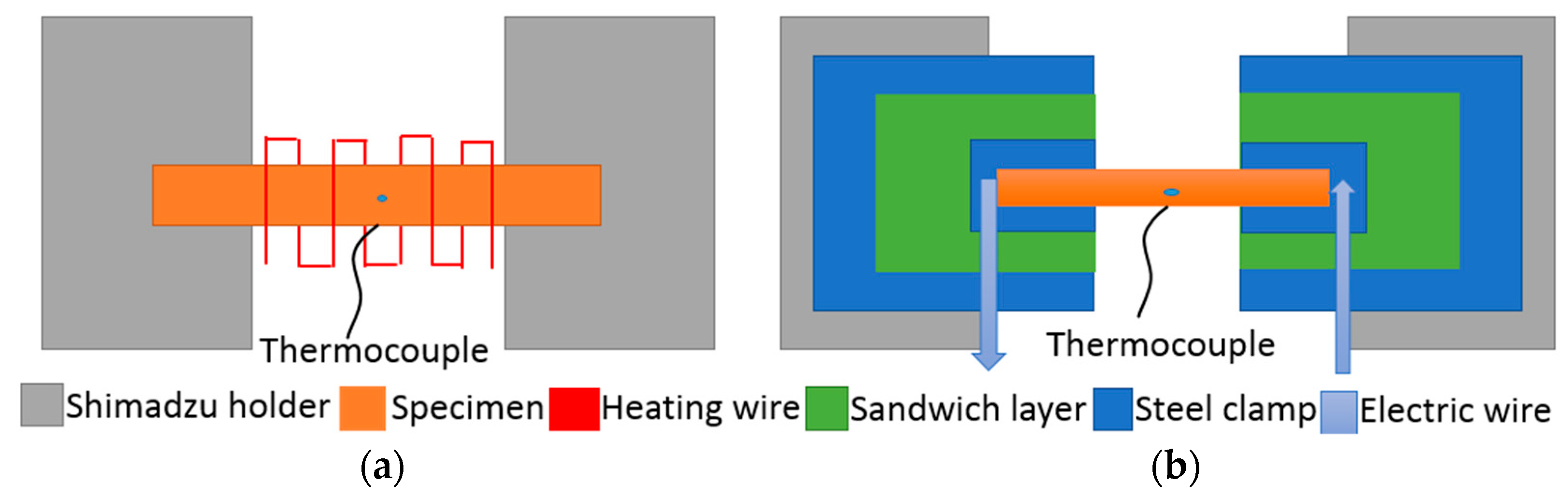

2.3. Resistance Heating

3. Results and Disccusion

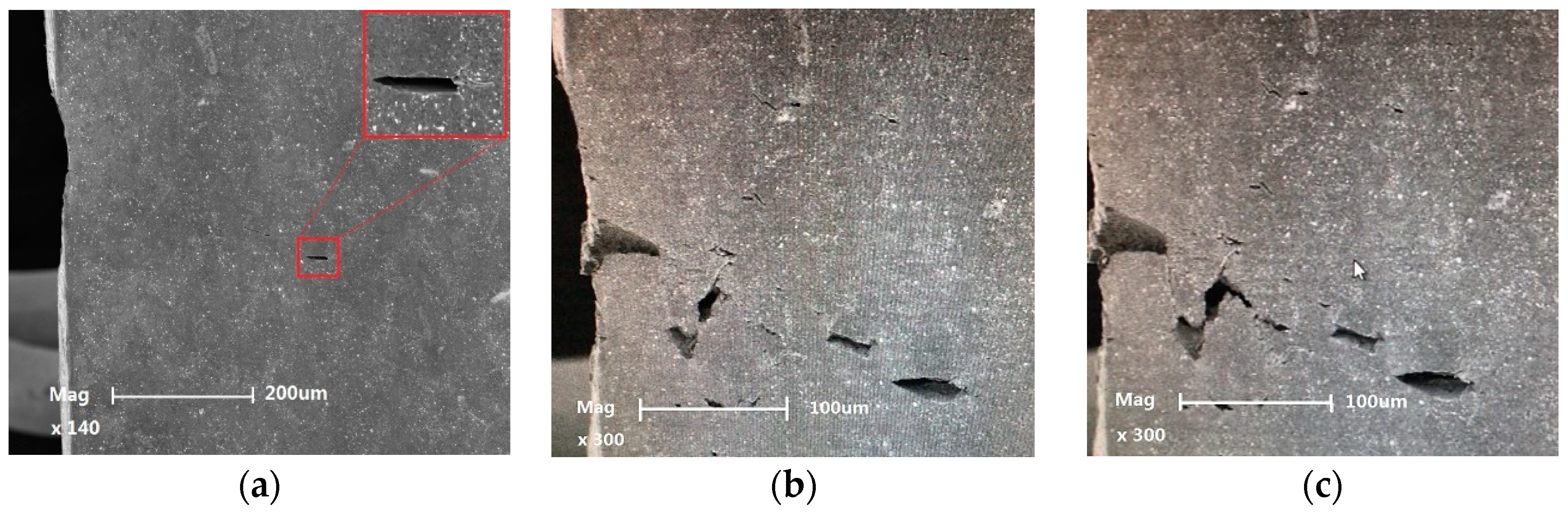

3.1. Observation of In Situ Failure Process of the Ni-Based Superalloy under High Temperature

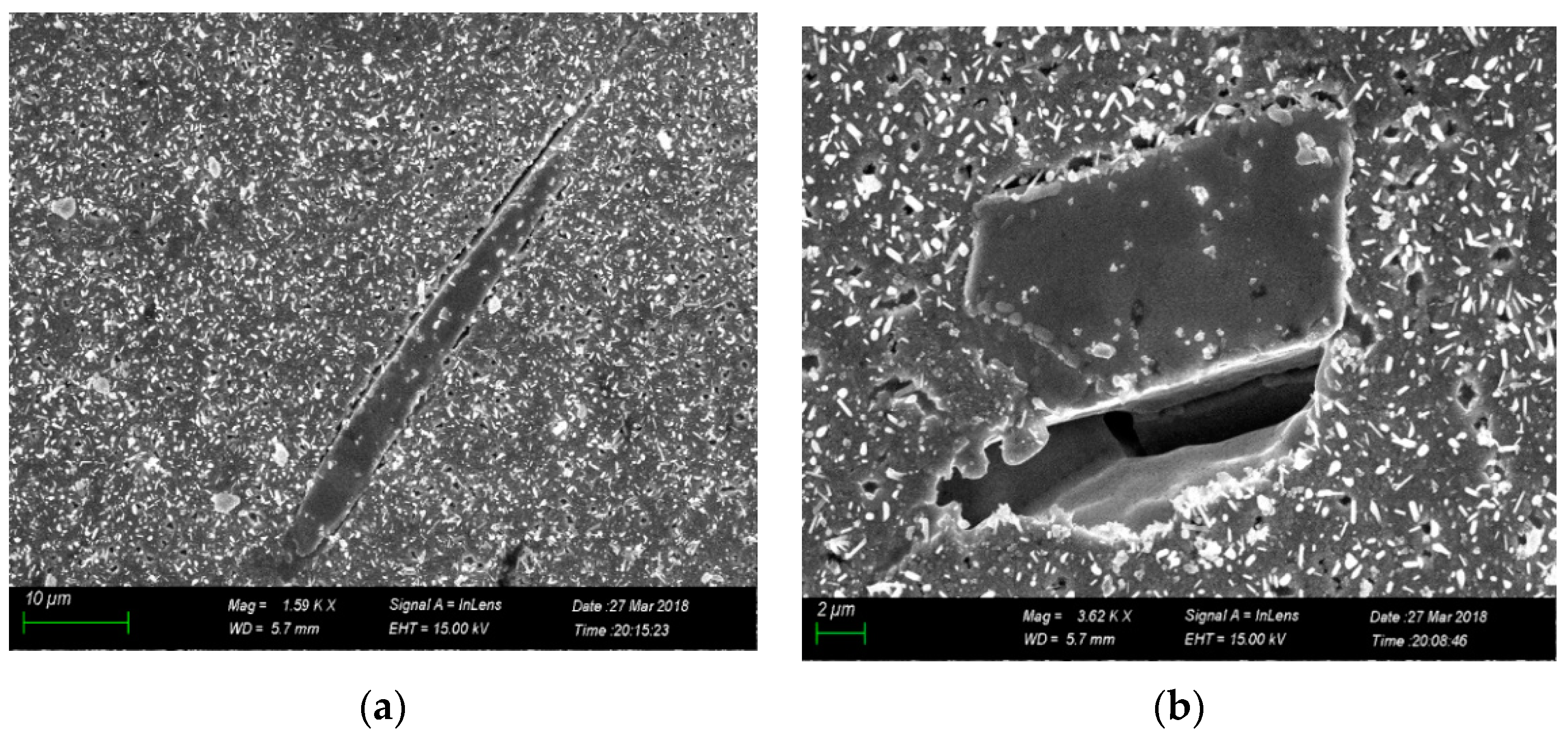

3.2. Failure Modes Caused by Inclusions

4. Conclusions

- The resistance heating system was established in the in situ high-temperature fatigue experimental apparatus, which raised the in-situ testing temperature to more than 1000 °C. We successfully carried out an in-situ tensile test at 900 °C, which proved the effectiveness of the heating method.

- It was found that at 900 °C, the initiation of cracks was mainly caused by debonding of inclusions, and holes would grow up and connect to each other. Finally, the tested specimen failed due to voids connecting and the crack propagating through the specimen section.

Acknowledgments

References

- Reed, R.C. Introduction. In The Superalloys: Fundermentals and Applications; Cambridge University Press: Cambridge, UK, 2006. [Google Scholar]

- He, Z.; Zhang, Y.; Qiu, W.; Shi, H.J.; Gu, J. Temperature effect on the low cycle fatigue behavior of a directionally solidified nickel-base superalloy. Mater. Sci. Eng. A 2016, 676, 246–252. [Google Scholar] [CrossRef]

- Liu, J.; Tang, W.; Li, J. Deformation and fracture behaviors of K403 Ni-based superalloy at elevated temperatures. J. Alloys Compd. 2017, 699, 581–590. [Google Scholar] [CrossRef]

- Summers, W.D.; Alabort, E.; Kontis, P.; Hofmann, F.; Reed, R.C. In-situ high-temperature tensile testing of a polycrystalline nickel-based superalloy. Mater. High Temp. 2016, 33, 338–345. [Google Scholar] [CrossRef]

- Qiu, W.; He, Z.; Fan, Y.N.; Shi, H.J.; Gu, J. Effects of secondary orientation on crack closure behavior of nickel-based single crystal superalloys. Int. J. Fatigue 2016, 83, 335–343. [Google Scholar] [CrossRef]

- Liang, J.; Wang, Z.; Xie, H.; Li, X. In situ scanning electron microscopy-based high-temperature deformation measurement of nickel-based single crystal superalloy up to 800 °C. Opt. Lasers Eng. 2018, 108, 1–4. [Google Scholar] [CrossRef]

- De Roos, G.; Fluit, J.M.; De Wit, J.H.; Geus, J.W. The reaction of NiO and α-Al2O3 studied by Rutherford backscattering. Surf. Interface Anal. 1981, 3, 229–234. [Google Scholar] [CrossRef]

- Wang, J.; Guo, W.G.; Su, Y.; Zhou, P.; Yuan, K. Anomalous behaviors of a single-crystal Nickel-base superalloy over a wide range of temperatures and strain rates. Mech. Mater. 2016, 94, 79–90. [Google Scholar] [CrossRef]

- Texier, D.; Cormier, J.; Villechaise, P.; Stinville, J.C.; Torbet, C.J.; Pierret, S.; Pollock, T.M. Crack initiation sensitivity of wrought direct aged alloy 718 in the very high cycle fatigue regime: The role of non-metallic inclusions. Mater. Sci. Eng. A 2016, 678, 122–136. [Google Scholar] [CrossRef]

- Rai, R.K.; Sahu, J.K.; Jena, P.S.; Das, S.K.; Paulose, N.; Fernando, C.D. High temperature tensile deformation of a directionally solidified nickel base superalloy: Role of micro constituents. Mater. Sci. Eng. A 2017, 705, 189–195. [Google Scholar] [CrossRef]

- Zhang, X.; Li, H.; Zhan, M. Mechanism for the macro and micro behaviors of the Ni-based superalloy during electrically-assisted tension: Local Joule heating effect. J. Alloys Compd. 2018, 742, 480–489. [Google Scholar] [CrossRef]

| Element | Cr | Co | Mo | Al | Ti | Ta | W | C | Ni |

| Content | 12.2 | 9.0 | 1.9 | 3.6 | 4.1 | 5.0 | 3.8 | 0.07 | Balance |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Z.; Liang, J.; Li, X. In-Situ SEM Deformation Testing of Ni-Based Superalloy Heated by the Joule Heat. Proceedings 2018, 2, 507. https://doi.org/10.3390/ICEM18-05415

Wang Z, Liang J, Li X. In-Situ SEM Deformation Testing of Ni-Based Superalloy Heated by the Joule Heat. Proceedings. 2018; 2(8):507. https://doi.org/10.3390/ICEM18-05415

Chicago/Turabian StyleWang, Zhen, Jiecun Liang, and Xide Li. 2018. "In-Situ SEM Deformation Testing of Ni-Based Superalloy Heated by the Joule Heat" Proceedings 2, no. 8: 507. https://doi.org/10.3390/ICEM18-05415

APA StyleWang, Z., Liang, J., & Li, X. (2018). In-Situ SEM Deformation Testing of Ni-Based Superalloy Heated by the Joule Heat. Proceedings, 2(8), 507. https://doi.org/10.3390/ICEM18-05415