Towards High-Power Printed Textile Supercapacitors †

Abstract

:1. Introduction

2. Materials and Methods

2.1. Ink Formulation

2.2. Printing Methodology

2.3. Electrochemical Characterization

3. Results and Discussion

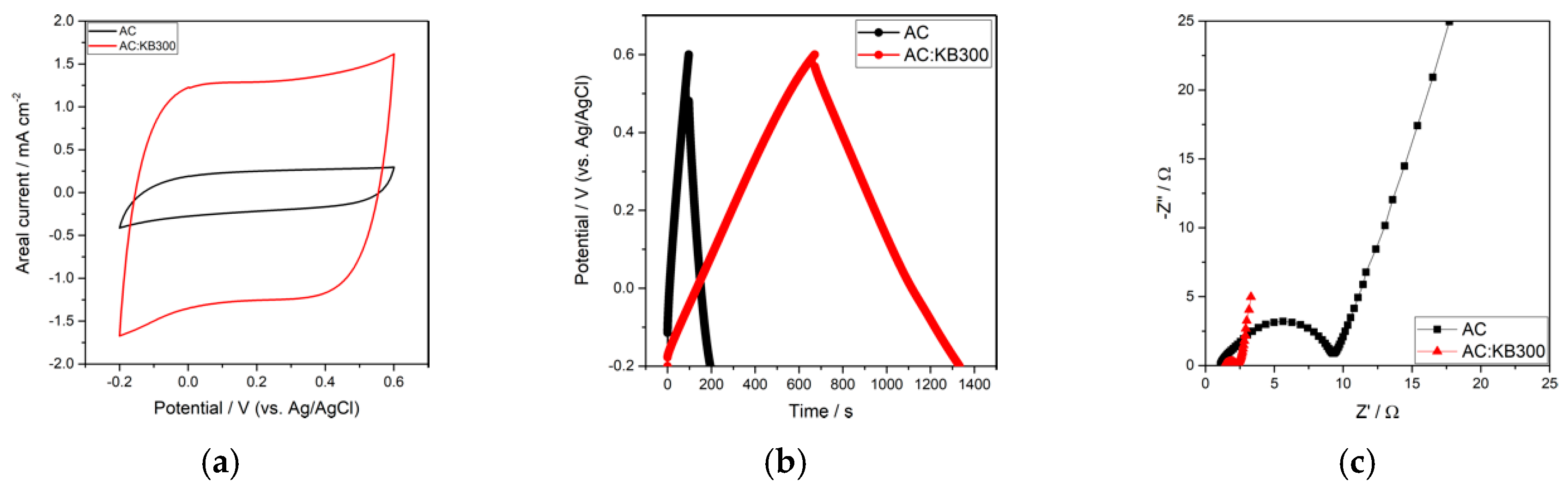

3.1. Electrochemical Performance of Printed Active Layers

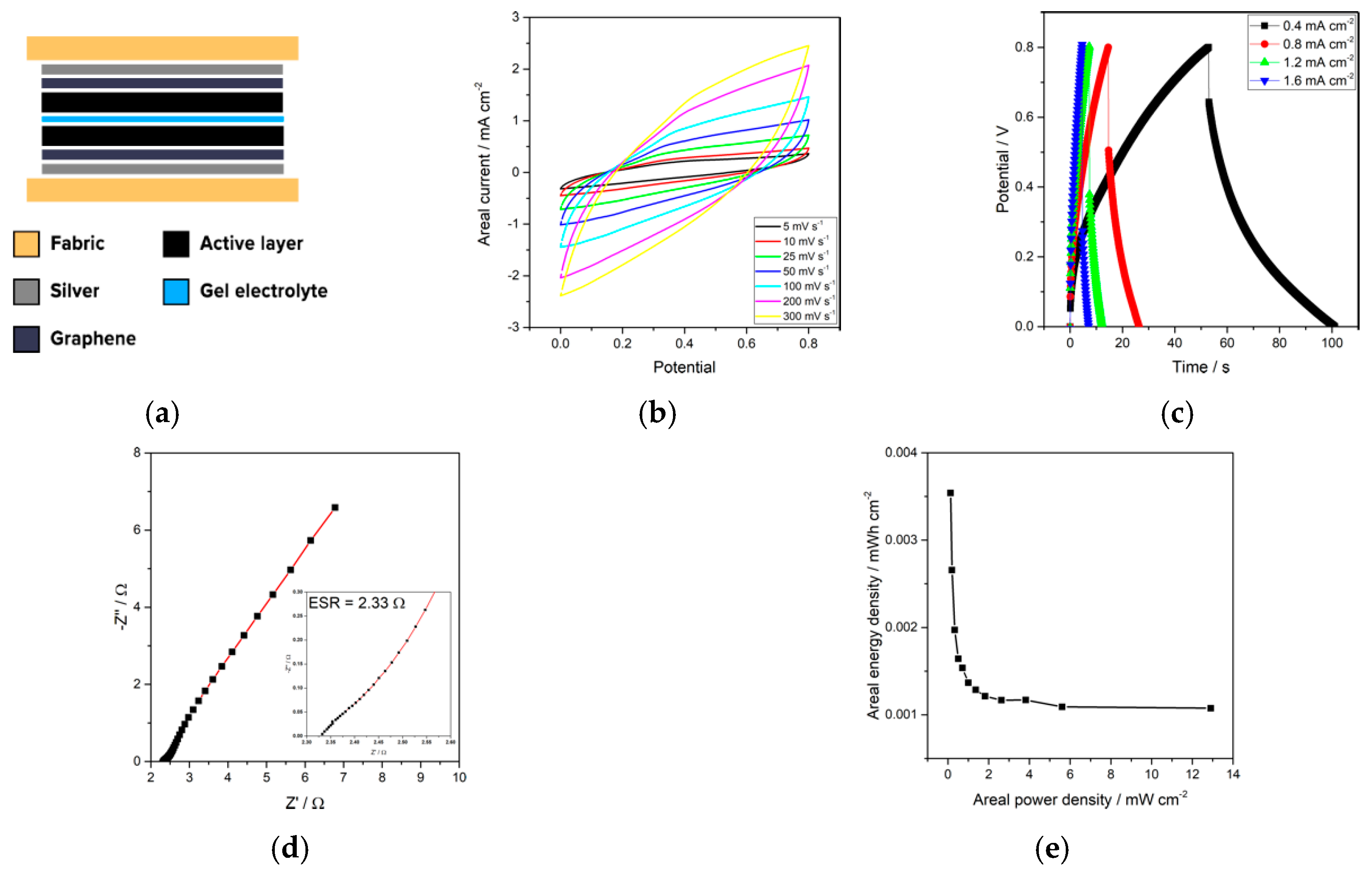

3.2. Electrochemical Performance of the Device

4. Conclusions and Future Work

Funding

Conflicts of Interest

References

- Stoppa, M.; Chiolerio, A. Wearable Electronics and Smart Textiles: A Critical Review. Sensors 2014, 14, 11957–11992. [Google Scholar] [CrossRef] [PubMed]

- Eftekhari, A. The mechanism of ultrafast supercapacitors. J. Mat. Chem. A 2018, 6, 2866–2876. [Google Scholar] [CrossRef]

- Qi, X.; Jinfeng, S.; Yan, H.; Minshen, Z.; Zengxia, P.; Hongfei, L.; Yukun, W.; Na, L.; Haiyan, Z.; Chunyi, Z. Recent Progress on Flexible and Wearable Supercapacitors. Small 2017, 13, 1701827. [Google Scholar]

- Jäckel, N.; Weingarth, D.; Schreiber, A.; Krüner, B.; Zeiger, M.; Tolosa, A.; Aslan, M.; Presser, V. Performance evaluation of conductive additives for activated carbon electrolytes in organic electrolyte. Electrochim. Acta 2016, 191, 284–298. [Google Scholar] [CrossRef]

- Venkata, K.R.R.; Venkata, A.K.; Karthik, P.S.; Surya, P.S. Conductive silver inks and their applications in printed and flexible electronics. RSC Adv. 2015, 5, 77760. [Google Scholar]

- Jagdeep, S.S.; Nicola, Y.; Darren, S.; Upul, K.G.W. Printed electrodes for flexible, light-weight solid-state supercapacitors—A feasibility study. Circuit World 2015, 41, 80–86. [Google Scholar]

| Ink | Screen Used | Drying Regime |

|---|---|---|

| Silver | Stainless steel 230T | 10 min at 130 °C |

| Conductive carbon | Stainless steel 230T | 60 min at 150 °C |

| Active layer | Monofilament polyester 32T | 30 min at 120 °C |

| Gel electrolyte | Monofilament polyester 32T | Room temperature |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Luís, P.; Sagu, J.; Southee, D.; Wijayantha, U.; Weaver, G. Towards High-Power Printed Textile Supercapacitors. Proceedings 2019, 32, 10. https://doi.org/10.3390/proceedings2019032010

Luís P, Sagu J, Southee D, Wijayantha U, Weaver G. Towards High-Power Printed Textile Supercapacitors. Proceedings. 2019; 32(1):10. https://doi.org/10.3390/proceedings2019032010

Chicago/Turabian StyleLuís, Paulo, Jagdeep Sagu, Darren Southee, Upul Wijayantha, and George Weaver. 2019. "Towards High-Power Printed Textile Supercapacitors" Proceedings 32, no. 1: 10. https://doi.org/10.3390/proceedings2019032010

APA StyleLuís, P., Sagu, J., Southee, D., Wijayantha, U., & Weaver, G. (2019). Towards High-Power Printed Textile Supercapacitors. Proceedings, 32(1), 10. https://doi.org/10.3390/proceedings2019032010