Real-Time Detection of Plastic Shards in Cheese Using Microwave-Sensing Technique †

Abstract

:1. Introduction

2. Experimental Setup and Methodology

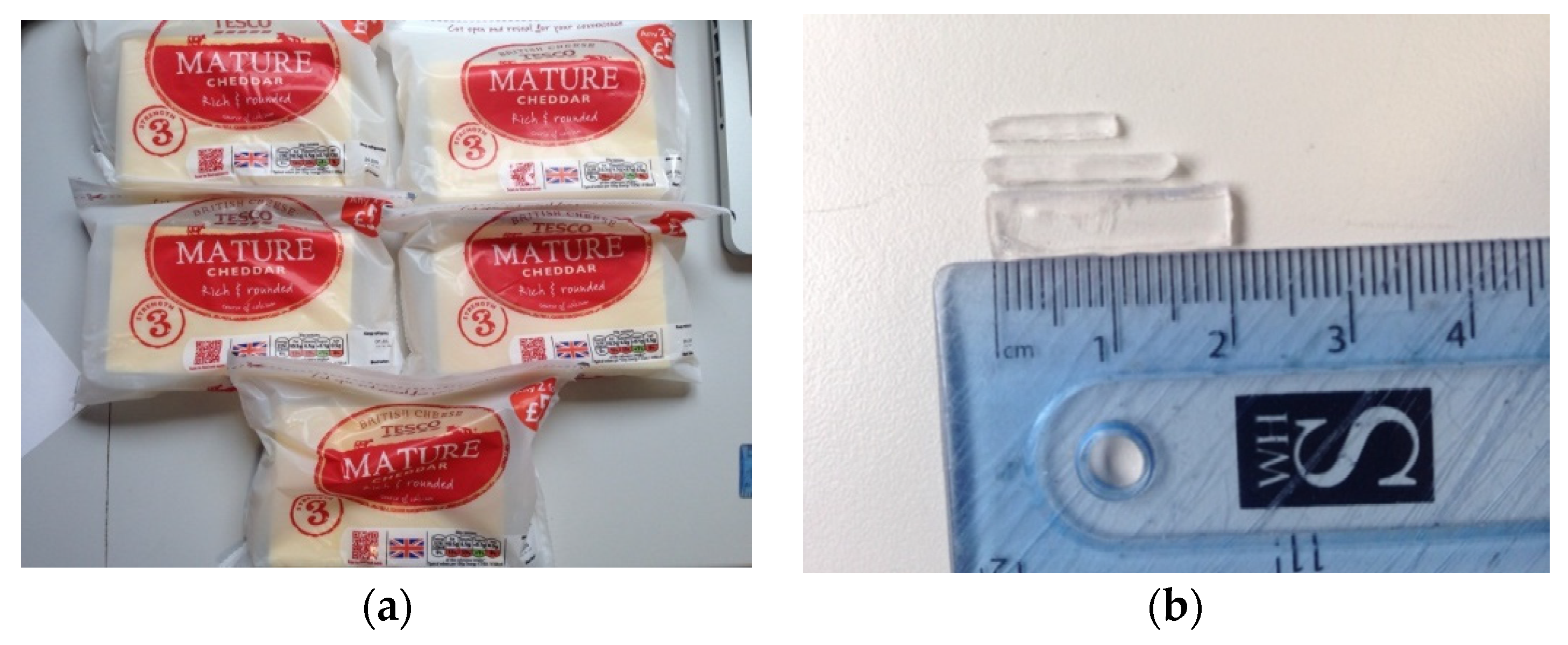

- (1)

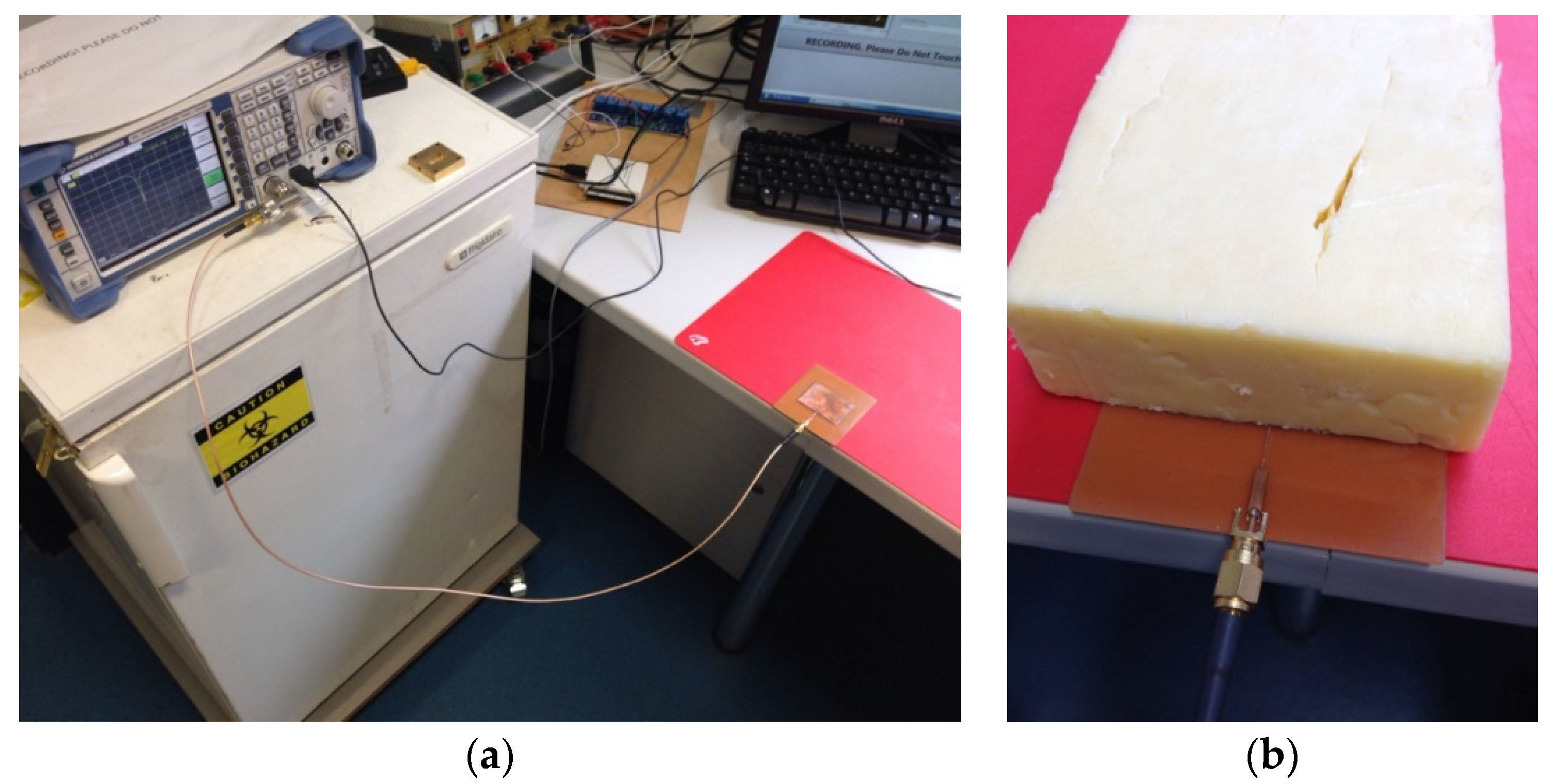

- Vector Network Analyser (VNA)

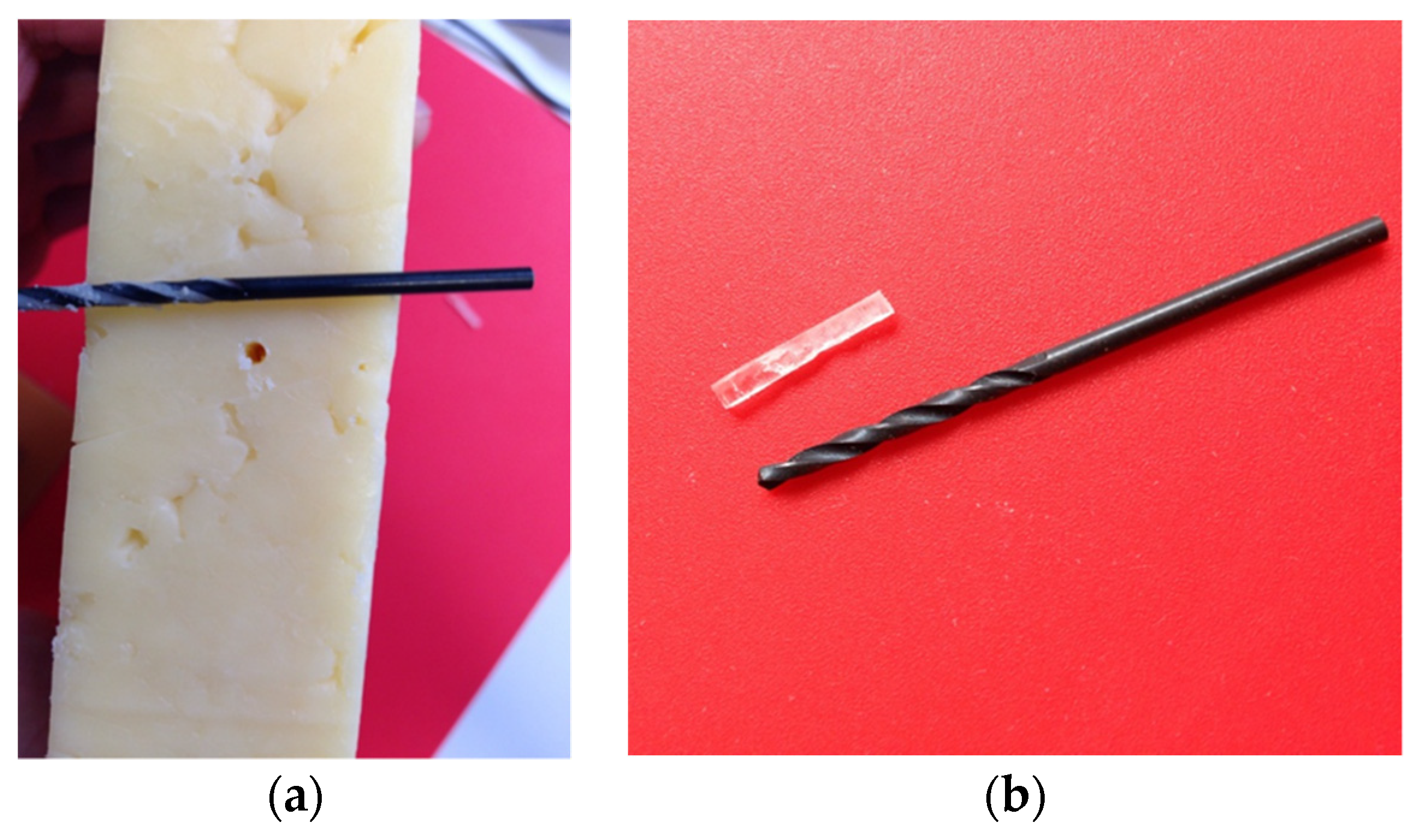

- (2)

- Plastic shards

- (3)

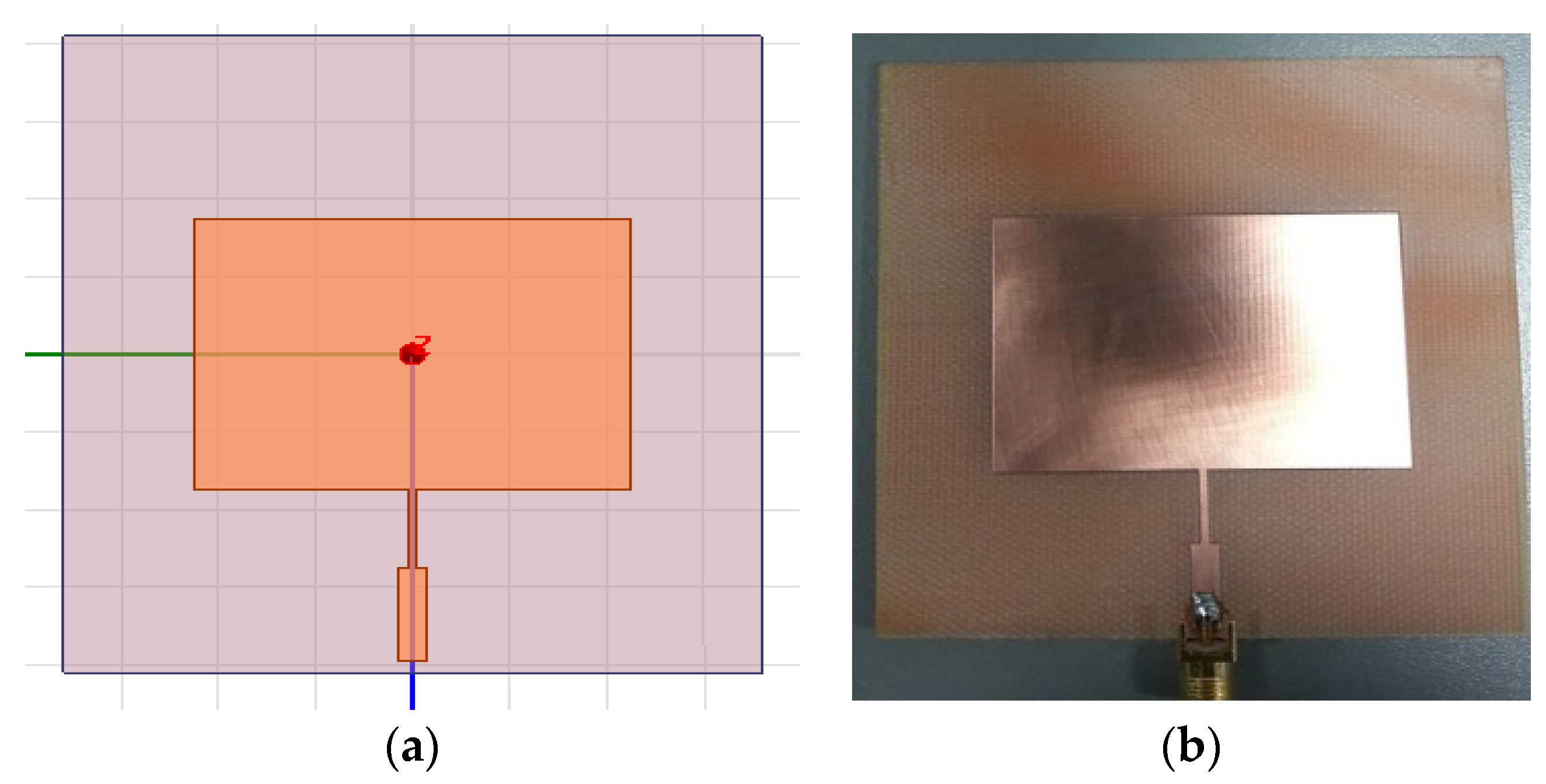

- 2.45 GHz patch antenna

- (4)

- Drill (to make holes for the plastic shards), Figure 2.

2.1. Samples and Plastic Shards Preparation

2.2. Microwave Patch Antenna

2.3. Experimental Setup and Data Acquisition

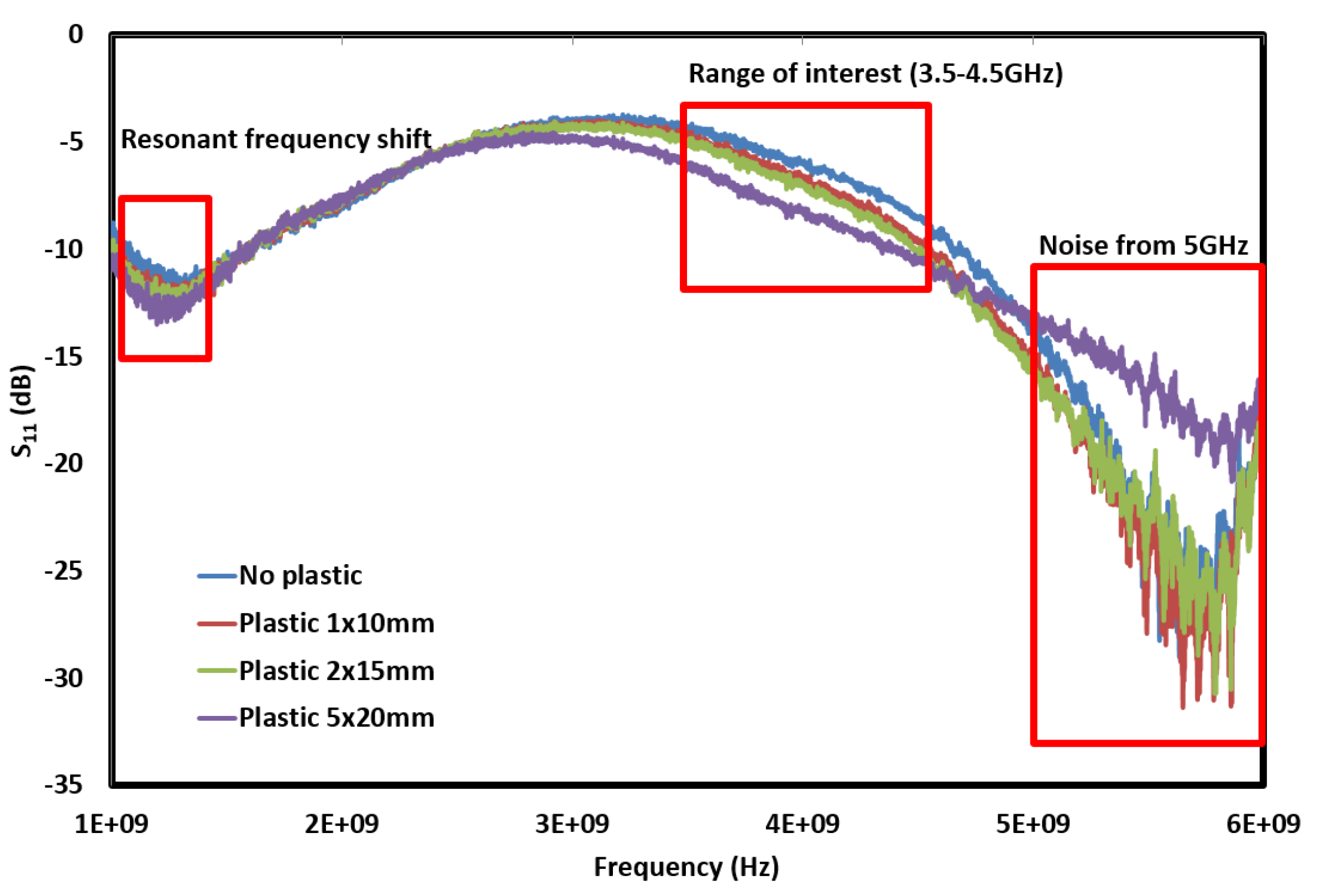

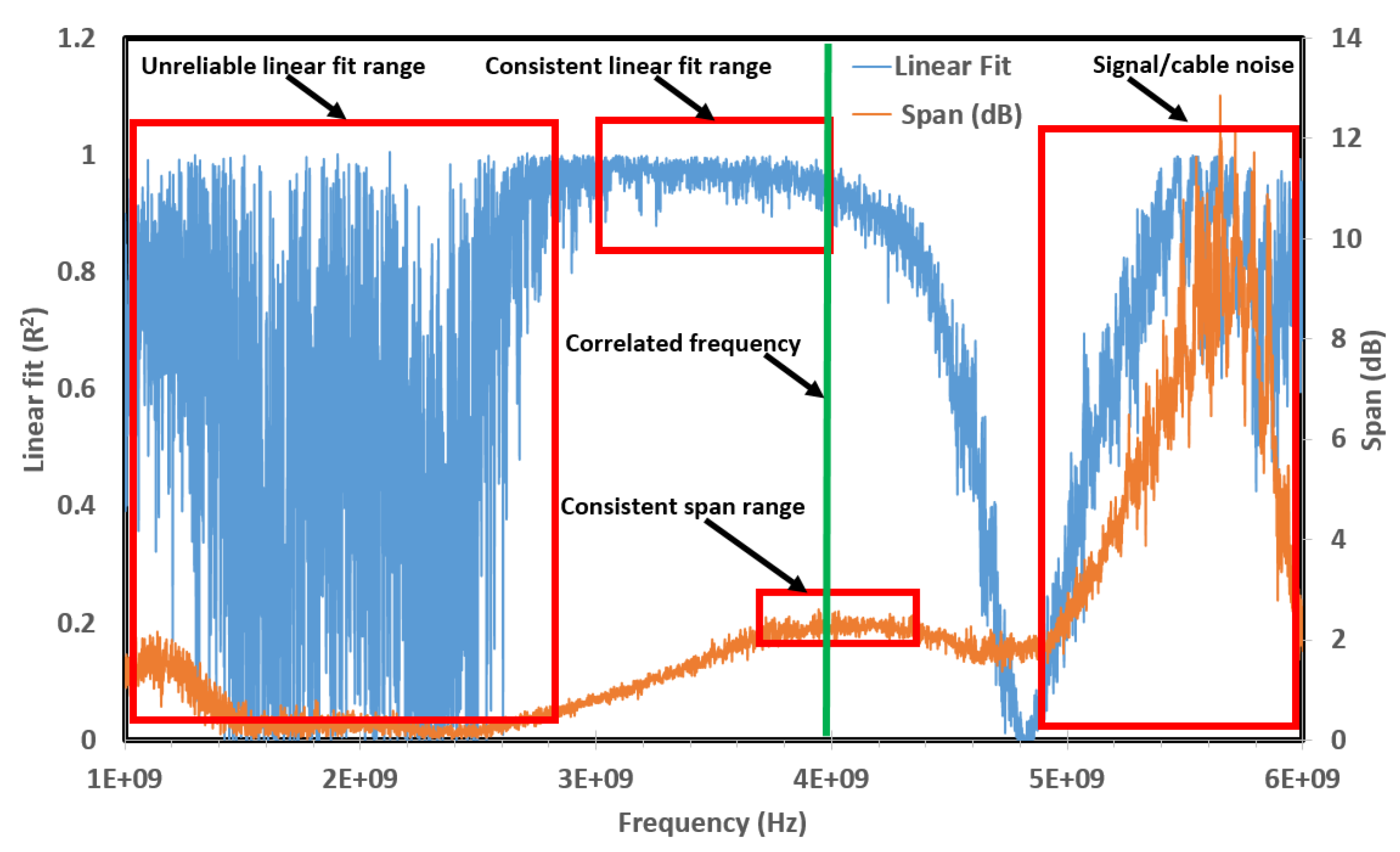

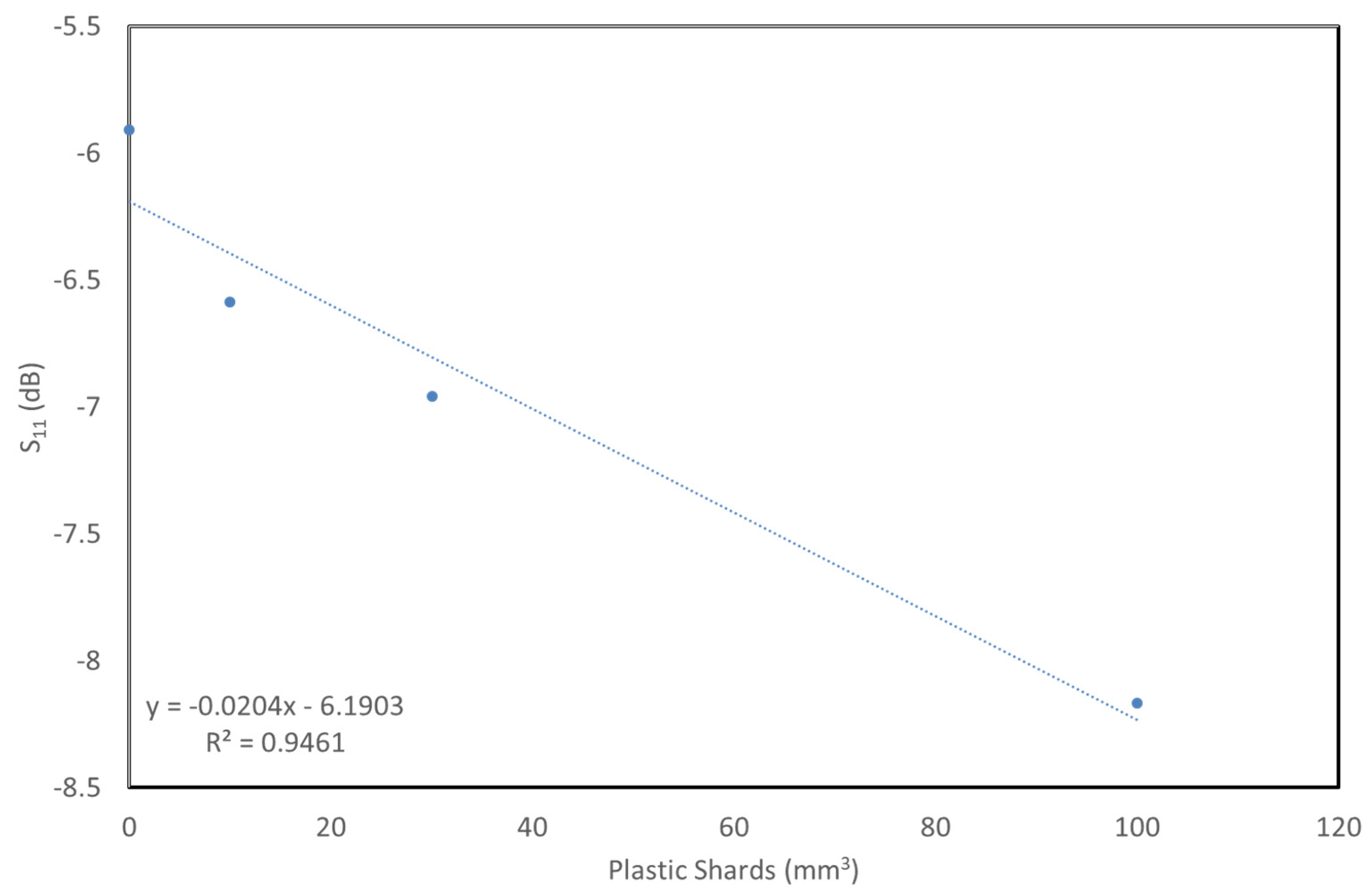

3. Results and Discussions

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Ok, G.; Choi, S.-W.; Park, K.H.; Chun, H.S. Foreign Object Detection by Sub-Terahertz Quasi-Bessel Beam Imaging. Sensors 2013, 13, 71–85. [Google Scholar] [CrossRef] [PubMed]

- HomeFitnessgarage. IMPORTANT RECALL AT LIDL: DANGEROUS PIECES OF PLASTIC IN THE CHEESE PRODUCT. Available online: https://homefitnessgarage.com/health-news/important-recall-at-lidl-dangerous-pieces-of-plastic-in-the-cheese-product/ (accessed on 13 April 2020).

- Meinlschmidt, P.; Maergner, V. Thermographic techniques and adapted algorithms for autmatic detection of foreign bodies in food. In Proceedings of the SPIE 5073 Thermosense XXV (AEROSENSE 2003), Orlando, FL, USA, 21–25 April 2003; pp. 168–177. [Google Scholar]

- Lee, Y.-K.; Choi, S.-W.; Han, S.-T.; Woo, D.H.; Chun, H.S. Detection of Foreign Bodies in Foods Using Continuous Wave Terahertz Imaging. J. Food Prot. 2012, 75, 179–183. [Google Scholar] [CrossRef]

- Cho, B.K.; Irudayaraj, J.M. Foreign Object and Internal Disorder Detection in Food Materials Using Noncontact Ultrasound Imaging. Food Eng. Phys. Prop. 2003, 68, 967–974. [Google Scholar] [CrossRef]

- Muradov, M.; Cullen, J.D.; Shaw, A.; Mason, A.; Al-Shamma’a, A.I.; Bjarnadottir, S.G.; Alvseike, O. Online non-destructuve monitoirng of meat drying using microwave spectroscopy. In Proceedings of the 2015 9th International Conference on Sensing Technology (ICST), Auckland, New Zealand, 8–10 December 2015; pp. 496–501. [Google Scholar]

- Mason, A.; Abdullah, B.; Muradov, M.; Korostynska, O.; Al-Shamma’a, A.; Bjarnadottir, S.G.; Lunde, K.; Alvseike, O. Theoretical Basis and Application for Measuring Pork Loin Drip Loss Using Microwave Spectroscopy. Sensors 2016, 16, 182. [Google Scholar] [CrossRef] [PubMed]

- Teng, K.H.; Kot, P.; Muradov, M.; Shaw, A.; Hashim, K.; Gkantou, M.; Al-Shamma’a, A. Embedded Smart Antenna for Non-Destructive Testing and Evaluation (NDT & E) of Moisture Content and Deterioration in Concrete. Sensors 2019, 19, 547. [Google Scholar]

- Kot, P.; Ali, A.S.; Shaw, A.; Riley, M.; Alias, A. The application of electromagnetic waves in monitoring water infiltration on concrete flat roof: The case of Malaysia. Constr. Build. Mater. 2016, 122, 435–445. [Google Scholar] [CrossRef]

- Kot, P.; Muradov, M.; Shaw, A.; Hemingway, J.; Deb, R.; Coleman, M. Identification of Optimal Frequencies to Determine Alpha-Cypermethrin using Machine Learning Feature Selection Techniques. In Proceedings of the IEEE Congress on Evolutionary Computation 2018, Rio de Janeiro, Brazil, 8–13 July 2018; pp. 1–7. [Google Scholar]

- Afridi, M.A. Microstrip Patch Antenna—Designing at 2.4 GHz Frequency. Biol. Chem. Res. 2015, 2015, 128–132. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Muradov, M.; Kot, P.; Ateeq, M.; Abdullah, B.; Shaw, A.; Hashim, K.; Al-Shamma’a, A. Real-Time Detection of Plastic Shards in Cheese Using Microwave-Sensing Technique. Proceedings 2020, 42, 54. https://doi.org/10.3390/ecsa-6-06557

Muradov M, Kot P, Ateeq M, Abdullah B, Shaw A, Hashim K, Al-Shamma’a A. Real-Time Detection of Plastic Shards in Cheese Using Microwave-Sensing Technique. Proceedings. 2020; 42(1):54. https://doi.org/10.3390/ecsa-6-06557

Chicago/Turabian StyleMuradov, Magomed, Patryk Kot, Muhammad Ateeq, Badr Abdullah, Andy Shaw, Khalid Hashim, and Ahmed Al-Shamma’a. 2020. "Real-Time Detection of Plastic Shards in Cheese Using Microwave-Sensing Technique" Proceedings 42, no. 1: 54. https://doi.org/10.3390/ecsa-6-06557

APA StyleMuradov, M., Kot, P., Ateeq, M., Abdullah, B., Shaw, A., Hashim, K., & Al-Shamma’a, A. (2020). Real-Time Detection of Plastic Shards in Cheese Using Microwave-Sensing Technique. Proceedings, 42(1), 54. https://doi.org/10.3390/ecsa-6-06557