Measurement of Dynamic Behavior of Running- Specific Prostheses by an Impact Test †

Abstract

:1. Introduction

2. Experimental Method

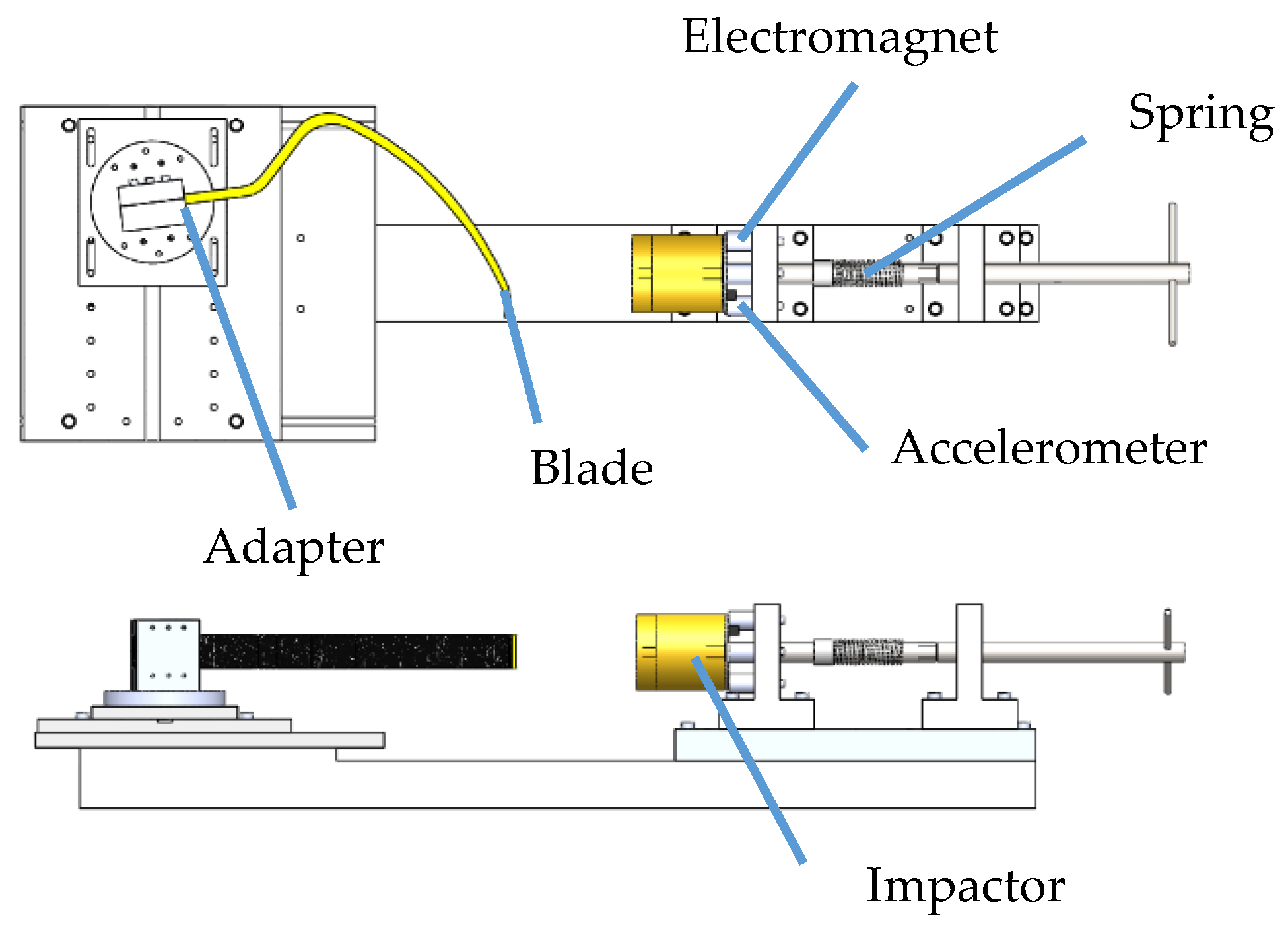

2.1. Design and Manufacture of Impact Testing Apparatus

2.2. Measurement Objects and Experimental Conditions

2.3. Measurement Items

3. Results and Discussion

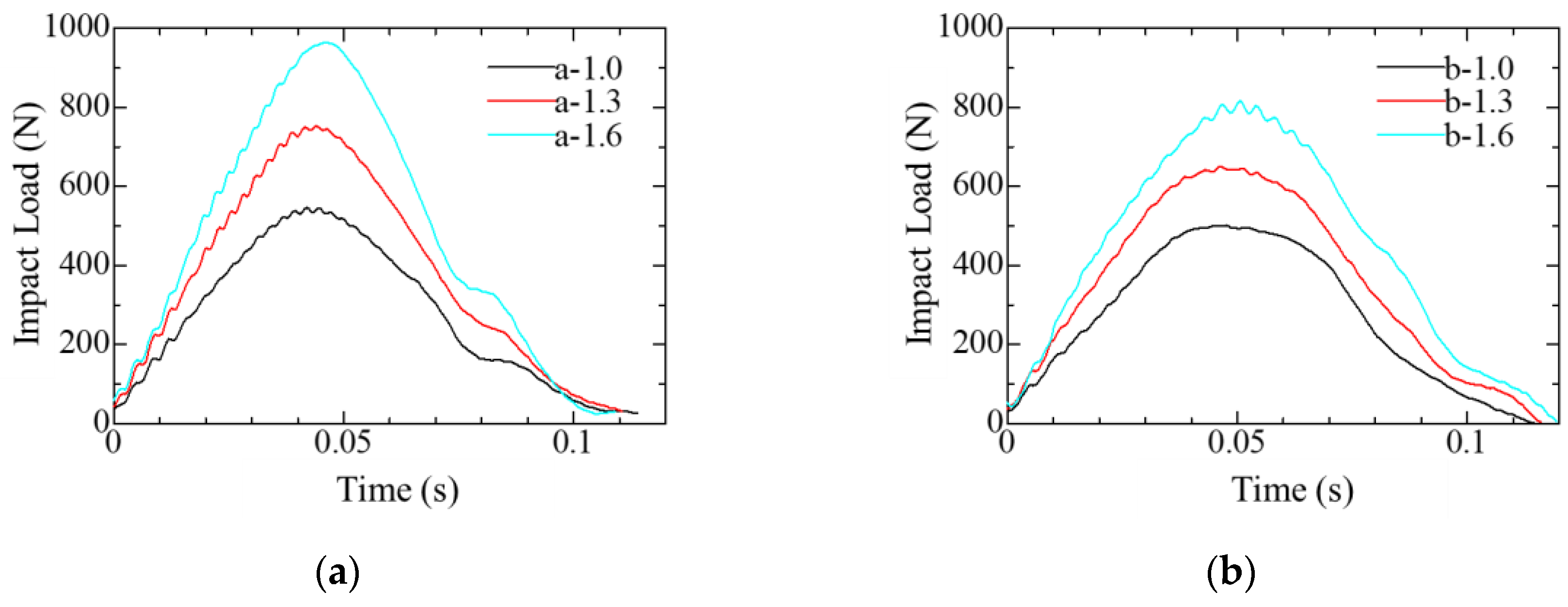

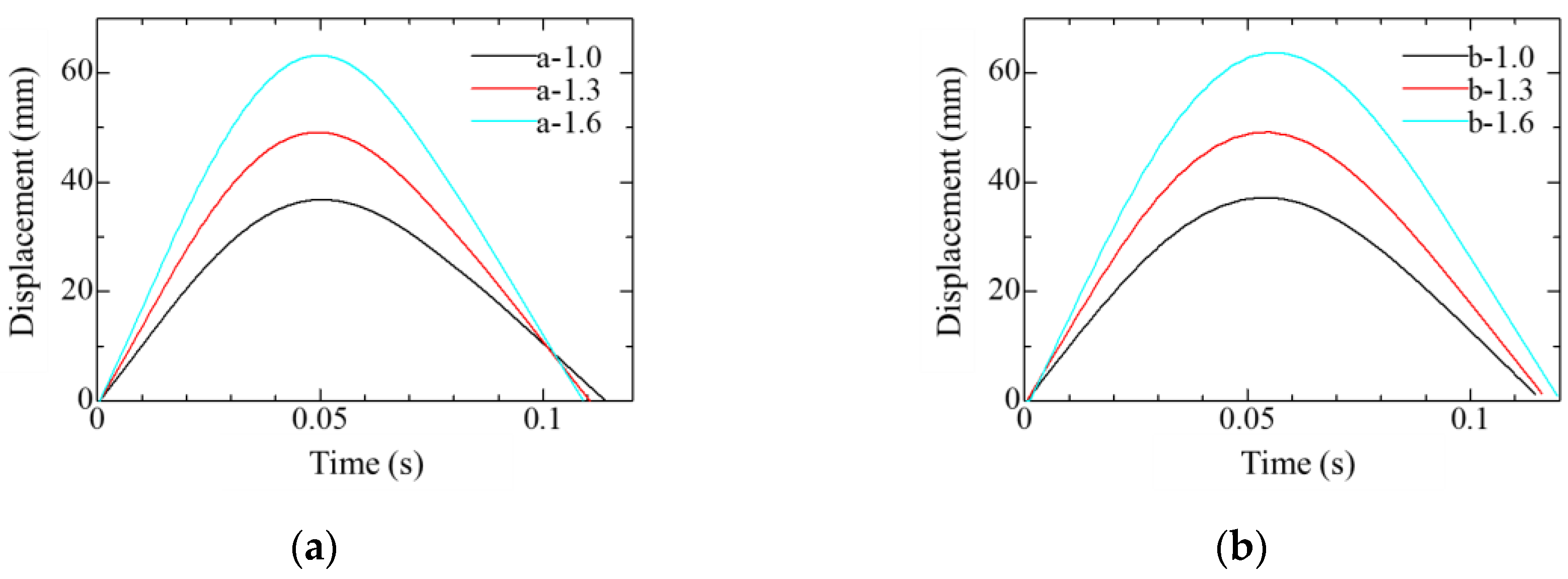

3.1. Impact Load and Displacement

3.2. Ratio of Velocity and Average Spring Stiffness

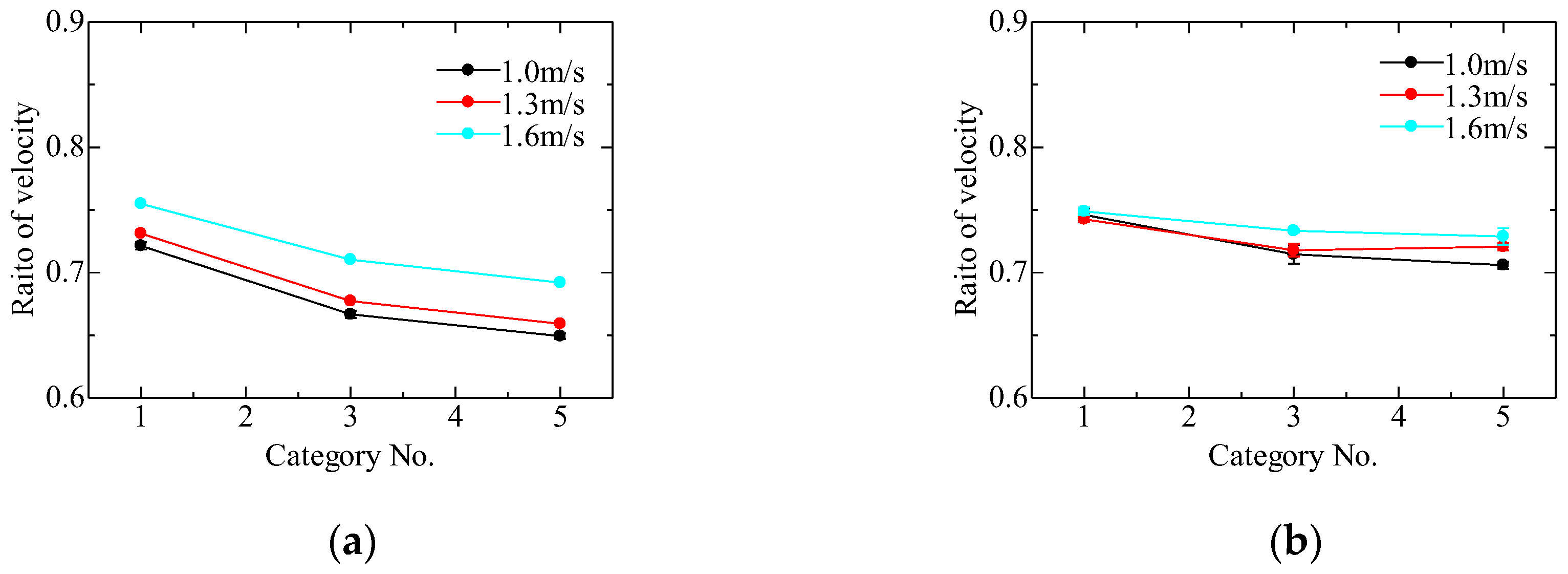

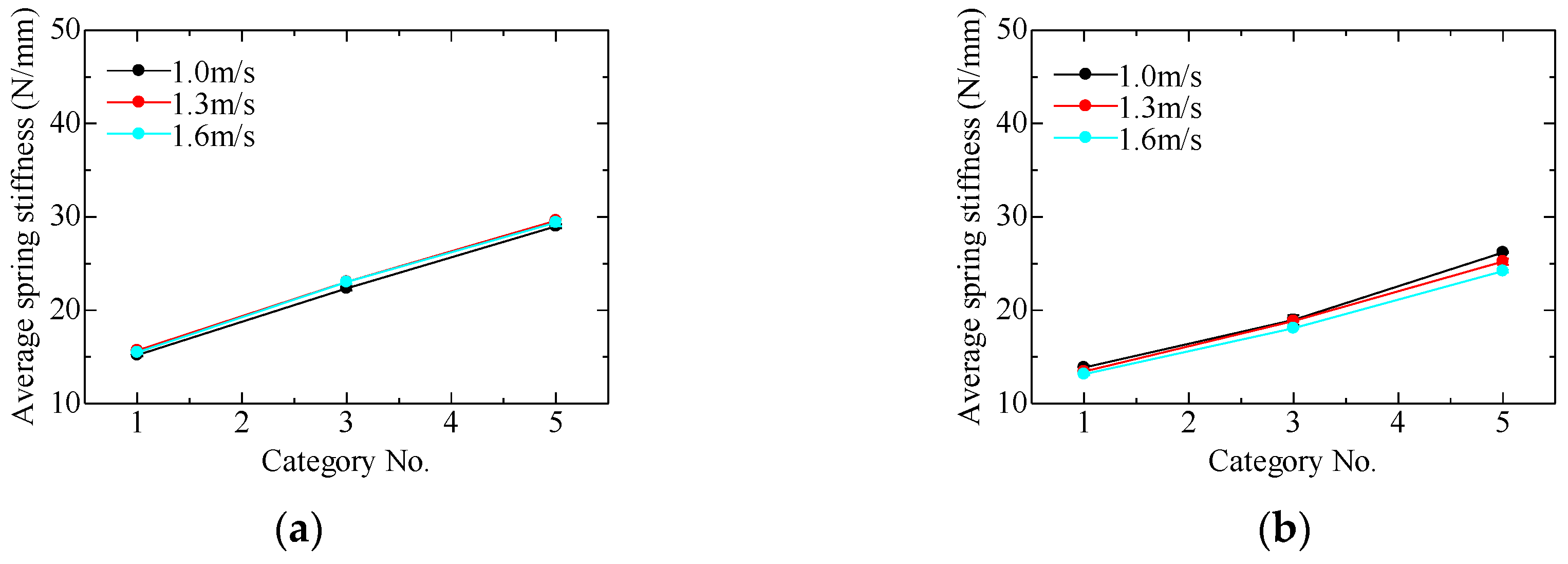

4. Conclusions

- The ratio of velocity can be an index which represents the difference between the types of blades, and roughly grasps the difference within the range of categories.

- The ASS was proposed as an index which can evaluate the rebound characteristics of the blade obtained from the displacement and the impact load. It could represent the difference between blades, but it could not sufficiently represent the difference of the measurement conditions in the experimental conditions. The characteristics between categories can be represented as the linear relationship between the ASS and category numbers.

- Regarding the ASS and the ratio of velocity, the ratio of velocity tends to generally decrease as the ASS increases within the range of the categories in this study.

References

- Miyata, Y.; Itahana, S. A Development of CFRP athlete’s prosthetic blade. J. Soc. Mater. Sci. 2019, 68, 394–400. (In Japanese) [Google Scholar] [CrossRef]

- World Para Athletics Rules and Regulations 2018–2019. Available online: https://www.paralympic.org/sites/default/files/document/180305150449200_World+Para+Athletics+Rules+and+Regulations+2018-2019_February.pdf (accessed on 16 October 2019).

- Brüggemann, G.P.; Arampatzis, A.; Emrich, F.; Potthast, W. Biomechanics of double transtibial amputee sprinting using dedicated sprinting prostheses. Sports Technol. 2008, 1, 220–227. [Google Scholar]

- Hobara, H. Advantage or Disadvantage? Dynamic Joint Stiffness during Running Using Running-specific Prostheses. Descent Sports Sci. 2014, 35, 140–141. (In Japanese) [Google Scholar]

- Baum, B.S.; Schultz, M.P.; Tian, A.; Shefter, B.; Wolf, E.J.; Kwon, H.J.; Shim, J.K. Amputee Locomotion: Determining the Inertial Properties of Running-Specific Prostheses. Arch. Phys. Med. Rehabil. 2013, 94, 1776–1783. [Google Scholar]

- Dyer, B.; Sewell, P.; Noroozi, S. How should we assess the mechanical properties of lower-limb prosthesis technology used in elite sport?—An initial investigation. J. Biomed. Sci. Eng. 2013, 6, 116–123. [Google Scholar]

- Beck, O.N.; Taboga, P.; Grabowski, A.M. How do prosthetic stiffness, height and running speed affect the biomechanics of athletes with bilateral transtibial amputations? J. R. Soc. Interface 2017, 14, 20170230. [Google Scholar]

- Murai, A.; Hobara, H.; Hashizume, S.; Kobayashi, Y.; Tada, M. Modeling and analysis of individual with lower extremity amputation locomotion using prosthetic feet and running-specific prostheses. Conf. Proc. IEEE. Eng. Med. Biol. Soc. 2017, 2017, 901–904. [Google Scholar]

| Frame rate (fps) | 2000 |

| Shutter speed (s) | 1/5000 |

| Image resolution (pixels) | 2560 × 1440 |

| F number | 16 |

| Lens focal length (mm) | 20 |

| Distance between blade and cameras (mm) | 750–800 |

| Blade | 1.0 m/s | 1.3 m/s | 1.6 m/s |

| A | 555 ± 8.74 | 751 ± 3.14 | 965 ± 2.89 |

| B | 501 ± 4.94 | 650 ± 2.76 | 824 ± 6.18 |

| Blade | 1.0 m/s | 1.3 m/s | 1.6 m/s |

| A | 37.9 ± 1.35 | 48.7 ± 0.392 | 62.7 ± 0.569 |

| B | 37.2 ± 0.249 | 49.2 ± 0.108 | 63.2 ± 0.576 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nakayama, H.; Takahashi, Y.; Tanaka, K. Measurement of Dynamic Behavior of Running- Specific Prostheses by an Impact Test. Proceedings 2020, 49, 145. https://doi.org/10.3390/proceedings2020049145

Nakayama H, Takahashi Y, Tanaka K. Measurement of Dynamic Behavior of Running- Specific Prostheses by an Impact Test. Proceedings. 2020; 49(1):145. https://doi.org/10.3390/proceedings2020049145

Chicago/Turabian StyleNakayama, Hiroki, Yuki Takahashi, and Katsumasa Tanaka. 2020. "Measurement of Dynamic Behavior of Running- Specific Prostheses by an Impact Test" Proceedings 49, no. 1: 145. https://doi.org/10.3390/proceedings2020049145

APA StyleNakayama, H., Takahashi, Y., & Tanaka, K. (2020). Measurement of Dynamic Behavior of Running- Specific Prostheses by an Impact Test. Proceedings, 49(1), 145. https://doi.org/10.3390/proceedings2020049145