Diagnostics and Prognostics of Energy Conversion Processes via Knowledge-Based Systems †

Abstract

:1. Introduction

- (a)

- plant shutdowns due to scheduled maintenance;

- (b)

- plant shutdowns due to unscheduled maintenance;

- (c)

- plant shutdowns due to sudden failures.

2. The General Conceptual Layout of a Diagnostic/Prognostic System

2.1. A Diagnostic System

- The intelligent agent (IA) must identify in “real time” the operational state of the process. This requires that the IA be endowed with an efficient interface with a data collection system which produces a vector of length N containing an ordered set of measurables, i.e., of process parameters that identify the state (mass flow rates, pressures, temperatures, vibration amplitudes, etc.);

- At each selected time step, the IA must compare the detected operational state with the expected one. To do this, the IA must have access either to a pre-determined operational process schedule, or, if the latter is not available, to a reliable process simulator that provides the IA with such a reference operating state;

- If the value of the kth measurable differs from the corresponding design value by more than a preset tolerance, the IA activates a monitoring-and-control procedure on the component this measurable pertains to;

- The IA verifies whether the ‘‘failure’’ condition just detected appears in one of the ‘’fault chains’’ contained in its Knowledge Base. If it does, then the IA proceeds to step 5 here below. If it does not, the IA activates a sub-procedure to monitor k for a prescribed period of time, and notifies the (human) plant operator of this action;

- If the event ‘‘kth measurable out of range’’ belongs to one or more fault chains known to the IA, the agent launches a monitoring-and-control procedure on all measurables i, j, …, p that appear together with k in the detected fault chains;

- If a fault chain is indeed identified as ‘‘active’’, the IA will: a—notify the plant operator; b—consult its Knowledge Base to search for remedial actions (e.g., adjustment of other process parameters to compensate for the derangement in k); c—decide whether it is possible to wait for the next scheduled maintenance intervention or a repair/substitution is immediately necessary.

2.2. A Prognostic System

- The IA must compare at a pre-determined time step the operational state of the process;

- The IA projects the detected operational state forward in time, founding this projection on the most recent time history (i.e., extrapolating from two or more previous time steps) of the process;

- If the projected value of the kth measurable at t + Δt activates one of the known fault signatures, or if it shows an undesirable trend in the time history of xk (e.g., “dxk/dt too high” according to some norm), the IA activates a monitoring-and-control procedure on the component to which this measurable pertains;

- The IA also launches a monitoring-and-control procedure on all measurables r, s, …, z that are related to k (i.e., whose values are known to be functionally linked to the value of xk);

- Otherwise, the IA continues monitoring xk for a pre-defined time interval, and notifies the plant operator of this action;

- If the IA estimates that a fault chain may be ‘‘activated’’ by an excessive variation of xk, it will:

- A.

- Notify the plant operator;

- B.

- Consult its Knowledge Base to search for and recommend suitable remedial actions (e.g., adjustment of other process parameters to compensate for the derangement in xk);

- C.

- Decide whether it is possible to wait for the next scheduled maintenance intervention or a repair/substitution is immediately necessary.

3. Theoretical and Practical Aspects of the Implementation of the Intelligent Agent

- ‘‘Complete’’ means that there must exist a one-to-one mapping of all rules and information available to the human operator and this KB.

- ‘‘Exact’’ means that this mapping must be logically consistent, i.e., that no logical chain of induction correctly derived from the KB contradicts any of the rules and information available to the human operator.

3.1. The Meta-Rules of Failure Detection

- There exists a finite number of possible types of failure, and for each one of them there exists at least one specific signature, i.e., a unique combination of the process parameters;

- There are no sudden failures; every possible failure is ‘‘forewarned’’ by a drifting of the point representative of the operational state of the plant, on a path that leads to a specific attractor in the state space (the failure point);

- Each one of these ‘‘drifting’’ processes has a characteristic time scale that depends both on the component and on the type of failure;

- A convenient way to represent such a drifting is that of employing a proper set of dimensionless indicators, each defined as the ratio of the instantaneous value of a measurable of interest to its ‘‘design’’ value. Notice that such a design value is in reality a time-dependent quantity; it is the value expected for the same instantaneous operative conditions but without any derangement;

- The process of ‘‘failure formation’’ is described by at least one ‘‘fault chain’’, i.e., an ordered list of the immediate causes of the failure. The detection of an “indicator derangement” may be related to more than one chain: the same final failure (“effect”) may be caused by different chains of initial derangements (“causes”). Each chain, though, has at least two fuzzy aspects—first, the ‘‘causes’’ it contains are necessary, but not sufficient (for example, for a creep failure in a first row statoric blade in a gas turbine, it is necessary that the gas temperature at the turbine inlet be higher than a certain design limit, but once the temperature exceeds this limit, failures are not certain). Second, even this necessity is affected by some degree of uncertainty (for example, a blade failure may happen even if the gas temperatures are below the design limit);

- Some of the fault chains may be concurrent. That is, the same failures stem from one or the other, or from a combination of two (or more), fault chains;

- Many of the fault signatures are non-local—the values of measurables detected at locations physically remote from the point where the failure actually takes place may be affected by the drifting process mentioned in point (2). In this case, we say that these measurables (and the indicators constructed on them) are correlated with the ones immediately affected by the failure.

3.2. Formalization of the Fault Signatures and Choice of the Fault Indicators

3.2.1. The Mathematical Formulation

3.2.2. The Knowledge Base Implementation

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

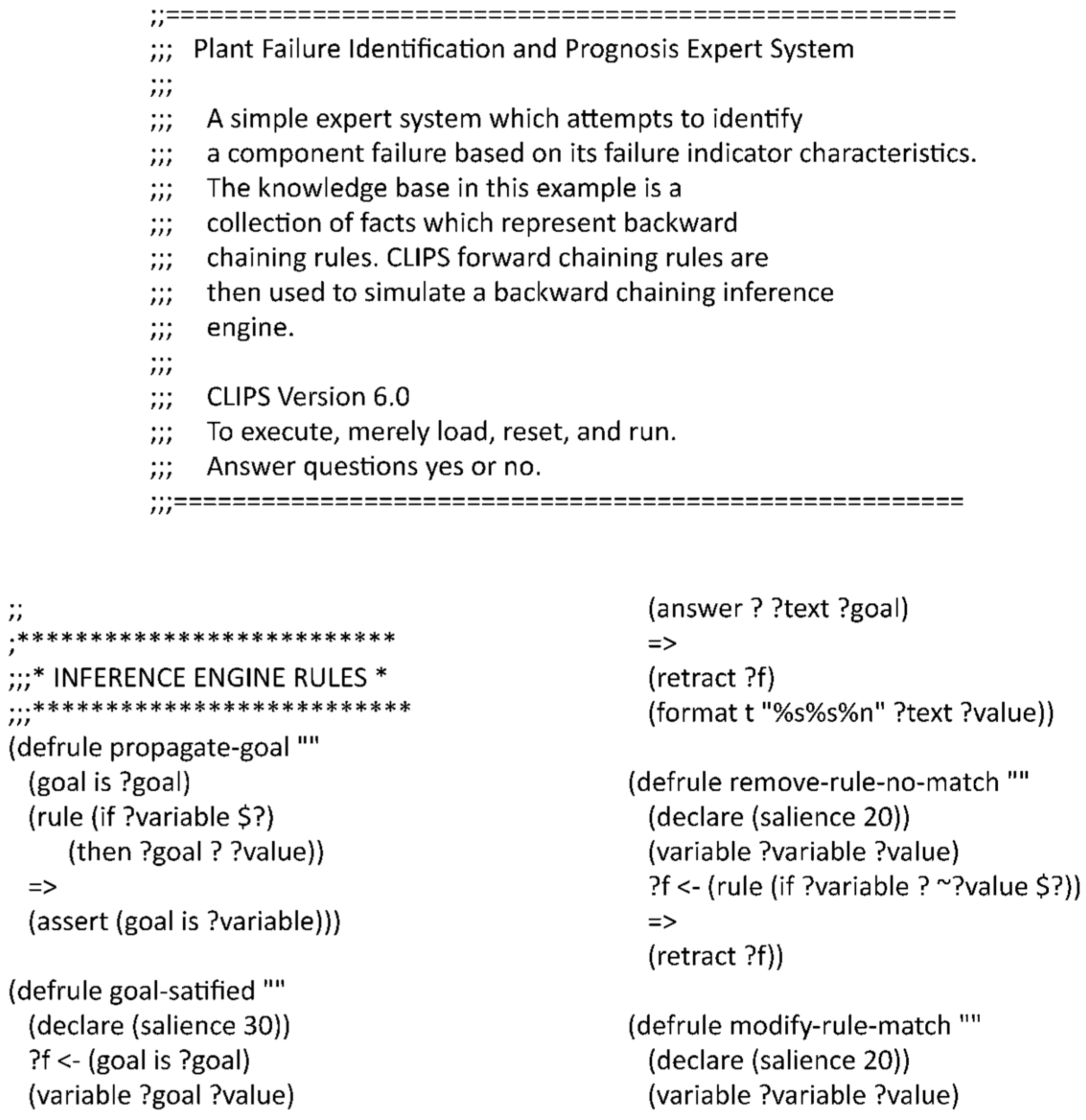

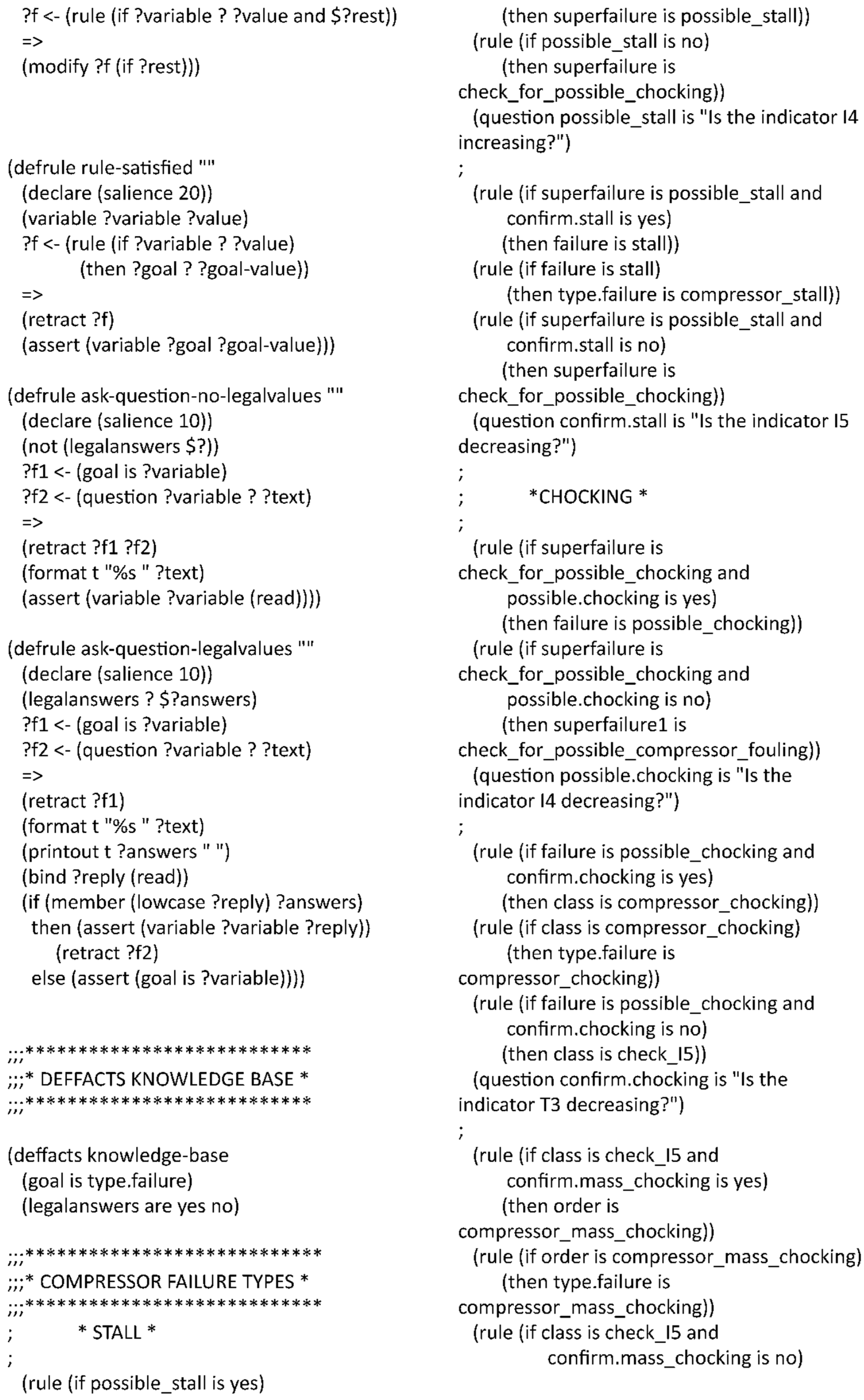

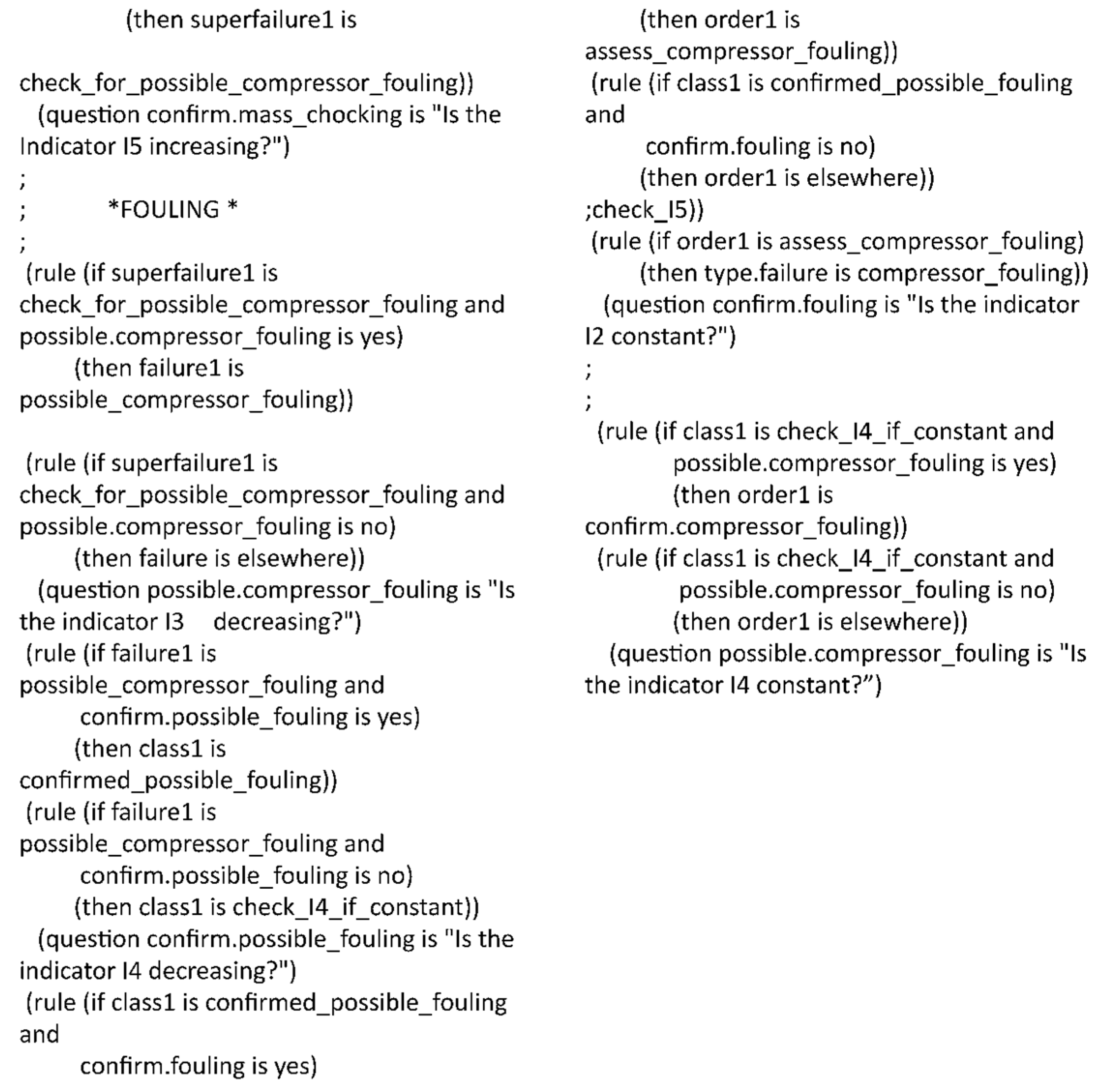

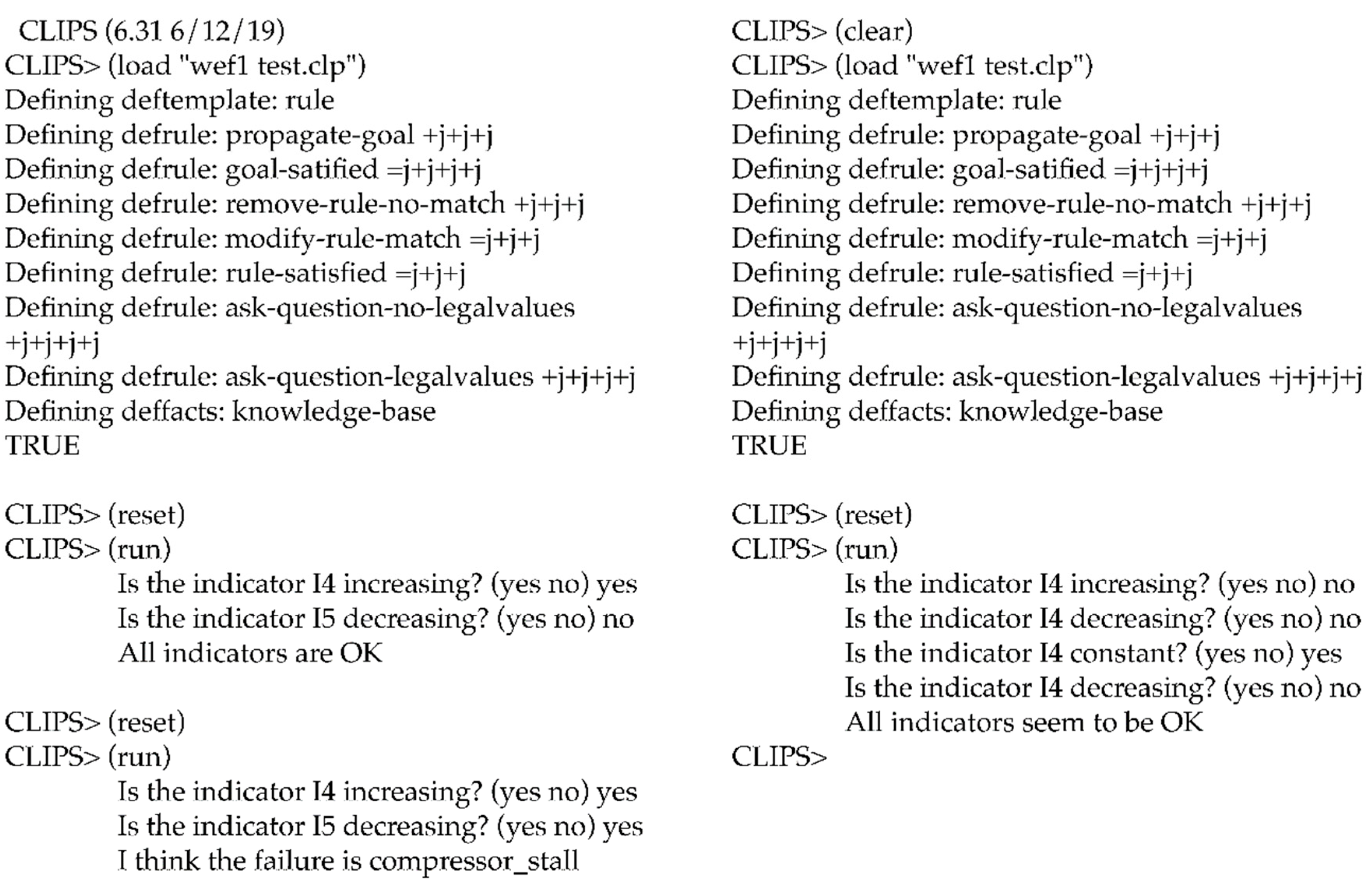

Appendix A. Example of PROMISA CLIPS Code for the Compressor Fault Chain

References

- PARC is turning 50: From Ethernet and Laser Printing to this Wild New Tech; ZDNet April 2020. Available online: https://www.zdnet.com/article/parc-is-turning-50-from-ethernet-and-laser-printing-to-this-wild-new-tech/ (accessed on 27 February 2020).

- Biagetti, T.; Sciubba, E. PROMISE: A tool for the on-line intelligent performance prediction of cogeneration plants. In Proceedings of the ECOS02, Berlin, Germany, 3–5 July 2002; pp. 463–471. [Google Scholar]

- Biagetti, T.; Sciubba, E. A first step towards unmanned intelligent process management: A procedure for the diagnostics and prognostics of energy conversion plants. Int. J. Appl. Thermodyn. 2002, 5, 85–99. [Google Scholar]

- Gülen, S.C.; Griffin, P.R.; Paolucci, S. Real Time On-Line Performance Diagnostics of Heavy-Duty Industrial Gas Turbines; ASME paper 2000-GT-312; American Society of Mechanical Engineers: New York, NY, USA, 2000. [Google Scholar]

- Roemer, M.J.; Kacprzynski, G.J. Advanced Diagnostics and Prognostics for Gas Turbine Engine Risk Assessment; ASME Paper 2000-GT-30; American Society of Mechanical Engineers: New York, NY, USA, 2000. [Google Scholar]

- Tsalavoutas, A.; Aretakis, N.; Mathioudakis, K.; Stamatis, A. Combining Advanced Data Analysis Methods for the Constitution of an Integrated Gas Turbine Condition Monitoring and Diagnostic System; ASME Paper 2000-GT-34; American Society of Mechanical Engineers: New York, NY, USA, 2000. [Google Scholar]

- Forsyth, G.; Delaney, J. Designing Diagnostics Expert Systems for Long-Term Supportability; ASME Paper, 2000-GT-31; ASME: New York, NY, USA, 2000. [Google Scholar]

- Ozgur, D.; Lakshminarasimha, A.N.; Rucigay, R.; Morjaria, M.; Sanborn, S. Remote Monitoring and Diagnostics System for GE Heavy-Duty Gas Turbines; ASME Paper, 2000-GT-314; ASME: New York, NY, USA, 2000. [Google Scholar]

- Sciubba, E.; Melli, R. Artificial Intelligence in Thermal Systems Design: Concepts and Applications; Nova Science: New York, NY, USA, 1998. [Google Scholar]

- Sriram, R.D. Intelligent Systems for Engineering; Springer: New York, NY, USA, 1997. [Google Scholar]

| Component | Possible Fault(s) | Component | Possible Fault(s) |

|---|---|---|---|

| Filter | Leakage Fouling | Secondary heat exchanger | Fouling |

| Compressor | Stall Choking Fouling Excessive exit temperature Malfunctioning | Lubrication loop | Fouling Leakage Lubricant deterioration |

| Primary combustion chamber | Fouling Excessive pressure losses CH4- or H2O valve failure | Cooling loop | Fouling Leakage |

| Primary fuel injector | Fouling | Main cooling pump | Cavitation malfunctioning |

| Secondary fuel injector | Secondary combustion reactions Fouling Leakage | Main shaft | Near-critical vibration frequencies |

| Turbine | Fouling Choking Excessive inlet temperature | Afterburner | CH4 injector fouling |

| Primary heat exchanger | Fouling |

| Air filter | I1 = Δp/Δpd | Turbine | I11 = ηc/ηcd I12 = Tex/Texd I13 = mex/mexd |

| Compressor | I2 = cp ΔT/cpΔTd I3 = ηc/ηcd I4 = βc/βcd = pc/pcd I5 = mc/mcd | Electrical generator | I14 = ωc/ωcd |

| Combustion chamber | I6 = Δpcc/Δpccd I7 = mcc/mccd | Afterburner | I14 = ΔT/ΔTd I15 = m/md |

| Fuel injector | I8 = mfi/mfid | Main pump | I16 = mp/mpd I17 = Δpp/Δppd |

| Boiler main stack | I9 = XNOX/XNOXd I10 = XCO2/XCO2d | Shaft (vibrations) | I18 = rms/rmsd |

| Compressor | Fouling Malfunctioning Choking Excessive T3 Stall | I2 = cp ΔT/cpΔTd I3 = ηc/ηcd I4 = βc/βcd = pc/pcd I5 = mc/mcd | (I3 low U I4 low) or (I3 low U I2 high) (I3 high U Wc high) (I4 low U I5 high) or (I4 low U T3 low) I2 high I4 low U I5 low |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Melli, R.; Sciubba, E. Diagnostics and Prognostics of Energy Conversion Processes via Knowledge-Based Systems. Proceedings 2020, 58, 1. https://doi.org/10.3390/WEF-06937

Melli R, Sciubba E. Diagnostics and Prognostics of Energy Conversion Processes via Knowledge-Based Systems. Proceedings. 2020; 58(1):1. https://doi.org/10.3390/WEF-06937

Chicago/Turabian StyleMelli, Roberto, and Enrico Sciubba. 2020. "Diagnostics and Prognostics of Energy Conversion Processes via Knowledge-Based Systems" Proceedings 58, no. 1: 1. https://doi.org/10.3390/WEF-06937

APA StyleMelli, R., & Sciubba, E. (2020). Diagnostics and Prognostics of Energy Conversion Processes via Knowledge-Based Systems. Proceedings, 58(1), 1. https://doi.org/10.3390/WEF-06937