Peculiarities Regarding the Reconstruction of a Broken Grooved Shaft †

Abstract

:1. Introduction

- -

- the groove is made through injection up to the polyamide;

- -

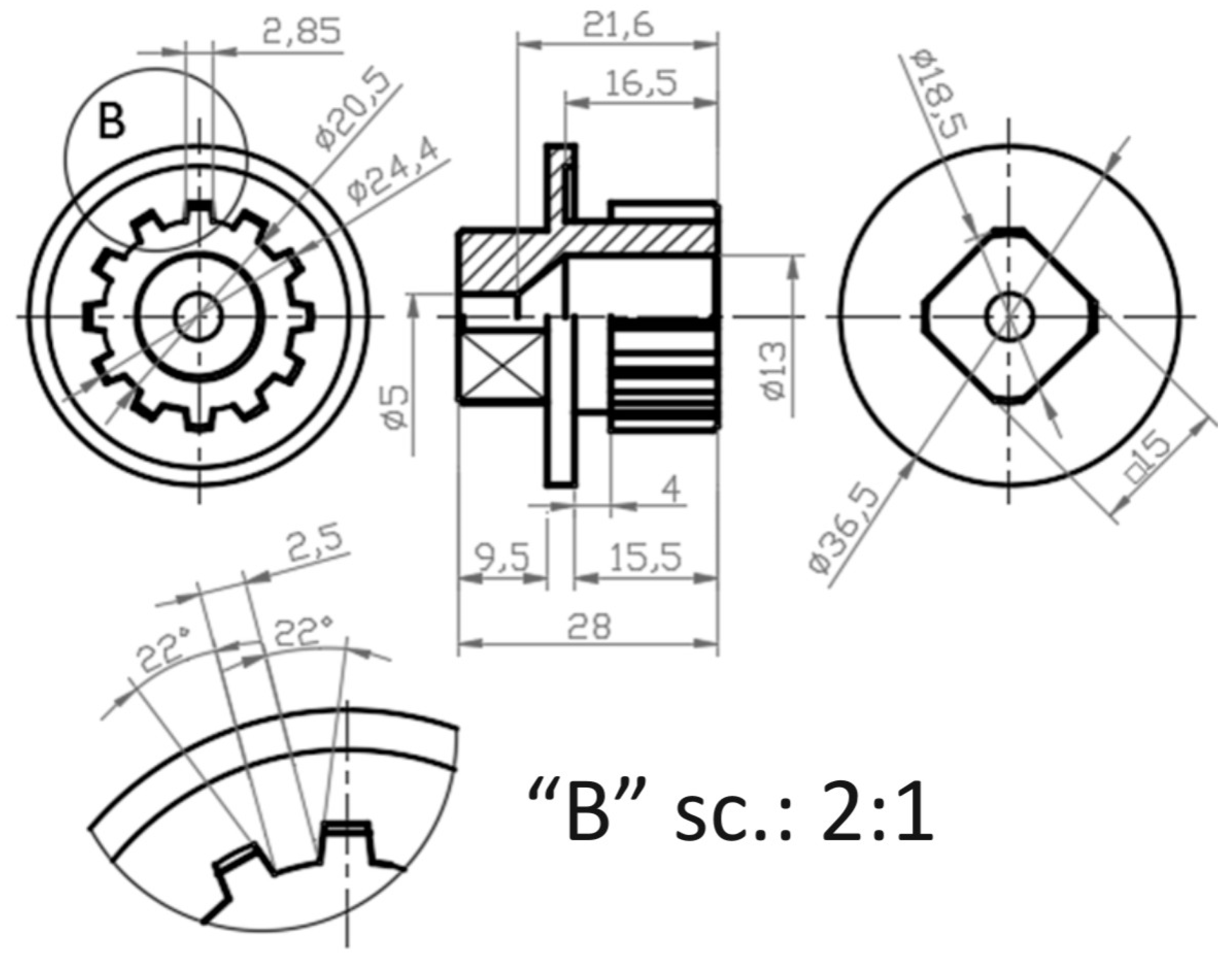

- contains two profiles, grooved and prismatic;

- -

- has the number z = 12 (channels);

- -

- has two bores, the smallest being intended for fixing the coupling with an M5 screw.

2. Working Method

- -

- determining the dimensions of the damaged piece;

- -

- the execution of the drawings nedeed;

- -

- material choosing;

- -

- establishing the method of manufacturing the part;

- -

- determining the time required for the manufacture;

- -

- determining deviations of the new grooved shaft.

2.1. Dimensions of the Piece and Execution Drawing

2.2. Choosing of the Material for the Grooved Shaft

- -

- it is desired to use a material with better properties in terms of impact/collision at breakage;

- -

- since the piece will be machined by splintering, the newly chosen material must have technological and thermal properties superior to the original one;

- -

- only one piece will be processed;

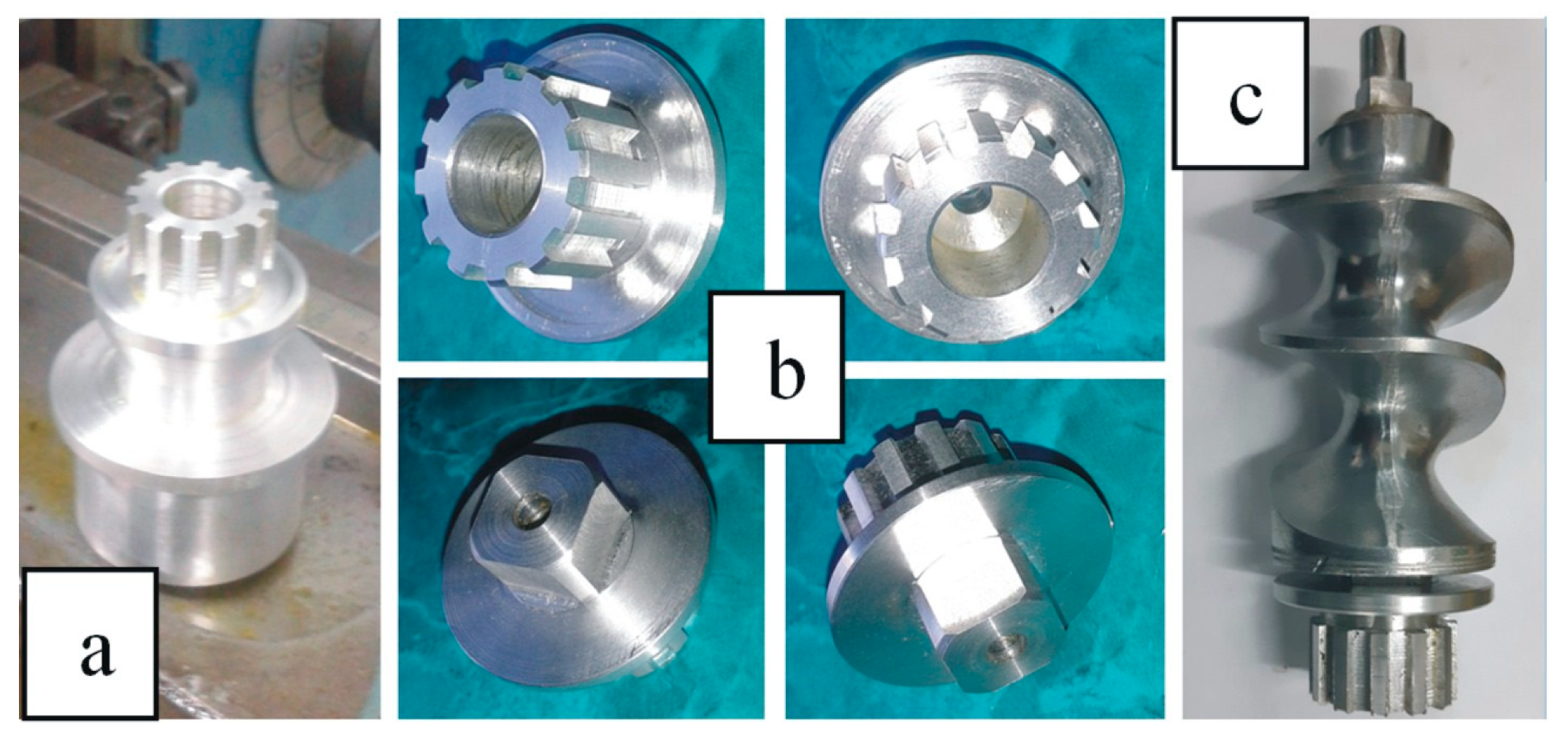

2.3. Machining of the New Grooved Piece

2.4. Initial Turning of the Grooved Shaft

2.5. Mortising the Grooved Profile

- -

- design and construction, as well the related holder bar for the slotting tool;

- -

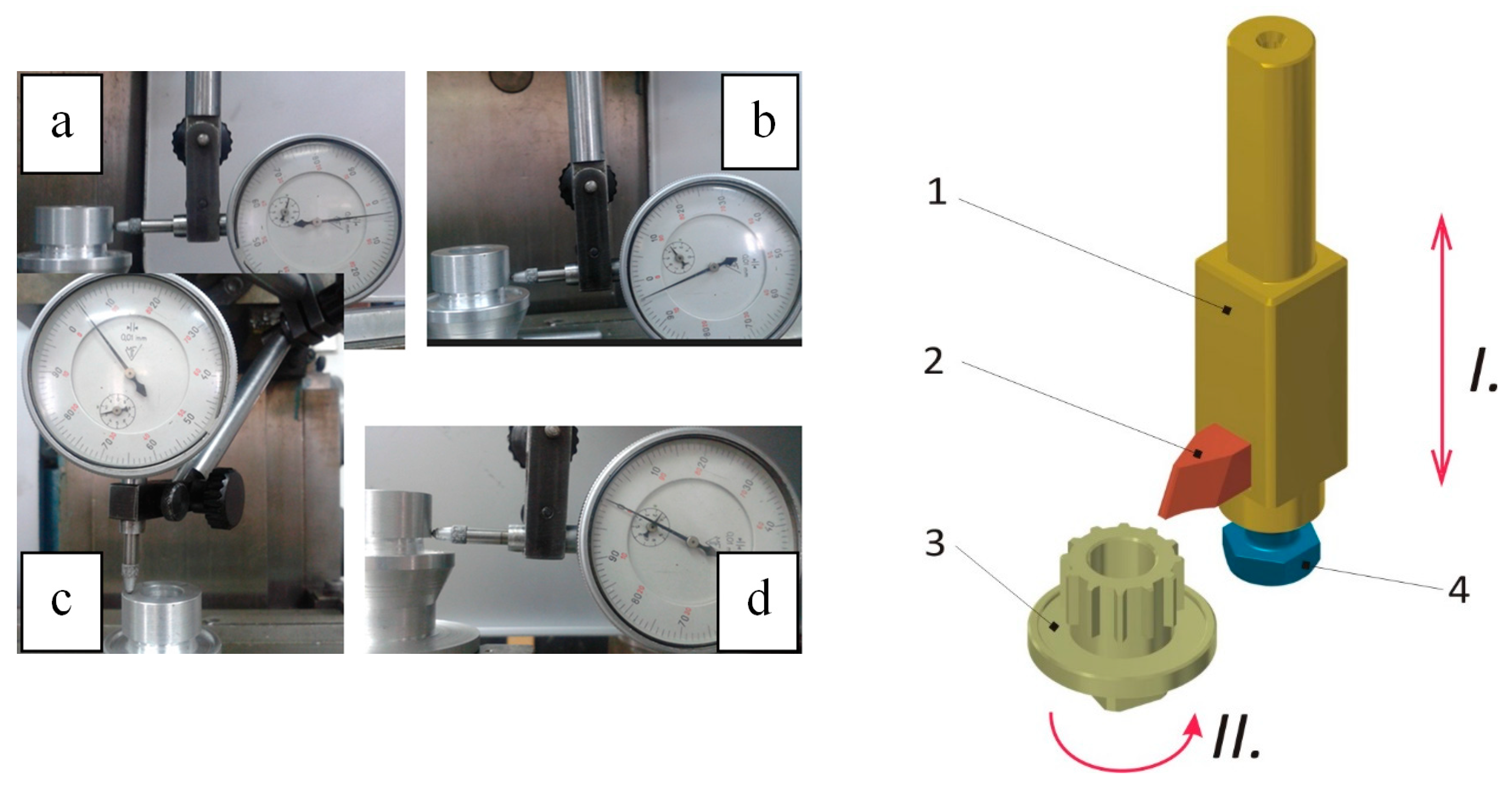

- the piece centered in the universal of the index head and the axis centered of the slotter ram with respect to the axis of the piece, implicitly of the index head, can be observed in Figure 4.

- -

- The measurement of the radial beat on surface “D”at a complete rotation of 360 °, the result of dimensional deviation is exactly 0.03 mm;

- -

- Axial deviation out of the X direction on surface “D” of the part, result of dimensional deviation is exactly 0.035 mm;

- -

- Axial deviation out of the Y direction on surface “D” of the part, the result of dimensional deviation is exactly 0.00 mm;

- -

- Measuring the frontal beat on surface “A” at a complete rotation of 360°, the result of dimensional deviation is exactly 0.045 mm.

3. Results and Discussion

4. Conclusions

References

- Paraschiv, D. Metal Surface Reconditioning and Processing of the ManufacturingTechnologies (Tehnologii de Recondiţionare şi Procesări ale Suprafeţelor Metalice); Junimea Publishing House: Iasi, Romania, 2005. [Google Scholar]

- Jula, A.; Lateş, M. Machine Parts (Organe de Maşini); Transilvania University Publishing House: Braşov, Romania, 2004. [Google Scholar]

- Tero, M.; Bucur, B.; Bratu, G. Descriptive Geometry and Technical Drawing (Geometrie Descriptivă şi Desen Tehnic); Napoca STAR Publishing House: Cluj-Napoca, Romania, 2013. [Google Scholar]

- Available online: https://gsb-international.de/media/pdftoimage/4C6A17BD7A044FB8B71D8F0108F4F21C.PDF (accessed on 31 December 2020).

- Available online: https://metcenter.ru/f/en_573-3.pdf (accessed on 31 December 2020).

- Available online: https://www.resinex.ro/tipurile-de-polimeri/pa.html (accessed on 31 December 2020).

- Socaciu, T. Elements of the Materials Science and Engineering (Elemente de Ştiinţa şi Ingineria materialelor); “Petru Maior” University Publishing House: Târgu Mureş, Romania, 2011. [Google Scholar]

- Nae, I.; Petrescu, M.G.; Bucuroiu, R. Modern Techniques in the Management and Supervision of the Technological Processes, Physics and Modern Technologies (Tehnici Moderne în Conducerea şi Supravegherea Proceselor Tehnologice, Fizica şi Tehnologiile Moderne); Society of Physics of Moldova: Chişinău, Moldova, 2008; Volume 6. [Google Scholar]

- Frăţilă, D. Manufacturing Basics (Bazele Fabricaţiei); UTPRESS Publishing House: Cluj-Napoca, Romania, 2019. [Google Scholar]

- Groover, M.P. Fundamentals of Modern Manufacturing, Materials, Processes, and Systems, 4th ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2010. [Google Scholar]

- The Machine Book—for Universal Lathes from Group B—Basic Type SNB 400 (Cartea Maşinii—Pentru Strungurile Universale din Grupa B—Tip de Bază SNB 400); Lathe Enterprise: Arad, Romania, 1979.

- Available online: https://kupdf.net/download/masina-de-frezat-universala-pentru-scularie-fus22-vol-1_5af5501fe2b6f5bb64666f16_pdf (accessed on 31 December 2020).

- Grama, L. Manufacturing Technologies in Machine Construction (Tehnologii de Fabricare in Constructia de Masini); “Petru Maior” University Publishing House: Târgu Mureş, Romania, 1999. [Google Scholar]

- Teodor, V. Basics of Machining Processes (Bazele Proceselor de Prelucrare prin aşchiere); “Dunarea de Jos” University Publishing House: Galaţi, Romania, 2008. [Google Scholar]

- Diţu, V. Basics of Metal Cutting. Theory and Applications (Bazele Aşchierii Metalelor. Teorie şi Aplicaţii); MatrixRom Publishing House: Bucureşti, Romania, 2008. [Google Scholar]

- Căpăţînă, N. Cutting Tools (Scule Aşchietoare); “Dunarea de Jos” University Publishing House: Galaţi, Romania, 2008. [Google Scholar]

- Rusu, Ş.; Rozsa, F. Guide book for Mortising Processing, (Îndrumar Pentru Prelucrări Prin Rabotare şi Mortezare); Technical Publishing House,: Bucureşti, Romania, 1983; Volume I. [Google Scholar]

| Characteristic Properties | M.U. | Metal | Nylon 6.6 | ||||

|---|---|---|---|---|---|---|---|

| Steel | Al | Mg | Monowire | 30% Fiberglass | 30% Carbonfiber | ||

| The coefficient of linear expansion | 10−6/K | 14 | 22 | 25 | 80 | 30 | 20 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bucur, B.; Bucur, C.; Andronic, G. Peculiarities Regarding the Reconstruction of a Broken Grooved Shaft. Proceedings 2020, 63, 65. https://doi.org/10.3390/proceedings2020063065

Bucur B, Bucur C, Andronic G. Peculiarities Regarding the Reconstruction of a Broken Grooved Shaft. Proceedings. 2020; 63(1):65. https://doi.org/10.3390/proceedings2020063065

Chicago/Turabian StyleBucur, Bogdan, Constantin Bucur, and Gabriela Andronic. 2020. "Peculiarities Regarding the Reconstruction of a Broken Grooved Shaft" Proceedings 63, no. 1: 65. https://doi.org/10.3390/proceedings2020063065

APA StyleBucur, B., Bucur, C., & Andronic, G. (2020). Peculiarities Regarding the Reconstruction of a Broken Grooved Shaft. Proceedings, 63(1), 65. https://doi.org/10.3390/proceedings2020063065