A Technology Platform for the Sustainable Recovery and Advanced Use of Nanostructured Cellulose from Agri-Food Residues (PANACEA Project) †

Abstract

:1. Introduction

- Simple, sustainable, and environmentally friendly processes;

- Cost-effective process cascades to valorize added-value compounds;

- Development of new functionalities and application markets.

- O.1

- Production of intermediate cellulose materials with bioactive molecules from AFRs by proprietary high-pressure technology.

- O.2

- Microbiome selection to degrade intermediate cellulose products.

- O.3

- Development of processes to isolate, purify, functionalize, and characterize NC at different levels of hierarchical organization.

- O.4

- Design of advanced functional materials such as food ingredients, edible coatings, functional colloids, biocides, and flame retardants.

2. State of the Art

3. Methodology

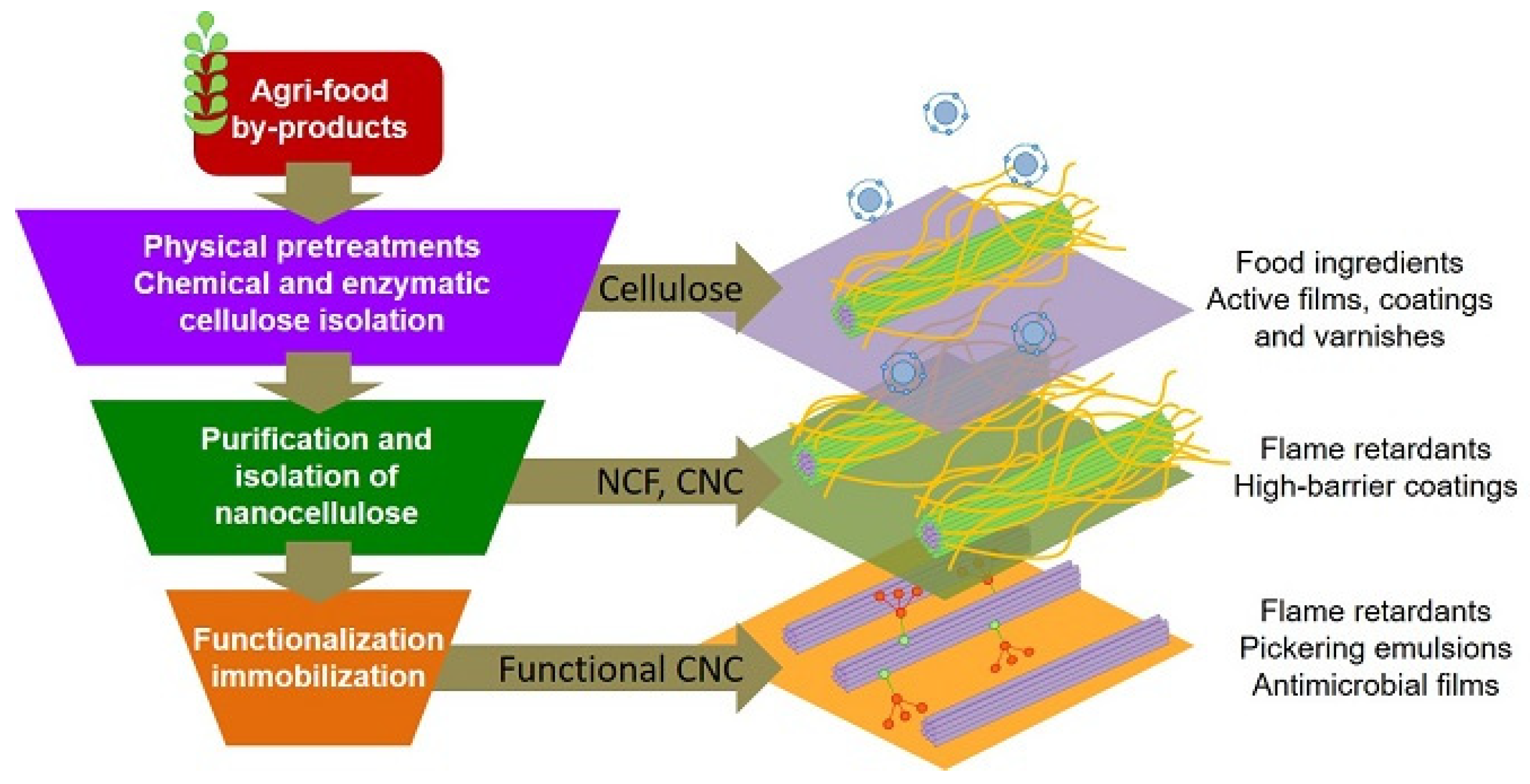

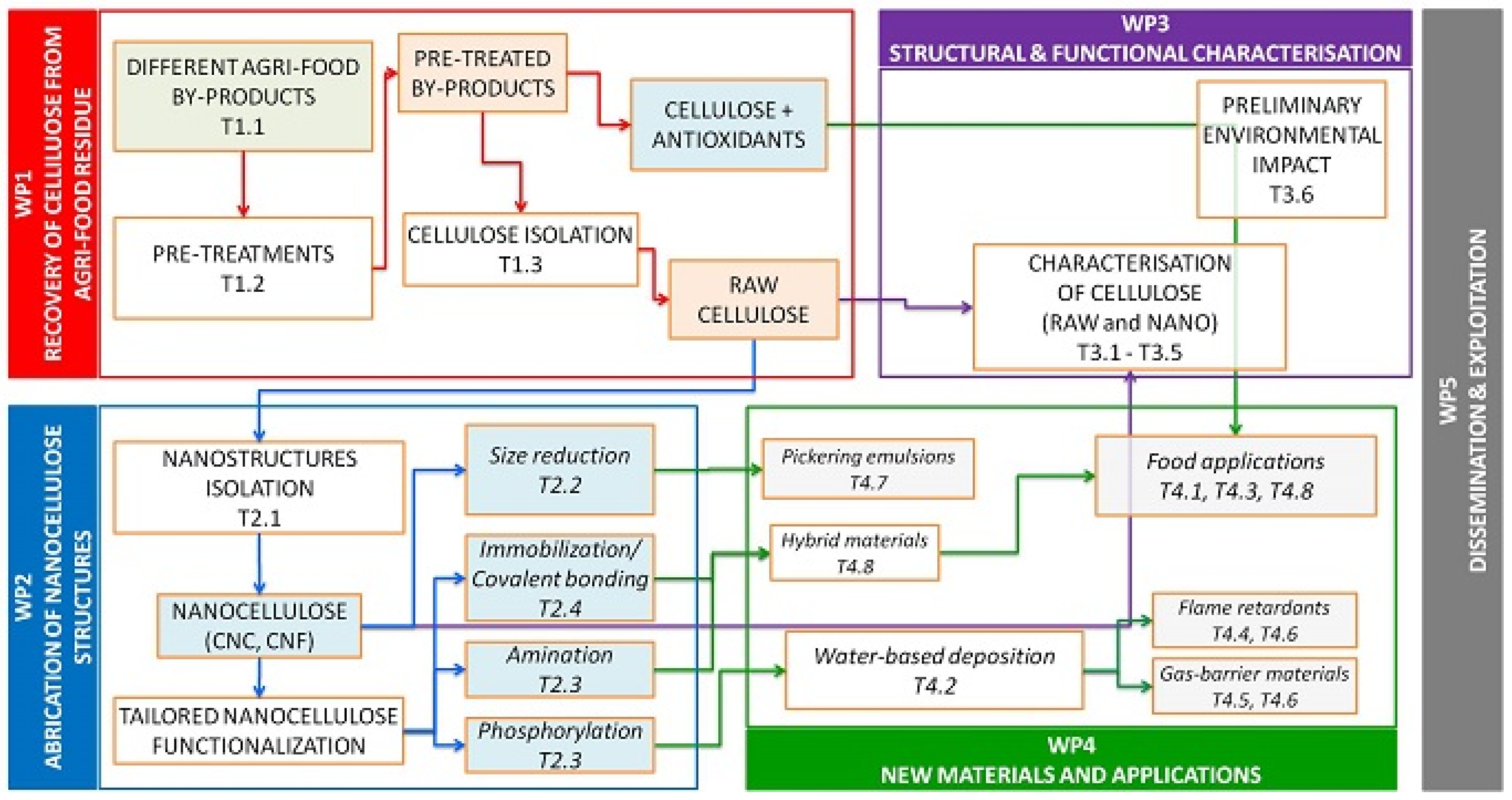

3.1. WP1—Cellulose from Agri-Food Residues

- T1.1:

- Ad hoc pre-treatment of different AFRs, selected also on the basis of their availability during the year (tomato peels and wheat straws, available in summer; coffee ground residues and rice bran, available all year round; grape marcs, available in summer and fall; orange peels, available in winter), chemical characterization and assessment of extractability of cellulose by conventional technologies.

- T1.2:

- Application of proprietary high-pressure homogenization (HPH) technology to micronize the residues in water and completely disintegrate the vegetable cells, unlocking all the intracellular and structural materials. Fractionation of the micronized residues is integrated into the HPH in order to recover insoluble fibers, enriched with bioactives, for food applications [15], for further processing (WP1 and WP2), or for film-forming materials.

- T1.3:

- Separation of hemicellulose–lignin–cellulose, which is carried out via conventional chemical fractionation on the basis of double acid/basic step hydrolysis or by a high-pressure/high-temperature autohydrolysis step. Combination of the HPH treatment with chemical or enzymatic pre-treatments or post-treatments allows for the ability to specifically target the recovery of cellulose and NC (preparatory to WP2).

3.2. WP2—Fabrication of NC Structures

- T2.1:

- Size-reduction of NC and variation of the ratio between crystalline and amorphous regions, via harsh chemical oxidation or mild enzymatic lysis, in order to produce CNF or CNC. The enzyme-mediated biological degradation is applied to fringe the crystallites, providing a site for the easier introduction of functional groups (T2.3).

- T2.2:

- Study of wet milling processes, such as HPH, ball milling, or ultrasounds, to (i) improve the water dispersion of NC, (ii) tailor the average length and diameter of CNF, (iii) activate the CNF surface in view of further chemical modifications, and (iv) partially disintegrate the amorphous cellulose chains while maintaining contact with the crystalline body for the formation of protruding soft biopolymer chains.

- T2.3:

- Reaction protocols for NC functionalization. CNC and CNF are supramolecular structures only marginally stable in solution. Amination enables the formation of hybrid materials with greatly different mechanical properties, or the production of polyampholytes, which undergo optimized interaction with biological systems [16]. Phosphorylation might contribute to developing flame-retarding properties.

- T2.4:

- Functionalization with limonene through (i) physical immobilization in NC hydrogel microbeads to protect limonene from oxidation, increase the water dispersion, and enable its controlled release, or (ii) covalent bonding to CNC for fabricating building blocks, eventually hybridized with inorganic fillers (silicates or graphene oxide), in order to develop antimicrobial materials with controlled release properties.

3.3. WP3—Structural and Functional Characterization

- T3.1:

- A multi-technique approach is applied to the products obtained from WP1 and WP2, on the basis of infrared spectroscopy (FTIR), solid-state NMR spectroscopy, scanning electron microscopy (SEM), transmission electron microscopy (TEM), X-ray diffraction (XRD), and thermal and thermogravimetric analysis. The size of cellulose agglomerates dispersed in water and the stability of the dispersions are evaluated by dynamic light scattering and the specific surface area through gas sorption techniques. The cellulose purity (content of lignin, cellulose, and hemicellulose) and the degree of fibrillation are also determined.

- T3.2:

- The influence of the wet milling processes on the bio-accessibility (through the simulated digestive process) of bioactive compounds and fibers is evaluated.

- T3.3:

- The filming capacity of the micronized residues or the separated fractions is assayed through the addition of suitable additives (such as food-grade plastifying agents) to obtain edible coatings for innovative food applications, such as encapsulation of fruit purees/juices.

- T3.4:

- Evaluation of the gas barrier properties of cellulose and NC recovered in WP1 and WP2.

- T3.5:

- Determination of rheological properties of cellulose and NC in terms of shear stress and viscosity of NC suspensions at equilibrium.

- T3.6:

- The cellulose yields, purity of NC, and associated energy, water, and reagent consumptions are determined to contribute to process sustainability assessment.

3.4. WP4—New Materials and Applications

- T4.1:

- Development of edible coatings, antimicrobial varnishes, and oil structuring materials using the cellulose-based output materials from WP1.

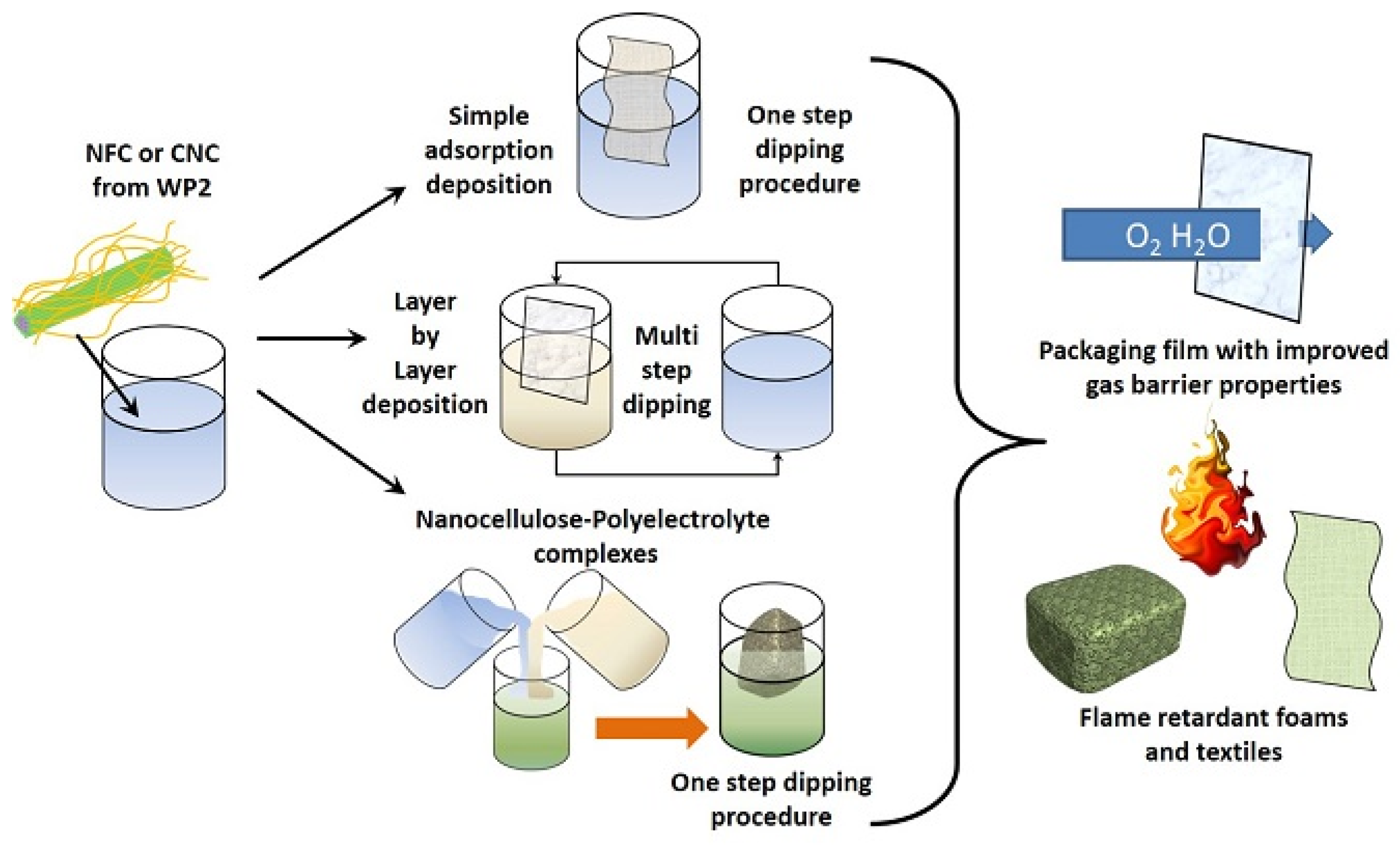

- T4.2:

- Water-based deposition process for NC-based colloids (from WP2) on selected substrates (biobased films, flexible foams, and fabrics), as schematized in Figure 3.

- T4.3:

- Packaging films treated with gas barrier coatings are tested, evaluating oxygen and water vapor permeability at different temperatures and relative humidity values.

- T4.4:

- Gas barrier coatings are tailored to limit the coating swelling in a humid environment in order to prevent the loss of gas barrier properties. The development of cross-linkable coatings will also improve the washing and deformation cycle resistance properties for long-term applications for textile and flexible foams, respectively.

- T4.5:

- Fabrics and foams treated with flame-retardant coatings are thoroughly characterized for flame retardancy. Flammability and cone calorimetry tests permit the checking of the efficiency of the deposited coatings in a realistic fire scenario when free flames can propagate.

- T4.6:

- Realization of advanced nanocomposite films, on the basis of polylactic acid (PLA), and poly(e-caprolactone) (PCL), and foams, on the basis of biopolyurethanes (bioPU) containing NC as nanofillers and treated with high gas barrier coatings and flame-retardant coatings. These materials will also be tested as flame retardants.

- T4.7:

- CNC as a stabilizer to form Pickering emulsions. Emulsions properties and stability is studied vs. solvent parameters, in strong collaboration with the characterization techniques of WP3.

- T4.8:

- Antimicrobial films and coatings are developed, exploiting the natural antimicrobial properties of total extracts from the residues (WP1) and immobilized limonene (WP2).

4. Discussion

- The suspensions, where intracellular compounds are fully unlocked, and cellulose is partly defibrillated (WP1), will be used for oil structuring, or active coatings containing natural antioxidant compounds and proteins, as preliminary demonstrated in pioneering works [15].

- The CNC compact nanostructures, thanks to the hydroxyl groups exposed at the surface, provide the interface for the self-assembly of the individual nanostructures into macroscopic phases such as hydro- or aerogels, foams, and films, or chemical modification, opening new opportunities for innovative applications.

- Replacement of traditional flame-retarding polymers, based on halogenated additives, posing severe environmental and health concerns, with approaches employing NC as building block for gas barrier and flame retardancy coatings,

- Enhancement of biopolymer gas barrier properties thanks to the use of NC in either multilayered high barrier thin coatings or as biobased filler.

- Realization of novel biobased or biodegradable polymer nanocomposite films (PLA, PCL) with advanced gas barrier properties and biobased nanocomposite foams (bioPU) with advanced flame-retardant properties, obtained by the effective embedding of properly functionalized NC within the polymer matrices and the application of functional NC-based coatings.

- Nanoparticle-stabilized emulsions (Pickering emulsions) form more stable suspensions than soluble surfactants. CNC is a promising yet underused material to develop such systems because of the large surface energy and the possibility to control the surface chemistry. Emulsion droplet size depends on the size of NC particles, which is hence the critical parameter to be controlled in WP2.

- Terpenes (i.e., limonene) are a versatile chemical platform for new synthetic building blocks. The combination of bioactivity and reactivity of limonene with the mechanical and structural properties of CNC is expected to add functionalities, particularly as natural biocides and pest-control agents, and flame-retardant materials, which have not been explored before.

5. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Fava, F.; Totaro, G.; Diels, L.; Reis, M.; Duarte, J.; Carioca, O.B.; Poggi-Varaldo, H.M.; Ferreira, B.S. Biowaste biorefinery in Europe: Opportunities and research & development needs. New Biotechnol. 2015, 32, 100–108. [Google Scholar] [CrossRef]

- Szymanska-Chargot, M.; Chylinska, M.; Gdula, K.; Koziol, A.; Zdunek, A. Isolation and characterization of cellulose from different fruit and vegetable pomaces. Polymers 2017, 9, 495. [Google Scholar] [CrossRef] [PubMed]

- Nawirska, A.; Uklanska, C. Waste products from fruit and vegetable processing as potential sources for food enrichment in dietary fibre. Acta Sci. Pol. Technol. Aliment. 2008, 7, 35–42. [Google Scholar]

- Dhillon, G.S.; Kaur, S.; Brar, S.K. Perspective of apple processing wastes as low-cost substrates for bioproduction of high value products: A review. Renew. Sustain. Energy Rev. 2013, 27, 789–805. [Google Scholar] [CrossRef]

- Nawirska, A.; Kwaśniewska, M. Dietary fibre fractions from fruit and vegetable processing waste. Food Chem. 2005, 91, 221–225. [Google Scholar] [CrossRef]

- Dufresne, A. Nanocellulose: A new ageless bionanomaterial. Mater. Today 2013, 16, 220–227. [Google Scholar] [CrossRef]

- Chen, H.; Seiber, J.N.; Hotze, M. ACS Select on Nanotechnology in Food and Agriculture: A Perspective on Implications and Applications. J. Agric. Food Chem. 2014, 62, 1209–1212. [Google Scholar] [CrossRef] [PubMed]

- Nechyporchuk, O.; Belgacem, M.N.; Bras, J. Production of cellulose nanofibrils: A review of recent advances. Ind. Crops Prod. 2016, 93, 2–25. [Google Scholar] [CrossRef]

- Das, H.; Singh, S.K. Useful Byproducts from Cellulosic Wastes of Agriculture and Food Industry—A Critical Appraisal. Crit. Rev. Food Sci. Nutr. 2004, 44, 77–89. [Google Scholar] [CrossRef] [PubMed]

- Shen, T.; Gnanakaran, S. The Stability of Cellulose: A Statistical Perspective from a Coarse-Grained Model of Hydrogen-Bond Networks. Biophys. J. 2009, 96, 3032–3040. [Google Scholar] [CrossRef] [PubMed]

- Klemm, D.; Kramer, F.; Moritz, S.; Lindström, T.; Ankerfors, M.; Gray, D.; Dorris, A. Nanocelluloses: A new family of nature-based materials. Angew. Chem. Int. Ed. 2011, 50, 5438–5466. [Google Scholar] [CrossRef] [PubMed]

- Afrin, S.; Karim, Z. Isolation and Surface Modification of Nanocellulose: Necessity of Enzymes over Chemicals. ChemBioEng Rev. 2017, 4, 289–303. [Google Scholar] [CrossRef]

- Mondal, S. Preparation, properties and applications of nanocellulosic materials. Carbohydr. Polym. 2017, 163, 301–316. [Google Scholar] [CrossRef] [PubMed]

- Gómez Hoyos, C.; Serpa, A.; Velásquez-Cock, J.; Gañán, P.; Castro, C.; Vélez, L.; Zuluaga, R. Vegetable nanocellulose in food science: A review. Food Hydrocoll. 2016, 57, 178–186. [Google Scholar] [CrossRef]

- Ferrari, G.; Mustafa, W.; Donsì, F. Use of agri-food residues for oil structuring and functionalization. Chem. Eng. Trans. 2017, 57, 1831–1836. [Google Scholar]

- Jurić, S.; Ferrari, G.; Velikov, K.P.; Donsì, F. High-pressure homogenization treatment to recover bioactive compounds from tomato peels. J. Food Eng. 2019, 262, 170–180. [Google Scholar] [CrossRef]

- Donsì, F.; Velikov, K.P. Mechanical cell disruption of mustard bran suspensions for improved dispersion properties and protein release. Food Funct. 2020, 11, 6273–6284. [Google Scholar] [CrossRef]

- Gali, L.; Bedjou, F.; Velikov, K.P.; Ferrari, G.; Donsì, F. High-pressure homogenization-assisted extraction of bioactive compounds from Ruta chalepensis. J. Food Meas. Charact. 2020, 14, 2800–2809. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Donsì, F.; Bartolucci, S.; Bettotti, P.; Carosio, F.; Contursi, P.; Gentile, G.; Scarpa, M.; Spigno, G. A Technology Platform for the Sustainable Recovery and Advanced Use of Nanostructured Cellulose from Agri-Food Residues (PANACEA Project). Proceedings 2021, 69, 16. https://doi.org/10.3390/CGPM2020-07212

Donsì F, Bartolucci S, Bettotti P, Carosio F, Contursi P, Gentile G, Scarpa M, Spigno G. A Technology Platform for the Sustainable Recovery and Advanced Use of Nanostructured Cellulose from Agri-Food Residues (PANACEA Project). Proceedings. 2021; 69(1):16. https://doi.org/10.3390/CGPM2020-07212

Chicago/Turabian StyleDonsì, Francesco, Simonetta Bartolucci, Paolo Bettotti, Federico Carosio, Patrizia Contursi, Gennaro Gentile, Marina Scarpa, and Giorgia Spigno. 2021. "A Technology Platform for the Sustainable Recovery and Advanced Use of Nanostructured Cellulose from Agri-Food Residues (PANACEA Project)" Proceedings 69, no. 1: 16. https://doi.org/10.3390/CGPM2020-07212

APA StyleDonsì, F., Bartolucci, S., Bettotti, P., Carosio, F., Contursi, P., Gentile, G., Scarpa, M., & Spigno, G. (2021). A Technology Platform for the Sustainable Recovery and Advanced Use of Nanostructured Cellulose from Agri-Food Residues (PANACEA Project). Proceedings, 69(1), 16. https://doi.org/10.3390/CGPM2020-07212