Using Olive Stone Powder for Biodegradation of Bio-Based Polyamide 5.6 †

Abstract

:1. Introduction

2. Experiments

2.1. Materials

2.2. Compounding and Sample Preparation

2.3. Fourier Transform Infrared (FTIR) Analysis

2.4. Biodegradability

3. Results

3.1. Fourier Transform Infrared (FTIR) Analysis

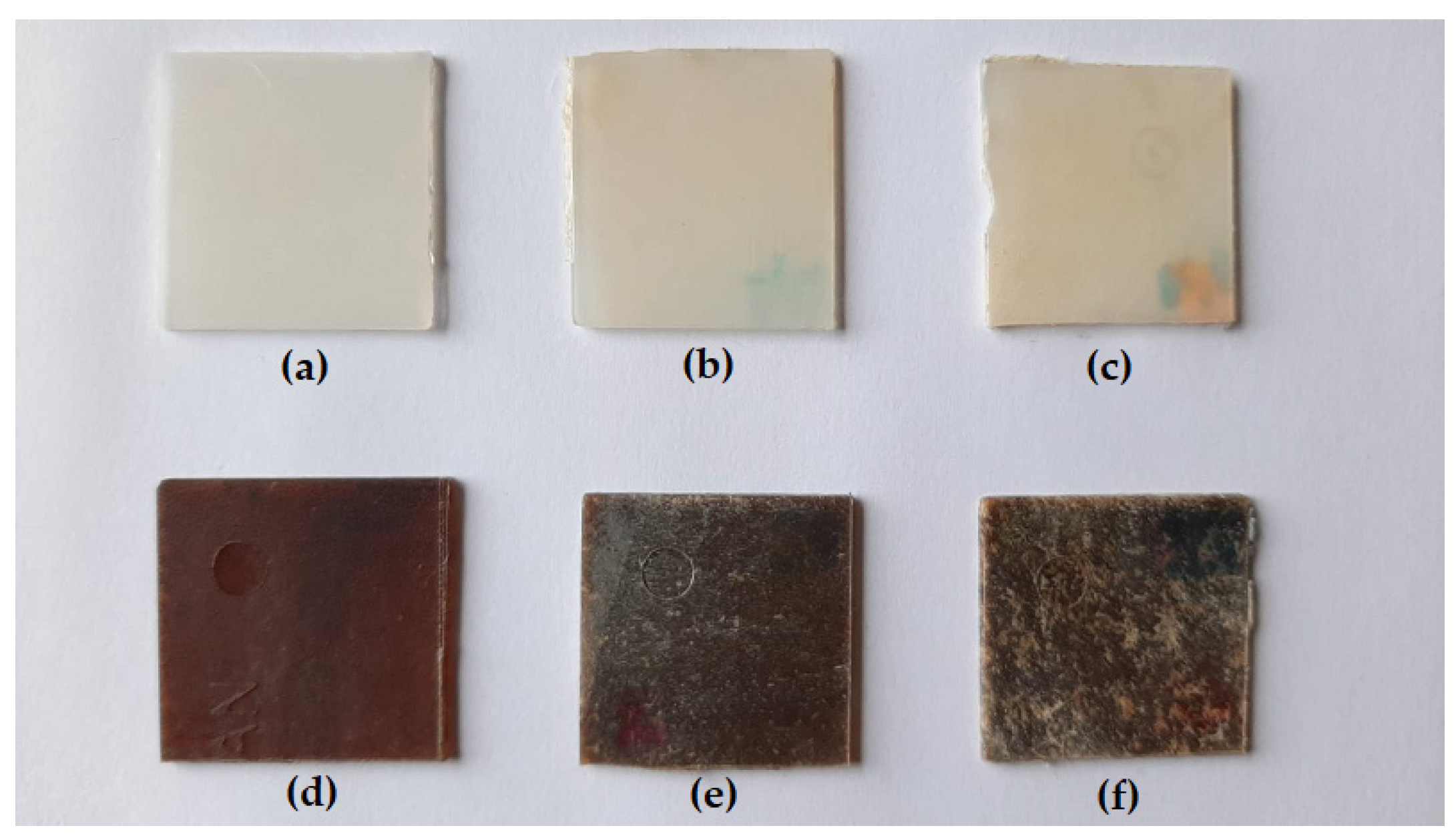

3.2. Biodegradability

4. Discussion

4.1. Fourier Transform Infrared (FTIR) Analysis

4.2. Biodegradability

5. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

Abbreviations

| PA56 | Polyamide 5.6 |

| OSP | Olive stone powder |

| FTIR | Fourier transform infrared |

References

- Plastics Europe AISBL. Plastics—The Facts 2019. Available online: https://www.plasticseurope.org/application/files/9715/7129/9584/FINAL_web_version_Plastics_the_facts2019_14102019.pdf (accessed on 14 October 2020).

- Aeschelmann, F.; Carus, M. Bio-based Building Blocks and Polymers in the World: Capacities, Production and Applications–Status Quo and Trends Towards 2020. Ind. Biotechnol. 2015, 11, 154–159. [Google Scholar] [CrossRef]

- Kyulavska, M.; Toncheva-Moncheva, N.; Rydz, J. Biobased Polyamide Ecomaterials and Their Susceptibility to Biodegradation. In Handbook of Ecomaterials; Martínez, L.M.T., Kharissova, O.V., Kharisov, B.I., Eds.; Springer International Publishing: Cham, Switzerland, 2017; pp. 2901–2934. [Google Scholar]

- Dotan, A. Biobased Thermosets. In Handbook of Thermoset Plastics, 3rd ed.; William Andrew Publishing: New York, NY, USA, 2014; pp. 577–622. [Google Scholar]

- Meraldo, A. Introduction to Bio-based Polymers. In Multilayer Flexible Packaging, 2nd ed.; William Andrew Publishing: New York, NY, USA, 2016; pp. 47–52. [Google Scholar]

- Reddy, R.L.; Reddy, V.S.; Gupta, G.A. Study of Bio-Plastics as Green and Sustainable Alternative to Plastics. Int. J. Emerg. Technol. Adv. Eng. 2013, 3, 82–89. [Google Scholar]

- Nakajima, H.; Dijkstra, P.; Loos, K. The Recent Developments in Biobased Polymers toward General and Engineering Applications: Polymers that are Upgraded from Biodegradable Polymers, Analogous to Petroleum-Derived Polymers, and Newly Developed. Polymers 2017, 9, 523. [Google Scholar] [CrossRef] [PubMed]

- Prasteen, P.; Thushyanthy, Y.; Mikunthan, T.; Prabhaharan, M. Bio-Plastics—An Alternative to Petroleum Based Plastics. Int. J. Res. Stud. Agric. Sci. 2018, 4, 1–7. [Google Scholar]

- Li, M.; Li, D.; Huang, Y.; Liu, M.; Wang, H.; Tang, Q.; Lu, F. Improving the Secretion of Cadaverine in Corynebacterium glutamicum by Cadaverine–Lysine Antiporter. J. Ind. Microbiol. Biotechnol. 2014, 41, 701–709. [Google Scholar] [CrossRef] [PubMed]

- Shah, A.A.; Hasan, F.; Hameed, A.; Ahmed, S. Biological Degradation of Plastics: A Comprehensive Review. Biotechnol. Adv. 2008, 26, 246–265. [Google Scholar] [CrossRef] [PubMed]

- Vroman, I.; Tighzert, L. Biodegradable polymers. Materials 2009, 2, 307–344. [Google Scholar] [CrossRef]

- Koutsomitopoulou, A.F.; Bénézet, J.C.; Bergeret, A.; Papanicolaou, G.C. Preparation and Characterization of Olive Pit Powder as a Filler to PLA-matrix Bio-composites. Powder Technol. 2014, 255, 10–16. [Google Scholar] [CrossRef]

- Food and Agriculture Organization of the United Nations. Available online: http://www.fao.org/faostat/en/#data/QC/visualize (accessed on 17 October 2020).

- Rodríguez, G.; Lama, A.; Rodríguez, R.; Jiménez, A.; Guillén, R.; Fernández-Bolanos, J. Olive Stone an Attractive Source of Bioactive and Valuable Compounds. Bioresour. Technol. 2008, 99, 5261–5269. [Google Scholar] [CrossRef]

- Matos, M.; Barreiro, M.F.; Gandini, A. Olive Stone as a Renewable Source of Biopolyols. Ind. Crop. Prod. 2010, 32, 7–12. [Google Scholar] [CrossRef]

- Naghmouchi, I.; Mutjé, P.; Boufi, S. Olive Stones Flour as Reinforcement in Polypropylene Composites: A Step Forward in the Valorization of the Solid Waste from the Olive Oil Industry. Ind. Crop. Prod. 2015, 72, 183–191. [Google Scholar] [CrossRef]

- Naghmouchi, I.; Mutjé, P.; Boufi, S. Polyvinyl Chloride Composites Filled With Olive Stone Flour: Mechanical, Thermal, and Water Absorption Properties. J. Appl. Polym. Sci. 2014, 131, 183–191. [Google Scholar] [CrossRef]

- Turkish State Meteorological Service. Available online: https://mgm.gov.tr/veridegerlendirme/sicaklik-analizi.aspx?s=a#sfB (accessed on 17 October 2020).

- Horikawa, Y.; Hirano, S.; Mihashi, A.; Kobayashi, Y.; Zhai, S.; Sugiyama, J. Prediction of Lignin Contents From Infrared Spectroscopy: Chemical Digestion And Lignin/Biomass Ratios of Cryptomeria japonica. Appl. Biochem. Biotechnol. 2019, 188, 1066–1076. [Google Scholar] [CrossRef] [PubMed]

- Yaacob, N.D.; Ismail, H.; Ting, S.S. Soil Burial of Polylactic Acid/Paddy Straw Powder Biocomposite. BioResources 2016, 11, 1255–1269. [Google Scholar] [CrossRef]

- Vert, M.; Doi, Y.; Hellwich, K.H.; Hess, M.; Hodge, P.; Kubisa, P.; Rinaudo, M.; Schué, F. Terminology for Biorelated Polymers And Applications. Pure Appl. Chem. 2012, 84, 377–410. [Google Scholar] [CrossRef]

- Tokiwa, Y.; Calabia, B.P.; Ugwu, C.U.; Aiba, S. Biodegradability of Plastics. Int. J. Mol. Sci. 2009, 10, 3722–3742. [Google Scholar] [CrossRef] [PubMed]

| Months | Average Temperature (°C) | Number of Rainy Days | Rainfall (mm) |

|---|---|---|---|

| February | 7.0 | 13 | 73 |

| March | 11.1 | 12 | 55 |

| April | 12.9 | 8 | 47 |

| May | 18.7 | 12 | 71 |

| June | 22.1 | 6 | 65 |

| July | 24.0 | 2 | 4 |

| Materials | PA56 Content (wt%) | OSP Content (wt%) | Weight Loss after 6 Months (%) |

|---|---|---|---|

| PA56 | 100% | 0% | 0.26% |

| PA56/OSP10 | 90% | 10% | 5.24% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gülel, Ş.; Güvenilir, Y. Using Olive Stone Powder for Biodegradation of Bio-Based Polyamide 5.6. Proceedings 2021, 69, 2. https://doi.org/10.3390/CGPM2020-07214

Gülel Ş, Güvenilir Y. Using Olive Stone Powder for Biodegradation of Bio-Based Polyamide 5.6. Proceedings. 2021; 69(1):2. https://doi.org/10.3390/CGPM2020-07214

Chicago/Turabian StyleGülel, Şebnem, and Yüksel Güvenilir. 2021. "Using Olive Stone Powder for Biodegradation of Bio-Based Polyamide 5.6" Proceedings 69, no. 1: 2. https://doi.org/10.3390/CGPM2020-07214