Abstract

The recently approved restriction on diisocyanates highlights the health and safety issues concerning polyurethane manufacturing and the relevance of developing sustainable insulating polymeric foams. This is particularly challenging for applications where the foam is subjected to high temperatures (>80 °C) and bear loads, such as insulating and bonding material for district heating pipes. As part of a PhD project concerning pre-insulated district heating pipes for the circular economy, polybutylene (PB-1) has been identified as a promising candidate for the application, due to its low thermal conductivity, high-temperature mechanical properties, retention, excellent environmental stress cracking resistance (ESCR) and outstanding creep resistance. It is a recyclable thermoplastic and of non-toxic nature, pre-requisites for circular product development. On the contrary to other polyolefins, PB-1 is reported to strain-harden and has high melt strength, required properties for foaming. The purpose of the study is to assess the foamability of PB-1 through extrusion foaming experiments. A twin-screw extruder was used with varying concentrations of a chemical blowing agent. The obtained samples have been characterised for density, expansion ratio and microstructure. Foams with a volume expansion ratio of 1.8 were achieved. The results confirm the foamability of this polymer. The increase of the die pressure and its contribution to strain hardening were identified as key parameters for successful foaming. Further research will include improving the expansion ratio with a physical blowing agent and mechanical characterization of the foam.

1. Introduction

District heating (DH) infrastructure is called to be a cornerstone element towards decarbonizing the heating sector. Thanks to a district heating network, the use of decentralized renewable and waste heat sources is enabled. For its technical and economic feasibility, correct insulation of district heating pipes is critical. As for state of the art, all district heating pipes are insulated with polyurethane foam (PU) [1].

PU foams present the lowest thermal conductivity among foamed polymers used commercially [2]. While PU has excellent thermal and mechanical properties, it has important environmental and toxicity drawbacks, which trigger the need for research in new and alternative insulating foams.

PU is produced from a ca. 50/50 mix of a polyol and either TDI (toluene diisocyanate) or MDI (methylene diphenyl diisocyanate). TDI and MDI are classified as suspected of causing cancer, as dermal and respiratory sensitizers, for acute toxicity following inhalation, as well as eye, skin and respiratory irritants under the EU’s CLP Regulation [3]. The European Commission has approved to restrict the use of diisocyanates to a concentration limit of 0.1% by weight under REACH on 4 August 2020 [4].

There is a need for developing environmentally friendly insulating foams following a holistic approach: conceptualized from the beginning out of non-toxic and recyclable materials and a safe manufacturing process. In this context, the foamability of PB-1 is explored. Promissing properties for the application are its low thermal conductivity of 0.114 W/mK [5], good mechanical property retention under high temperature, excellent environmental stress cracking resistance (ESCR) and outstanding creep resistance [6]. It is a recyclable thermoplastic and of non-toxic nature, pre-requisites for circular product development. In contrast to other polyolefins, PB-1 is reported to strain harden and has high melt strength [6], required properties for foaming [7]. However, its foaming behaviour has not been found reported in the open literature. In this study, the foamability of PB-1 is studied through extrusion foaming experiments with a chemical blowing agent. The obtained samples have been characterised for density, expansion ratio and microstructure. Foamability is assessed in terms of achieved volume expansion ratio, microstrucure and processing window using available extrusion equipment. Optimization of the foaming process is out of the scope of this study. The presented results are part of a larger screening of commercial PB-1 grades.

2. Experiments

2.1. Materials

Toppyl PB0110M PB-1 from LyondellBasell was extrusion foamed using Hydrocerol CT 550 chemical blowing agent (CBA), kindly provided by Clariant.

2.2. Extrusion Foaming Process

The extrusion process was undertaken with a twin screw ZSE 27 MAXX extruder (Leistritz Extrusionstechnik GmbH, Nürnberg, Germany), with D = 28.3 mm, L/D = 48, and 12 modular barrels with 2.1 kW heating power each and water cooling. A strand die with three strands of 4 mm diameter each was used. The feeding temperature was set as low as possible as to create a melt seal and avoid premature degassing of the CBA, which was set at 140 °C. The temperature was progressively increased to 175 °C after the CBA dosing point, which as to allow its complete decomposition, and then progressively lowered. The amount of dosed CBA was varied from 4.2 to 10% wt., for die exit temperatures of 110 and 115 °C. Screw speed rate and feed rate were kept constant to 100 rpm and 4 kg/h respectively.

2.3. Foam Characterization

The foam samples were randomly collected at each processing condition after achieving the steady state and characterized for density, volume expansion, cell size and cell density.

The density was determined with a 100 mL glass pycnometer, distilled water and a Sartorius AC 211 S (Goettingen, Germany) balance.

Foam volume expansion ratio is often determined as the ratio between the density of the polymer and the density of the foam. However, since a CBA is used—for which the effective foaming components amount to 70% wt., and up to 10% wt.—CBA was dosed, resulting in the addition of 3.3% wt. of the decomposition products. It was found to be more accurate to determine the volume expansion ratio Vexp as

in an analogous method to the one used by [8].

The diameter of the obtained foam samples and neat polymer extrudates were obtained from photographs taken using a Nikon D700 camera and a tripod. Photographs were recorded from immediately after collection (max. time between collection and initial photo 20 s) up to over 2 h after extrusion, in 20 s time-lapse intervals. The diameter of each strand was measured in five different locations of each strand once its dimension was stable using Fiji [9]. The average of the five measurements is presented in each case.

The morphology of the foams was examined in an optical microscope (Leica DMLP, Wetzlar, Germany). Cell size was measured from the obtained micrographs using Fiji [9]. Cell population density (N0), defined as the number of cells per unit volume of the original unfoamed polymer, was calculated as [10,11]:

where (N0) is the cell population density (cell/cm3), n is the number of cells in the micrograph and A the area of the micrograph (cm2).

3. Results and Discussion

The density of the obtained samples is presented in Table 1.

Table 1.

Density for samples under different process conditions.

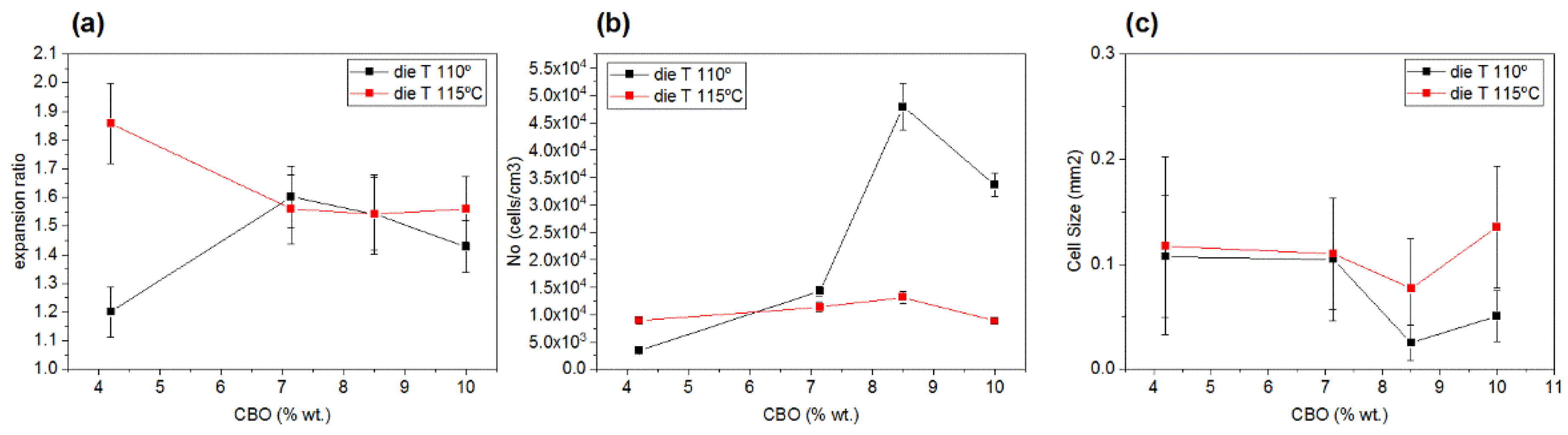

The determined volume expansion ratio, cell population density and cell size and their relation to the process conditions can be found in Figure 1.

Figure 1.

(a) Expansion ratio vs. introduced amount of CBA. (b) Cell population density vs. introduced amount of CBA. (c) Cell size vs. introduced amount of CBA.

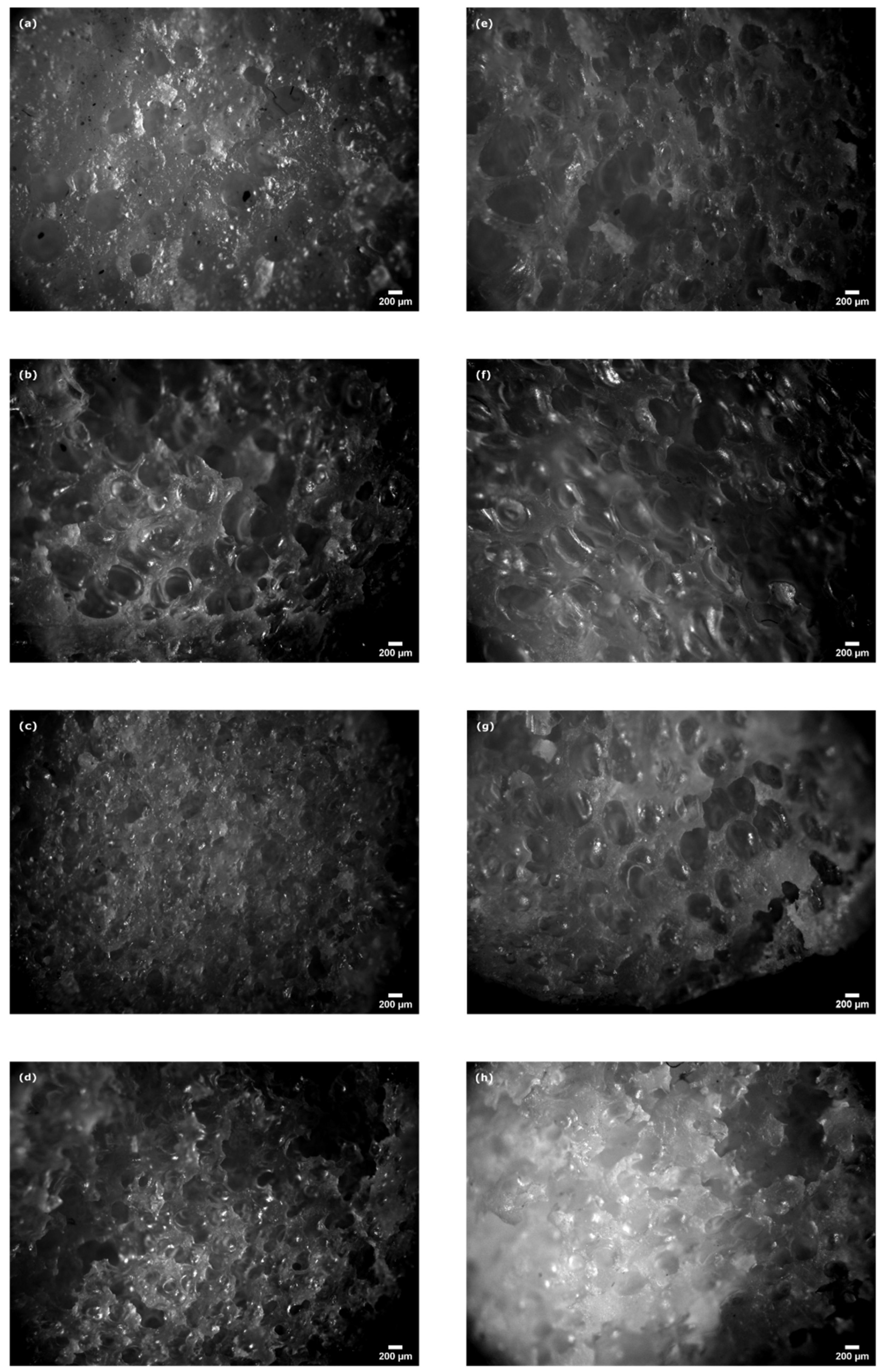

Representative micrographs for each process condition can be found in Figure 2.

Figure 2.

Micrographs of obtained foams under different process conditions: die T° = 110 °C and 4.2% CBA (a); 7.1% CBA (b); 8.5% CBA (c) and 10% CBA (d) die T° = 115 °C and 4.2% CBA (e); 7.1% CBA (f); 8.5% CBA (g) and 10% CBA (h).

3.1. Microstructural Characterization and the Relationship with the Process Conditions

As can be seen in Figure 1c and Figure 2, foams present large pores with significant cell size variability. The two die temperatures used did not produce any difference in the obtained cell size for CBA concentrations of 4.2 and 7.1% wt. Cell size decreased for 8.5% wt. as cell population density increased. This inverse trend has been previously reported [12]. This effect is particularly significant for the 110 °C die T° trial, where the average cell size was reduced by more than 50%. After this point N0 decreased again and cell size increased. This can be explained as the increase of CBA provides more available gas for cell nucleation, until a maximum is reached. With further gas increase and cell growth, cells collide against each other, reducing the n° of cells and increasing their size [13], as can be observed by the trends in Figure 1b,c.

3.2. Effect of Process Conditions on the Volume Expansion Ratio

The two die temperatures tested were selected as a result of a preliminary process parameter screening. With die T° over 120 °C, limited expansion was achieved. This is an indication for low melt strength, which prevents the polymer melt from withstanding the stretching forces of the bubble growth, leading to cell collapse, and of high gas diffusion out of the polymer matrix. The lower processing temperature was conditioned by viscosity, being 110 °C the lowest temperature at which the melt would flow out of the extruder.

As can be seen in Figure 1a, with the die T° of 110 °C, the expansion ratio increased until a maximum and then decreased. This indicated that at this temperature the expansion behaviour is governed by the polymer melt’s stiffness. Expansion increases with increasing CBA concentration due to the plasticisation effect of the gas [12]. After reaching a maximum, the gas starts diffusing out of the polymer’s hot skin. For the 115 °C die temperature series, the maximum expansion was achieved with the lowest concentration of CBA tested. Since the cell size and cell population density of the samples obtained at the lowest concentration (4.2%) was not higher than those obtained with increasing CBA dosages, we can conclude that from that dosage the increased level of gas just increased the diffusion out of the hot skin of the extrudates, thus the volume expansion remained at constant levels.

During the execution of the trials, a transient situation was encountered where the die pressure was increased from the 45 bar of the reported trials up to 75 bar. Under these conditions, a higher volume expansion was obtained, and strain hardening was observed on the extrudates. The relationship between strain hardening and successful foaming is known in the field [7], as well as the relation between pressure drop and cell population density [14]. The data of this obtained foam are not included due to the non-reproductible process conditions (transient), but show the potential of improved foaming of this resin under optimal process conditions. As mentioned in the introduction, process optimization is out of the scope of this study, which aims at screening foamability.

4. Conclusions

An experimental study on the extrusion foaming behaviour of a commercial PB-1 resin was presented. Foamability of the resin was confirmed. High-density foams were produced, with a volume expansion of 1.8. The processing window was screened and the influence of process conditions on the microstructure and volume expansion of the obtained foams was studied, indicating that PB-1 foam of medium density can be produced when the foaming process is optimized.

Author Contributions

L.D. was responsible for the study design and conception, performing the experiments, analysing the data, and chiefly responsible for preparing the manuscript. I.W. provided scientific supervision of the study. Both authors contributed to the critical discussion of the results and editing of the manuscript. All authors have read and agreed to the published version of the manuscript.

Acknowledgments

The work reported is self-funded by the HafenCity University. Xihua Hu and Irina Smirnova, from the Technical University of Hamburg, are gratefully thanked for making the extruder available. The Hamburg Energy Research Network (EFH) is kindly acknowledged for facilitating the cooperation.

Conflicts of Interest

The authors declare no conflict of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| PB-1 | Polybutylene |

| ESCR | Environmental stress cracking resistance |

| DH | District heating |

| PU | Polyurethane |

| TDI | Toluene diisocyanate |

| MDI | Methylene diphenyl diisocyanate |

| EU | European Union |

| CLP Regulation | Classification, labelling and packaging of substances and mixtures regulation |

| REACH | Registration, evaluation, authorisation and restriction of chemicals |

| CBA | Chemical blowing agent |

| wt. | Weight |

| T° | Temperature |

References

- Nilsson, S.F. New developments in pipes and related network components for district heating. In Advanced District Heating and Cooling (DHC) Systems; Elsevier: Amsterdam, The Netherlands, 2016; pp. 191–214. ISBN 9781782423744. [Google Scholar]

- Kurańska, M.; Prociak, A. Bio-Based Polyurethane Foams for Heat-Insulating Applications. In Nano and Biotech Based Materials for Energy Building Efficiency; Pacheco Torgal, F., Buratti, C., Kalaiselvam, S., Granqvist, C.-G., Ivanov, V., Eds.; Springer International Publishing: Cham, Switzerland, 2016; pp. 357–373. ISBN 978-3-319-27503-1. [Google Scholar]

- The European Parliament and the Council of the European Union. CLP Regulation; (EC) No 1272/2008. Off. J. Eur. Union 2008.

- Commission Regulation (EU). 2020/1149 of 3 August 2020 Amending Annex XVII to Regulation (EC) No 1907/2006 of the European Parliament and of the Council Concerning the Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH) as Regards Diisocyanates: (EU) 2020/1149. Off. J. Eur. Union 2020. [Google Scholar]

- Wypych, G. Handbook of Plasticizers, 3rd ed.; Chemtec: Toronto, ON, Canada, 2017; ISBN 9781895198973. [Google Scholar]

- Olabisi, O.; Adewale, K. Handbook of Thermoplastics; CRC Press: Boca Raton, FL, USA, 2016; ISBN 1466577223. [Google Scholar]

- Lee, S.-T.; Park, C.B. (Eds.) Foam Extrusion. Principles and Practice, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2014; ISBN 9781439898598. [Google Scholar]

- Jeong, B.; Xanthos, M.; Seo, Y. Extrusion Foaming Behavior of PBT Resins. J. Cell. Plast. 2006, 42, 165–176. [Google Scholar] [CrossRef]

- Schindelin, J.; Arganda-Carreras, I.; Frise, E.; Kaynig, V.; Longair, M.; Pietzsch, T.; Preibisch, S.; Rueden, C.; Saalfeld, S.; Schmid, B.; et al. Fiji: An open-source platform for biological-image analysis. Nat. Methods 2012, 9, 676–682. [Google Scholar] [CrossRef]

- Liu, H.; Wang, X.; Liu, W.; Liu, B.; Zhou, H.; Wang, W. Reactive Modification of Poly(ethylene terephthalate) and its Foaming Behavior. Cell. Polym. 2014, 33, 189–212. [Google Scholar] [CrossRef]

- Reignier, J.; Gendron, R.; Champagne, M.F. Autoclave Foaming of Poly(ε-Caprolactone) Using Carbon Dioxide: Impact of Crystallization on Cell Structure. J. Cell. Plast. 2007, 43, 459–489. [Google Scholar] [CrossRef]

- Kaewmesri, W.; Lee, P.C.; Park, C.B.; Pumchusak, J. Effects of CO2 and Talc Contents on Foaming Behavior of Recyclable High-melt-strength PP. J. Cell. Plast. 2006, 42, 405–428. [Google Scholar] [CrossRef]

- Matuana, L.M.; Faruk, O.; Diaz, C.A. Cell morphology of extrusion foamed poly(lactic acid) using endothermic chemical foaming agent. Bioresour. Technol. 2009, 100, 5947–5954. [Google Scholar] [CrossRef]

- Guo, Q.; Wang, J.; Park, C.B.; Ohshima, M. A Microcellular Foaming Simulation System with a High Pressure-Drop Rate. Ind. Eng. Chem. Res. 2006, 45, 6153–6161. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).