Smart Odour Sensing for Automated Monitoring of Bread Products †

Abstract

1. Introduction

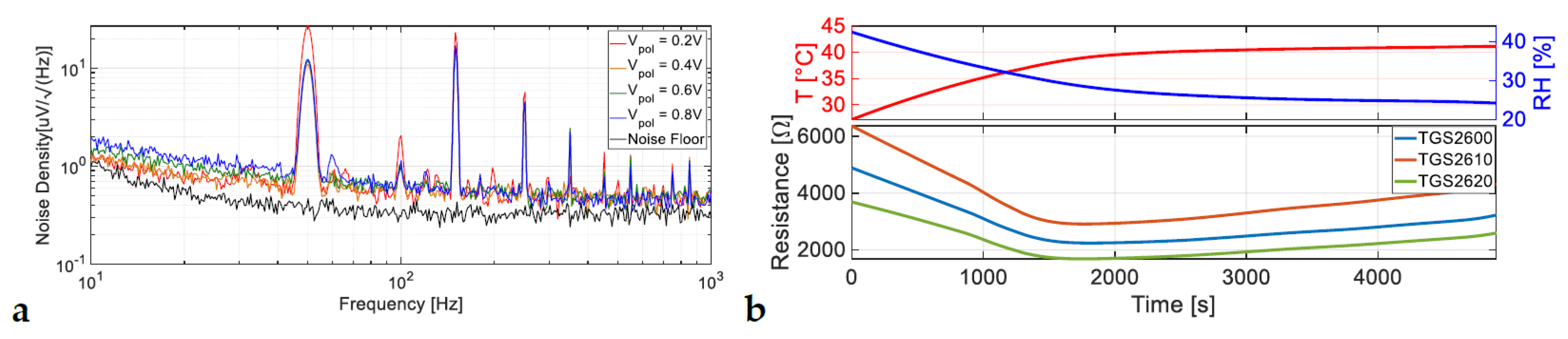

2. Materials and Methods

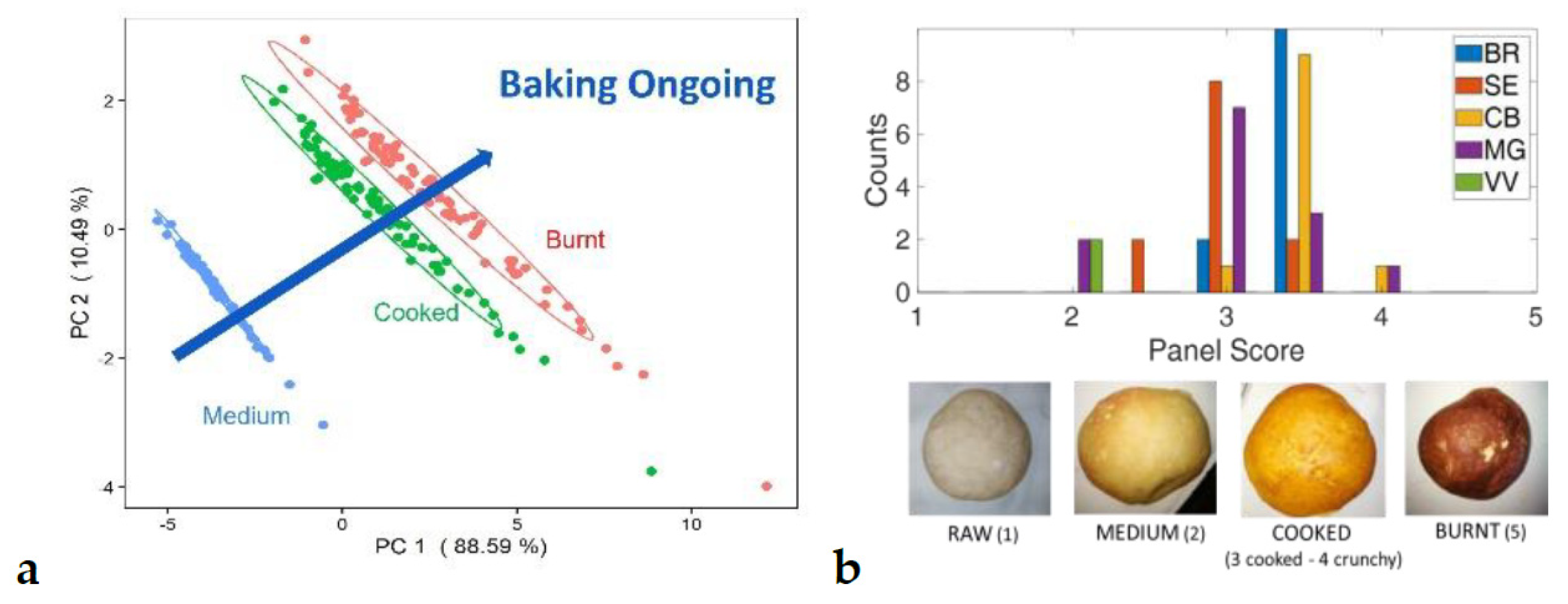

3. Discussion

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Tan, J.; Xu, J. Applications of electronic nose (e-nose) and electronic tongue (e-tongue) in food quality-related properties determination: A review. Artif. Intell. Agric. 2020, 4, 104–115. [Google Scholar] [CrossRef]

- Gancarz, M.; Malaga-Toboła, U.; Oniszczuk, A.; Tabor, S.; Oniszczuk, T.; Gawrysiak-Witulska, M.; Rusinek, R. Detection and measurement of aroma compounds with the electronic nose and a novel method for MOS sensor signal analysis during the wheat bread making process. Food Bioprod. Process. 2021, 127, 90–98. [Google Scholar] [CrossRef]

- Ponzoni, A.; Depari, A.; Falasconi, M.; Comini, E.; Flammini, A.; Marioli, D.; Taroni, A.; Sberveglieri, G. Bread baking aromas detection by low-cost electronic nose. Sens. Actuators B Chem. 2008, 130, 100–104. [Google Scholar] [CrossRef]

- di Diodoro, B.; Bax, C.; Dellarosa, N.; Corazza, F.; Langfelder, G.; Capelli, L. Bread baking monitoring by smart sensory system: A feasibility study. In Proceedings of the 2022 IEEE International Symposium on Olfaction and Electronic Nose (ISOEN), Aveiro, Portugal, 29 May–1 June 2022; pp. 1–4. [Google Scholar]

- Macku, R.; Smulko, J.; Koktavy, P.; Trawka, M.; Sedlak, P. Analytical fluctuation enhanced sensing by resistive gas sensors. Sens. Actuators B Chem. 2015, 213, 390–396. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bax, C.; di Diodoro, B.; Ticozzi, A.; Dellarosa, N.; Corazza, F.; Langfelder, G.; Capelli, L. Smart Odour Sensing for Automated Monitoring of Bread Products. Proceedings 2024, 97, 172. https://doi.org/10.3390/proceedings2024097172

Bax C, di Diodoro B, Ticozzi A, Dellarosa N, Corazza F, Langfelder G, Capelli L. Smart Odour Sensing for Automated Monitoring of Bread Products. Proceedings. 2024; 97(1):172. https://doi.org/10.3390/proceedings2024097172

Chicago/Turabian StyleBax, Carmen, Bianca di Diodoro, Alessandro Ticozzi, Nicolò Dellarosa, Flavio Corazza, Giacomo Langfelder, and Laura Capelli. 2024. "Smart Odour Sensing for Automated Monitoring of Bread Products" Proceedings 97, no. 1: 172. https://doi.org/10.3390/proceedings2024097172

APA StyleBax, C., di Diodoro, B., Ticozzi, A., Dellarosa, N., Corazza, F., Langfelder, G., & Capelli, L. (2024). Smart Odour Sensing for Automated Monitoring of Bread Products. Proceedings, 97(1), 172. https://doi.org/10.3390/proceedings2024097172