Flexural Plate Wave Piezoelectric MEMS Pressure Sensor †

Abstract

:1. Introduction

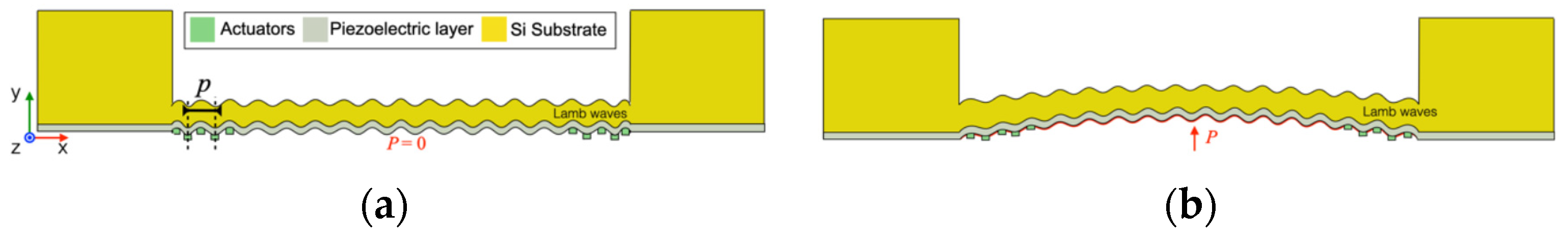

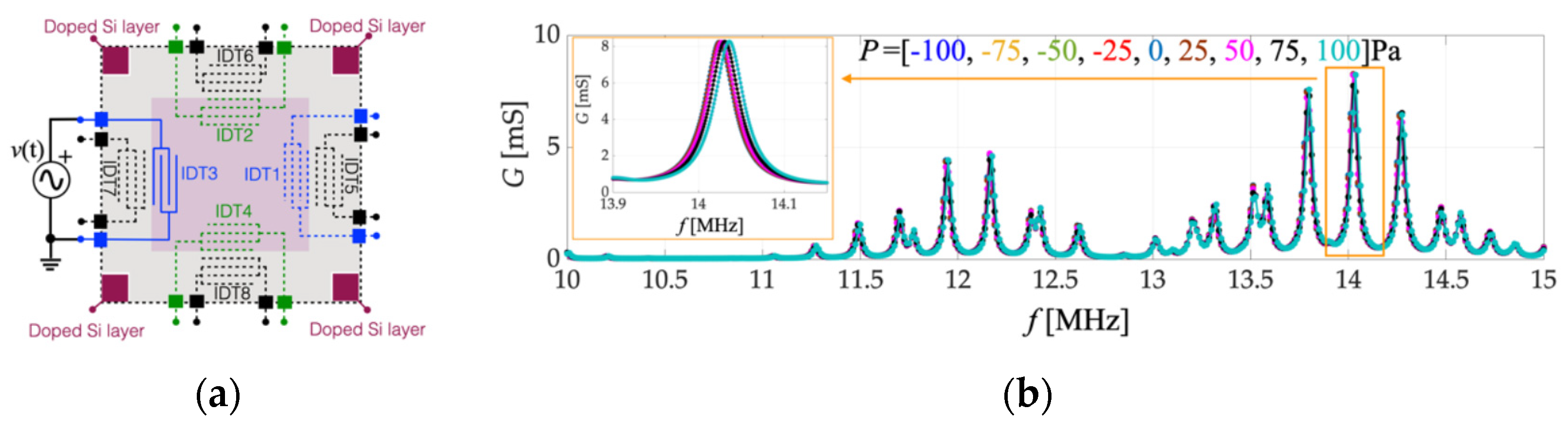

2. Description and Validation of the MEMS Pressure Sensor

Author Contributions

Funding

Conflicts of Interest

References

- Kropelnicki, P.; Muckensturm, K.-M.; Mu, X.J.; Randles, A.B.; Cai, H.; Ang, W.C.; Tsai, J.M.; Vogt, H. CMOS- compatible ruggedized high-temperature Lamb wave pressure sensor. J. Micromech. Microeng. 2013, 23, 085018. [Google Scholar] [CrossRef]

- Wenzel, S.W.; White, R.M. A multisensor employing an ultrasonic Lamb-wave oscillator. IEEE Trans. Electron Devices 1988, 35, 735–743. [Google Scholar] [CrossRef]

- Nastro, A.; Ferrari, M.; Rufer, L.; Basrour, S.; Ferrari, V. Piezoelectric MEMS Acoustic Transducer with Electrically-Tunable Resonant Frequency. Micromachines 2022, 13, 96. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nastro, A.; Bertelli, S.; Ferrari, M.; Rufer, L.; Basrour, S.; Ferrari, V. Flexural Plate Wave Piezoelectric MEMS Pressure Sensor. Proceedings 2024, 97, 185. https://doi.org/10.3390/proceedings2024097185

Nastro A, Bertelli S, Ferrari M, Rufer L, Basrour S, Ferrari V. Flexural Plate Wave Piezoelectric MEMS Pressure Sensor. Proceedings. 2024; 97(1):185. https://doi.org/10.3390/proceedings2024097185

Chicago/Turabian StyleNastro, Alessandro, Stefano Bertelli, Marco Ferrari, Libor Rufer, Skandar Basrour, and Vittorio Ferrari. 2024. "Flexural Plate Wave Piezoelectric MEMS Pressure Sensor" Proceedings 97, no. 1: 185. https://doi.org/10.3390/proceedings2024097185