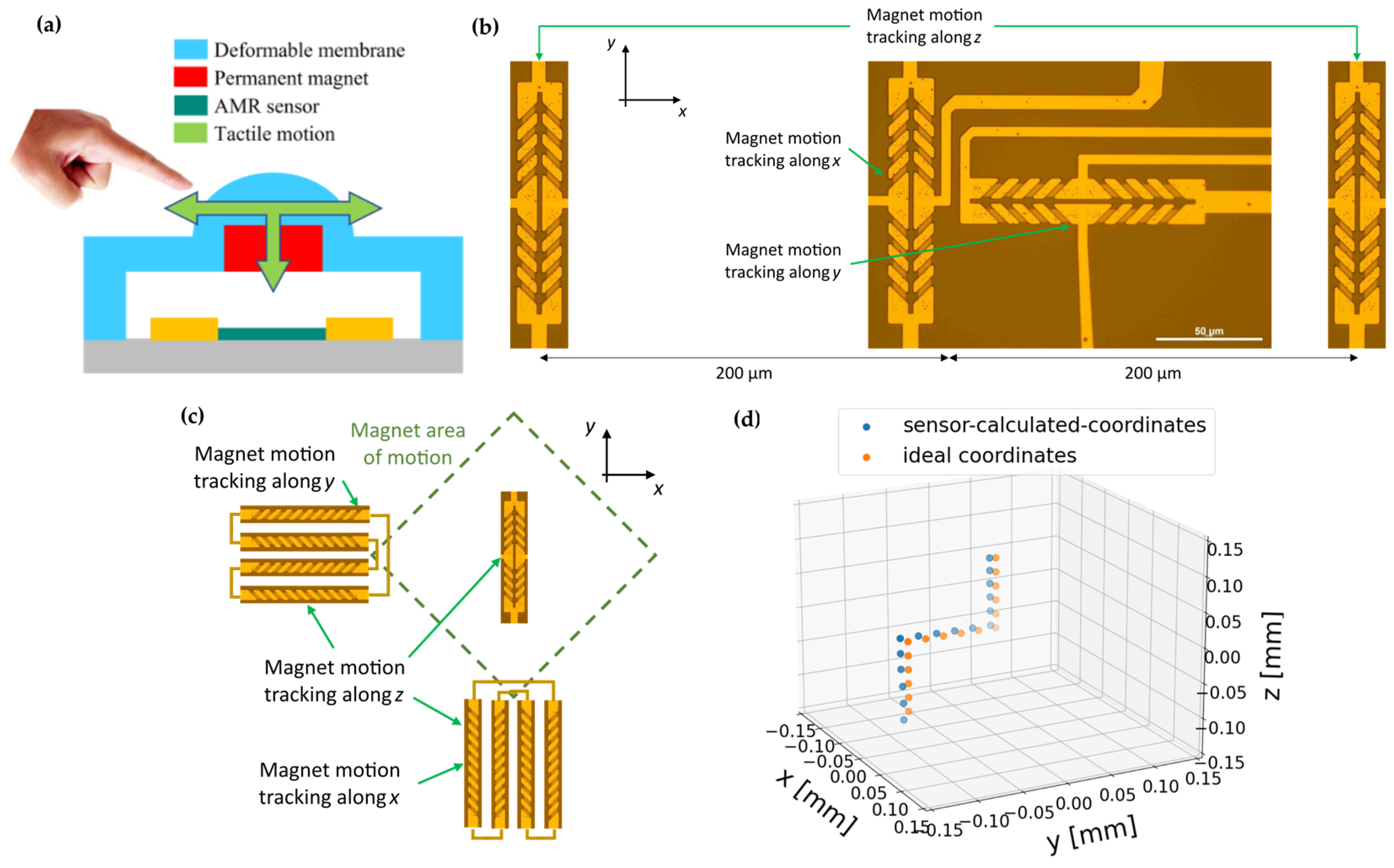

AMR Sensor Array Design for the Realization of a 3D Magnetic Tactile Sensor †

Abstract

1. Introduction

2. Materials and Methods

3. Discussion

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Dahiya, R.S.; Metta, G.; Valle, M.; Sandini, G. Tactile Sensing—From Humans to Humanoids. IEEE Trans. Robot. 2010, 26, 1–20. [Google Scholar] [CrossRef]

- Kuijk, K.E.; van Gestel, W.J.; Gorter, F.W. The barber pole, a linear magnetoresistive head. IEEE Trans. Magn. 1975, 11, 1215–1217. [Google Scholar] [CrossRef]

- Vansteenkiste, A.; Leliaert, J.; Dvornik, M.; Helsen, M.; Garcia-Sanchez, F.; Van Waeyenberge, B. The design and verification of MuMax3. AIP Adv. 2014, 4, 107133. [Google Scholar] [CrossRef]

- Ortner, M.; Coliado Bandeira, L.G. Magpylib: A free Python package for magnetic field computation. SoftwareX 2020, 11, 100466. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lumetti, S.; Malagò, P.; Stürmer, P.-A.; Relvão, F.F.; Ortner, M. AMR Sensor Array Design for the Realization of a 3D Magnetic Tactile Sensor. Proceedings 2024, 97, 198. https://doi.org/10.3390/proceedings2024097198

Lumetti S, Malagò P, Stürmer P-A, Relvão FF, Ortner M. AMR Sensor Array Design for the Realization of a 3D Magnetic Tactile Sensor. Proceedings. 2024; 97(1):198. https://doi.org/10.3390/proceedings2024097198

Chicago/Turabian StyleLumetti, Stefano, Perla Malagò, Peter-Andreas Stürmer, Francisco Ferreira Relvão, and Michael Ortner. 2024. "AMR Sensor Array Design for the Realization of a 3D Magnetic Tactile Sensor" Proceedings 97, no. 1: 198. https://doi.org/10.3390/proceedings2024097198

APA StyleLumetti, S., Malagò, P., Stürmer, P.-A., Relvão, F. F., & Ortner, M. (2024). AMR Sensor Array Design for the Realization of a 3D Magnetic Tactile Sensor. Proceedings, 97(1), 198. https://doi.org/10.3390/proceedings2024097198