Mapping, Modeling and Designing a Marble Quarry Using Integrated Electric Resistivity Tomography and Unmanned Aerial Vehicles: A Study of Adaptive Decision-Making

Abstract

1. Introduction

2. Materials and Methods

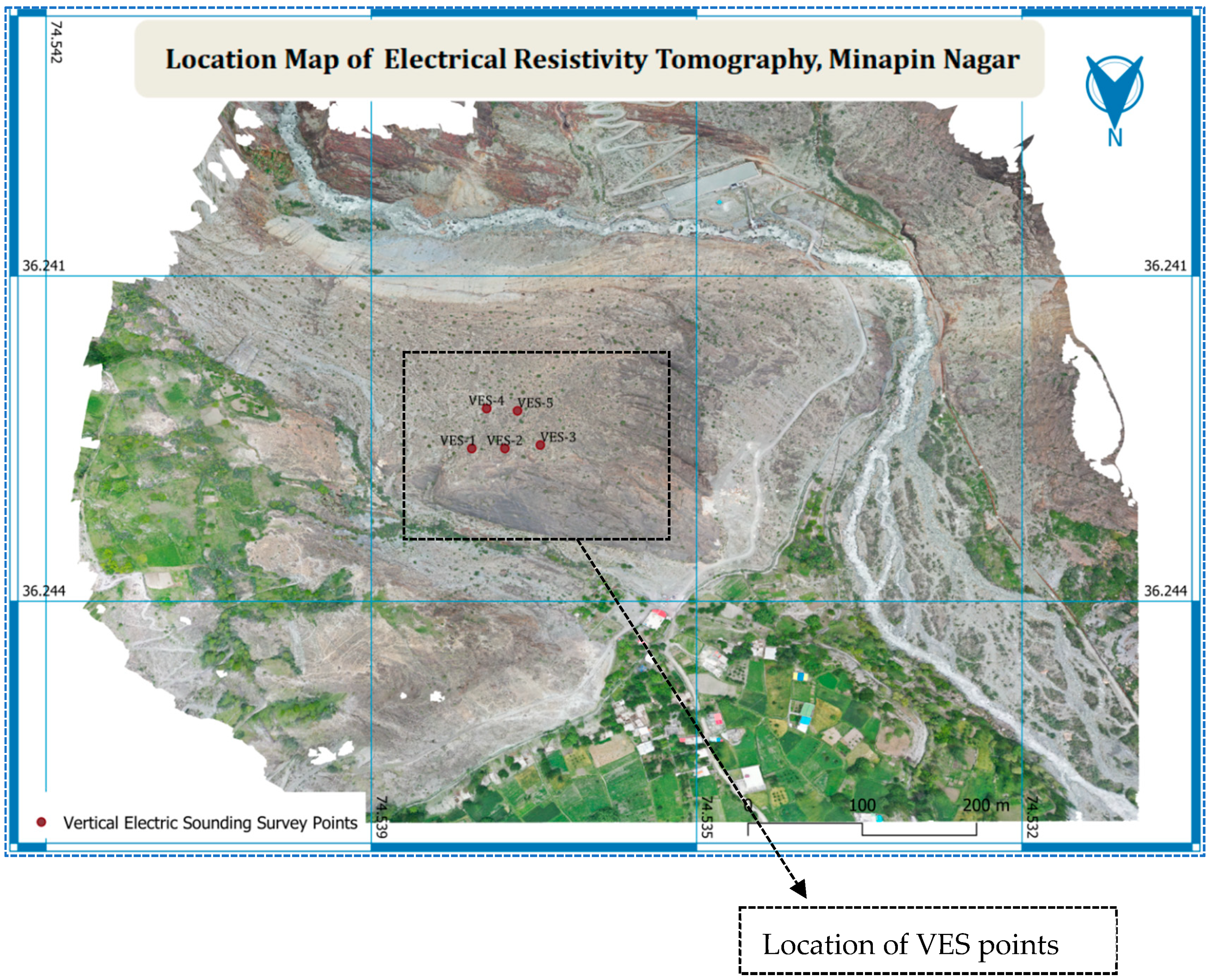

2.1. Location Map of the Study Area

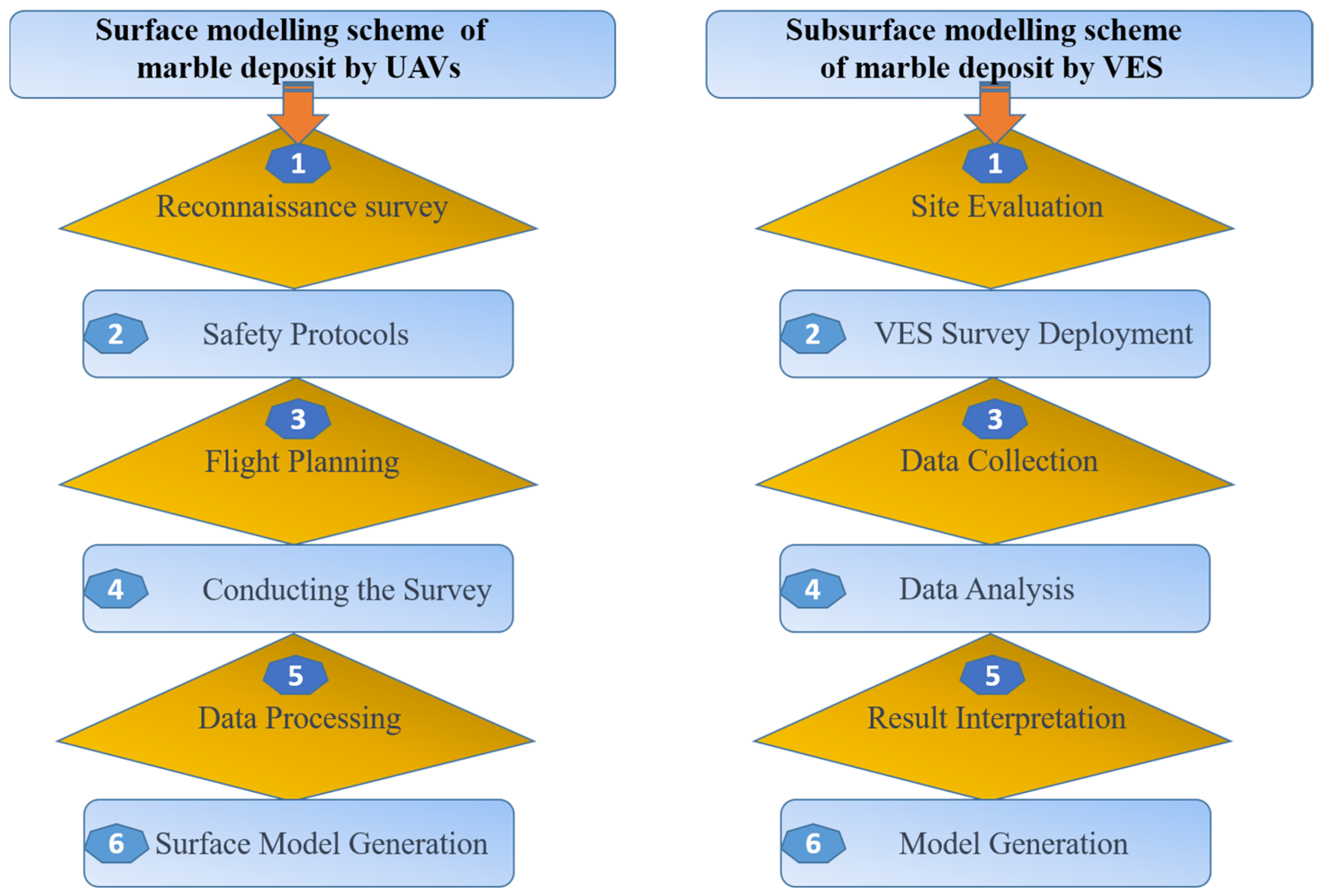

2.2. Data Collection

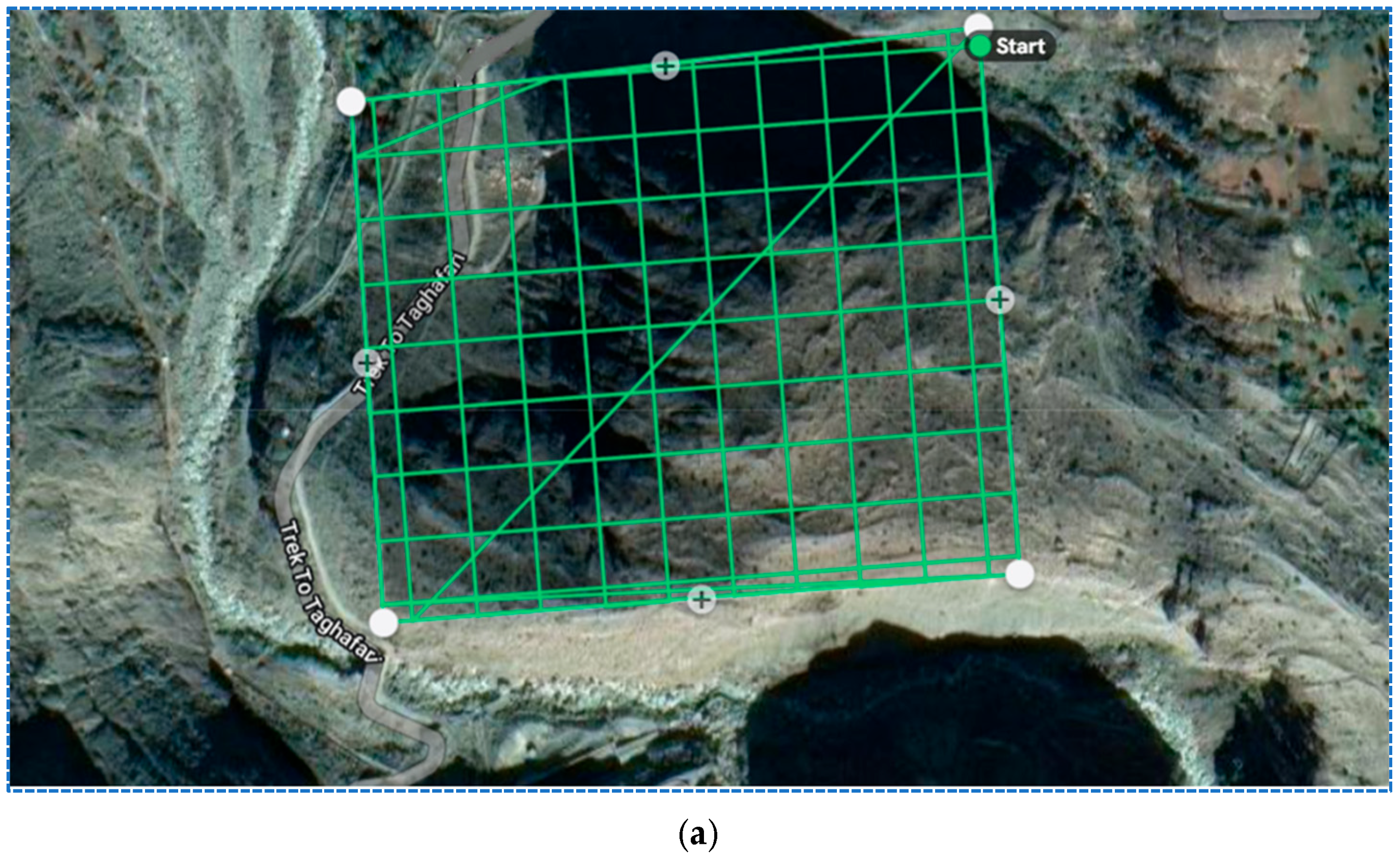

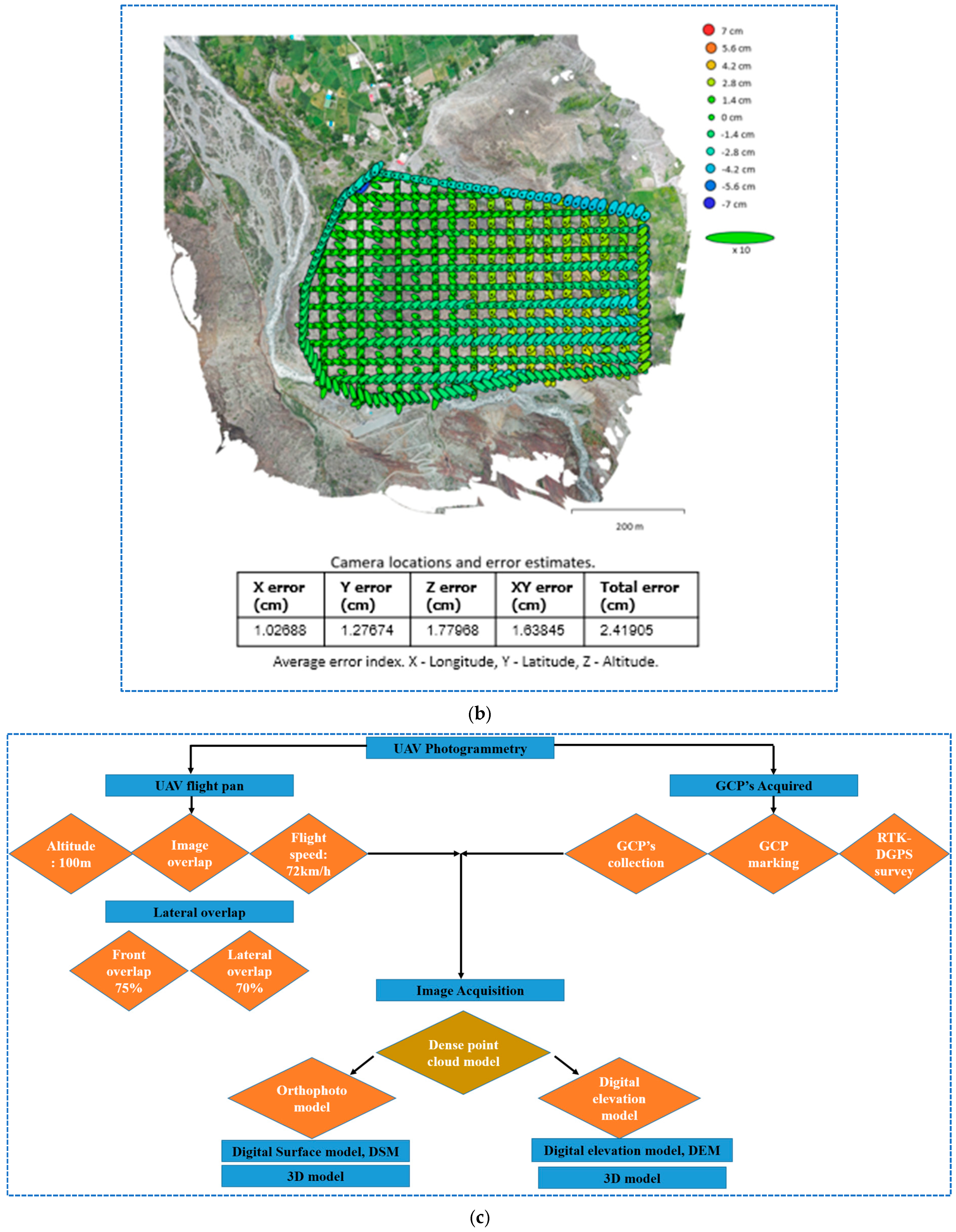

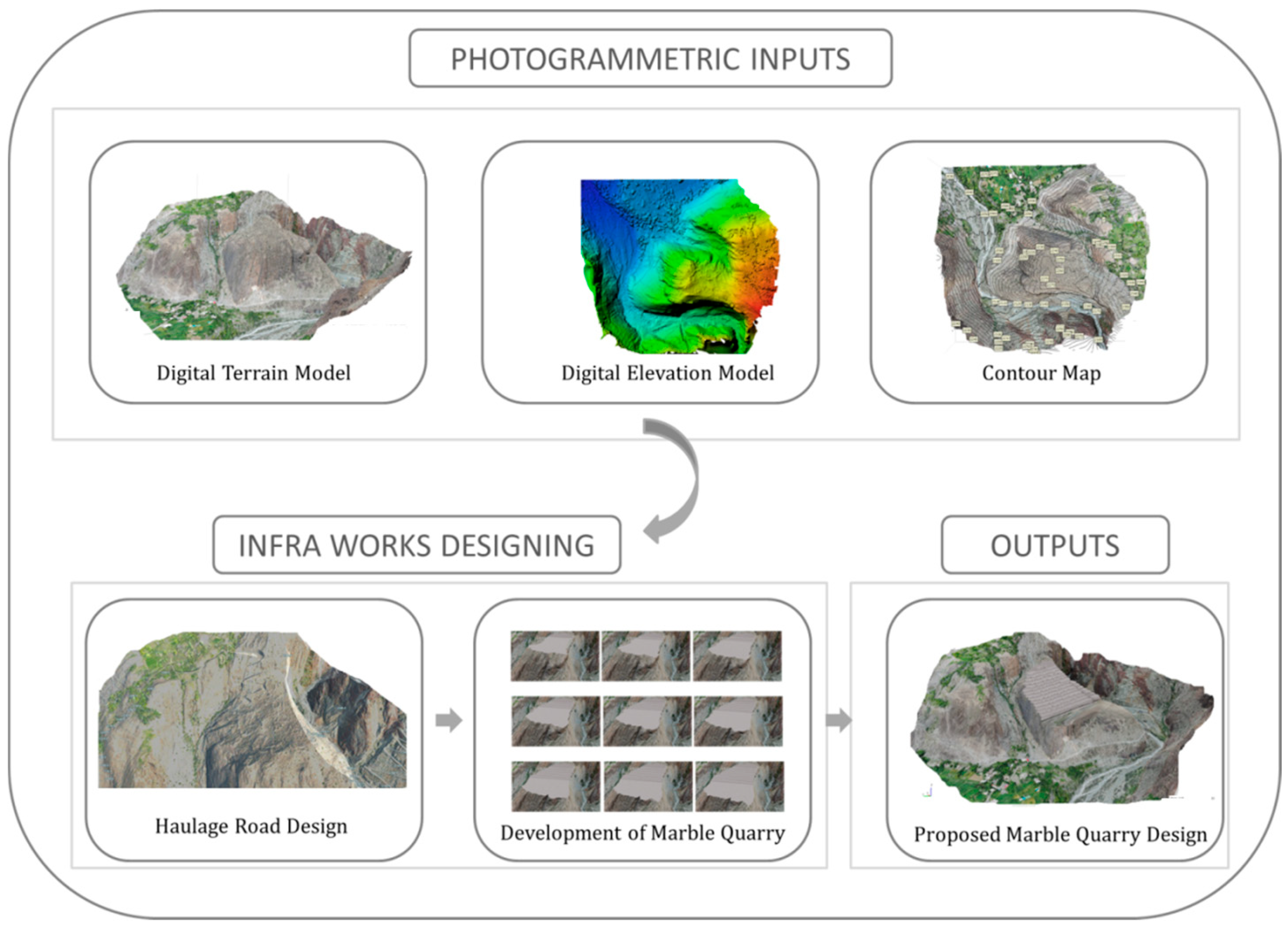

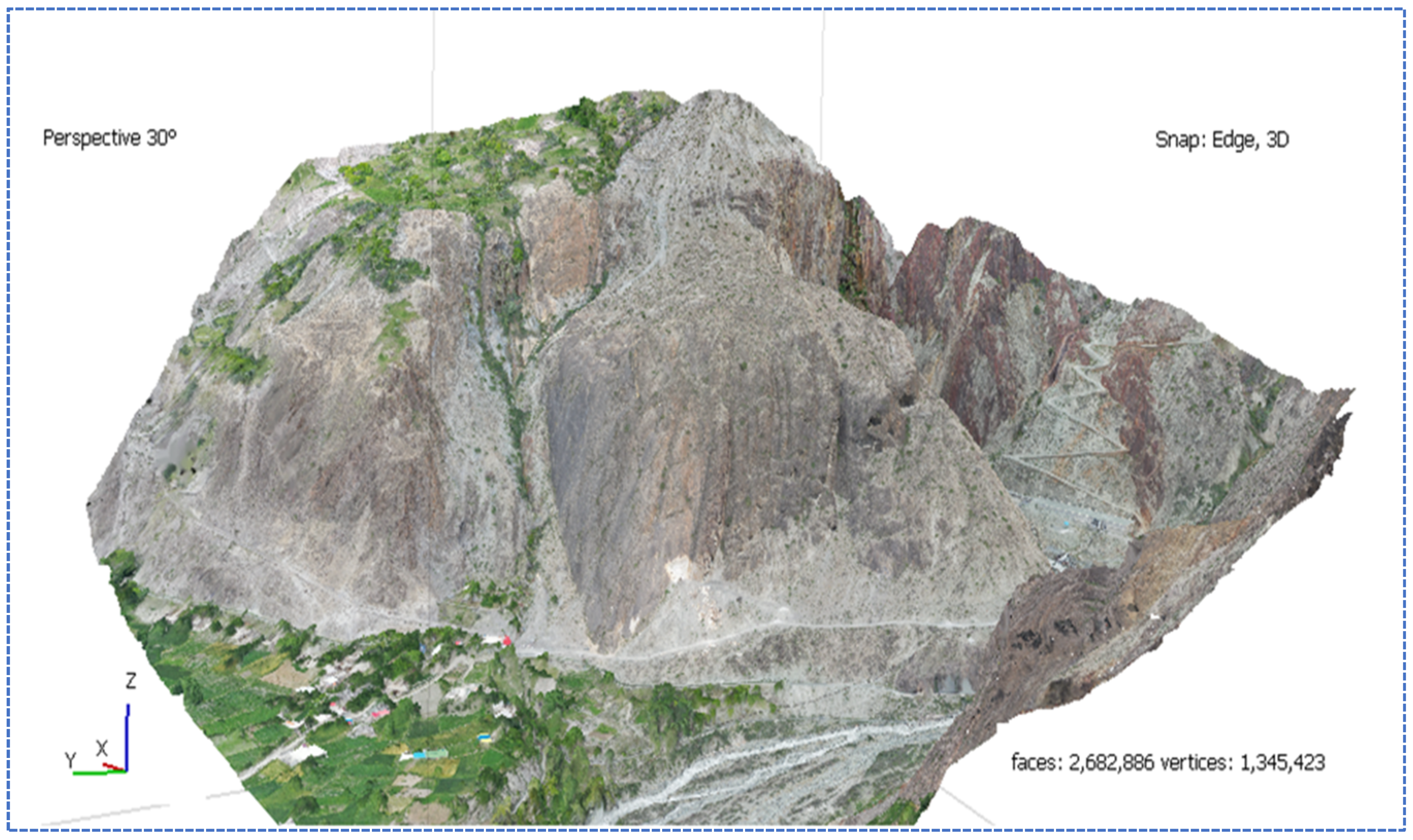

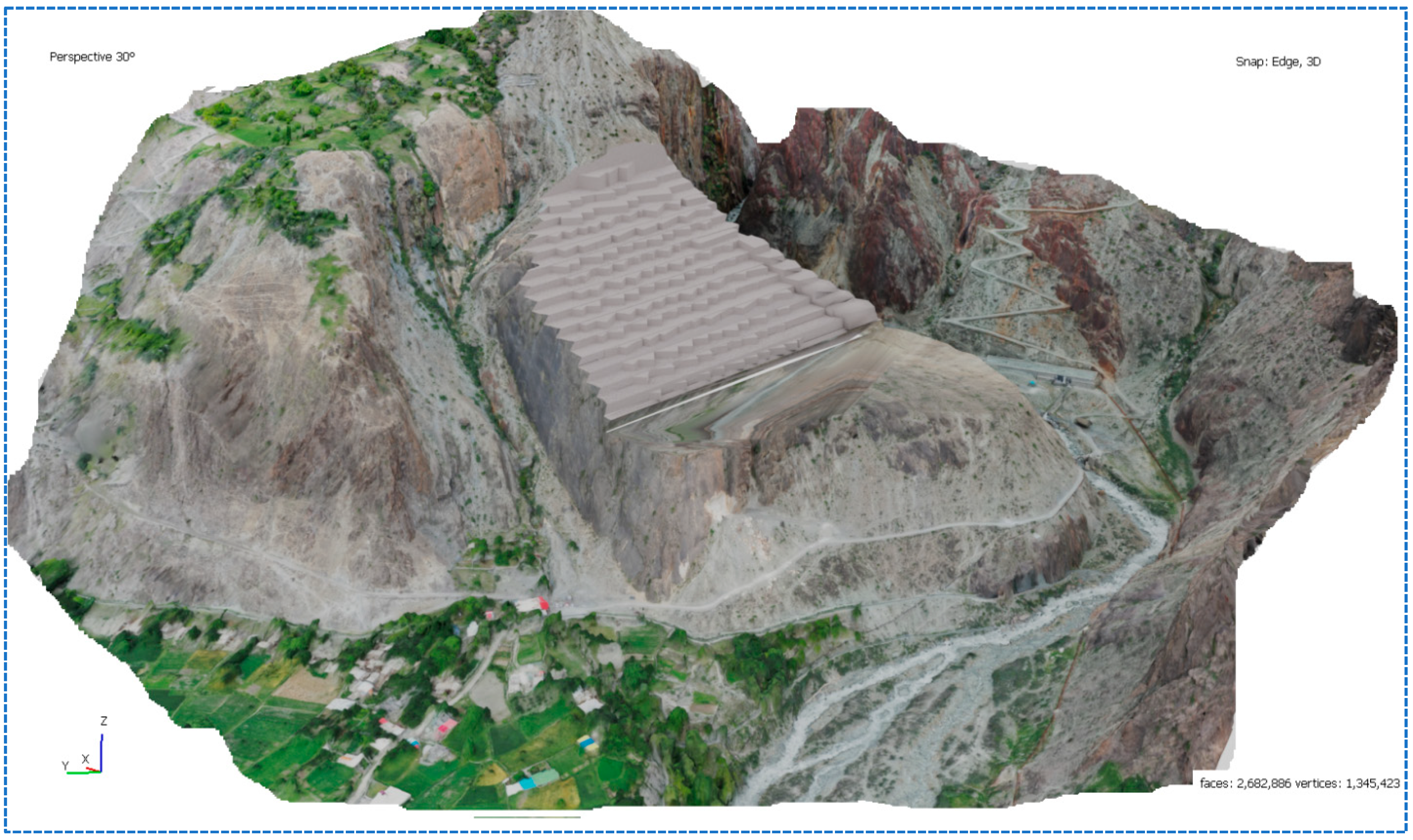

2.2.1. UAV Survey Data Acquisition and Processing

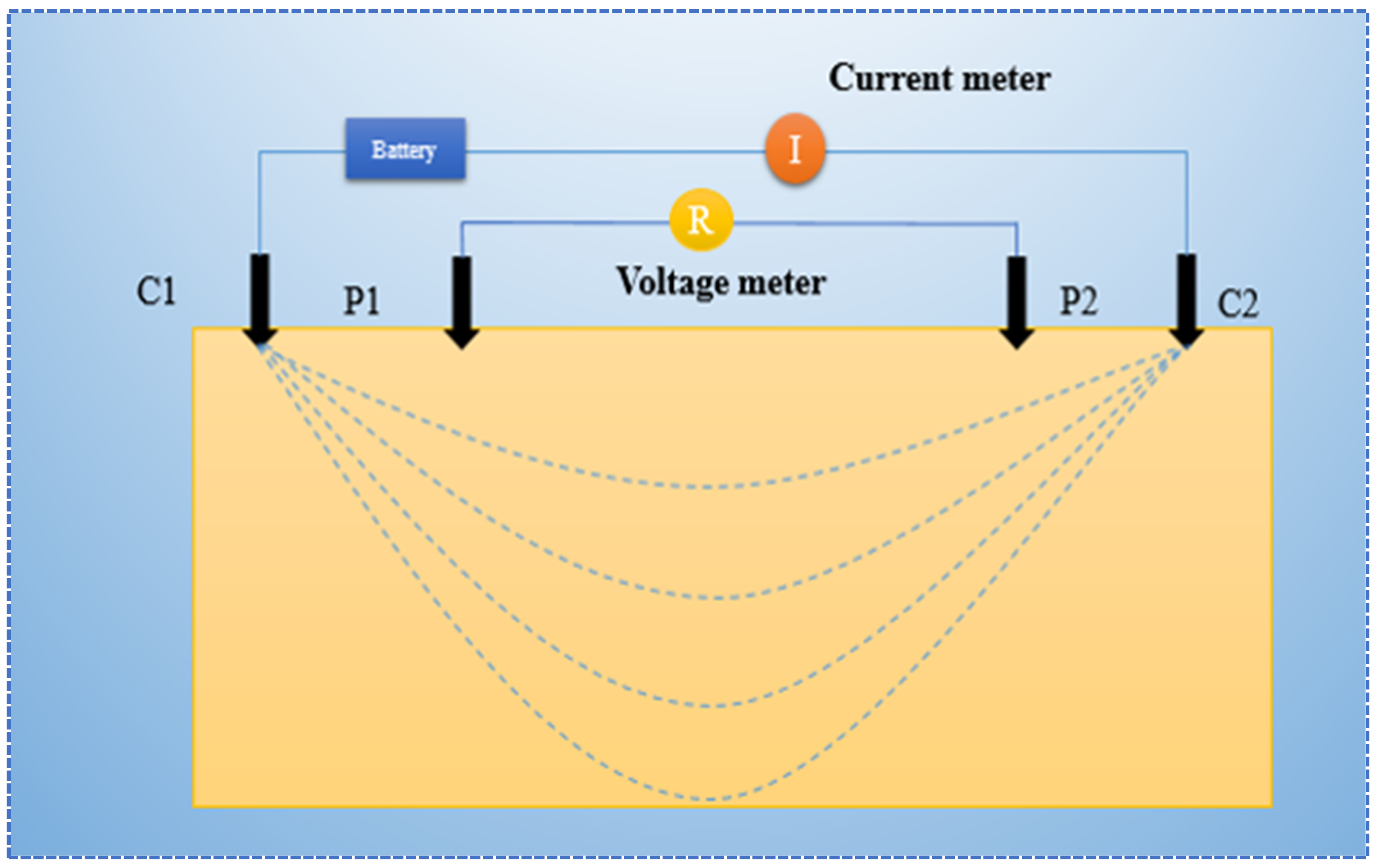

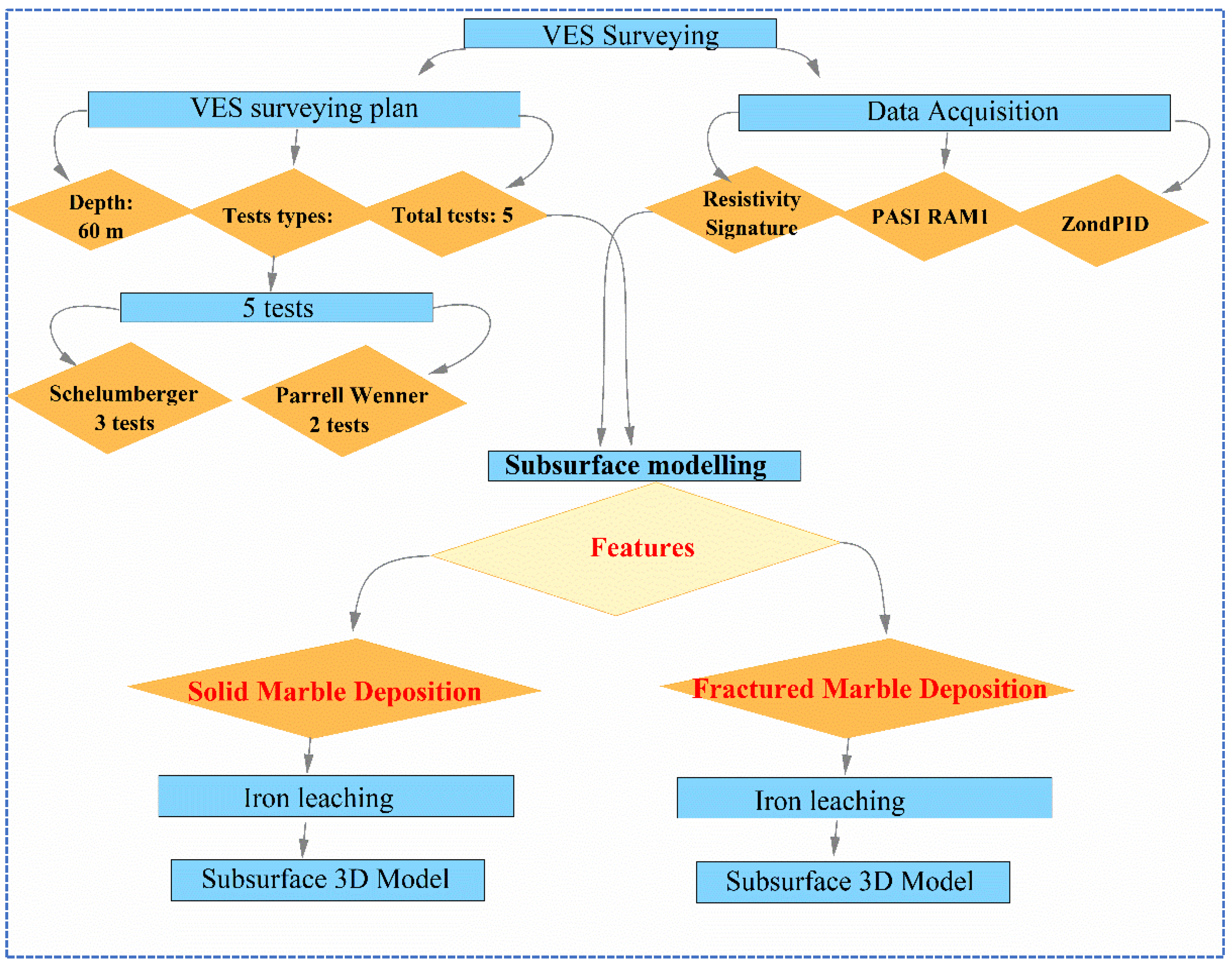

2.2.2. Vertical Electric Sounding (Data Acquisition and Interpretation)

2.3. Quarry Design Processes

3. Results and Discussion

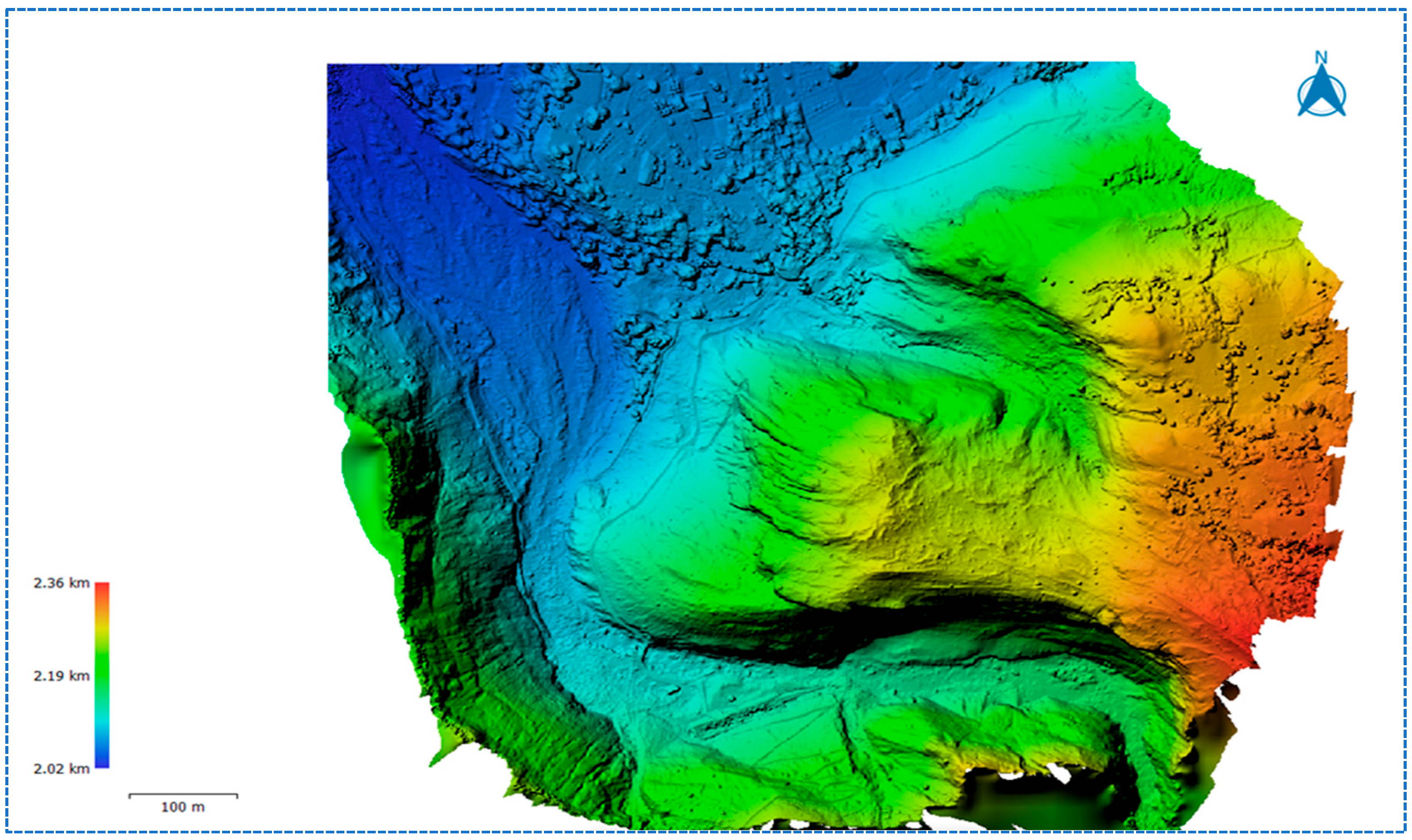

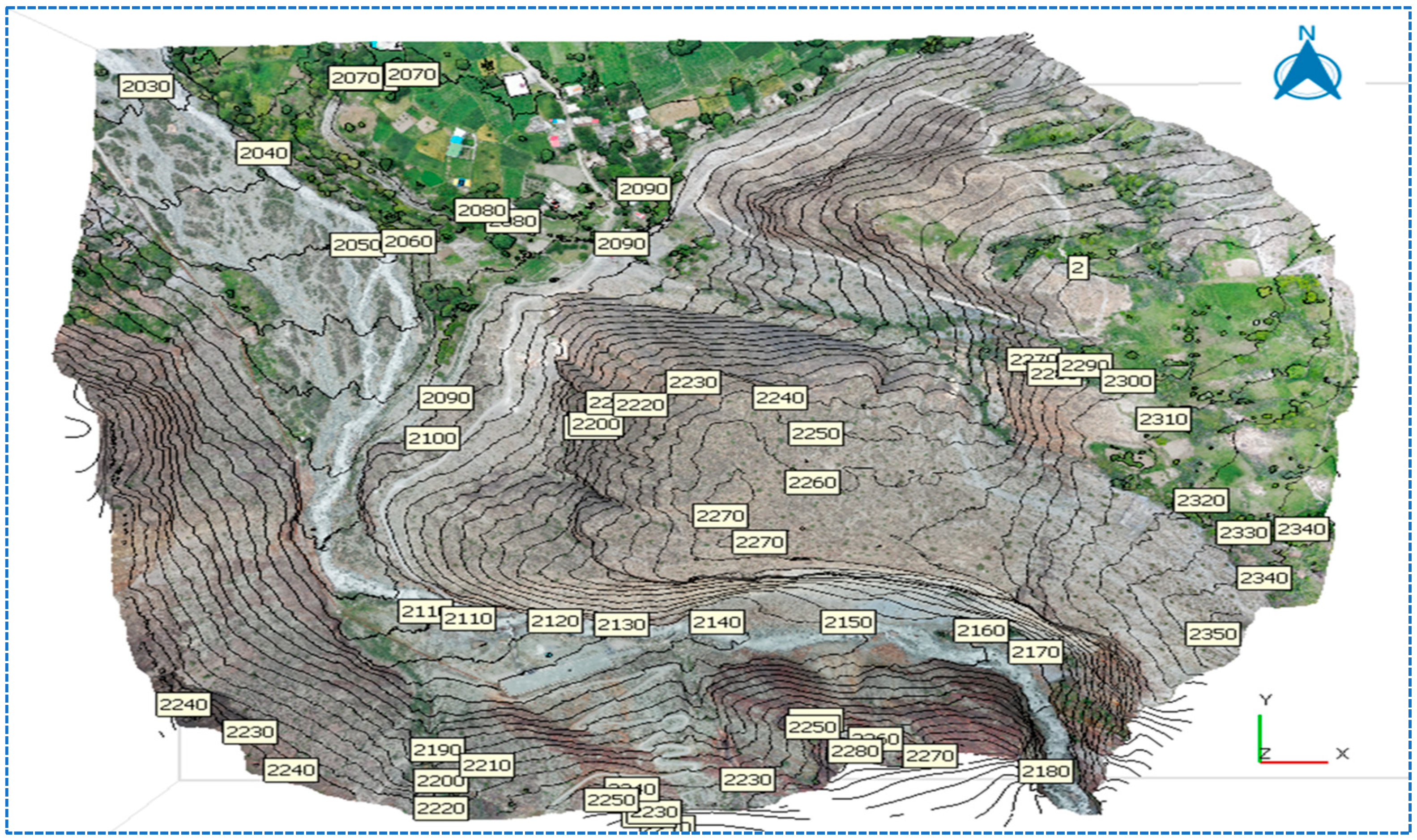

3.1. UAV Survey

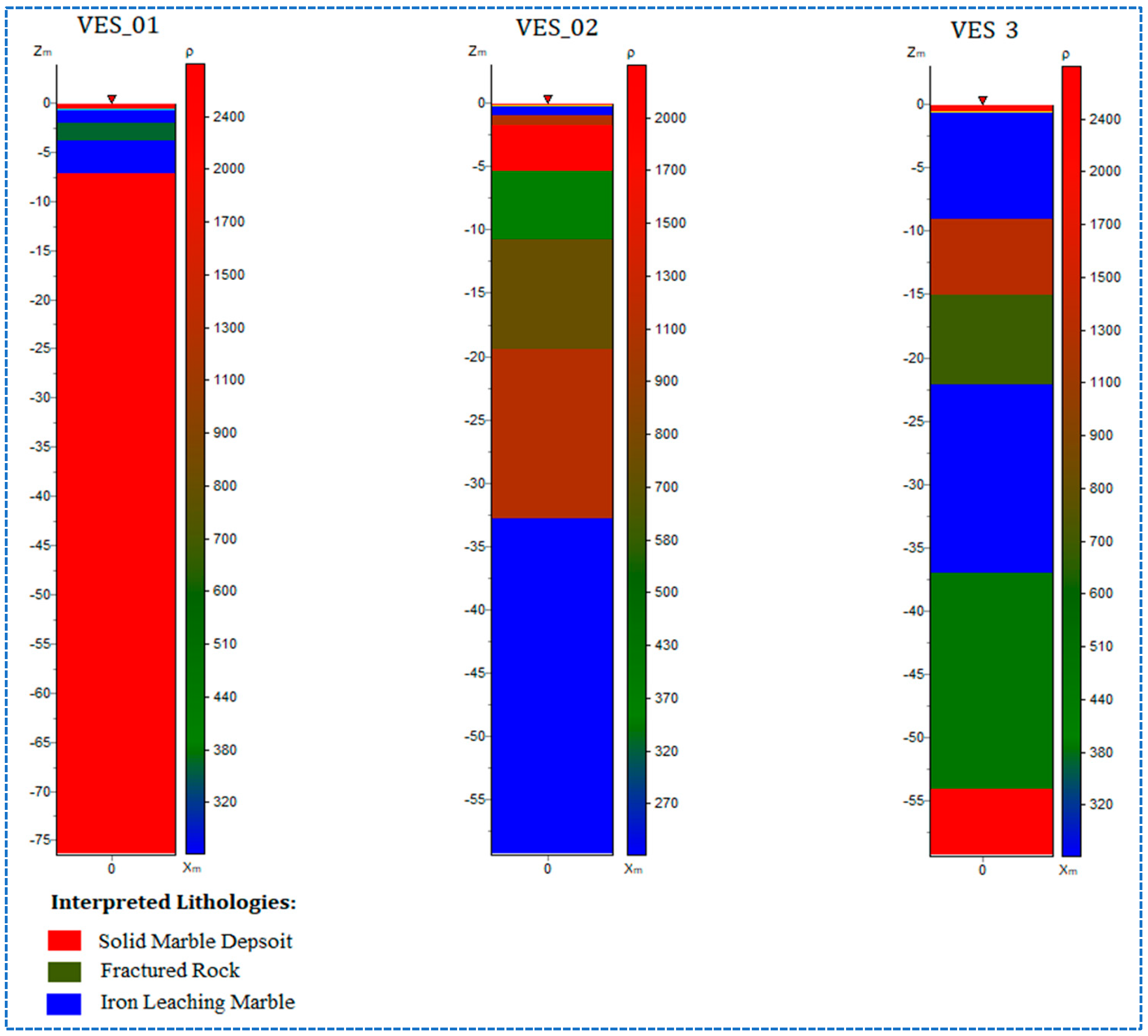

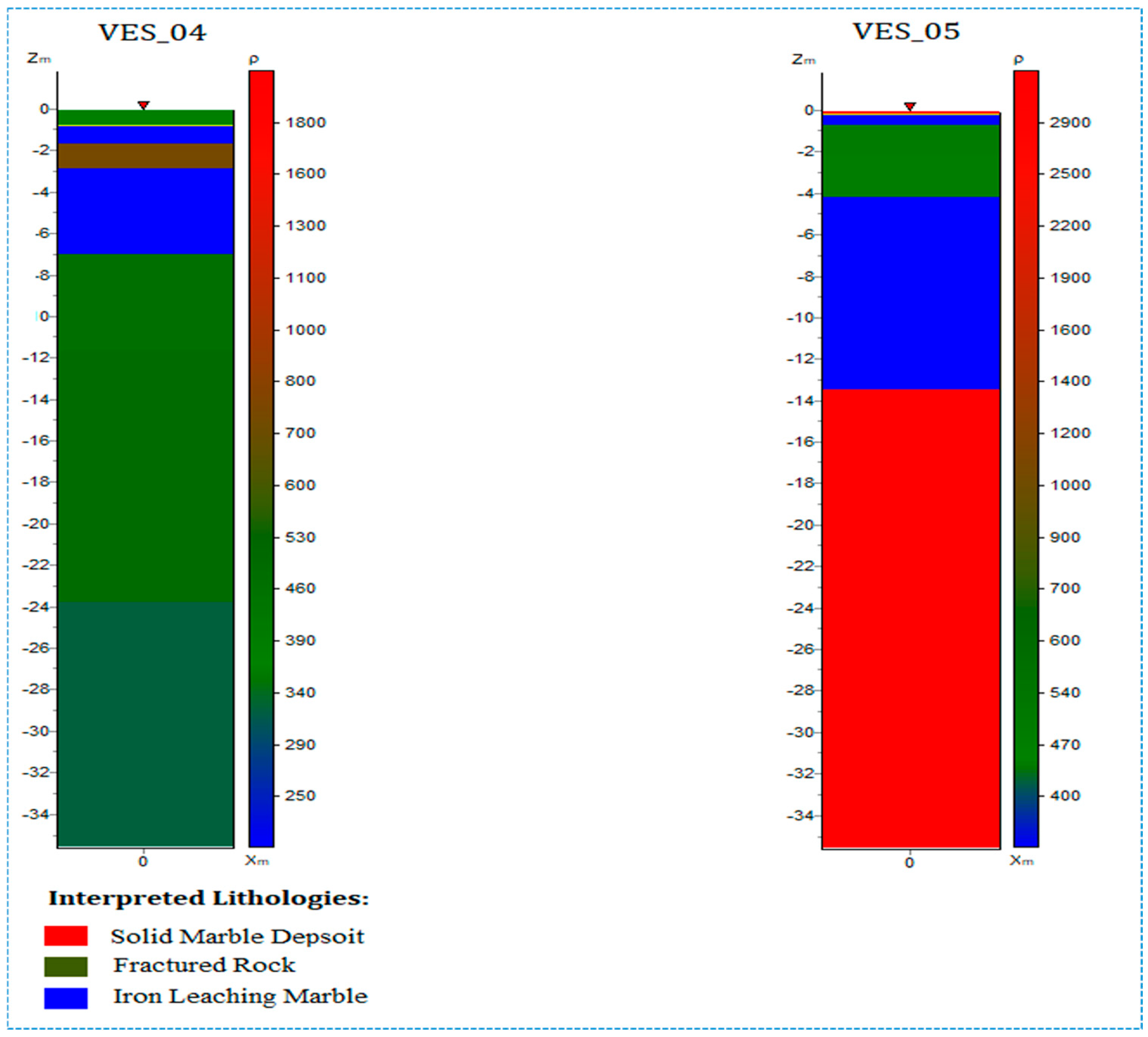

3.2. Electric Resistivity Sounding

3.3. Total Quarry Design Concept

3.3.1. Haulage Road Geometry

3.3.2. Development of a Quarry

3.4. Cost–Benefit Anlysis

4. Conclusions

- (1)

- The synergistic use of UAVs and ERT offers a cost-effective, efficient, and non-destructive alternative to traditional surveying techniques. This integrated approach is particularly advantageous in challenging terrains, where conventional methods are often impractical or labor-intensive.

- (2)

- By accurately mapping subsurface anomalies such as solid rock, fractured zones, and areas of iron leaching, this approach minimizes material waste during extraction. The optimized quarry design, with bench heights of 30 feet and widths of 50 feet, ensures efficient resource recovery and reduces environmental impact. This promotes sustainable quarrying practices by maximizing resource utilization and minimizing unnecessary excavation.

- (3)

- While this study focuses on marble deposits, the proposed methodology can be extended to other dimensional stones (e.g., granite, limestone) and mineral resources in different geological settings. Future research should explore the applicability of this approach in diverse environments, such as sedimentary or igneous terrains, to evaluate its effectiveness across a wider range of geological conditions.

- (4)

- Future research should also investigate the integration of advanced machine learning algorithms for enhanced data interpretation and predictive modeling, which could further improve the accuracy and efficiency of deposit characterization. Additionally, the use of UAVs and ERT could be expanded to monitor post-extraction land rehabilitation, contributing to sustainable mining practices by ensuring effective land restoration and minimizing environmental impact.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhou, S. Platforming for industrialized building: A comparative case study of digitally-enabled product platforms. Build. Res. Inf. 2023, 52, 4–18. [Google Scholar] [CrossRef]

- Vagnon, F.; Dino, G.A.; Umili, G.; Cardu, M.; Ferrero, A.M. New developments for the sustainable exploitation of ornamental stone in carrara basin. Sustainability 2020, 12, 9374. [Google Scholar] [CrossRef]

- Siegesmund, S.; Török, Á. Building stones. In Stone in Architecture: Properties, Durability; Springer: Berlin/Heidelberg, Germany, 2010; pp. 11–95. [Google Scholar]

- Sun, T.; Chen, F.; Zhong, L.; Liu, W.; Wang, Y. GIS-based mineral prospectivity mapping using machine learning methods: A case study from Tongling ore district, eastern China. Ore Geol. Rev. 2019, 109, 26–49. [Google Scholar] [CrossRef]

- Junaid, M.; Abdullah, R.A.; Sa’ari, R.; Ali, W.; Islam, A.; Sari, M. 3D Modelling and Feasibility Assessment of Granite Deposit using 2D Electrical Resistivity Tomography, Borehole, and Unmanned Aerial Vehicle Survey. J. Min. Environ. 2022, 13, 929–942. [Google Scholar]

- Junaid, M.; Abdullah, R.A.; Sa’ari, R.; Ali, W.; Rehman, H.; Alel, M.N.A.; Ghani, U. 2D Electrical Resistivity Tomography an advance and expeditious exploration technique for current challenges to mineral industry. J. Himal. Earth Sci. 2021, 54, 11–22. [Google Scholar]

- Scheidt, C.; Li, L.; Caers, J. Quantifying Uncertainty in Subsurface Systems; Wiley: Hoboken, NJ, USA, 2018; ISBN 9780875900056. [Google Scholar]

- Mishra, V.; Prakash, S.; Sharma, A.; Nautiyal, D.; Thakur, A.; Sharma, R.S. Limestone Mining in the Himalayas: Advancing Adaptive Governance for Ecological and Socioeconomic Resilience. In The Himalayas in the Anthropocene: Environment and Development; Springer: Cham, Switzerland, 2024; pp. 185–201. [Google Scholar]

- Wang, S.; Bai, Z.; Lv, Y.; Zhou, W. Monitoring Extractive Activity-Induced Surface Subsidence in Highland and Alpine Opencast Coal Mining Areas with Multi-Source Data. Remote Sens. 2022, 14, 3442. [Google Scholar] [CrossRef]

- Junaid, M.; Abdullah, R.A.; Abdelrahman, K.; Ullah, A.; Mahmood, S.; Sa’Ari, R.; Islam, A. Assigning Resistivity Values To Rock Quality Designation Indices Using Integrated Unmanned Aerial Vehicle and 2D Electrical Resistivity Tomography in Granitic Rock. Geocarto Int. 2024, 39. [Google Scholar] [CrossRef]

- Dandois, J.P.; Olano, M.; Ellis, E.C. Optimal Altitude, Overlap, and Weather Conditions for Computer Vision UAV Estimates of Forest Structure. Remote Sens. 2015, 7, 13895–13920. [Google Scholar] [CrossRef]

- Guisado-Pintado, E.; Jackson, D.W.T.; Rogers, D. 3D mapping efficacy of a drone and terrestrial laser scanner over a temperate beach-dune zone. Geomorphology 2019, 328, 157–172. [Google Scholar] [CrossRef]

- Mesas-Carrascosa, F.-J.; de Castro, A.I.; Torres-Sánchez, J.; Triviño-Tarradas, P.; Jiménez-Brenes, F.M.; García-Ferrer, A.; López-Granados, F. Classification of 3D point clouds using color vegetation indices for precision viticulture and digitizing applications. Remote Sens. 2020, 12, 317. [Google Scholar] [CrossRef]

- Hugenholtz, C.; Brown, O.; Walker, J.; Barchyn, T.E.; Nesbit, P.; Kucharczyk, M.; Myshak, S. Spatial accuracy of UAV-derived orthoimagery and topography: Comparing photogrammetric models processed with direct geo-referencing and ground control points. Geomatica 2016, 70, 21–30. [Google Scholar] [CrossRef]

- Zietara, A.M. Creating Digital Elevation Model (DEM) Based on Ground Points Extracted from Classified Aerial Images Obtained from Unmanned Aerial Vehicle (UAV). Master’s Thesis, Norwegian University of Science and Technology, Trondheim, Norway, 2017. [Google Scholar]

- Chaudhry, M.H.; Ahmad, A.; Gulzar, Q.; Farid, M.S.; Shahabi, H.; Al-Ansari, N. Assessment of DSM based on radiometric transformation of UAV data. Sensors 2021, 21, 1649. [Google Scholar] [CrossRef] [PubMed]

- Bharti, A.K.; Singh, K.K.K.; Ghosh, C.N.; Mishra, K. Detection of subsurface cavity due to old mine workings using electrical resistivity tomography: A case study. J. Earth Syst. Sci. 2022, 131, 39. [Google Scholar] [CrossRef]

- Falae, P.O.; Kanungo, D.P.; Chauhan, P.K.S.; Dash, R.K. Electrical resistivity tomography (ERT) based subsurface characterisation of Pakhi Landslide, Garhwal Himalayas, India. Environ. Earth Sci. 2019, 78, 430. [Google Scholar] [CrossRef]

- Briški, M.; Stroj, A.; Kosović, I.; Borović, S. Characterization of aquifers in metamorphic rocks by combined use of electrical resistivity tomography and monitoring of spring hydrodynamics. Geosciences 2020, 10, 137. [Google Scholar] [CrossRef]

- Searle, M.P.; Khan, M.A.; Fraser, J.E.; Gough, S.J.; Jan, M.Q. The tectonic evolution of the Kohistan-Karakoram collision belt along the Karakoram Highway transect, north Pakistan. Tectonics 1999, 18, 929–949. [Google Scholar]

- Bustillo Revuelta, M. Dimension Stone. In Construction Materials: Geology, Production and Applications; Springer International Publishing: Cham, Switzerland, 2021; pp. 55–90. [Google Scholar] [CrossRef]

- Selonen, O.; Luodes, H.; Ehlers, C. Exploration for dimensional stone—Implications and examples from the Precambrian of southern Finland. Eng. Geol. 2000, 56, 275–291. [Google Scholar] [CrossRef]

- Jiang, S.; Jiang, C.; Jiang, W. Efficient structure from motion for large-scale UAV images: A review and a comparison of SfM tools. ISPRS J. Photogramm. Remote Sens. 2020, 167, 230–251. [Google Scholar] [CrossRef]

- Eltner, A.; Sofia, G. Structure from motion photogrammetric technique. Dev. Earth Surf. Process. 2020, 23, 1–24. [Google Scholar]

- Török, Á.; Bögöly, G.; Somogyi, Á.; Lovas, T. Application of UAV in Topographic Modelling and Structural Geological Mapping of Quarries and Their Surroundings—Delineation of Fault-Bordered Raw Material Reserves. Sensors 2020, 20, 489. [Google Scholar] [CrossRef]

- Skondras, A.; Karachaliou, E.; Tavantzis, I.; Tokas, N.; Valari, E.; Skalidi, I.; Bouvet, G.A.; Stylianidis, E. UAV Mapping and 3D Modeling as a Tool for Promotion and Management of the Urban Space. Drones 2022, 6, 115. [Google Scholar] [CrossRef]

- Scivetti, N.; Marcos, P.; Benedini, L.; Arrouy, M.J.; Bahía, M.E.; Miralles, F.R.; Poiré, D.G. Multi-proxy geophysical modeling of subsurface Neoproterozoic limestones: Applications for mining industry in the Tandilia System, Argentina. J. S. Am. Earth Sci. 2021, 111, 103436. [Google Scholar] [CrossRef]

- Wu, S.; Zhang, X. Visualization of Railway Transportation Engineering Management Using BIM Technology under the Application of Internet of Things Edge Computing. Wirel. Commun. Mob. Comput. 2022, 2022, 4326437. [Google Scholar] [CrossRef]

- Gao, W.; Shi, L.; Han, J.; Zhai, P. Dynamic monitoring of water in a working face floor using 2D electrical resistivity tomography (ERT). Mine Water Environ. 2017, 37, 423–430. [Google Scholar] [CrossRef]

- Liang, H.; Jin, S.; Wei, W.; Gao, R.; Ye, G.; Zhang, L.; Yin, Y.; Lu, Z. Lithospheric electrical structure of the middle Lhasa terrane in the south Tibetan plateau. Tectonophysics 2018, 731–732, 95–103. [Google Scholar] [CrossRef]

- Su, O.; Momayez, M. Indirect estimation of electrical resistivity by abrasion and physico-mechanical properties of rocks. J. Appl. Geophys. 2017, 143, 23–30. [Google Scholar] [CrossRef]

- Jones, A.G.; Garcia, X. Electrical resistivity structure of the Yellowknife River Fault Zone and surrounding region, Gold Yellowknife Greenstone Belt, Northwest Territ. Results EXTECH III Multidiscip. Res. Proj. 2006, 3, 126–141. [Google Scholar]

- Loke, M.H. Electrical imaging surveys for environmental and engineering studies. Pract. Guid. 1999, 2, 70. [Google Scholar]

- Martínez, J.; Rey, J.; Sandoval, S.; Hidalgo, M.C.; Mendoza, R. geophysical prospecting using ERT and IP techniques to locate galena veins. Remote Sens. 2019, 11, 2923. [Google Scholar] [CrossRef]

- Tannant, D.; Regensburg, B. Guidelines for Mine Haul Road Design; University of British Columbia Library: Vancouver, BC, Canada, 2001. [Google Scholar] [CrossRef]

- Thompson, R. Mine haul road design and management best practices for safe and cost-efficient truck haulage. In Proceedings of the Society for Mining, Metallurgy and Exploration 2010, Phoenix, AZ, USA, 28 February–3 March 2010; Conference Proceedings Pre-Print. 2010; pp. 1–10. [Google Scholar]

- Chen, S.H. Mining Patterns and Factors Contributing to Crash Severity on Road Curves. Ph.D. Thesis, Queensland University of Technology, Brisbane, Australia, 2010. Available online: https://eprints.qut.edu.au/31711/2/Shin_Chen_Thesis.pdf (accessed on 26 March 2025).

- Bauer, J. Development of a Mining Concept for the Reactivation of a Limestone Quarry in a Multiple Pit Operation Considering Alternative Locations for Mobile Pre-Screening and Crushing Plants. Master’s Thesis, Aalto University Learning Centre, Espoo, Finland, 2018. [Google Scholar]

- Bar, N.; Barton, N. The Q-slope method for rock slope engineering. Rock Mech. Rock Eng. 2017, 50, 3307–3322. [Google Scholar] [CrossRef]

- Scott, B.; Ranjith, P.G.; Choi, S.K.; Khandelwal, M. A review on existing opencast coal mining methods within Australia. J. Min. Sci. 2010, 46, 280–297. [Google Scholar] [CrossRef]

- Soltanmohammadi, H.; Osanloo, M.; Sami, A.; Malekzadeh, S.B. Selection of practical bench height in open pit mining using a multi-criteria decision making solution. J. Geol. Min. Res. 2010, 2, 48–59. [Google Scholar]

- Alejano, L.; Pons, B.; Bastante, F.; Alonso, E.; Stockhausen, H. Slope geometry design as a means for controlling rockfalls in quarries. Int. J. Rock Mech. Min. Sci. Géoméch. Abstr. 2007, 44, 903–921. [Google Scholar] [CrossRef]

- Kose, H.; Aksoy, C.O.; G�nen, A.; Kun, M.; Malli, T. Economic evaluation of optimum bench height in quarries. J. S. Afr. Inst. Min. Metall. 2005, 105, 127–135. [Google Scholar]

| Category | Parameter | Setting/Value |

|---|---|---|

| Image alignment | Accuracy | High |

| projections | 2,708,734 | |

| Tie Point Limit | 170,191 | |

| Re-projection error | 1.54 pixels | |

| Camera stations | 930 | |

| Number of images | 980 | |

| Flying altitude | 221 m | |

| Coverage area | 0.696 km2 | |

| Camera parameters | Camera model | Test pro (10.26 mm) |

| Focal length | 10.26 mm | |

| Pixel size | 2.41 µm |

| Resistivity Range (Ω·m) | Interpretation | Depth Range (m) |

|---|---|---|

| >1000 | Solid Marble | 7–75 (VES-1), 12–33 (VES-2), 8–15 (VES-3), 13–35 (VES-5) |

| 350–1000 | Fractured Marble | 2–3 (VES-1), 6–12 (VES-2), 36–54 (VES-3), 7–35 (VES-4), 1–4 (VES-5) |

| <350 | Iron Leaching | 4–8 (VES-1), 33–60 (VES-2), 22–36 (VES-3), 3–7 (VES-4), 4–14 (VES-5) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hussain, Z.; Haider, H.u.D.; Li, J.; Yu, Z.; Fu, J.; Zhang, S.; Zhu, S.; Ni, W.; Hitch, M. Mapping, Modeling and Designing a Marble Quarry Using Integrated Electric Resistivity Tomography and Unmanned Aerial Vehicles: A Study of Adaptive Decision-Making. Drones 2025, 9, 266. https://doi.org/10.3390/drones9040266

Hussain Z, Haider HuD, Li J, Yu Z, Fu J, Zhang S, Zhu S, Ni W, Hitch M. Mapping, Modeling and Designing a Marble Quarry Using Integrated Electric Resistivity Tomography and Unmanned Aerial Vehicles: A Study of Adaptive Decision-Making. Drones. 2025; 9(4):266. https://doi.org/10.3390/drones9040266

Chicago/Turabian StyleHussain, Zahid, Hanan ud Din Haider, Jiajie Li, Zhengxing Yu, Jianxin Fu, Siqi Zhang, Sitao Zhu, Wen Ni, and Michael Hitch. 2025. "Mapping, Modeling and Designing a Marble Quarry Using Integrated Electric Resistivity Tomography and Unmanned Aerial Vehicles: A Study of Adaptive Decision-Making" Drones 9, no. 4: 266. https://doi.org/10.3390/drones9040266

APA StyleHussain, Z., Haider, H. u. D., Li, J., Yu, Z., Fu, J., Zhang, S., Zhu, S., Ni, W., & Hitch, M. (2025). Mapping, Modeling and Designing a Marble Quarry Using Integrated Electric Resistivity Tomography and Unmanned Aerial Vehicles: A Study of Adaptive Decision-Making. Drones, 9(4), 266. https://doi.org/10.3390/drones9040266