1. Introduction

The current machine tools are sophisticated mechatronic systems, as reviewed by Altintas et al. [

1]. The machine tool feed drive system is used for positioning the machine components carrying the cutter and workpiece to the desired location. Hence, their positioning accuracy and dynamics will determine the quality of the produced part and the manufacturing productivity.

Machine tool manufacturers typically implement one of three main kinds of feed drive systems (ball-screw, linear motor, and rack and pinion), according to each machine’s operational requirements [

1,

2]. One of the main aspects to take into account is the travelling distance of the axis, as it will directly affect the cost and performance of the drive. The double pinion and rack solution is adopted for the case of long travelling distances, usually exceeding five metres [

3]. This is mainly because, by adding several racks together, very long strokes can be realized without modifying the stiffness of the system, independent of the travel distance. Uriarte et al. [

4] reviewed the engineering principles of large machine tools, and they recommended this type of feed drive for machines combining long travelling distances and high loads. Rack and pinion drives have seldom been studied in the literature, as opposed to the linear and ball-screw drives, which have received most of the attention of the research community.

The clearance between the double pinion and rack generates the so-called backlash effect. This effect directly influences the overall static and dynamic properties of the driven machine. Although there are mechanical solutions to suppress this effect [

5], the current industrial trend is to use an electronic preload that is managed by the CNC controller of the machine. Engelberth et al. [

6] analysed the effect of the electronically preload on the static stiffness, bandwidth, and backlash. The typical preload values are in the range of 10–30% of the rated motor torque, according to Zirn [

7]. Although a clearance free system is desirable, the increment of the preload torque leads to a reduction of the maximum achievable acceleration and an increase of the machine’s power consumption. Heidenhain [

8] offers an option, called Motion-dependent Adaptation of Control parameters (MAC), which varies the tensioning torque for increasing the achievable acceleration. Following this procedure, Verl et al. [

9] developed an improvement of the adaptive preloading system to increase the energy efficiency of the feed drive system. At the same time, they concluded that a tensioning torque of only 4% of the rated motor torque is enough to compensate the clearance.

Pritschow [

10] described the importance of achieving high servo bandwidth in order to be able to track sudden changes in the motion commands accurately, while the disturbance effects, such as friction or cutting forces, are minimized. Erkorkmaz et al. [

11] presented a high bandwidth controller that improved the servo accuracy. Bearee et al. [

12] formulated the contouring error according to the main servo parameters. In a similar way, Lee et al. [

13] proposed a servo parameter tuning method for improving the contour accuracy. Later, Feng et al. [

14] proposed an automatic servo tuning in order to minimize both tracking and following errors.

However, the first resonance constitutes a major limitation in achieving a higher control bandwidth, as noted by Pritschow [

2]. In large machine tool applications, the low structural natural frequencies coming from the machine are usually the limiting resonances. The low structural natural frequencies [15–200 Hz] have modal shapes that affect the feedback sensor readings, as described by Iglesias et al. [

15]. Altintas et al. [

1] commented that if the vibration can be felt by the servo system, the controller could become unstable leading into an unsafe operating condition of the machine. Furthermore, the dynamics of the machine tool can be improved by passive and active damping systems, as summarized by Munoa et al. [

16]. Among the different reviewed techniques, Munoa et al. [

17] used an additional acceleration feedback control loop to damp chatter vibrations while using a double pinion and rack feed drive. Later, Beudaert et al. [

18] described the limiting factors of this technique. Regenerative chatter vibrations can be characterized by stability lobe diagrams, as presented by Mohammadi et al. [

19]. Iglesias et al. [

20] presented a dedicated variable pitch tools for further chatter avoidance. Furthermore, Industry 4.0 has brought advantages for near real-time data analysis for detecting anomalous machine working conditions [

21] or even to realize smart chatter suppression hybrid systems [

22].

Uriarte et al. [

4] discussed the regular servo tuning methods, which often pay more attention to the response on the motor side rather than at the tool centre point dynamics. Altintas et al. [

1,

23] reviewed the simulation techniques to estimate the interaction between the machine mechanical structure and the servo controller during the design stage. In the same way, Zirn [

7] remarked the influence of the velocity proportional gain in the damping that was introduced by the feedback control loop. Zirn performed a root locus analysis with a combination of the servo system and a flexible load. Consequently, Zirn proposed a specific tuning method for this control gain with the objective to maximize the damping coefficient that the feed drive controller can provide to the driven flexible machine. Albertelli et al. [

24] proposed a process stability oriented tuning method in order to maximize the disturbance rejection transfer function around a certain frequency region. Beudaert et al. [

25] simulated that a correct tuning of the controller could positively impact the dynamic stiffness, especially when the tool centre point frequency response function (FRF) is taken into account in the commissioning procedure. Later, Grau et al. [

26] analysed the ball-screw controller parametrization effect to a medium size lathe compliance, concluding that the machining capabilities could be increased by up to 25%. Finally, Zaeh et al. [

27] analysed the control parameters’ effect to a ball-screw axial mode compliance.

So far, the academic community has not extensively targeted the double motor pinion and rack feed drive system, and only a few publications can be found regarding this solution. Furthermore, the existing documentation mainly focuses on energy and positioning improvements, neglecting its dynamic behaviour and interaction with the machine. The conducted research analyses the influence of the servo control parameters on the cutting point dynamic compliance. A frequency domain-based response prediction approach is proposed that is based on the Linear Fractional Transformation technique, which allows for the coupling of the analytical definition of the P-PI servo controller scheme and the structural machine tool dynamics. The derived model is implemented and validated in a large heavy-duty machine tool while using a double motor pinion and rack mechanism that is controlled by a closed industrial CNC. The experimental observations show how the feedback sensor readings are modified by an applied force at the cutting point. Additionally, the effect of the machine joint stiffness variation through the modification of the coupling preload at the ‘tool-tip’ compliance is analysed.

The paper is organized, as follows.

Section 2 presents the machine tool feed drive system model. Subsequently,

Section 3 presents the experimental implementation.

Section 4 shows the validation of the developed simulation tool. Finally,

Section 5 presents the paper’s conclusions and further work.

3. Machine Experimental Implementation

An experimental modal analysis has been carried out in order to analyse the dynamic behaviour of the machine. An instrumented impact hammer (PCB 086D20) is used to excite the structure at the ‘tool-tip’, and a triaxial accelerometer (PCB 356A16) is moved along several points of the machine structure to measure the acceleration response.

Figure 4a shows the overall machine description with the ram being placed at its maximum overhang (1500 mm).

Figure 4b shows the main modal shape of the machine ram, identified at 35 Hz, with a damping ratio of 2.6%.

Figure 5a shows a detailed view of the ram and console with an overlaid sketch of the feed drive system used for

x-axis positioning. The deformed shape of the machine is overlapped, where it can be seen that the mode is coming from the whole carriage rocking movement and the ram bending. This deformation due to a disturbance being applied at the tool centre point modifies the sensor readings.

Figure 5b shows the CNC internal variable readings when an impact at the tool centre point is applied. As external perturbations are observable through the feedback encoders, the control actuation force will be directly affected, as shown in the commanded torque. This indicates that this particular mode shape is controllable and observable through the feed drive feedback system. Hence, the control parameters can affect the machine dynamic characteristics.

3.1. Commanded Preload Effect

Engelberth et al. [

6] described how the bandwidth of the feed drive could be increased by raising the commanded preload value when the dynamics were limited by the servo system’s natural frequencies. This section studies the commanded preload effect at the tested machine tool dynamics.

Figure 6a shows the experimental setup conceptual sketch, where the disturbance has been applied through a medium-size shaker that delivers up to 100N force (GW-V20/PA100E). The force used to dynamically excite the machine has been measured by means of a load cell (PCB 208C02) placed at the shaker’s stinger. At the same time, the ‘tool-tip’ acceleration has been measured by using an industrial accelerometer (PCB 603C01). The quality of the FRFs used to build the model is of vital importance, as the mathematical model derived in

Section 2.2 is based on complex vector operations. For that reason, the use of the shaker rather than the dynamometric impact hammer has been considered. The machine tool is equipped with a SIEMENS 840D Solution Line CNC, which offers a data logger tool, called ServoTrace. In addition, a fast analogue to digital switch converter has been installed to be able to measure both ‘tool-tip’ acceleration and applied disturbance force. This implies that internal and external variables are synchronously acquired at the same sampling frequency of 500 Hz.

Figure 6b shows the influence of the commanded torque bias

on the dynamical response at the tool centre point. The shaker actuator is fed with a chirp signal from 25 Hz to 100 Hz, covering the frequency range of interest, in order to obtain the FRFs. The excitation is repeated four times to improve the response coherence, and the chirp length has been fixed to 20 s, as this yields an overall high quality measurement with sufficient frequency resolution. As expected, the preload value modifies the boundary conditions of the feed drive system, which directly affects the

x-axis machine dynamic characteristics. A higher preload value shows an increment in the machine natural frequency, as well as a decrease of the damping ratio (see

Table 1), especially for the main resonance at 35 Hz. In the same way, the remarkable difference between a non-powered (Power OFF) and powered frequency responses can be emphasized. The main mode shifts to a poorly damped 32 Hz resonance and the second main mode shape (35 Hz) almost disappears due to the high damping value.

The user-defined preload magnitude should be high enough to suppress the existing backlash, as previously commented in

Section 1.

Figure 7 shows the master and slave rotary encoder-captured displacement in response to disturbance excitation that was applied at the tool centre point. As can be seen, the commanded preload value plays an important role in modifying the displacement ratio between the two motors. This ratio should ideally be 1:1 to have a balanced displacement of both motors. This ideal is closely achieved with a preload value of 10%, where the behaviour is similar to a straight line. In contrast, for 5% and 2.5% preload, it can be seen how the displacement ratio varies. Finally, the response for 1% also achieves an almost ideal ratio on average, but, when compared to the 10% response, the 1%, 2.5%, and 5% cases also show dynamic variation in the instantaneous displacement ratio, being marked by the increase in width for the phase plane plots between the master and slave drive positions.

3.2. Machine Open-Loop Extraction

The first step is to characterize both the controller and the open-loop response of the machine assembly in order to predict the effect of the control parameters on the dynamics of the machine.

The controller can be characterized by the schemes that the CNC manufacturers provide in their documentation. The dynamic characterization of the machine, however, involves difficulties, such as non-linearities due to friction or machine joints. In addition, the machine dynamics can significantly vary, depending on the cutting position, as shown in [

15]. Similarly, the dynamic behaviour of the machine changes significantly with and without electrical power. Therefore, obtaining the response without the controller effect cannot be achieved by means of a non-powered frequency response. This would lead to non-linear behaviour, such as backlash, normally being suppressed by the preload provided by the controller, to become very significant. For this reason, a fixed preload value of 10% has been applied during the proceeding tests. However, the invariance of this control parameter would lead to developing certain assumptions that are described in

Section 3.2.2.

Furthermore, a dedicated ‘compiled cycle’ has been developed to allow for the addition of external commands to position, velocity, and torque reference points. This offers the possibility to inject a specified signal into the machine and excite it through the existing feed drive actuators. With this, and the ServoTrace tool mentioned earlier, the matrix P that defines the open-loop MIMO FRF for the machine, for a certain position, can be measured through excitation via the two kinds of input sources: the disturbance force Fdis and the motor torques (, ).

3.2.1. Tool Centre Point Force Disturbance Side Characterization

As previously discussed, the machine dynamical behaviour (

Figure 6b) is different with and without electrical power, especially due to the variation of the preload. For that reason, in this research, the machine has been powered up, but the control parameters have been set to very low values (

Kv = 1 [(m/min)/mm],

Ti = 50 [ms], and

Kp = 0.05 [Nms/rad]) to minimize the influence of the control actuation force while maintaining the preload of 10%. On the other hand, the experiment has been conducted four times, obtaining, as a result, an average response with a successful signal coherence check in order to increase the signal quality and minimize the uncertainty.

Figure 8a shows the complete (four sections of 20 s) acquired time-domain data for the disturbance force and ‘tool-tip’ acceleration. The exerted force amplitude of the electromagnetic actuator located at the tool tip decay almost linearly with the excitation frequency. At the beginning of the excitation (25 Hz), the force amplitude is close to 70 N and, as a result, of the actuator’s response characteristics, at 100 Hz the force has decreased up to 60 N (

Figure 8b). However, under the assumption of a linear system, this does not generate major problems. The time-domain acquired data show the dynamic behavior of the tested machine, where two clear amplifications are present at 5.8 s and 6.3 s. The two rotary and linear encoders’ data are synchronously registered in order to generate the FRFs that are shown in

Figure 8c–e. The main two natural frequencies are located at 32 Hz and 35 Hz, as expected from the experimental analysis and time-domain data. Moreover, the frequency domain magnitude difference of roughly a factor ten between the cutting point (

Figure 8c) and linear scale (

Figure 8d) sensors can be explained by the mode shape that is shown in

Figure 4.

The data represented in

Figure 8c–e is used to fill the first column of the

P matrix (

Figure 2b).

3.2.2. Feed Drive Response Characterization

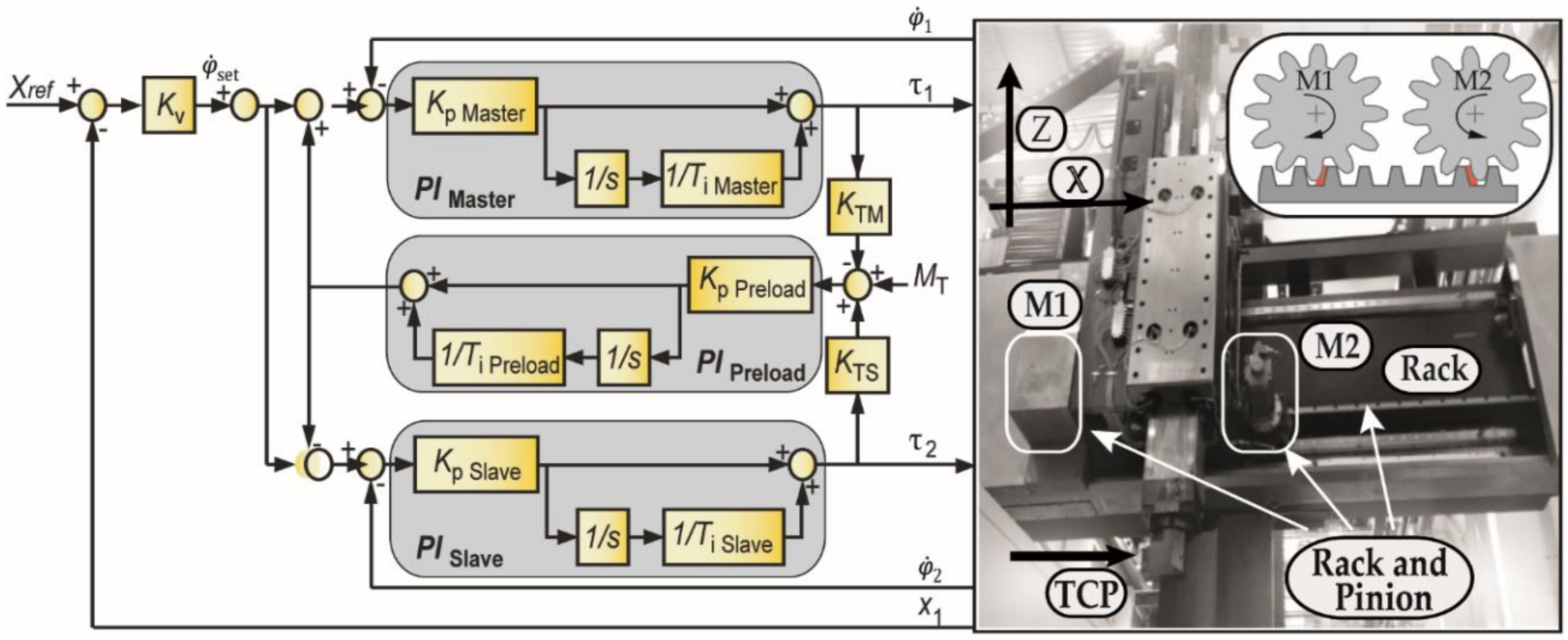

The response to excitation from both machine actuators is required to be able to couple the analytically defined controller effect and machine tool structural dynamics. Usually, the machine feed drive actuators should be individually excited in order to characterize the response. However, the tested machine uses a double pinion and rack mechanism with a Master–Slave control coupling, as described in

Section 2.1. In achieving the removal of backlash, the ‘torque equalization controller’ couples both motor’s actuation. This means that, even if the excitation signal is carried out by a single motor, due to the torque equalization controller, the secondary motor also follows the excitation signal to obtain the desired torque bias. Hence, the response at a specific output point

is affected by both motors’ excitation (

,

). In the following equations the general output

can be replaced by any output of the matrix

P (

,

,

and

).

The expressions in (18)–(19) can be used in order to be able to decouple the motor actuations and obtain the individual excitation response from each motor. The aim is to get at least two non-proportional measurements of the desired input (

,

) and output (

). These measurements can be obtained by modifying the velocity PI controller of each motor independently. This will generate a different torque command for each motor. As shown, the resolution of the system FRF that is composed of two or more experimental measurements with different controllers allows for obtaining the open-loop frequency response functions of the matrix

P.

Even though the procedure described above is valid for a general case, for the research reported in this paper, this method could not be implemented due to practical reasons that are associated with the control system measurement. However, the following simplifications have been considered due to the machine topology. Both motors are identical, they have the same weighting factors

and PI gains (

, so it is assumed that the same torque command is generated for both motors

. In addition to this, if the excitation signal is given as a velocity command through a compiled cycle in the CNC, the generated reference torque

will be equally divided between both motors

. This assumption is only valid when the static part of the torque command is removed, for example, for the selected excitation frequency band (25 to 100 Hz).

In addition, when considering that the motors and sensors are symmetrically located with respect to the machine’s main resonance mode shape, the frequency response can be equalized

. This assumption can be extrapolated to all of the measured outputs referred to in this paper (

,

,

, and

).

With the previous hypotheses, it is assumed that the open-loop frequency response functions can be obtained, even if both of the motors are simultaneously exciting the system. With the tested tension torque of 10%, the time-domain amplitude difference between the torque commands (, ) is ±0.5 Nm, or an 88% of equivalence. At the same time, the frequency response function between both torque commands have shown a +0% and −15% amplitude difference with respect to the ideal ratio of 1:1 within the frequency range of interest. These assumptions demonstrate the capabilities and limitations of the developed simulation model, as the velocity PI controller gains for each motor cannot be independently modified. Additionally, the followed measurement methodology cannot be generalized to all machine configurations, for example, to machines having different motors and different weighting factors for the preload. Nonetheless, in the case of the studied machine tool, the practically obtained FRFs via dual motor excitation can still be used. Future research will address these points and investigate the decoupling of individual single-input FRFs from experimental multi-input frequency response data.

Similar to the previous subsection,

Figure 9a,b shows the acquired time-domain signals. As the excitation signal has been placed outside the velocity feedback loop, it can be seen in

Figure 9a how the torque commands are sensitive to the structural vibrations. In addition to this, as a result of the Master–Slave coupling configuration, both commanded torques are of inverse sign to successfully suppress the existing backlash. The static value is ±7 Nm as the preload value is set to 10% of the motor rated torque (70 Nm). The excitation chirp signal is added to this static value.

Figure 9b shows the acquired data for both rotary encoders and cutting point acceleration during the excitation process. The machine tool structural resonance at 35 Hz generates an anti-resonance at the same frequency in both rotary encoders, as seen in

Figure 9c. Moreover, this is how the machine tool natural frequency interacts with the specified servo controller. This resonance manifests itself as an anti-resonance in the encoder feedback. Furthermore, when commissioning the velocity loop, the implemented control parameters affect the characteristics of the resonance on the machine ‘tool-tip’ side, and its reflection back to the control loop as anti-resonance.

Figure 10 shows the computed frequency responses from both actuators to the linear scale, ‘tool-tip’ displacement, and both rotary encoders (

,

,

, and

). Those frequency response functions are directly obtained from the experiment realized with both motors acting simultaneously on the system. These ‘pseudo’ open-loop responses are used in the matrix

P under the hypotheses that the motors and the velocity controllers are identical. The figure validates the hypotheses, as the responses are practically similar up to 40 Hz. Furthermore, the complexity of the responses shows the advantage of deriving the model in the frequency-domain rather than performing the curve fittings needed for time-domain analyses. Analysing the frequency response magnitudes in detail, the previously commented order of magnitude difference between the linear scale and ‘tool-tip’ accelerometer is present. Additionally, the commented resonance at 35 Hz in the accelerometer generates an anti-resonance (or motor-locked frequency) in both rotary encoders.

The frequency-domain signals that are shown in

Figure 10 are used in the

P matrix as ‘pseudo’-open-loop responses. With the experimental characterization presented in this section, the analytical effect of the implemented controller can be coupled with the machine tool dynamics.