Assessment of Mechanisms for Particle Migration in Semi-Solid High Pressure Die Cast Aluminium-Silicon Alloys

Abstract

:1. Introduction

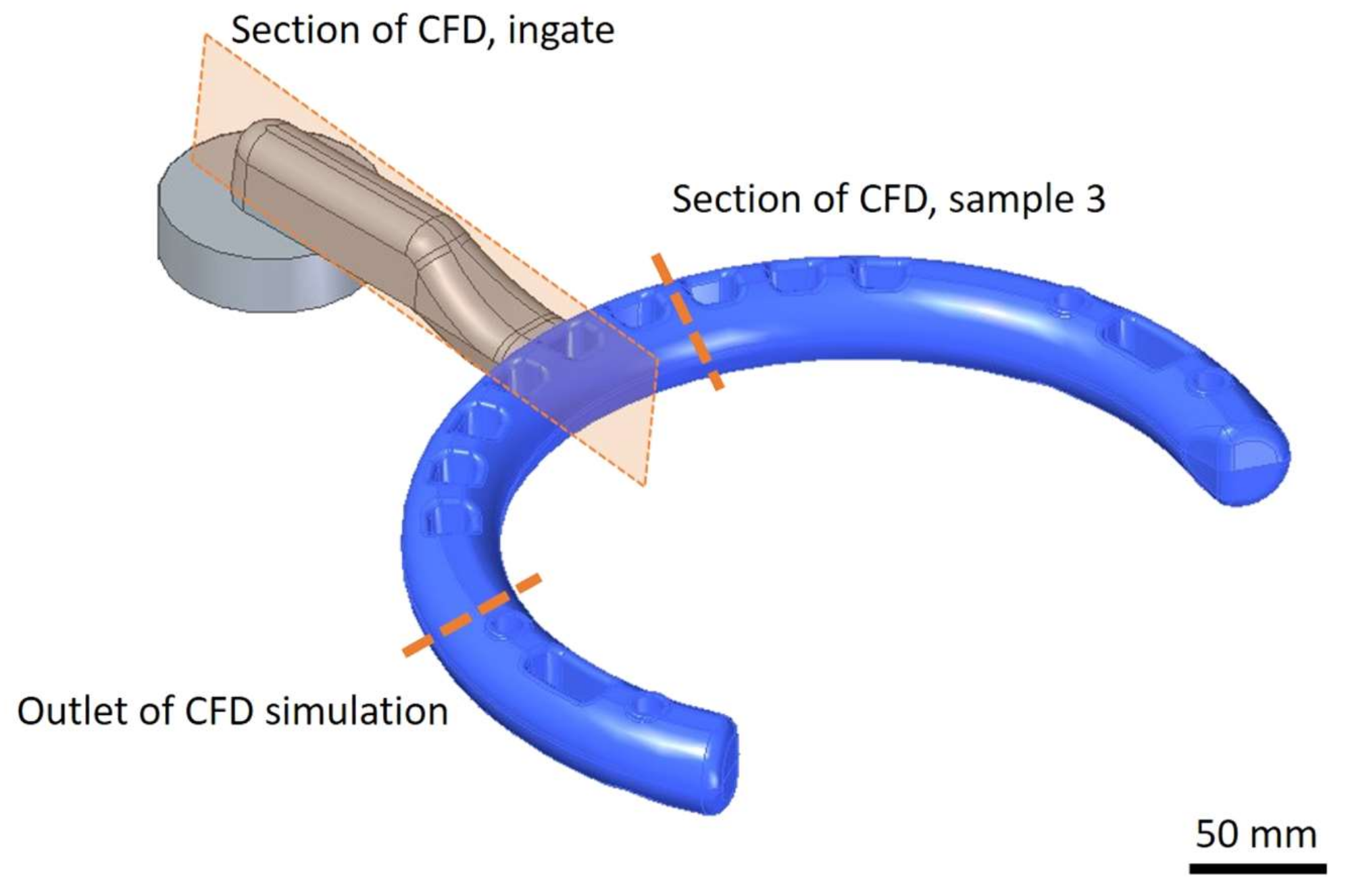

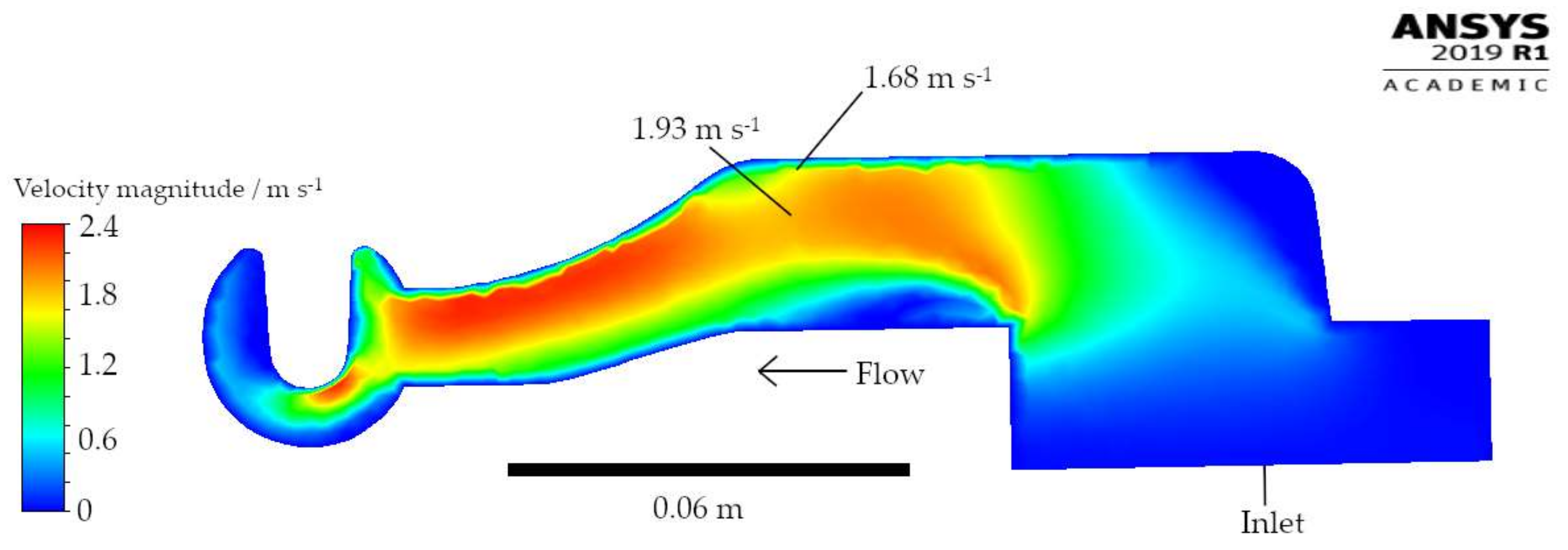

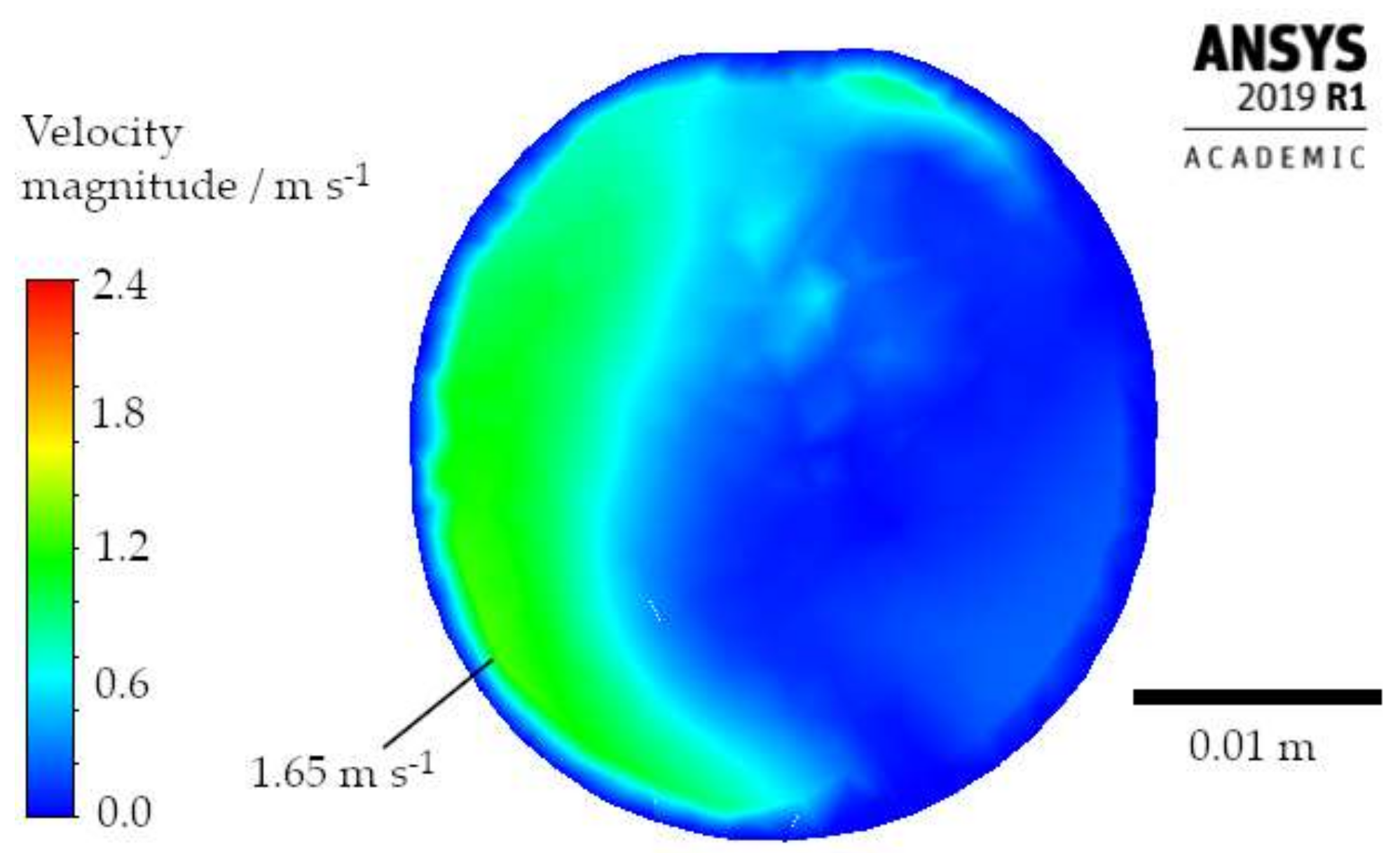

2. Materials and Methods

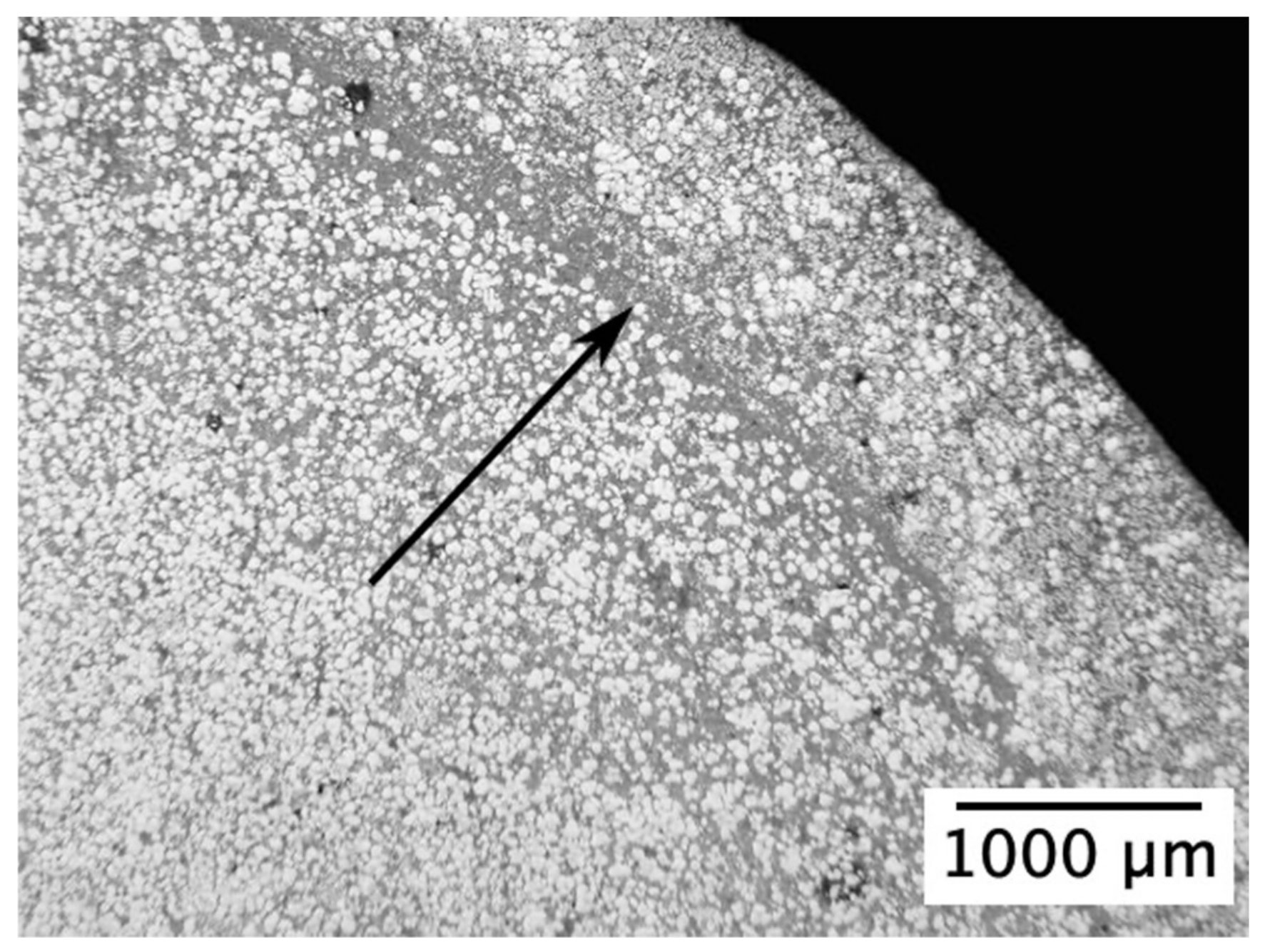

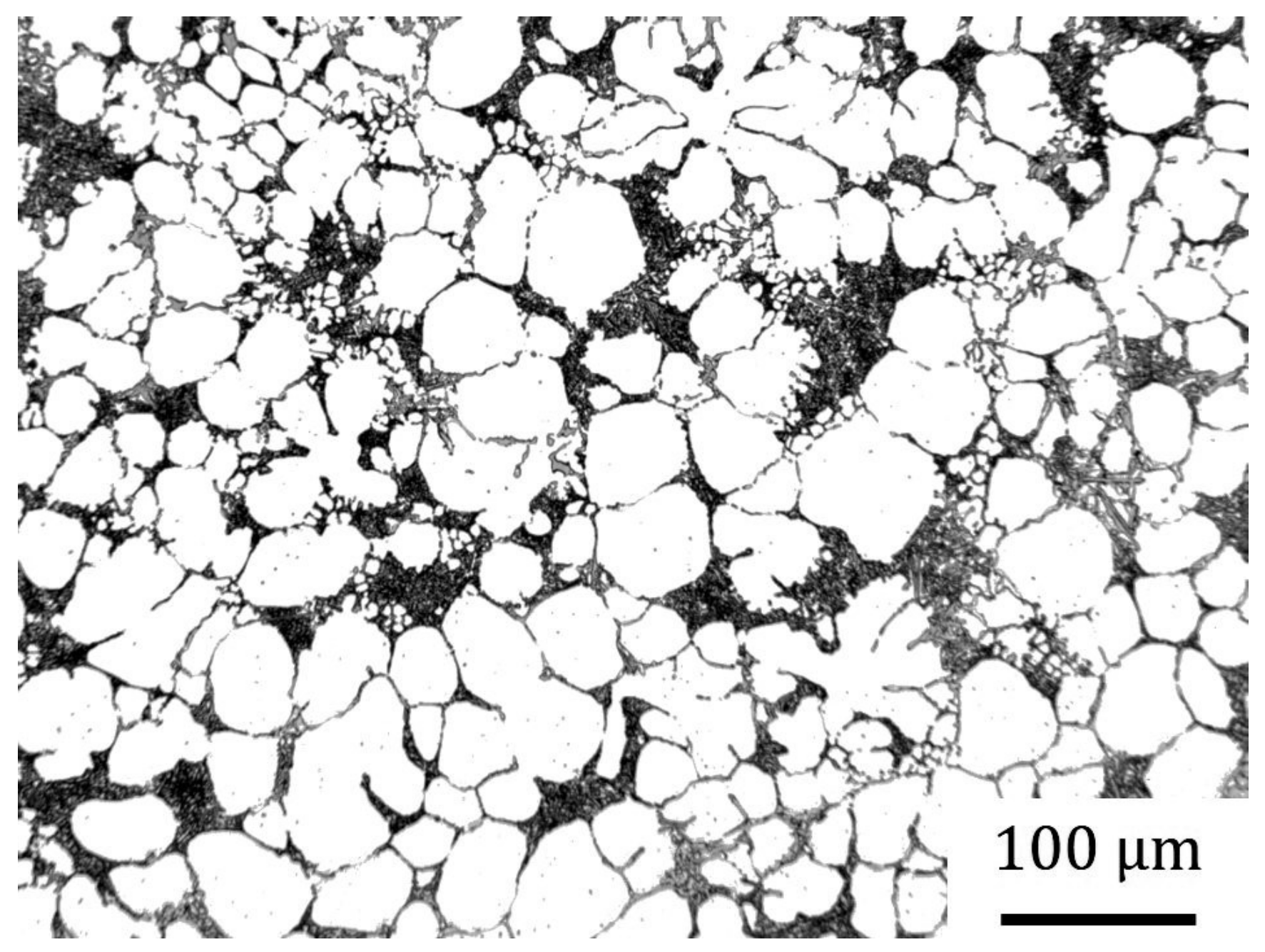

3. Results

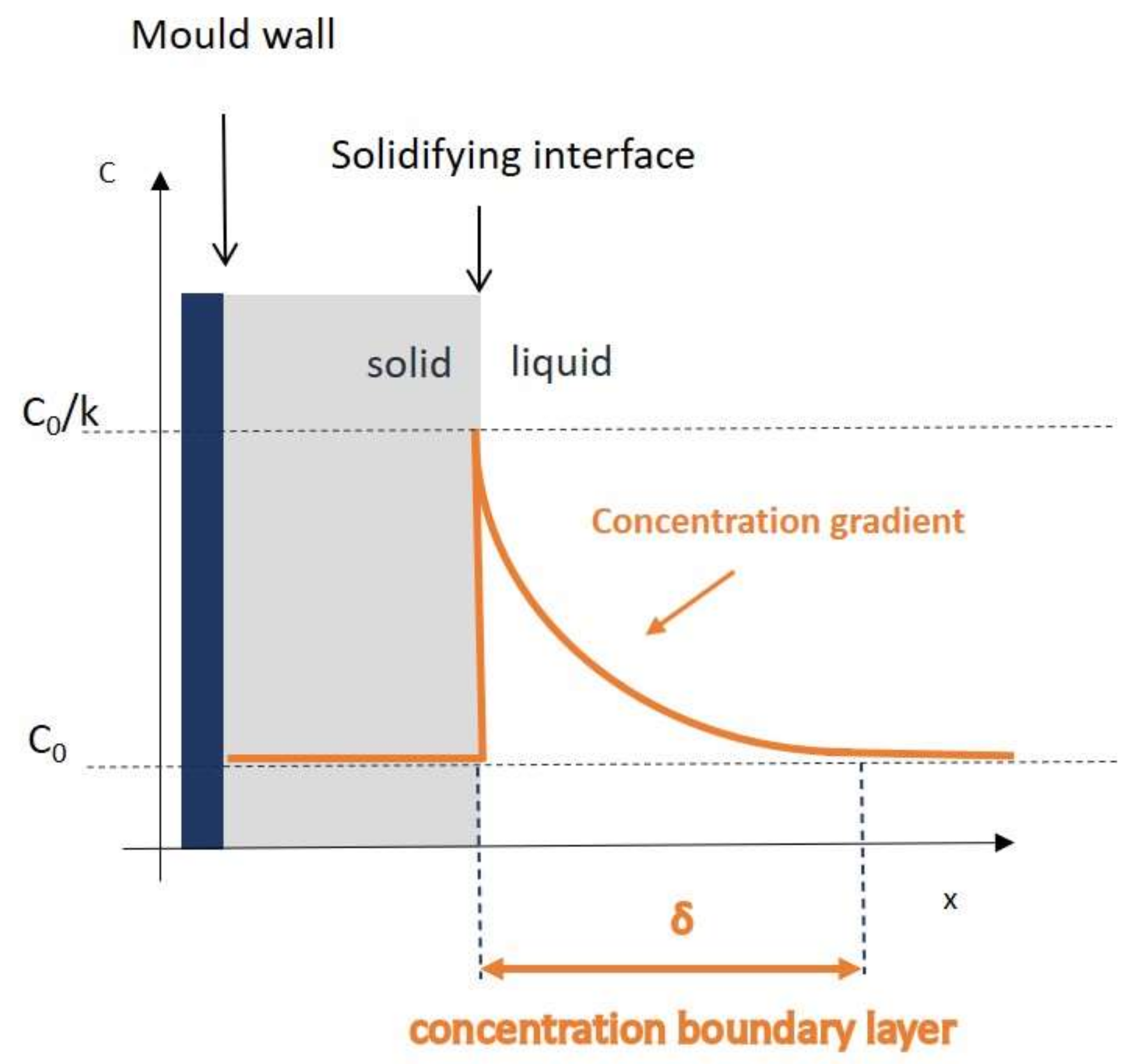

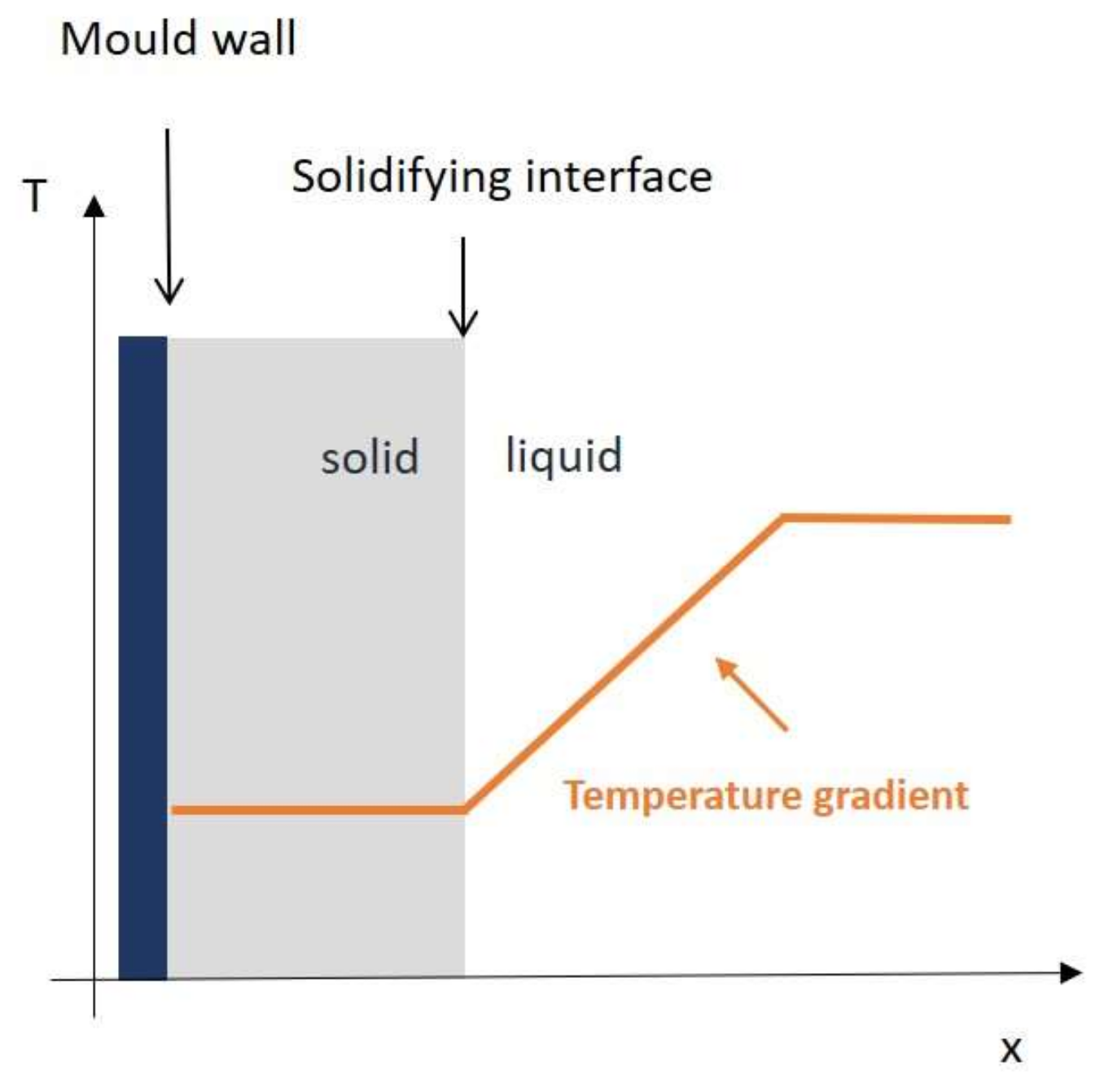

3.1. Solidification Front

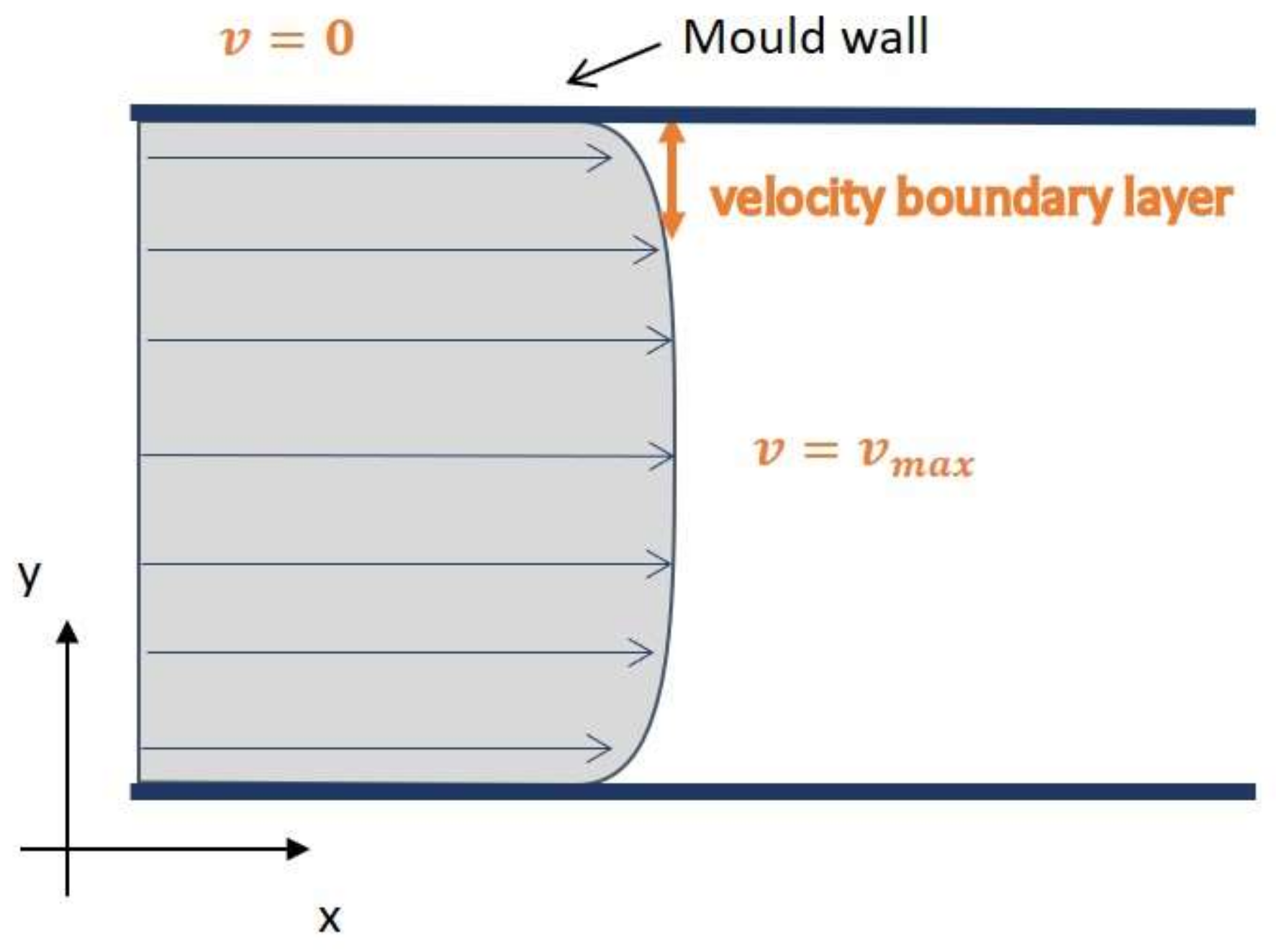

3.2. Saffman Lift Force

3.3. Magnus Lift Force

3.4. Wall Effects

3.5. Hydrodynamic Diffusion

3.6. Dilatant Shear

3.7. Mukai-Lin-Laplace Effect

4. Discussion

4.1. Saffman Lift Force

4.2. Magnus Lift Force

4.3. Hydrodynamic Diffusion

4.4. Mukai-Lin-Laplace Effect

4.5. Future Work

5. Conclusions

- It is not possible to positively identify a single mechanism that is responsible for the banding observed in the previous high pressure die casting experiments using theoretical considerations alone.

- Of all mechanisms investigated in this paper, two are considered most likely to be responsible for the migration of the particles found: Saffman lift force and/or the Mukai-Lin-Laplace effect.

- Calculations and literature results suggest that the effect of a temperature gradient leads to a difference in surface/interfacial tension across the externally solidified crystals of aluminium, which leads to a net force according to the Mukai-Lin-Laplace effect.

- This force is capable of moving the particles ahead of the solidification front.

- The velocity gradient in the boundary layer is sufficient to lead to particle migration via the Saffman lift force.

- More sophisticated simulations, such as computational fluid dynamics with coupled heat transfer, could help advance the current work.

- More exact fluid properties would also improve the accuracy of any future simulations.

- It is very likely that experiments are necessary to find the mechanism responsible for particle migration with confidence.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

Appendix B

| Quantity | Symbol | Value | Source | Calculations Where the Value is Used |

|---|---|---|---|---|

| Liquid alloy density | [29] | 1 | ||

| Distance from start of flow | Experiment | 1 | ||

| Liquid viscosity (Al-12wt%Si) | [29] | 1, 3 | ||

| Kinematic viscosity | Calculated [29] | 4 | ||

| Slurry density (Al-6wt%Si) | [29] | 3 | ||

| Liquid density (Al-12wt%Si) | [29] | 10 | ||

| Maximum velocity | CFD | 1, 8 | ||

| Al-Si eutectic surface tension | [32] | CFD | ||

| Solute concentration at which the boundary layer ends | 1.01 | Assertion | 2 | |

| Partitioning coefficient | 0.13 | [36] | 2 | |

| Diffusion coefficient | [37] | 2 | ||

| Solidification fronts average velocity | Approximation | 2 | ||

| characteristic length | Experiment | 3 | ||

| characteristic length | Experiment | 3 | ||

| Average velocity of fluid (plunger velocity) | Experiment | 3 | ||

| Average velocity of fluid | Experiment | 3 | ||

| Exponent of rheology | 0.4 | [25] | 3 | |

| Spherical radius | Experiment | 4, 9, 10 | ||

| Relative velocity of particle | CFD | 4 | ||

| Magnitude of velocity gradient | Calculated | 4 | ||

| Rotational velocity of particles | Approximation | 5 | ||

| Spherical diameter | Experiment | 5 | ||

| Net velocity | CFD | 5 | ||

| Dimensionless parameter | 1 | [11] | 6 | |

| Fraction solid (volume) | 0.30 | Experiment | 6 | |

| Shear stress | Calculated, [25,30] | 6, 7 | ||

| Shear rate | Experiment, [25] | 7, 8, A2, A9 | ||

| Local shear stress | Experiment, [30] | 6, A9 | ||

| Herschel-Bulkley yield stress | [30] | 7, A6 | ||

| Consistency index | [30] | 7, A6, A8 | ||

| Constant | [30] | 7, A6, A8 | ||

| Generalised consistency index | Calculated [26] | 1 | ||

| Tube radius | Experiment | 8 | ||

| Tube diameter | Experiment | 8 | ||

| Rheological properties exponent | [25] | 8 | ||

| Distance from tube wall | Experiment, CFD | 8 | ||

| Interfacial tension gradient | Calculated [39] | 9, 10 | ||

| Surface tension | Calculated [39] | 9, 10 | ||

| Temperature gradient | 30,900 | Experiment | 9, 10 | |

| [29] | 4, 10 | |||

| Density of the liquid | [29] | 10 | ||

| Density of the particle | [29] | 5, 10 |

References

- Fan, Z.; Liu, G.; Wang, Y. Microstructure and mechanical properties of rheo-diecast AZ91D magnesium alloy. J. Mater. Sci. 2006, 41, 3631–3644. [Google Scholar] [CrossRef]

- Möller, H.; Curle, U.A.; Masuku, E.P. Characterization of surface liquid segregation in SSM-HPDC aluminium alloys 7075, 2024, 6082 and A201. Trans. Nonferrous Met. Soc. China 2010, 20, 847–851. [Google Scholar] [CrossRef]

- Bladh, M.; Wessén, M.; Dahle, A.K. Shear Band Formation in a Shaped Rheocast Aluminium Component at Various Plunger Velocities. Trans. Nonferrous Met. Soc. China 2010, 20, 1749–1755. [Google Scholar] [CrossRef]

- Law, M. Investigations on the Formation of Defect Bands in Semi-Solid High Pressure Die Cast Aluminium-Silicon Alloys. Master’s Thesis, KTH Royal Institute of Technology, Stockholm, Sweden, 8 May 2020. Available online: http://urn.kb.se/resolve?urn=urn%3Anbn%3Ase%3Akth%3Adiva-272086 (accessed on 8 May 2020).

- Li, X.; Xiong, S.M.; Guo, Z. On the tensile failure induced by defect band in high pressure die casting of AM60B magnesium alloy. Mater. Sci. Eng. A 2016, 674, 687–695. [Google Scholar] [CrossRef]

- Laukli, H.I.; Gourlay, C.M.; Dahle, A.K. Migration of Crystals during Filling of Semi-Solid Castings. Met. Trans. A 2005, 36, 805–818. [Google Scholar] [CrossRef]

- Saffman, P.G. The lift on a Small Sphere in a Slow Shear Flow. J. Fluid Mech. 1965, 22, 385–400. [Google Scholar] [CrossRef] [Green Version]

- Saffman, P.G. Corrigendum. J. Fluid Mech. 1968, 31, 624. [Google Scholar] [CrossRef]

- Crowe, C.; Sommerfeld, M.; Tsuji, Y. Multiphase Flows with Droplets and Particles; CRC Press: Boca Raton, FL, USA, 1998; pp. 95–99. [Google Scholar]

- Seshadri, V.; Sutera, S.P. Concentration changes of suspension of rigid spheres flowing through tubes. J. Colloid Interface Sci. 1968, 27, 101–110. [Google Scholar] [CrossRef]

- Leighton, D.; Acrivos, A. The shear-induced migration of particles in concentrated suspensions. J. Fluid Mech. 1987, 181, 415–439. [Google Scholar] [CrossRef]

- Mukai, K.; Lin, W. Motion of Small Particles in Solution with a Interfacial Tension Gradient and Engulfment of the Particles by Solidifying Interface. Tetsu Hagané 1994, 80, 527–532. [Google Scholar] [CrossRef] [Green Version]

- Mukai, K.; Lin, W. Behavior of Non-metallic Inclusions and Bubbles in Front of Solidifying Interface of Liquid Iron. Tetsu Hagané 1994, 80, 533–538. [Google Scholar] [CrossRef] [Green Version]

- Mukai, K.; Matsushita, T. Interfacial Physical Chemistry of High. Temperature Melts; CRC Press: Boca Raton, FL, USA, 2019; p. 104. [Google Scholar]

- Garvin, J.W.; Udaykumar, H.S. Drag on a particle being pushed by a solidification front and its dependence on thermal conductivities. J. Cryst. Growth 2004, 267, 724–737. [Google Scholar] [CrossRef]

- Mortensen, A.; Jin, I. Solidification processing of metal matrix composites. Int. Mater. Rev. 1992, 37, 101–128. [Google Scholar] [CrossRef]

- Gourlay, C.M.; Dahle, A.K. Dilatant shear bands in solidifying metals. Nature 2007, 445, 70–73. [Google Scholar] [CrossRef] [PubMed]

- Zou, X.; Cheng, H.; Zhang, C.; Zhao, Y. Effects of the Magnus and Saffman forces on the saltation trajectories of sand grain. Geomorphology 2007, 90, 11–22. [Google Scholar] [CrossRef]

- Stone, H. Philip Saffman and viscous flow theory. J. Fluid Mech. 2000, 409, 165–183. [Google Scholar] [CrossRef]

- Briggs, L.; Lyman, J. Effect of Spin and Speed on the Lateral Deflection (Curve) of a Baseball; and the Magnus Effect for Smooth Spheres. Am. J. Phys. 1959, 27, 589–596. [Google Scholar] [CrossRef]

- Zhao, Y. Settling behaviour of polymer flocculated water-treatment sludge I: Analyses of settling curves. Sep. Purif. Technol. 2004, 35, 71–80. [Google Scholar] [CrossRef] [Green Version]

- Tan, M.; Le, D.; Chiam, K. Hydrodynamic diffusion of a suspension of elastic capsules in bounded simple shear flow. Soft Matter 2012, 8, 2243–2251. [Google Scholar] [CrossRef]

- Duran, J. Sands, Powders, and Grains: An Introduction to the Physics of Granular Materials (Partially Ordered Systems); Springer: New York, NY, USA, 2000. [Google Scholar]

- Wang, Z.; Mukai, K.; Lee, I.J. Behavior of Fine Bubbles in Front of the Solidifying Interface. ISIJ Int. 1999, 39, 553–562. [Google Scholar] [CrossRef]

- Hu, X.; Zhu, Q.; Atkinson, H.; Lu, H.; Zhang, F.; Dong, H.; Kang, Y. A time-dependent power law viscosity model and its application in modelling semi-solid die casting of 319s alloy. Acta Mater. 2017, 124, 410–420. [Google Scholar] [CrossRef] [Green Version]

- Hartnett, J.; Cho, Y. Handbook of Heat Transfer, 3rd ed.; Rohsenow, W., Hartnett, J., Cho, Y., Eds.; McGraw-Hill: New York, NY, USA, 1998. [Google Scholar]

- Metzner, A.B.; Reed, J.C. Flow of non-Newtonian fluids—Correlation of the laminar, transition, and turbulent-flow regions. AIChE J. 1955, 1, 434–440. [Google Scholar] [CrossRef]

- Bird, R.; Lightfoot, E.; Stewart, W. Transport Phenomena, 2nd ed.; Wiley: New York, NY, USA, 2007. [Google Scholar]

- Mills, K.C. Recommended Values of Thermophysical Properties for Selected Commercial Alloys; Woodhead Publishing: Cambridge, UK, 2002. [Google Scholar]

- Tonmukayakul, N.; Pan, Q.Y.; Alexandrou, A.N.; Apelian, D. Transient Flow Characteristics and Properties of Semi-Solid Aluminium Alloy A365. Proceedings of 8th International Conference of Semi-Solid Processing of Alloys and Composites S2P, Limassol, Cyprus, 21–23 September 2004; pp. 167–172. [Google Scholar]

- Massey, B.S. Mechanics of Fluids, 6th ed.; Van Nostrand Reinhold: London, UK, 1989. [Google Scholar]

- Davies, V.L.; West, J.M. Factors affecting modification of aluminium-silicon eutectic. J. Inst. Met. 1964, 92, 208. [Google Scholar]

- Hur, B.; Park, S.; Hiroshi, A. Viscosity and surface tension of Al and effects of additional element. Mater. Sci. Forum 2003, 439, 51–56. [Google Scholar] [CrossRef]

- Goicoechea, J.; Garcia-Cordovilla, C.; Louis, E.; Pamies, A. Surface tension of binary and ternary aluminium alloys of the systems Al-Si-Mg and Al-Zn-Mg. J. Mater. Sci. 1992, 27, 5247–5252. [Google Scholar] [CrossRef]

- Zeze, M.; Mukai, K. Effect of Solute Contents on the Entrapment of Gas Bubbles and Non-Metallic Inclusions by the Solidifying Shell in Continuous Casting of Steel. ICS. In Proceedings of the 3rd International Congress on the Science and Technology of Steelmaking, Charlotte, NC, USA, 9–12 May 2005; pp. 873–880. [Google Scholar]

- DoITPoMS Teaching and Learning Package on Solidification of Alloys. Available online: https://www.doitpoms.ac.uk/tlplib/solidification_alloys/printall.php (accessed on 18 August 2019).

- Du, Y.; Chang, Y.; Huang, B.; Gong, W.; Jin, Z.; Xu, H.; Yuan, Z.; Liu, Y.; He, Y.; Xie, F.-Y. Diffusion coefficients of some solutes in fcc and liquid Al: Critical evaluation and correlation. Mater. Sci. Eng. A 2003, 363, 140–151. [Google Scholar] [CrossRef]

- Zubko, A.M.; Lobanov, V.G.; Nikonova, V.V. Reaction of Foreign Particles with a Crystallization Front. Sov. Phys. Crystallogr. 1973, 18, 239–245. [Google Scholar]

- Kobatake, H.; Brillo, J.; Schmitz, J.; Pichon, P. Surface tension of binary Al—Si liquid alloys. J. Mater. Sci. 2015, 50, 3351–3360. [Google Scholar] [CrossRef]

- Cao, Y.; Guo, Z.; Xiong, S. Determination of the metal/die interfacial heat transfer coefficient of high pressure die cast B390 alloy. IOP Conf. Ser. Mater. Sci. Eng. 2012, 33, 012010. [Google Scholar] [CrossRef] [Green Version]

- Stokes’ law. Available online: https://en.wikipedia.org/wiki/Stokes%27_law (accessed on 12 May 2020).

- The Benefits of Semi-Solid Casting for Aluminum Alloys. Available online: https://www.foundrymag.com/melt-pour/article/21928694/the-benefits-of-semisolid-casting-for-aluminum-alloys (accessed on 6 March 2020).

- Herschel, W.H.; Bulkley, R. Konsistenzmessungen von Gummi-Benzollösungen. Colloid Polym. Sci. 1926, 39, 291–300. [Google Scholar] [CrossRef]

- Fluid Mechanics. Available online: https://acikders.ankara.edu.tr/pluginfile.php/16644/mod_resource/content/1/WEEK%2012%20OF%20AQS110%20FLUID%20MECHANICS.pdf (accessed on 6 March 2020).

| Slurry (Al-6wt%Si) | Liquid (Al-12wt%Si) | Reference | |

|---|---|---|---|

| Density of fluid, | 2496 | 2474 | [29] |

| 0.08 | 0.0001 | ||

| Characteristic flow velocity | 0.15 | 1.68 | |

| 5.65 | - | [30] | |

| 6.42 | - | ||

| 0.0015 | [29] | ||

| 0.4 | 1 | [25] | |

| Generalised Reynolds number, | 24 | 277 |

| Saffman Lift | Magnus Lift | Hydrodynamic Diffusion | MLL Effect (Temperature) | |

|---|---|---|---|---|

| 16 000 | * | |||

| Terminal Velocity, | * | * |

| Saffman Lift | Magnus Lift | Hydrodynamic Diffusion | MLL Effect (Temperature) | |

|---|---|---|---|---|

| 16 000 | * | |||

| Terminal Velocity, | * | * |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Law, M.; Hulme-Smith, C.N.; Matsushita, T.; Jönsson, P.G. Assessment of Mechanisms for Particle Migration in Semi-Solid High Pressure Die Cast Aluminium-Silicon Alloys. J. Manuf. Mater. Process. 2020, 4, 51. https://doi.org/10.3390/jmmp4020051

Law M, Hulme-Smith CN, Matsushita T, Jönsson PG. Assessment of Mechanisms for Particle Migration in Semi-Solid High Pressure Die Cast Aluminium-Silicon Alloys. Journal of Manufacturing and Materials Processing. 2020; 4(2):51. https://doi.org/10.3390/jmmp4020051

Chicago/Turabian StyleLaw, Madeleine, Christopher Neil Hulme-Smith, Taishi Matsushita, and Pär G. Jönsson. 2020. "Assessment of Mechanisms for Particle Migration in Semi-Solid High Pressure Die Cast Aluminium-Silicon Alloys" Journal of Manufacturing and Materials Processing 4, no. 2: 51. https://doi.org/10.3390/jmmp4020051

APA StyleLaw, M., Hulme-Smith, C. N., Matsushita, T., & Jönsson, P. G. (2020). Assessment of Mechanisms for Particle Migration in Semi-Solid High Pressure Die Cast Aluminium-Silicon Alloys. Journal of Manufacturing and Materials Processing, 4(2), 51. https://doi.org/10.3390/jmmp4020051