Effect of the Laser Processing Parameters on the Selective Laser Melting of TiC–Fe-Based Cermets

Abstract

:1. Introduction

2. Materials and Methods

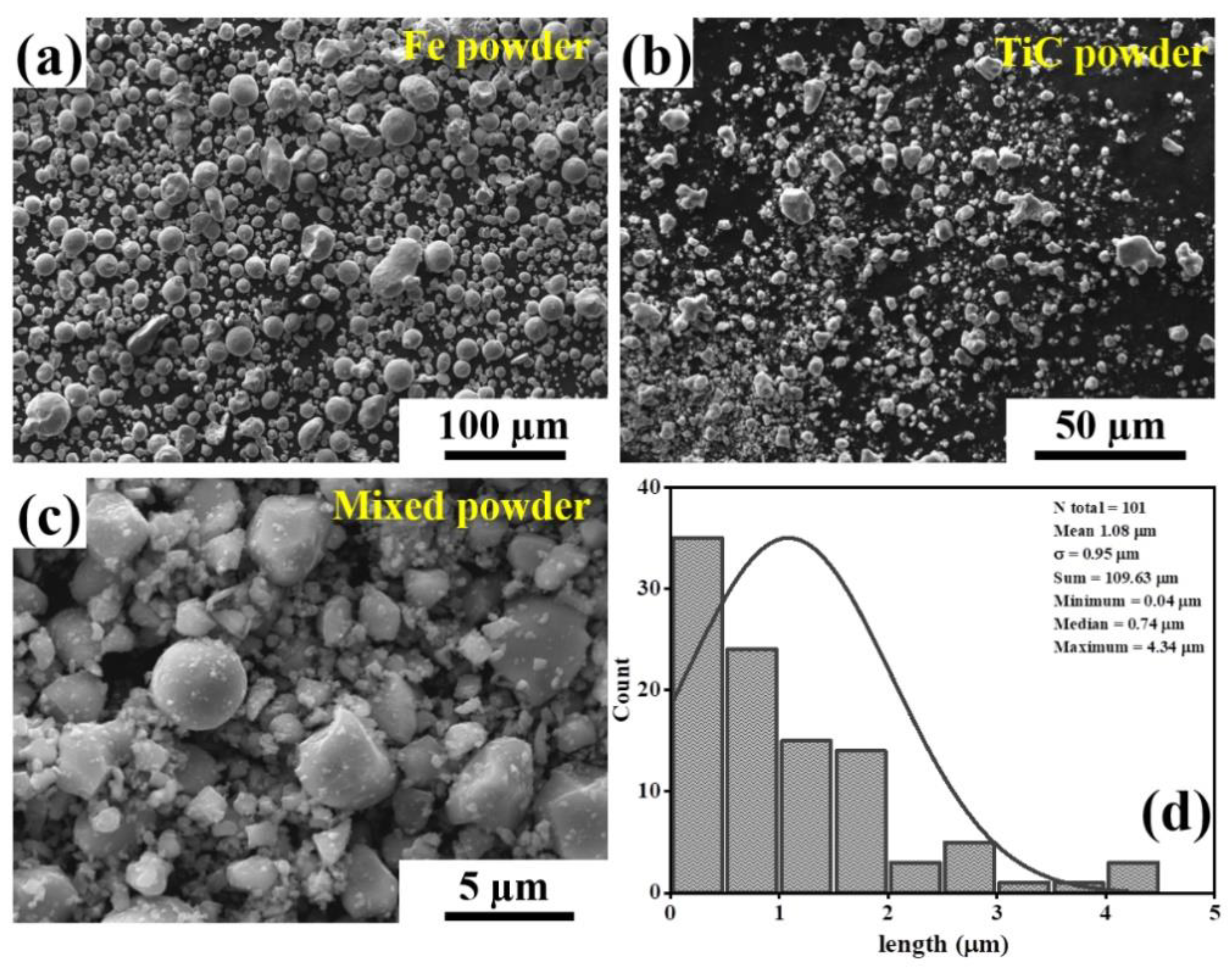

2.1. Powder Feedstock

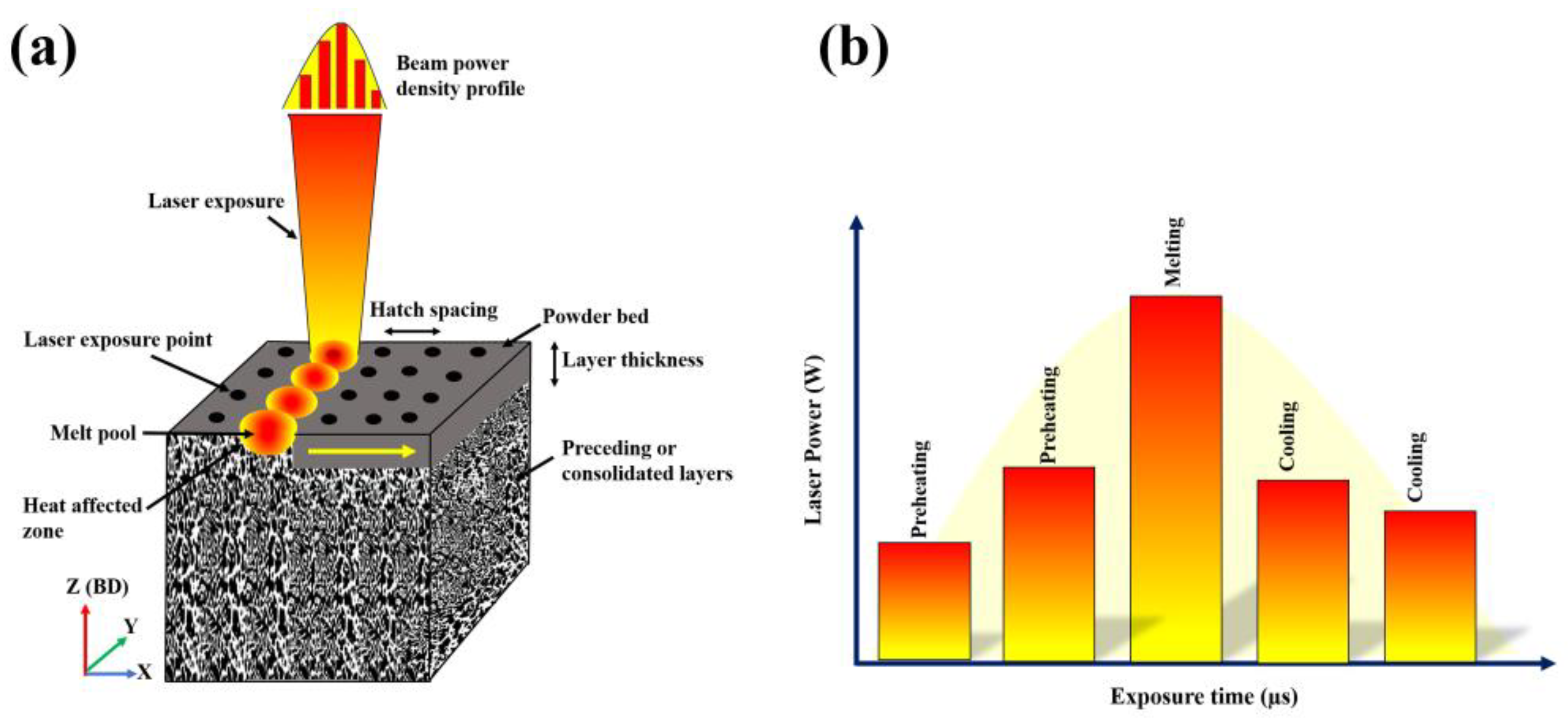

2.2. SLM Fabrication

2.3. Microstructural Characterization and Mechancial Testing

3. Results and Discussion

3.1. Phase Analysis

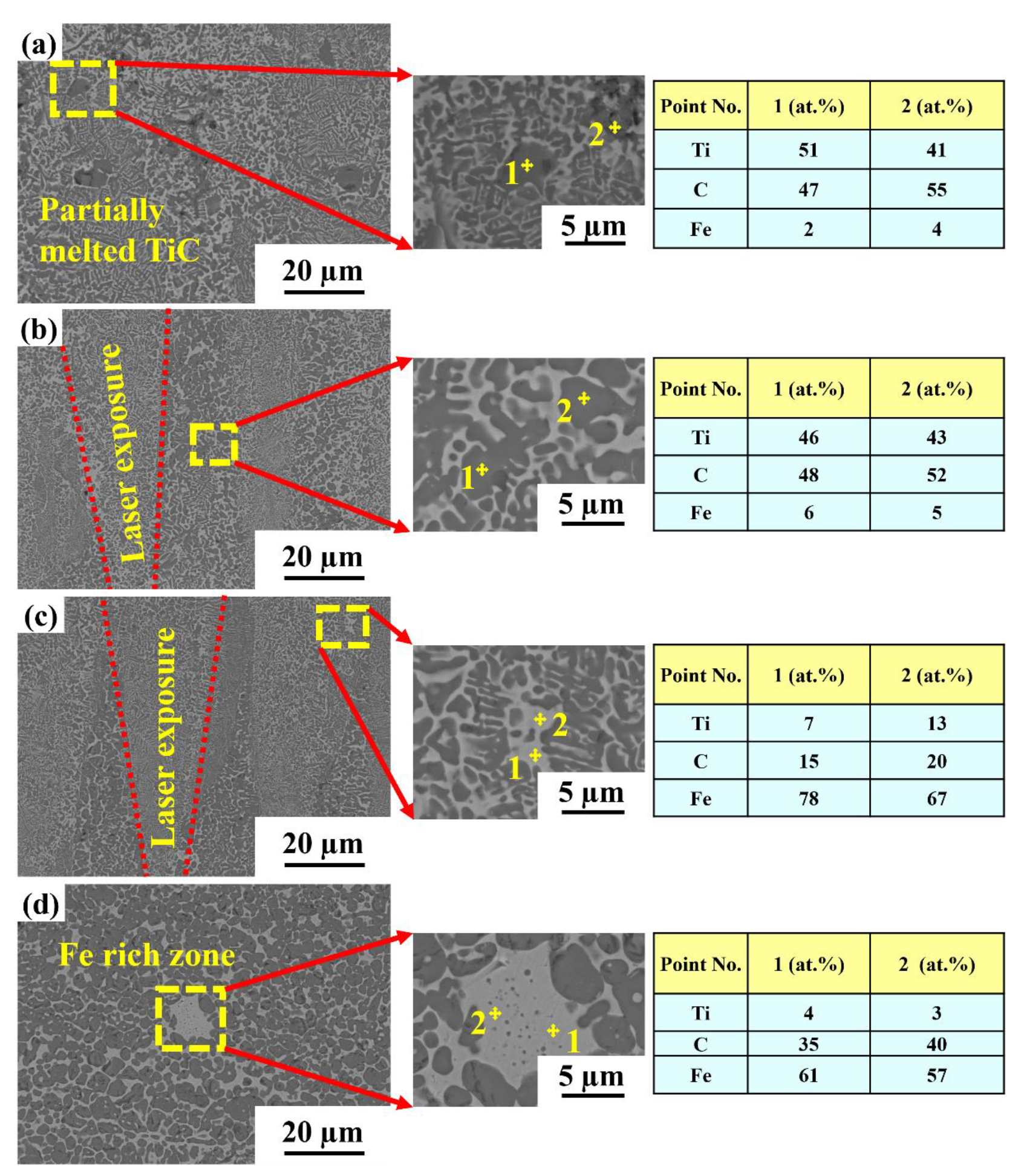

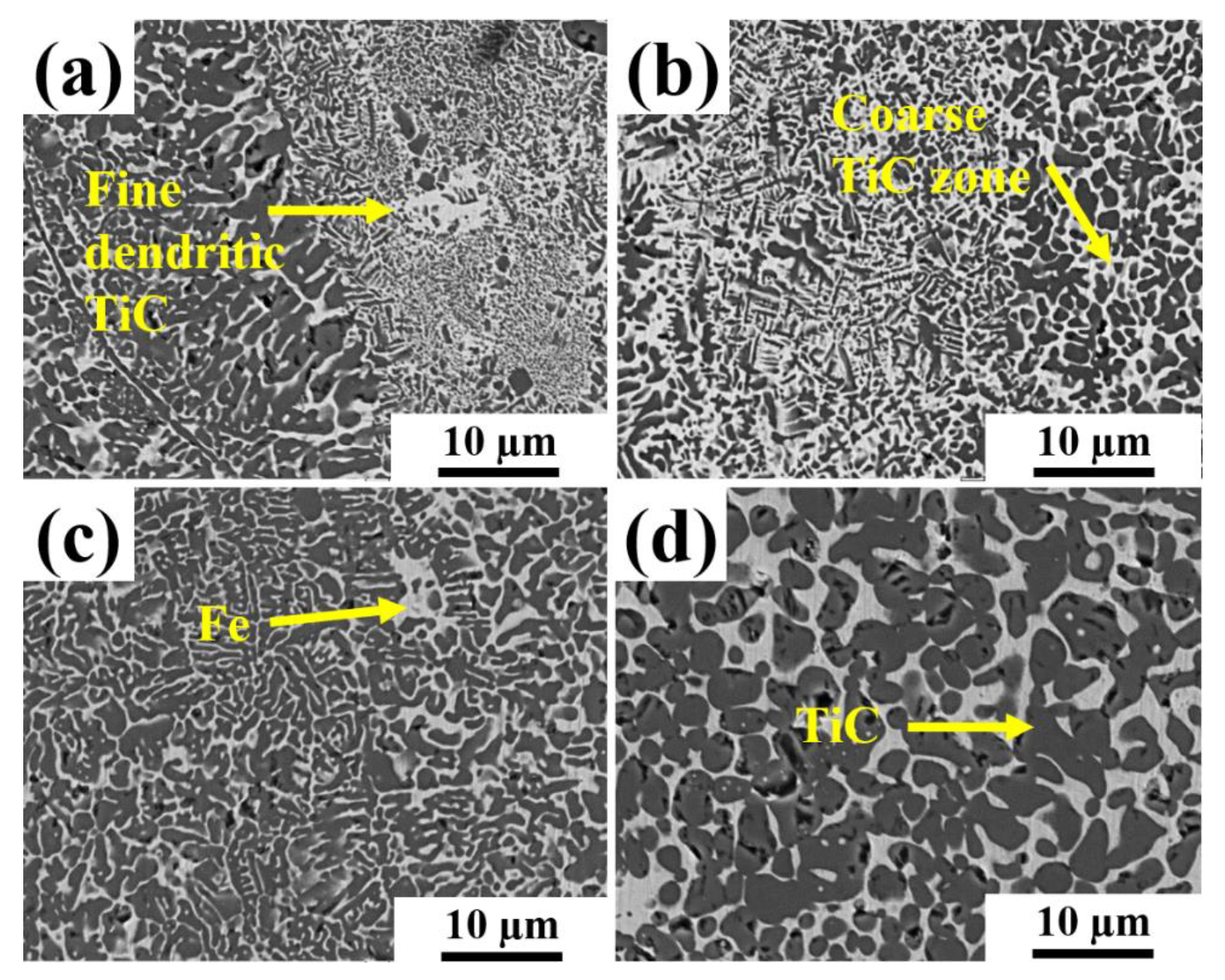

3.2. Microstructural Characterization

3.3. Mechanical Properties

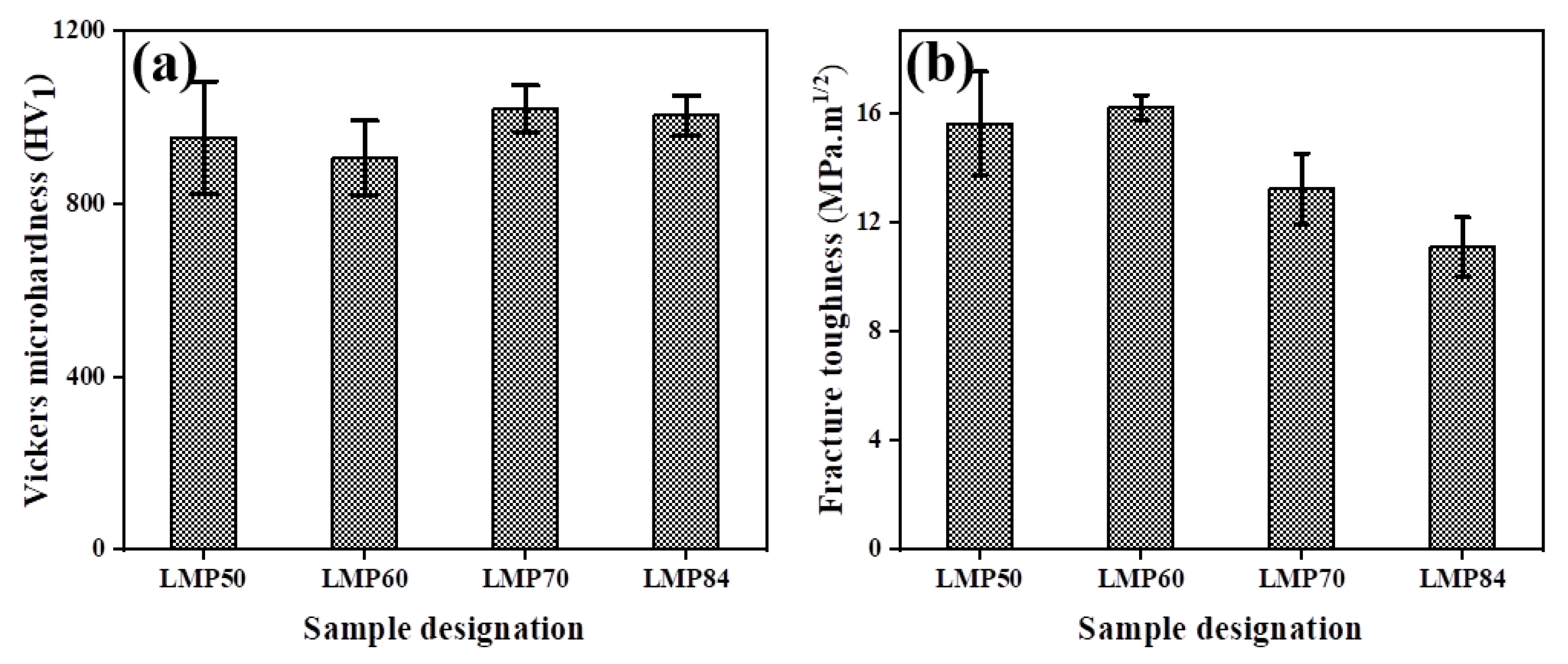

3.3.1. Hardness

3.3.2. Fracture Toughness

4. Conclusions

- Laser melting peaks have an impact on the microstructure formation of the as-built parts. The microstructure of the sample changes from a coarser to a finer dendritic TiC phase as the laser melting peak power changes.

- The melting/cooling rate is controlled by the laser peaks and exposure time of a single pulse during the solidification of the melt pool, which gradually influences the microstructure and mechanical properties of the samples.

- In brittle materials such as TiC–Fe-based cermets, the laser pulse shaping technique appears to be an effective way to remove cracks in as-built samples by reducing thermal residual stress.

- The maximum microhardness and fracture toughness achieved for the as-built parts were 1020 ± 53 HV1 for LMP70 and 16.2 ± 0.4 MPa m1/2 for LMP60.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kübarsepp, J.; Klaasen, H.; Pirso, J. Behavior of TiC-Base Cermets in Different Wear Conditions. Wear 2001, 249, 229–234. [Google Scholar] [CrossRef]

- Ettmayer, P. Hardmetals and Cermets. Annu. Rev. Mater. Sci. 1989, 19, 145–164. [Google Scholar] [CrossRef]

- Kenneth, J.A. Brookes Hardmetals and Other Hard Materials; International Carbide Data: East Barnet, Herts, UK, 1992. [Google Scholar]

- Kübarsepp, J.; Juhani, K. Cermets with Fe-Alloy Binder: A Review. Int. J. Refract. Met. Hard Mater. 2020, 92, 105290. [Google Scholar] [CrossRef]

- Das, K.; Bandyopadhyay, T.K.; Das, S. A Review on the Various Synthesis Routes of TiC Reinforced Ferrous Based Composites. J. Mater. Sci. 2002, 37, 3881–3892. [Google Scholar] [CrossRef]

- Wu, Y.; Xiong, J.; Guo, Z.; Yang, M.; Chen, J.; Xiong, S.; Fan, H.; Luo, J. Microstructure and fracture toughness of Ti(C0.7N0.3)-WC-Ni cermets. Int. J. Refract. Met. Hard Mater. 2011, 29, 85–89. [Google Scholar] [CrossRef]

- Oh, N.R.; Lee, S.K.; Hwang, K.C.; Hong, H.U. Characterization of Microstructure and Tensile Fracture Behavior in a Novel Infiltrated TiC-Steel Composite. Scr. Mater. 2016, 112, 123–127. [Google Scholar] [CrossRef]

- Prashanth, K.; Löber, L.; Klauss, H.-J.; Kühn, U.; Eckert, J. Characterization of 316L Steel Cellular Dodecahedron Structures Produced by Selective Laser Melting. Technologies 2016, 4, 34. [Google Scholar] [CrossRef] [Green Version]

- Herzog, D.; Seyda, V.; Wycisk, E.; Emmelmann, C. Additive Manufacturing of Metals. Acta Mater. 2016, 117, 371–392. [Google Scholar] [CrossRef]

- Singh, N.; Hameed, P.; Ummethala, R.; Manivasagam, G.; Prashanth, K.G.; Eckert, J. Selective Laser Manufacturing of Ti-Based Alloys and Composites: Impact of Process Parameters, Application Trends, and Future Prospects. Mater. Today Adv. 2020, 8, 100097. [Google Scholar] [CrossRef]

- Wang, P.; Eckert, J.; Prashanth, K.G.; Wu, M.W.; Kaban, I.; Xi, L.; Scudino, S. A Review of Particulate-Reinforced Aluminum Matrix Composites Fabricated by Selective Laser Melting. Trans. Nonferrous Met. Soc. China 2020, 30, 2001–2034. [Google Scholar] [CrossRef]

- Prashanth, K.G.; Scudino, S.; Klauss, H.J.; Surreddi, K.B.; Löber, L.; Wang, Z.; Chaubey, A.K.; Kühn, U.; Eckert, J. Microstructure and Mechanical Properties of Al-12Si Produced by Selective Laser Melting: Effect of Heat Treatment. Mater. Sci. Eng. A 2014, 590, 153–160. [Google Scholar] [CrossRef]

- DebRoy, T.; Wei, H.L.; Zuback, J.S.; Mukherjee, T.; Elmer, J.W.; Milewski, J.O.; Beese, A.M.; Wilson-Heid, A.; De, A.; Zhang, W. Additive Manufacturing of Metallic Components—Process, Structure and Properties. Prog. Mater. Sci. 2018, 92, 112–224. [Google Scholar] [CrossRef]

- Wang, Z.; Xie, M.; Li, Y.; Zhang, W.; Yang, C.; Kollo, L.; Eckert, J.; Prashanth, K.G. Premature Failure of an Additively Manufactured Material. NPG Asia Mater. 2020, 12, 30. [Google Scholar] [CrossRef]

- Maity, T.; Chawake, N.; Kim, J.T.; Eckert, J.; Prashanth, K.G. Anisotropy in Local Microstructure—Does It Affect the Tensile Properties of the SLM Samples? Manuf. Lett. 2018, 15, 33–37. [Google Scholar] [CrossRef]

- Zhao, C.; Wang, Z.; Li, D.; Kollo, L.; Luo, Z.; Zhang, W.; Gokuldoss, K.; Prashanth, K.G. Selective Laser Melting of Cu—Ni—Sn: A Comprehensive Study on the Microstructure, Mechanical Properties, and Deformation Behavior. Int. J. Plast. 2021, 138, 102926. [Google Scholar] [CrossRef]

- Prashanth, K.G.; Scudino, S.; Maity, T.; Das, J.; Eckert, J. Is the Energy Density a Reliable Parameter for Materials Synthesis by Selective Laser Melting? Mater. Res. Lett. 2017, 5, 386–390. [Google Scholar] [CrossRef] [Green Version]

- Suryawanshi, J.; Prashanth, K.G.; Scudino, S.; Eckert, J.; Prakash, O.; Ramamurty, U. Simultaneous Enhancements of Strength and Toughness in an Al-12Si Alloy Synthesized Using Selective Laser Melting. Acta Mater. 2016, 115, 285–294. [Google Scholar] [CrossRef]

- Zhang, B.; Li, Y.; Bai, Q. Defect Formation Mechanisms in Selective Laser Melting: A Review. Chin. J. Mech. Eng. 2017, 30, 515–527. [Google Scholar] [CrossRef] [Green Version]

- Klaasen, H.; Kollo, L.; Kübarsepp, J. Mechanical Properties and Wear Performance of Compression Sintered TiC Based Cermets. Powder Metall. 2007, 50, 132–136. [Google Scholar] [CrossRef]

- Santos, E.C.; Osakada, K.; Shiomi, M.; Kitamura, Y.; Abe, F. Microstructure and Mechanical Properties of Pure Titanium Models Fabricated by Selective Laser Melting. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2004, 218, 711–719. [Google Scholar] [CrossRef]

- Maurya, H.S.; Kollo, L.; Tarraste, M.; Juhani, K.; Sergejev, F.; Prashanth, K.G. Selective Laser Melting of TiC-Fe via Laser Pulse Shaping: Microstructure and Mechanical Properties. 3D Print. Addit. Manuf. 2021; ahead of print. [Google Scholar]

- Prashanth, K.G.; Shakur Shahabi, H.; Attar, H.; Srivastava, V.C.; Ellendt, N.; Uhlenwinkel, V.; Eckert, J.; Scudino, S. Production of High Strength Al85Nd8Ni5Co2 Alloy by Selective Laser Melting. Addit. Manuf. 2015, 6, 1–5. [Google Scholar] [CrossRef]

- Schwab, H.; Prashanth, K.G.; Löber, L.; Kühn, U.; Eckert, J. Selective Laser Melting of Ti-45Nb Alloy. Metals 2015, 5, 686–694. [Google Scholar] [CrossRef] [Green Version]

- Mumtaz, K.; Hopkinson, N. Selective Laser Melting of Inconel 625 Using Pulse Shaping. Rapid Prototyp. J. 2010, 16, 248–257. [Google Scholar] [CrossRef] [Green Version]

- Demir, A.G.; Pangovski, K.; O’Neill, W.; Previtali, B. Investigation of Pulse Shape Characteristics on the Laser Ablation Dynamics of TiN Coatings in the Ns Regime. J. Phys. D Appl. Phys. 2015, 48, 235202. [Google Scholar] [CrossRef]

- Mumtaz, K.A.; Hopkinson, N. Selective Laser Melting of Thin Wall Parts Using Pulse Shaping. J. Mater. Processing Technol. 2010, 210, 279–287. [Google Scholar] [CrossRef]

- Tonelli, L.; Fortunato, A.; Ceschini, L. CoCr Alloy Processed by Selective Laser Melting (SLM): Effect of Laser Energy Density on Microstructure, Surface Morphology, and Hardness. J. Manuf. Processes 2020, 52, 106–119. [Google Scholar] [CrossRef]

- Bian, P.; Shi, J.; Liu, Y.; Xie, Y. Influence of Laser Power and Scanning Strategy on Residual Stress Distribution in Additively Manufactured 316L Steel. Opt. Laser Technol. 2020, 132, 106477. [Google Scholar] [CrossRef]

- Waqar, S.; Guo, K.; Sun, J. Evolution of Residual Stress Behavior in Selective Laser Melting (SLM) of 316L Stainless Steel through Preheating and in-Situ Re-Scanning Techniques. Opt. Laser Technol. 2022, 149, 107806. [Google Scholar] [CrossRef]

- Yu, Z.; Xu, Z.; Guo, Y.; Xin, R.; Liu, R.; Jiang, C.; Li, L.; Zhang, Z.; Ren, L. Study on Properties of SLM-NiTi Shape Memory Alloy under the Same Energy Density. J. Mater. Res. Technol. 2021, 13, 241–250. [Google Scholar] [CrossRef]

- Gu, D.; Hagedorn, Y.C.; Meiners, W.; Meng, G.; Batista, R.J.S.; Wissenbach, K.; Poprawe, R. Densification Behavior, Microstructure Evolution, and Wear Performance of Selective Laser Melting Processed Commercially Pure Titanium. Acta Mater. 2012, 60, 3849–3860. [Google Scholar] [CrossRef]

- Prashanth, K.G.; Debalina, B.; Wang, Z.; Gostin, P.F.; Gebert, A.; Calin, M.; Kühn, U.; Kamaraj, M.; Scudino, S.; Eckert, J. Tribological and Corrosion Properties of Al-12Si Produced by Selective Laser Melting. J. Mater. Res. 2014, 29, 2044–2054. [Google Scholar] [CrossRef]

- Zhao, C.; Wang, Z.; Li, D.; Kollo, L.; Luo, Z.; Zhang, W.; Prashanth, K.G. Cu-Ni-Sn Alloy Fabricated by Melt Spinning and Selective Laser Melting: A Comparative Study on the Microstructure and Formation Kinetics. J. Mater. Res. Technol. 2020, 9, 13097–13105. [Google Scholar] [CrossRef]

- Prashanth, K.; Scudino, S.; Chatterjee, R.; Salman, O.; Eckert, J. Additive Manufacturing: Reproducibility of Metallic Parts. Technologies 2017, 5, 8. [Google Scholar] [CrossRef] [Green Version]

- Gokuldoss Prashanth, K.; Scudino, S.; Eckert, J. Tensile Properties of Al-12Si Fabricated via Selective Laser Melting (SLM) at Different Temperatures. Technologies 2016, 4, 38. [Google Scholar] [CrossRef] [Green Version]

- Yan, C.; Hao, L.; Hussein, A.; Young, P.; Huang, J.; Zhu, W. Microstructure and Mechanical Properties of Aluminium Alloy Cellular Lattice Structures Manufactured by Direct Metal Laser Sintering. Mater. Sci. Eng. A 2015, 628, 238–246. [Google Scholar] [CrossRef]

- Sahoo, C.K.; Masanta, M. Microstructure and Mechanical Properties of TiC-Ni Coating on AISI304 Steel Produced by TIG Cladding Process. J. Mater. Processing Technol. 2017, 240, 126–137. [Google Scholar] [CrossRef]

- Gaier, M.; Todorova, T.Z.; Russell, Z.; Farhat, Z.N.; Zwanziger, J.W.; Plucknett, K.P. The Influence of Intermetallic Ordering on Wear and Indentation Properties of TiC-Ni3 Al Cermets. Wear 2019, 426–427, 390–400. [Google Scholar] [CrossRef]

- Lu, L.; Fuh, J.Y.H.; Chen, Z.D.; Leong, C.C.; Wong, Y.S. In Situ Formation of TiC Composite Using Selective Laser Melting. Mater. Res. Bull. 2000, 35, 1555–1561. [Google Scholar] [CrossRef]

- Li, W.; Li, S.; Liu, J.; Zhang, A.; Zhou, Y.; Wei, Q.; Yan, C.; Shi, Y. Effect of Heat Treatment on AlSi10Mg Alloy Fabricated by Selective Laser Melting: Microstructure Evolution, Mechanical Properties and Fracture Mechanism. Mater. Sci. Eng. A 2016, 663, 116–125. [Google Scholar] [CrossRef]

- Suryawanshi, J.; Prashanth, K.G.; Ramamurty, U. Tensile, Fracture, and Fatigue Crack Growth Properties of a 3D Printed Maraging Steel through Selective Laser Melting. J. Alloy. Compd. 2017, 725, 355–364. [Google Scholar] [CrossRef]

- Suryawanshi, J.; Prashanth, K.G.; Ramamurty, U. Mechanical Behavior of Selective Laser Melted 316L Stainless Steel. Mater. Sci. Eng. A 2017, 696, 113–121. [Google Scholar] [CrossRef]

| LMP (W) | v (mm/s) | h (mm) | t (mm) | LED (J/mm3) |

|---|---|---|---|---|

| 50; 60; 70; 84 | 250 | 0.05 | 0.035 | 114.2; 137.1; 160.0; 192.0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Maurya, H.S.; Kollo, L.; Tarraste, M.; Juhani, K.; Sergejev, F.; Prashanth, K.G. Effect of the Laser Processing Parameters on the Selective Laser Melting of TiC–Fe-Based Cermets. J. Manuf. Mater. Process. 2022, 6, 35. https://doi.org/10.3390/jmmp6020035

Maurya HS, Kollo L, Tarraste M, Juhani K, Sergejev F, Prashanth KG. Effect of the Laser Processing Parameters on the Selective Laser Melting of TiC–Fe-Based Cermets. Journal of Manufacturing and Materials Processing. 2022; 6(2):35. https://doi.org/10.3390/jmmp6020035

Chicago/Turabian StyleMaurya, Himanshu S., Lauri Kollo, Marek Tarraste, Kristjan Juhani, Fjodor Sergejev, and Konda Gokuldoss Prashanth. 2022. "Effect of the Laser Processing Parameters on the Selective Laser Melting of TiC–Fe-Based Cermets" Journal of Manufacturing and Materials Processing 6, no. 2: 35. https://doi.org/10.3390/jmmp6020035

APA StyleMaurya, H. S., Kollo, L., Tarraste, M., Juhani, K., Sergejev, F., & Prashanth, K. G. (2022). Effect of the Laser Processing Parameters on the Selective Laser Melting of TiC–Fe-Based Cermets. Journal of Manufacturing and Materials Processing, 6(2), 35. https://doi.org/10.3390/jmmp6020035