Enhanced Abrasion Resistance of Spark Plasma Sintered and HVOF Sprayed Hadfield High Manganese Steel by Turning and Diamond Smoothing

Abstract

:1. Introduction

2. Materials and Methods

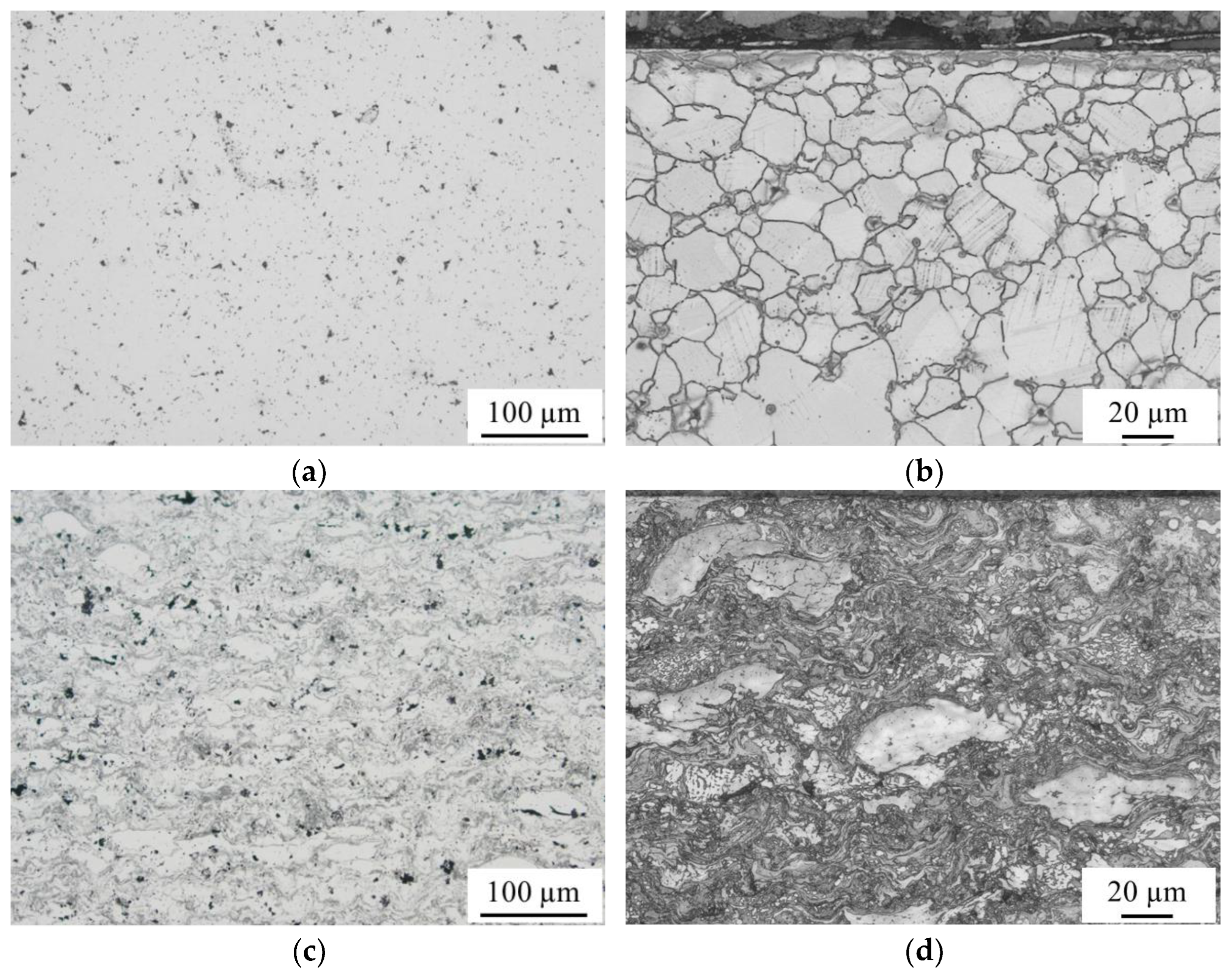

2.1. Sample Manufacturing

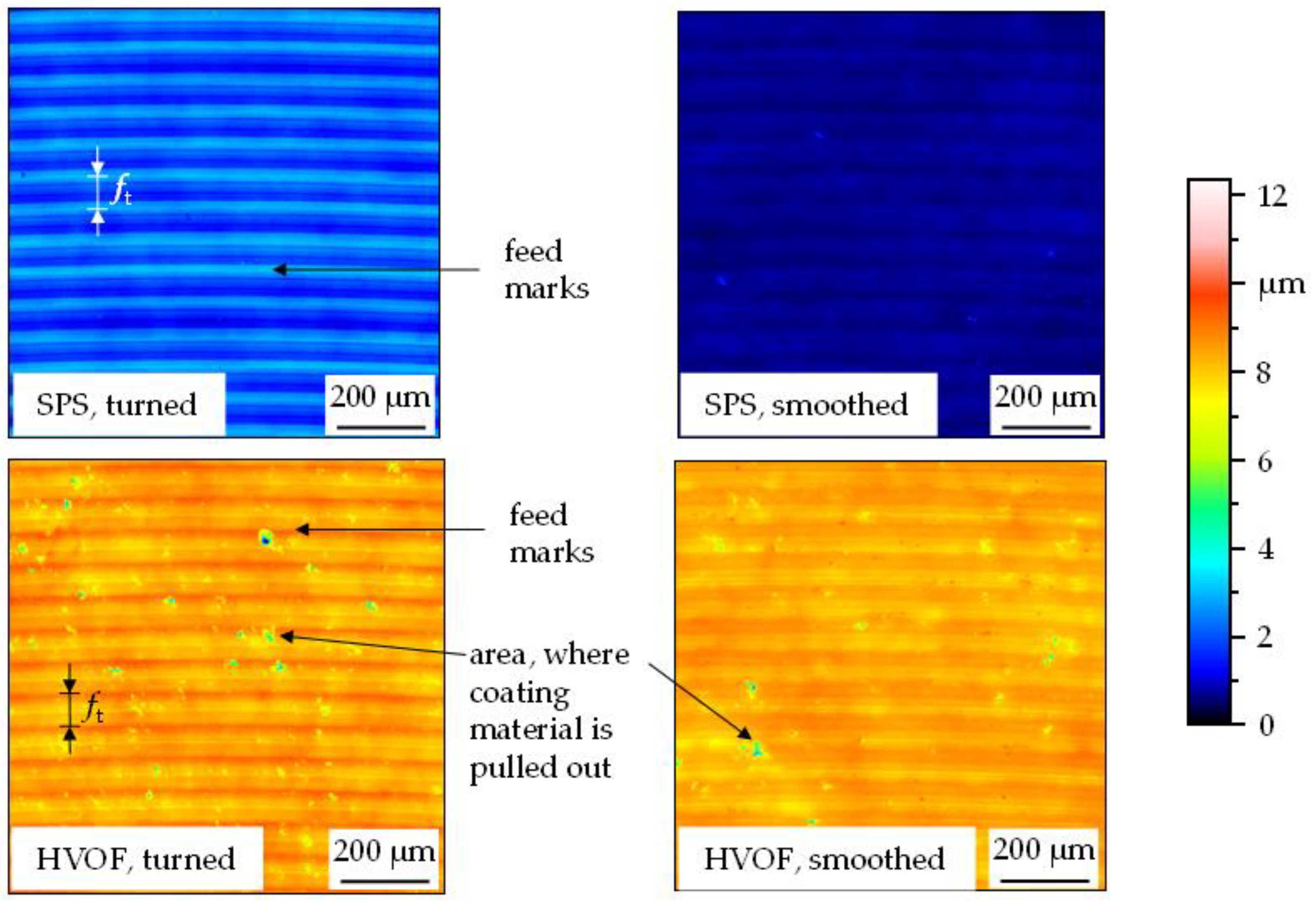

2.2. Mechanical Surface Finishing

2.3. Characterization

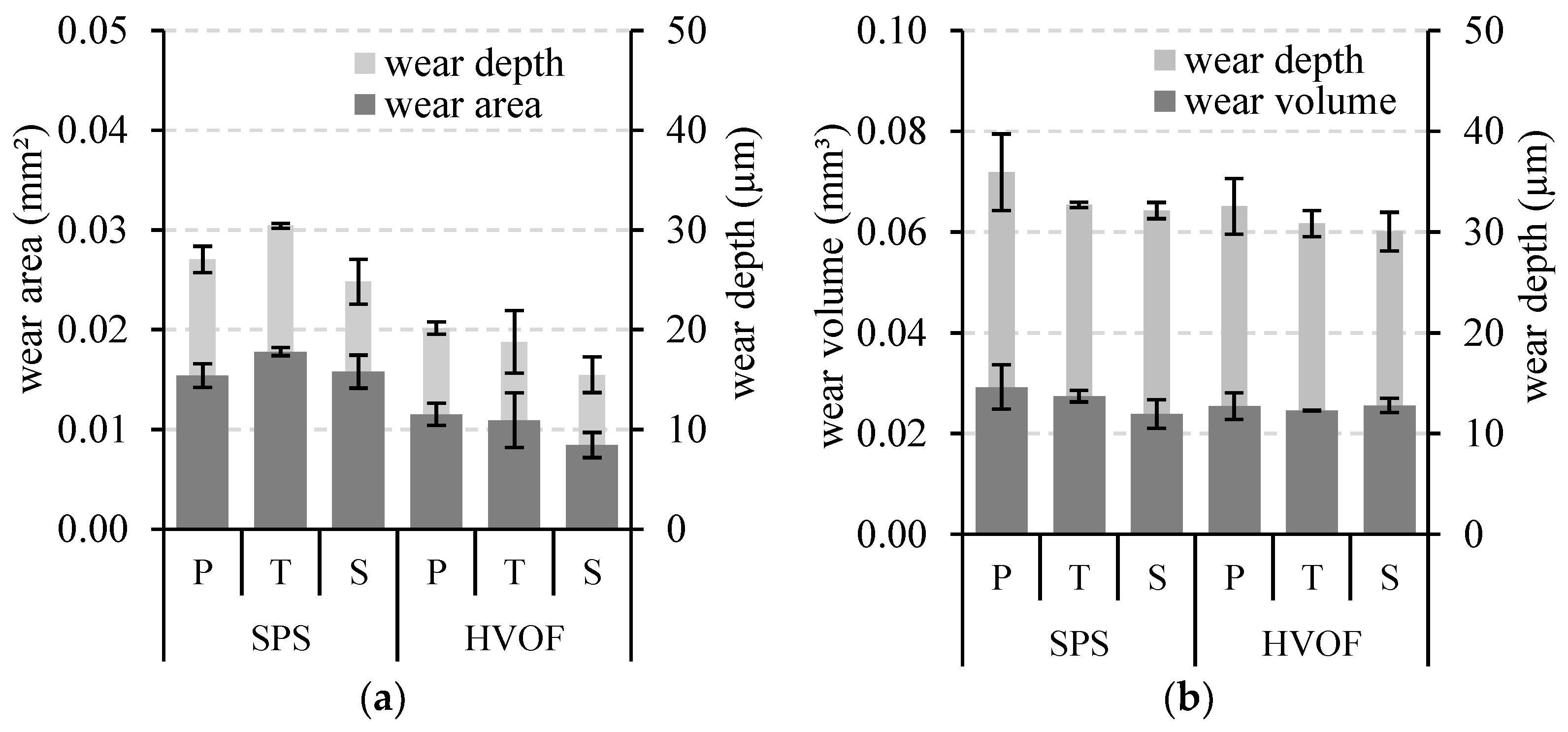

3. Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sabzi, M.; Farzam, M. Hadfield manganese austenitic steel: A review of manufacturing processes and properties. Mater. Res. Express 2019, 6, 1065C2. [Google Scholar] [CrossRef]

- Allende-Seco, R.; Artigas, A.; Bruna, H.; Carvajal, L.; Monsalve, A.; Sklate-Boja, M.F. Hardening by Transformation and Cold Working in a Hadfield Steel Cone Crusher Liner. Metals 2021, 11, 961. [Google Scholar] [CrossRef]

- Lychagin, D.V.; Filippov, A.V.; Novitskaya, O.S.; Kolubaev, A.V.; Moskvichev, E.N.; Fortuna, S.V.; Chumlyakov, Y.I. Deformation and wear of Hadfield steel single crystals under dry sliding friction. Wear 2022, 488–489, 204126. [Google Scholar] [CrossRef]

- Lychagin, D.V.; Filippov, A.V.; Kolubaev, E.A.; Novitskaia, O.S.; Chumlyakov, Y.I.; Kolubaev, A.V. Dry sliding of Hadfield steel single crystal oriented to deformation by slip and twinning: Deformation, wear, and acoustic emission characterization. Tribol. Int. 2018, 119, 1–18. [Google Scholar] [CrossRef]

- Emurlaev, K.; Gerasimenko, T.; Abdimazhan, D. Nondestructive evaluation of material state near the friction interface under dry sliding. Mater. Today Proc. 2021, 38, 1526–1529. [Google Scholar] [CrossRef]

- Chen, C.; Lv, B.; Ma, H.; Sun, D.; Zhang, F. Wear behavior and the corresponding work hardening characteristics of Hadfield steel. Tribol. Int. 2018, 121, 389–399. [Google Scholar] [CrossRef]

- Ingber, J.; Lippmann, S.; Kunert, M. Two-body abrasion resistance of high-carbon metastable austenitic steels. In Proceedings of the 30th Anniversary International Conference on Metallurgy and Materials, Brno, Czech Republic, 26–28 May 2021; pp. 459–465. [Google Scholar] [CrossRef]

- Tęcza, G. Changes in Abrasive Wear Resistance during Miller Test of High-Manganese Cast Steel with Niobium Carbides Formed in the Alloy Matrix. Appl. Sci. 2021, 11, 4794. [Google Scholar] [CrossRef]

- Qian, L.; Feng, X.; Zhang, F. Deformed microstructure and hardness of hadfield high manganese steel. Mater. Trans. 2011, 52, 1623–1628. [Google Scholar] [CrossRef] [Green Version]

- Machado, P.C.; Pereira, J.I.; Sinatora, A. Subsurface microstructural dynamic recrystallization in multiscale abrasive wear. Wear 2021, 486–487, 204111. [Google Scholar] [CrossRef]

- Zhang, C.; Xie, J.; Lu, H.; Huang, X.; Wang, W.; Wang, A.; Ma, F.; Ding, G. Study on the microstructure of high manganese steel composites strengthened by ceramic. In Proceedings of the 9th World Foundry Congress 2010, Hangzhou, China, 16–20 October 2010; Volume 3, pp. 911–913. [Google Scholar]

- Tęcza, G. Changes in Microstructure and Abrasion Resistance during Miller Test of Hadfield High-Manganese Cast Steel after the Formation of Vanadium Carbides in Alloy Matrix. Materials 2022, 15, 1021. [Google Scholar] [CrossRef]

- Zhou, Z.; Shan, Q.; Jiang, Y.; Li, Z.; Zhang, Z. Effect of nanoscale V2C precipitates on the three-body abrasive wear behavior of high-Mn austenitic steel. Wear 2019, 436–437, 203009. [Google Scholar] [CrossRef]

- Vdovin, K.; Pesin, A.; Feoktistov, N.; Gorlenko, D. Surface Wear in Hadfield Steel Castings DOPED with Nitrided Vanadium. Metals 2018, 8, 845. [Google Scholar] [CrossRef] [Green Version]

- Siafakas, D.; Matsushita, T.; Lauenstein, Å.; Ekengård, J.; Jarfors, A.E.W. The Influence of Deoxidation Practice on the As-Cast Grain Size of Austenitic Manganese Steels. Metals 2017, 7, 186. [Google Scholar] [CrossRef] [Green Version]

- Jafarian, H.R.; Sabzi, M.; Mousavi Anijdan, S.H.; Eivani, A.R.; Park, N. The influence of austenitization temperature on microstructural developments, mechanical properties, fracture mode and wear mechanism of Hadfield high manganese steel. J. Mater. Res. Technol. 2021, 10, 819–831. [Google Scholar] [CrossRef]

- Mousavi Anijdan, S.H.; Sabzi, M. The Effect of Heat Treatment Process Parameters on Mechanical Properties, Precipitation, Fatigue Life, and Fracture Mode of an Austenitic Mn Hadfield Steel. J. Mater. Eng. Perform. 2018, 27, 5246–5253. [Google Scholar] [CrossRef]

- Bandanadjaja, B.; Hidayat, E. The effect of two-step solution heat treatment on the impact properties of Hadfield austenitic manganese steel. J. Phys. Conf. Ser. 2020, 1450, 012125. [Google Scholar] [CrossRef]

- Ayadi, S.; Hadji, A. Effect of Chemical Composition and Heat Treatments on the Microstructure and Wear Behavior of Manganese Steel. Int. J. Met. 2021, 15, 510–519. [Google Scholar] [CrossRef]

- Zellagui, R.; Hemmouche, L.; Bouchafaa, H.; Belrechid, R.; Aitsadi, H.; Chelli, A.; Touil, M.; Djalleb, N. Effect of Heat Treatments on the Microstructure, Mechanical, Wear and Corrosion Resistance of Casted Hadfield Steel. Int. J. Met. 2022, 1–15. [Google Scholar] [CrossRef]

- El-Fawkhry, M.K.; Fathy, A.M.; Eissa, M.M.; El-Faramway, H. Eliminating heat treatment of hadfield steel in stress abrasion wear applications. Int. J. Met. 2014, 8, 29–36. [Google Scholar] [CrossRef]

- Volynova, T.F.; Medov, I.B.; Sidorova, I.B. Cold shortness and nature of failure of iron-manganese powder alloys. Sov. Powder Metall. Met. Ceram. 1987, 26, 1016–1021. [Google Scholar] [CrossRef]

- Volynova, T.F.; Emel’yanova, I.Z.; Sidorova, I.B. Special features of structurization in powdered iron-manganese alloys in deformation and recrystallization. I. Formation of the deformation structure in hot extrusion. Sov. Powder Metall. Met. Ceram. 1992, 31, 395–402. [Google Scholar] [CrossRef]

- Volynova, T.F.; Emel’yanova, I.Z.; Sidorova, I.B. Special traits of structure formation in powdered iron-manganese alloys in deformation and recrystallization. II. Formation of the recrystallization structure after cold deformation in dependence on the type of crystal lattice and the energy of stacking faults. Sov. Powder Metall. Met. Ceram. 1992, 31, 461–466. [Google Scholar] [CrossRef]

- Farayibi, P.K.; Blüm, M.; Theisen, W.; Weber, S. Development of Multilayer Sinter Cladding of Cold Work Tool Steel on Hadfield Steel Plates for Wear-Resistant Applications. J. Mater. Eng. Perform. 2019, 28, 1833–1847. [Google Scholar] [CrossRef]

- Šalak, A.; Selecká, M. Manganese in Powder Metallurgy Steels; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2012; Volume 9781907343759, pp. 135–136. [Google Scholar] [CrossRef]

- Pelletier, J.M.; Oucherif, F.; Sallamand, P.; Vannes, A.B. Hadfield steel coatings on low carbon steel by laser cladding. Mater. Sci. Eng. A 1995, 202, 142–147. [Google Scholar] [CrossRef]

- Pelletier, J.M.; Sauger, E.; Gachon, Y.; Vannes, A.B. Mechanical and tribological properties of Hadfield steel coatings manufactured by laser processing. J. Mater. Sci. 1999, 34, 2955–2969. [Google Scholar] [CrossRef]

- Lindner, T.; Löbel, M.; Lampke, T. Phase Stability and Microstructure Evolution of Solution-Hardened 316L Powder Feedstock for Thermal Spraying. Metals 2018, 8, 1063. [Google Scholar] [CrossRef] [Green Version]

- Lindner, T.; Löbel, M.; Grimm, M.; Fiebig, J. Cold Gas Spraying of Solution-Hardened 316L Grade Stainless Steel Powder. Metals 2022, 12, 30. [Google Scholar] [CrossRef]

- Kutschmann, P.; Lindner, T.; Liborius, H.; Grund, T.; Schubert, A.; Lampke, T. Influence of Thermochemical Treatment on the Surface Properties of Finish Turned Wire Arc Sprayed 17Cr Steel Coatings. Appl. Sci. 2021, 11, 6520. [Google Scholar] [CrossRef]

- Clauß, B.; Liborius, H.; Lindner, T.; Löbel, M.; Schubert, A.; Lampke, T. Influence of the cutting parameters on the surface properties in turning of a thermally sprayed AlCoCrFeNiTi coating. Procedia CIRP 2020, 87, 19–24. [Google Scholar] [CrossRef]

- Liborius, H.; Nestler, A.; Löbel, M.; Lindner, T.; Uhlig, T.; Schubert, A.; Wagner, G.; Lampke, T. Influence of the composition of thermally sprayed (Al)CoCrFeNi(Mo) high-entropy alloy coatings in face turning and diamond smoothing. In Proceedings of the 21st EUSPEN 2021, Copenhagen, Denmark, 7–10 June 2021; pp. 347–350. [Google Scholar]

- Liborius, H.; Grund, T.; Nestler, A.; Paczkowski, G.; Schubert, A.; Lampke, T. Influence of the finish-machining by turning and diamond smoothing on the tribological properties of Fe17Cr2Ni0.2C thermally sprayed coatings. Surf. Coat. Technol. 2021, 405, 126731. [Google Scholar] [CrossRef]

- Kopac, J. Hardening phenomena of Mn-austenite steels in the cutting process. J. Mater. Process. Technol. 2001, 109, 96–104. [Google Scholar] [CrossRef]

- Cebron, M.; Kosal, F.; Kopac, J. Effect of cutting on surface hardness and residual stresses for 12Mn austenitic steel. J. Achiev. Mater. Manuf. Eng. 2012, 55, 80–89. [Google Scholar]

- Liborius, H.; Nestler, A.; Paczkowski, G.; Schubert, A.; Grund, T.; Lampke, T. Surface integrity in turning of Fe17Cr2Ni0.2C iron based thermally sprayed coatings with special respect to the influence of the feed. MM Sci. J. 2019, 3220–3227. [Google Scholar] [CrossRef]

- Grund, T.; Paczkowski, G.; Lampke, T.; Liborius, H.; Nestler, A.; Schubert, A. Finish Turning of FeCr17Ni2C0.2 Iron-based Sprayed Coatings: Influences of Substrate Preparation, Cutting Speed and Feed on the Coating and Surface Properties. J. Therm. Spray Technol. 2020, 29, 308–318. [Google Scholar] [CrossRef]

- Lindner, T.; Günen, A.; Töberling, G.; Vogt, S.; Karakas, M.S.; Löbel, M.; Lampke, T. Boriding of Laser-Clad Inconel 718 Coatings for Enhanced Wear Resistance. Appl. Sci. 2021, 11, 11935. [Google Scholar] [CrossRef]

| Element | Fe | C | Si | Mn | Cr |

|---|---|---|---|---|---|

| wt.% | balance | 1.1–1.3 | 0.3–0.5 | 12–13 | 1.5 |

| O2 | Kerosene | λ | Nozzle | Powder Feed Rate | Spraying Distance | Relative Traverse Speed | Spray Path Offset |

|---|---|---|---|---|---|---|---|

| 900 L/min | 26 L/h | 1.0 | 150/14 | 2 × 50 g/min | 350 mm | 1.0 m/s | 5 mm |

| Ball-On-Disk Test | Reciprocating Wear Test | Scratch Wear Test | |||

|---|---|---|---|---|---|

| force | 20 N | force | 26 N | mode | constant |

| radius | 5 mm | frequency | 40 Hz | force | 25; 50; 75; 100 N |

| speed | 96 RPM | time | 900 s | speed | 2.5 mm/min |

| cycles | 15,916 | amplitude | 0.5 mm | length | 5 mm |

| counter-body | Al2O3 (ø 6 mm) | counter-body | Al2O3 (ø 10 mm) | tip | truncated diamond cone |

| SPS | HVOF | |||||

|---|---|---|---|---|---|---|

| Polished | Turned | Smoothed | Polished | Turned | Smoothed | |

| Ra | 0.021 ± 0.003 | 0.416 ± 0.004 | 0.040 ± 0.003 | 0.043 ± 0.010 | 0.286 ± 0.026 | 0.226 ± 0.017 |

| Rz | 0.267 ± 0.064 | 2.126 ± 0.038 | 0.443 ± 0.027 | 0.515 ± 0.203 | 2.909 ± 0.830 | 2.188 ± 0.992 |

| Rvk | 0.051 ± 0.023 | 0.236 ± 0.042 | 0.067 ± 0.001 | 0.115 ± 0.131 | 0.536 ± 0.108 | 0.413 ± 0.082 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lindner, T.; Liborius, H.; Preuß, B.; Hanisch, N.; Schubert, A.; Lampke, T. Enhanced Abrasion Resistance of Spark Plasma Sintered and HVOF Sprayed Hadfield High Manganese Steel by Turning and Diamond Smoothing. J. Manuf. Mater. Process. 2022, 6, 48. https://doi.org/10.3390/jmmp6020048

Lindner T, Liborius H, Preuß B, Hanisch N, Schubert A, Lampke T. Enhanced Abrasion Resistance of Spark Plasma Sintered and HVOF Sprayed Hadfield High Manganese Steel by Turning and Diamond Smoothing. Journal of Manufacturing and Materials Processing. 2022; 6(2):48. https://doi.org/10.3390/jmmp6020048

Chicago/Turabian StyleLindner, Thomas, Hendrik Liborius, Bianca Preuß, Niclas Hanisch, Andreas Schubert, and Thomas Lampke. 2022. "Enhanced Abrasion Resistance of Spark Plasma Sintered and HVOF Sprayed Hadfield High Manganese Steel by Turning and Diamond Smoothing" Journal of Manufacturing and Materials Processing 6, no. 2: 48. https://doi.org/10.3390/jmmp6020048

APA StyleLindner, T., Liborius, H., Preuß, B., Hanisch, N., Schubert, A., & Lampke, T. (2022). Enhanced Abrasion Resistance of Spark Plasma Sintered and HVOF Sprayed Hadfield High Manganese Steel by Turning and Diamond Smoothing. Journal of Manufacturing and Materials Processing, 6(2), 48. https://doi.org/10.3390/jmmp6020048