A Review of Automotive Spare-Part Reconstruction Based on Additive Manufacturing

Abstract

:1. Introduction

2. Digital Processes

2.1. Reverse Engineering

- Scanning and data capturing.

- Point cloud processing and segmentation.

- Feature classification and extraction.

- The generation of analytical surfaces and features.

- CAD model reconstruction.

2.2. Additive Manufacturing

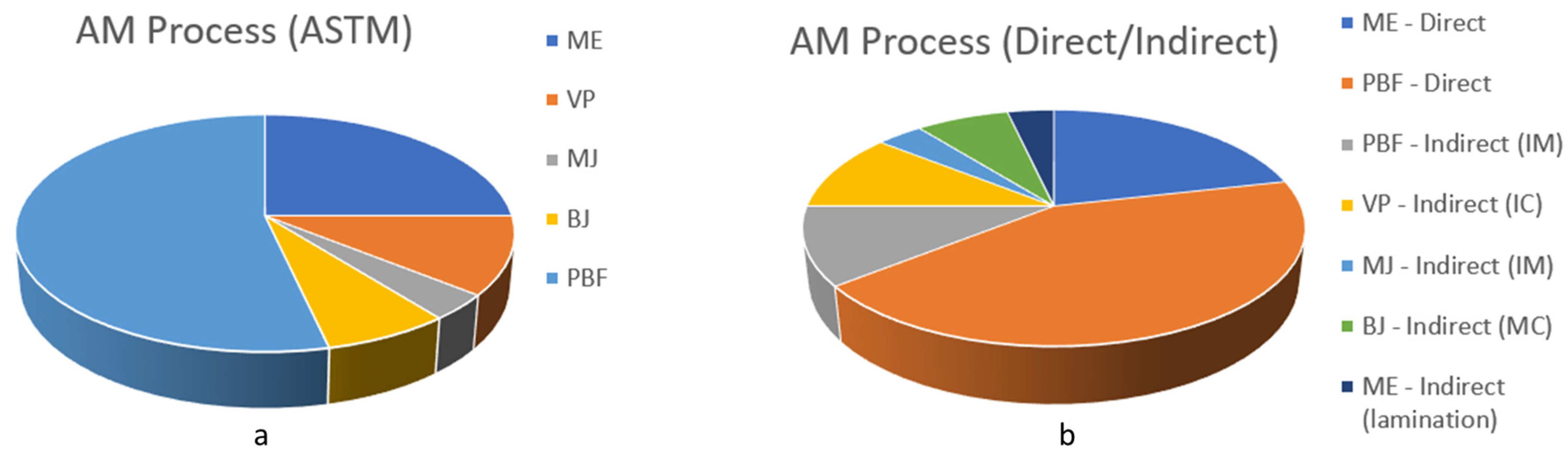

- Binder Jetting (BJ):

- 3D printing (3DP), S-Print, M-Print, etc.

- Directed Energy Deposition (DED):

- Laser Deposition/Laser Metal Deposition/Direct Metal Deposition (LD/LMD/DMD), Laser Engineered Net Shaping (LENS), etc.

- Material Extrusion (ME):

- Fused-Filament Fabrication/Fused Deposition Modelling (FFF/FDM), etc.

- Material Jetting (MJ):

- PolyJet, Nanoparticle Jetting (NPJ), Drop On Demand (DOD), etc.

- Powder-Bed Fusion (PBF):

- Selective Laser Melting/Direct Metal Laser Sintering (SLM/DMLS), Electron Beam Melting/Electron Beam Powder-Bed Fusion (EBM/EB-PBF), Selective Laser Sintering (SLS), Multi-jet Fusion (MJF), etc.

- Sheet Lamination (SL):

- Laminated Object Manufacturing (LOM), Ultrasonic Additive Manufacturing (UAM), etc.

- Vat Photopolymerisation (VP):

- Stereolithography (SLA), Digital Light Processing (DLP), Continuous Liquid Interface Production (CDLP), etc.

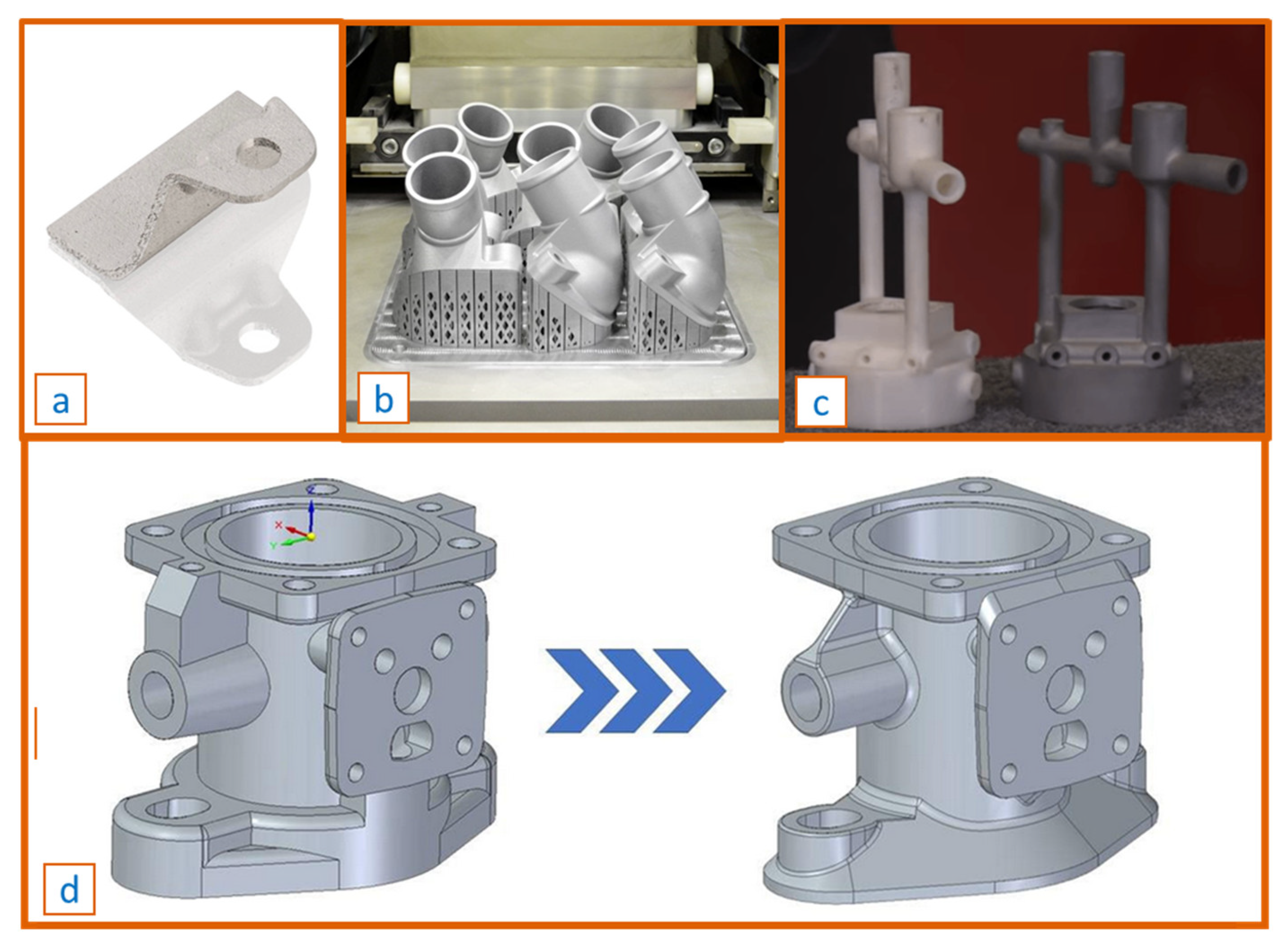

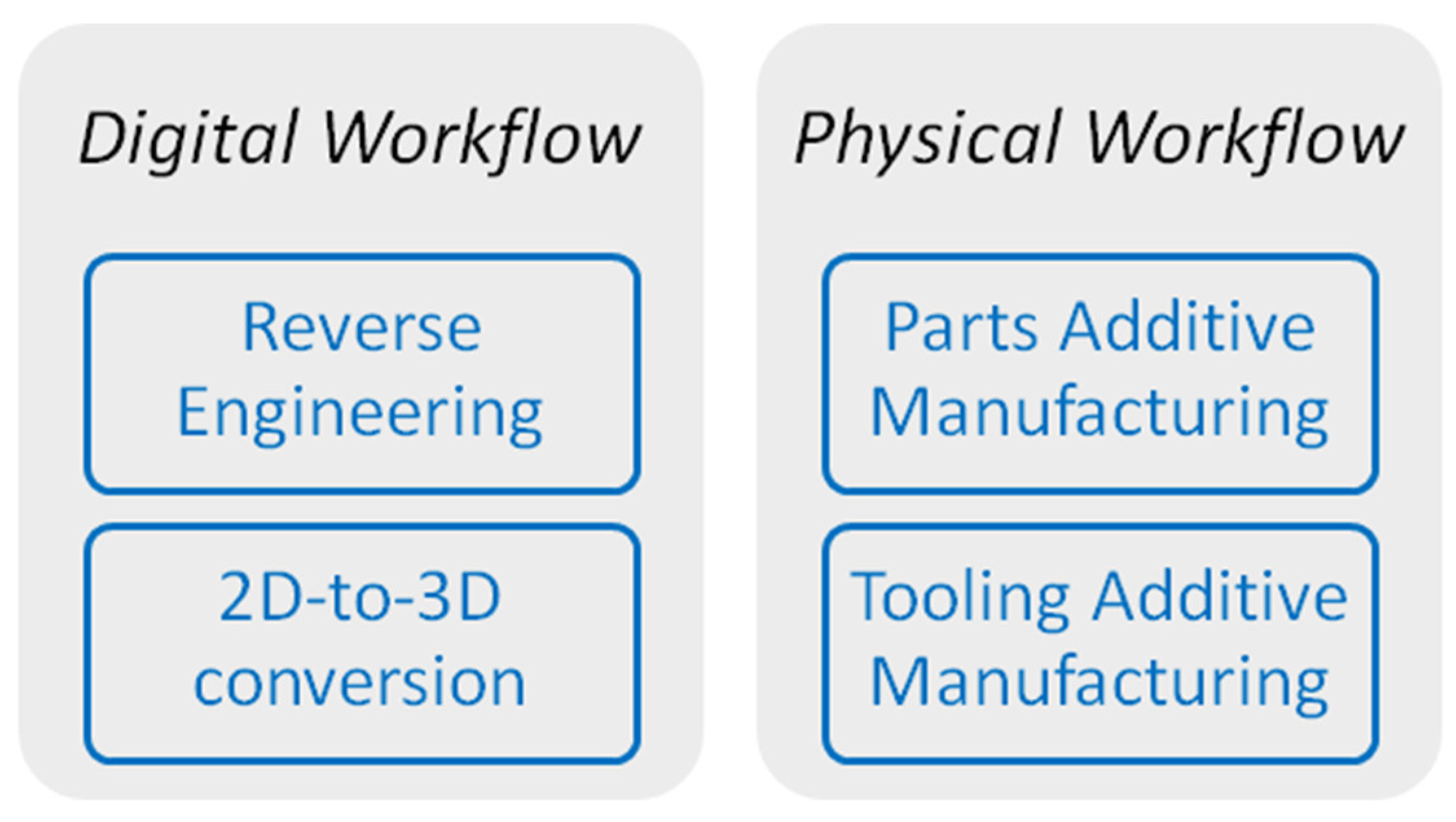

2.3. Generic Digital and Physical Workflow

- An RE (or reverse modelling) process of an existing physical part.

- A 2D-to-3D conversion process.

- The AM of parts (i.e., direct processes)

- The AM of tooling (i.e., indirect processes)

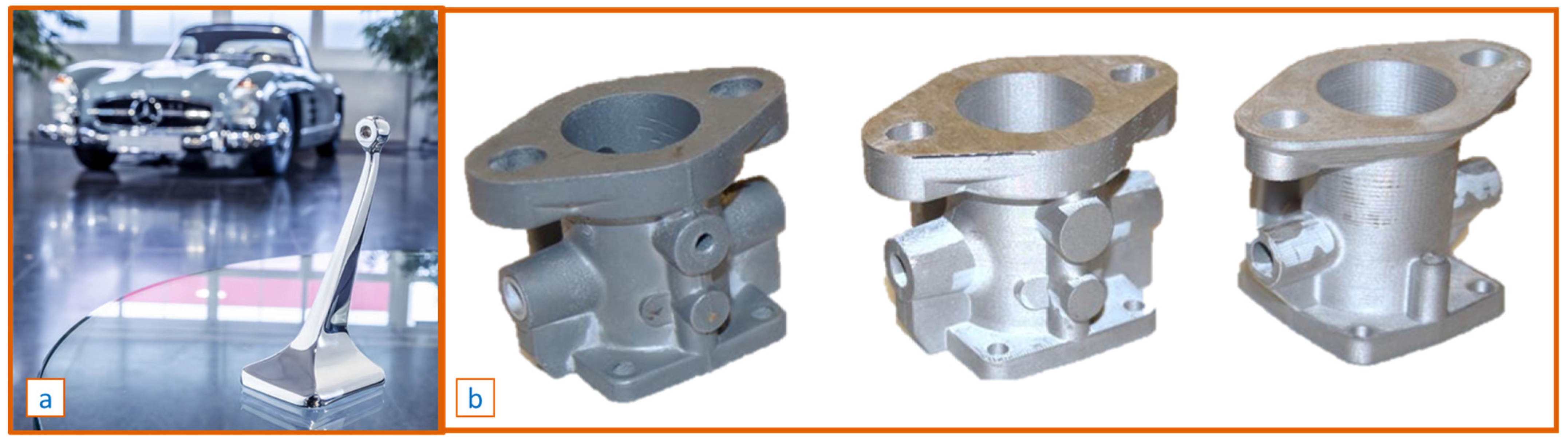

3. Automotive Spare-Part Reconstruction Based on Additive Manufacturing

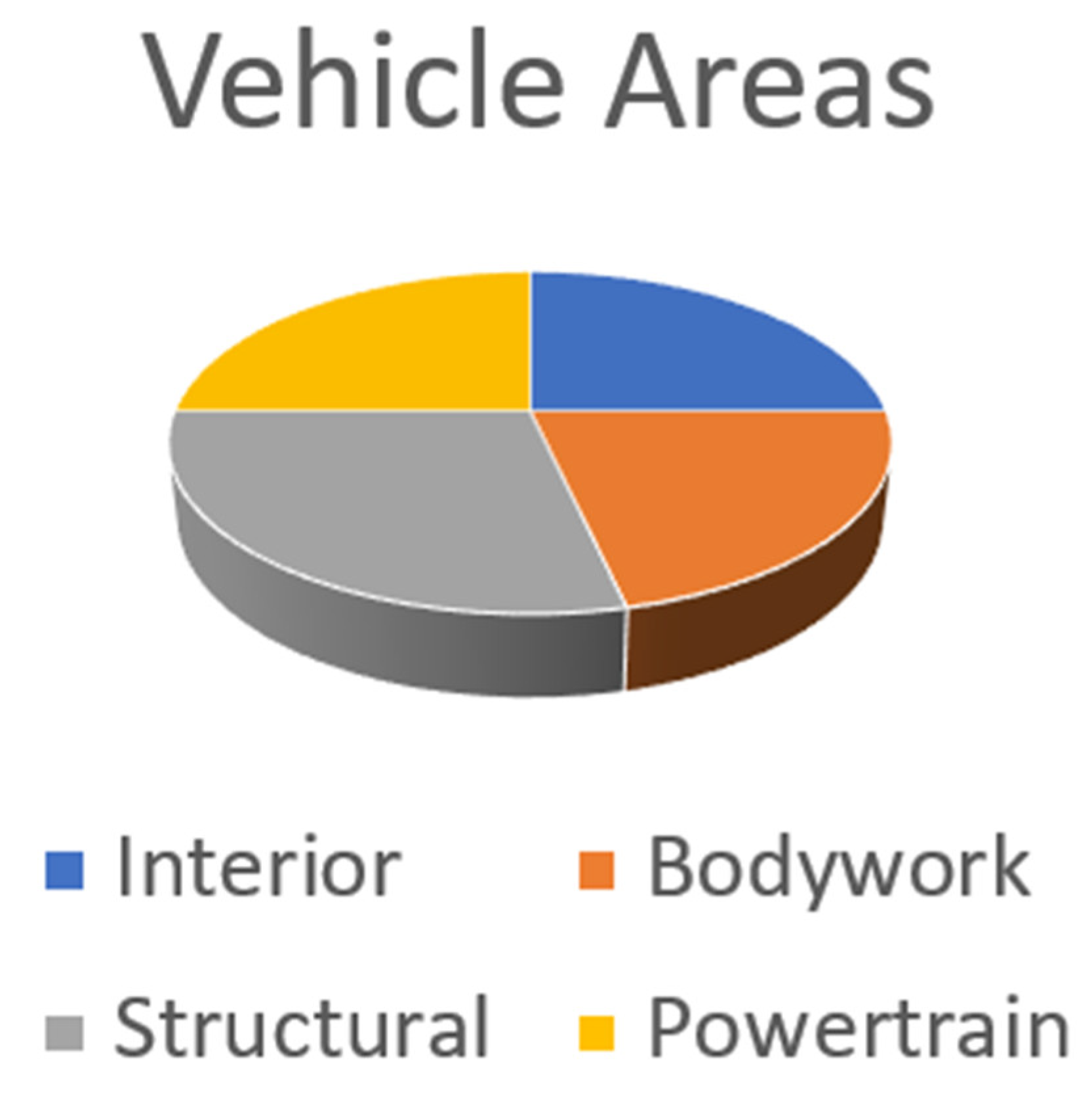

- Interior: the dashboard, consoles, air vents, mirror, control levers, handles, switches, trims, etc.

- Bodywork: the body panels, fenders, bumpers, mirrors, headlights/indicators, grilles, handles, trims, etc.

- Structural parts: the suspensions, wheels, subframe components, brackets, etc.

- Powertrain: the gearbox, engine, differential, carburettors, pumps, etc.

- Material: polymer parts; metal parts; composite parts.

- Process: direct AM process, indirect AM process.

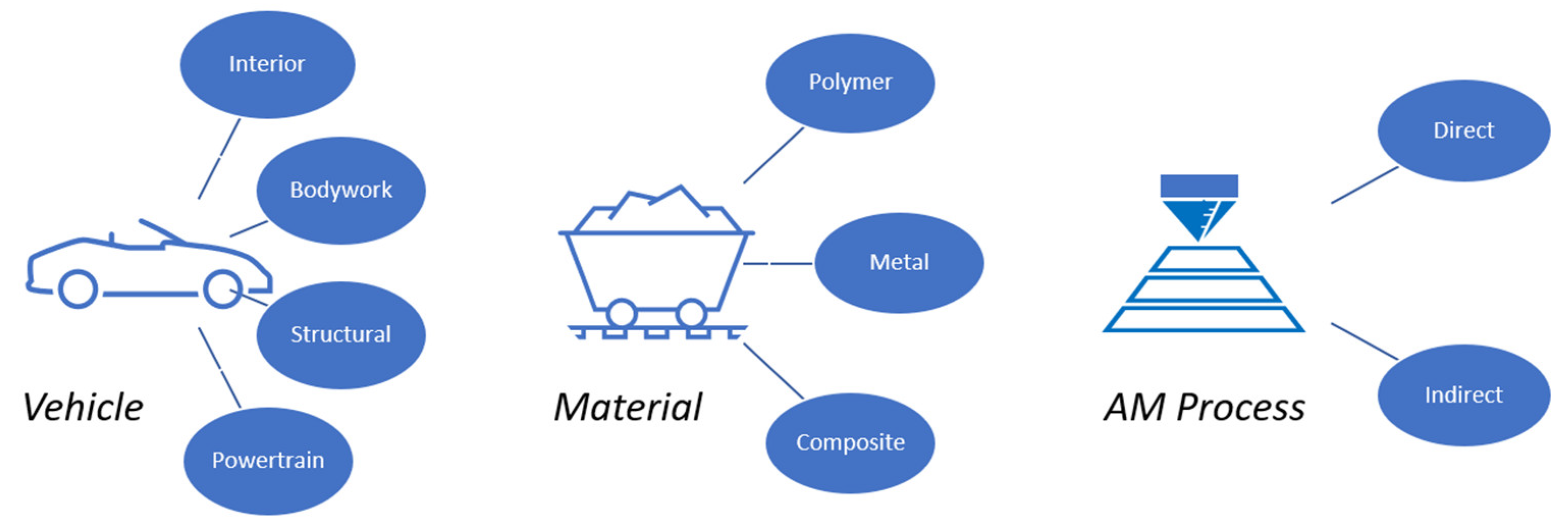

3.1. Polymer Spare Parts

3.1.1. Direct AM Processes

3.1.2. Indirect AM Processes

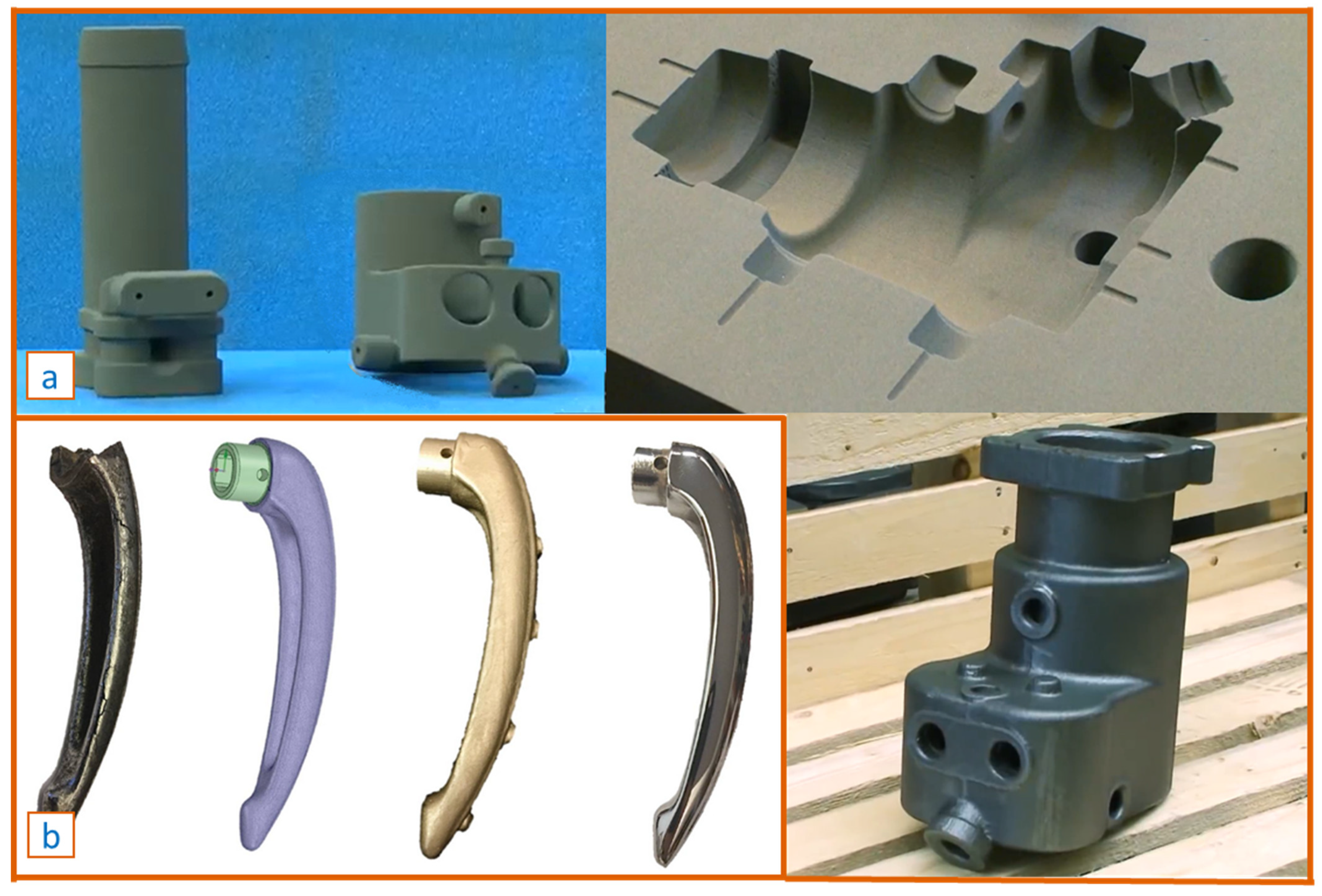

3.2. Metal Spare Parts

3.2.1. Direct AM processes

3.2.2. Indirect AM Processes

3.3. Composite Spare Parts

3.3.1. Direct AM Processes

3.3.2. Indirect AM Processes

4. Automotive Spare-Part Reconstruction Based on Additive Manufacturing

5. Conclusions

- All types of AM technologies are used to produce automotive spare parts, although some technologies predominate (such as so-called polymeric Material Extrusion processes) for their ease-of-use, and cost-effectiveness in terms of both equipment and materials. In other cases, AM is used as an intermediate process in conventional primary technologies, such as sand casting and investment casting, contributing to the digital transformation of traditional manufacturing processes.

- The users of AM technologies range from car manufacturers, OEMs, and restoration body shops, to small-sized companies such as start-ups dedicated to this market niche. Moreover, in many of the selected case studies, a provider of AM equipment was involved in the development of a specific solution in terms of processes or materials.

- On the one hand, the technology providers, car manufacturers, and technology scholars aim to improve the finish and performance of AM as a primary process; on the other hand, post-processing for additively manufactured parts has been developed to be capable of limiting the main criticalities of layer-by-layer processes.

- The framework that emerges from the case studies presented in this review leads to the abstraction of a complete methodology for the reproduction of components based on a digital and physical workflow, which uses AM for both part production and tooling.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

References

- Deloitte Insights. Industry 4.0 in Automotive. Digitizing the End-to-End Automotive Value Chain. Deloitte Development LLC. 2020. Available online: https://www2.deloitte.com/content/dam/insights/us/articles/automotive-news_industry-4-0-in-automotive/DI_Automotive-News-Supplement.pdf (accessed on 12 August 2022).

- Rüßmann, M.; Lorenz, M.; Gerbert, P.; Waldner, M.; Justus, J.; Engel, P.; Harnisch, M. Industry 4.0: The future of productivity and growth in manufacturing industries. Boston Consult. Group 2015, 9, 54–89. Available online: https://www.bcg.com/publications/2015/engineered_products_project_business_industry_4_future_productivity_growth_manufacturing_industries (accessed on 12 August 2022).

- Butt, J. Exploring the Interrelationship between Additive Manufacturing and Industry 4.0. Designs 2020, 4, 13. [Google Scholar] [CrossRef]

- Plocher, J.; Panesar, A. Review on Design and Structural Optimisation in Additive Manufacturing: Towards next-Generation Lightweight Structures. Mater. Des. 2019, 183, 108164. [Google Scholar] [CrossRef]

- Dalpadulo, E.; Pini, F.; Leali, F. Integrated CAD Platform Approach for Design for Additive Manufacturing of High Performance Automotive Components. Int. J. Interact. Des. Manuf. 2020, 14, 899–909. [Google Scholar] [CrossRef]

- Dalpadulo, E.; Pini, F.; Leali, F. Systematic integration of topology optimization techniques in design for additive manufacturing methodologies applied to automotive settings. In Proceedings of the ASME 2020 International Mechanical Engineering Congress and Exposition, Virtual, Online, 16–19 November 2020; Volume 6, p. V006T06A016. [Google Scholar] [CrossRef]

- Bubna, P.; Humbert, M.P.; Wiseman, M.; Manes, E. Barriers to Entry in Automotive Production and Opportunities with Emerging Additive Manufacturing Techniques. SAE Tech. Pap. 2016, 2016-01-0329. [Google Scholar] [CrossRef]

- Leal, R.; Barreiros, F.M.; Alves, L.; Romeiro, F.; Vasco, J.C.; Santos, M.; Marto, C. Additive manufacturing tooling for the automotive industry. Int. J. Adv. Manuf. Technol. 2017, 92, 1671–1676. [Google Scholar] [CrossRef]

- Salifu, S.; Desai, D.; Ogunbiyi, O.; Mwale, K. Recent development in the additive manufacturing of polymer-based composites for automotive structures—a review. Int. J. Adv. Manuf. Technol. 2022, 119, 6877–6891. [Google Scholar] [CrossRef]

- Khajavi, S.H.; Salmi, M.; Holmström, J. Additive manufacturing as an enabler of digital spare parts. In Managing 3D Printing; Eyers, D., Ed.; Palgrave Macmillan: Cham, Switzerland, 2020; pp. 45–60. [Google Scholar] [CrossRef]

- Isasi-Sanchez, L.; Morcillo-Bellido, J.; Ortiz-Gonzalez, J.I.; Duran-Heras, A. Synergic sustainability implications of additive manufacturing in automotive spare parts: A case analysis. Sustainability 2020, 12, 8461. [Google Scholar] [CrossRef]

- Wiese, M.; Leiden, A.; Rogall, C.; Thiede, S.; Herrmann, C. Modeling energy and resource use in additive manufacturing of automotive series parts with multi-jet fusion and selective laser sintering. Procedia CIRP 2021, 98, 358–363. [Google Scholar] [CrossRef]

- Thomas, D. Costs, benefits, and adoption of additive manufacturing: A supply chain perspective. Int. J. Adv. Manuf. Technol. 2016, 85, 1857–1876. [Google Scholar] [CrossRef] [Green Version]

- Koller, J.; Häfner, R.; Döpper, F. Decentralized Spare Parts Production for the Aftermarket using Additive Manufacturing-A Literature Review. Procedia CIRP 2022, 107, 894–901. [Google Scholar] [CrossRef]

- Mecheter, A.; Pokharel, S.; Tarlochan, F. Additive Manufacturing Technology for Spare Parts Application: A Systematic Review on Supply Chain Management. Appl. Sci. 2022, 12, 4160. [Google Scholar] [CrossRef]

- Lim, J.; Le, K.Q.; Lu, Q.; Wong, C. An Overview of 3-D Printing in Manufacturing, Aerospace, and Automotive Industries. IEEE Potentials 2016, 35, 18–22. [Google Scholar] [CrossRef]

- Delic, M.; Eyers, D.R. The effect of additive manufacturing adoption on supply chain flexibility and performance: An empirical analysis from the automotive industry. Int. J. Prod. Econ. 2020, 228, 107689. [Google Scholar] [CrossRef]

- Giffi, C.A.; Gangula, B.; Illinda, P. 3D Opportunity in the Automotive Industry: Additive Manufacturing Hits the Road. A Deloitte Series on Additive Manufacturing. Deloitte University press. 2014. Available online: https://www2.deloitte.com/content/dam/insights/us/articles/additive-manufacturing-3d-opportunity-in-automotive/DUP_707-3D-Opportunity-Auto-Industry_MASTER.pdf (accessed on 12 August 2022).

- Wohlers, T.T. Wohlers Report 2019. Analysis. Trends. Forecasts. In 3D Printing and Additive Manufacturing State of the Industry; Wohlers Associates Inc.: Fort Collins, CO, USA, 2019; p. 369. [Google Scholar]

- Tuazon, B.J.; Custodio, N.A.V.; Basuel, R.B.; Delos Reyes, L.A.; Dizon, J.R.C. 3D Printing Technology and Materials for Automotive Application: A Mini-Review. Key Eng. Mater. 2022, 913, 3–16. [Google Scholar] [CrossRef]

- Hawken, R. Classic Cars Make Great Investment Vehicles. Modern Trader. 2018. Available online: http://www.futuresmag.com/2018/03/16/classic-cars-make-great-investment-vehicles (accessed on 12 August 2022).

- Johnson, S. Classic cars: Keep motoring heritage alive. Eng. Technol. 2021, 16, 1–6. [Google Scholar] [CrossRef]

- Valerga, A.P.; Batista, M.; Bienvenido, R.; Fernández-Vidal, S.R.; Wendt, C.; Marcos, M. Reverse Engineering Based Methodology for Modelling Cutting Tools. Procedia Eng. 2015, 132, 1144–1151. [Google Scholar] [CrossRef] [Green Version]

- Zhang, X.; Cui, W.; Li, W.; Liou, F. A Hybrid Process Integrating Reverse Engineering, Pre-Repair Processing, Additive Manufacturing, and Material Testing for Component Remanufacturing. Materials 2019, 12, 1961. [Google Scholar] [CrossRef] [Green Version]

- Strong, D.; Kay, M.; Wakefield, T.; Sirichakwal, I.; Conner, B.; Manogharan, G. Rethinking reverse logistics: Role of additive manufacturing technology in metal remanufacturing. J. Manuf. Technol. Manag. 2019, 31, 124–144. [Google Scholar] [CrossRef]

- Dúbravčík, M.; Kender, Š. Application of reverse engineering techniques in mechanics system services. Procedia Eng. 2012, 48, 96–104. [Google Scholar] [CrossRef]

- Buican, G.R.; Oancea, G.; Manolescu, A. Remanufacturing of damaged parts using selective laser melting technology. Appl. Mech. Mater. 2014, 693, 285–290. [Google Scholar] [CrossRef]

- Palka, D. Use of reverse engineering and additive printing in the reconstruction of gears. Multidiscip. Asp. Prod. Eng. 2020, 3, 274–284. [Google Scholar] [CrossRef]

- Edinbarough, I.; Akundi, A. Rapid manufacturing of critical industrial parts: A method based on reverse engineering, rapid prototyping, and coordinate metrology. In Proceedings of the ASEE Annual Conference and Exposition, Online, 21–24 June 2020; p. 1162. [Google Scholar] [CrossRef]

- Sasson, A.; Johnson, J.C. The 3D printing order: Variability, supercenters and supply chain reconfigurations. Int. J. Phys. Distrib. Logist. Manag. 2016, 46, 82–94. [Google Scholar] [CrossRef] [Green Version]

- Taylor, E.; Cremer, A. Daimler Trucks to Use 3D Printing in Spare Parts Production. Reuters, Frankfurt, 13 July 2016. Available online: www.reuters.com/article/us-daimler-3dprintingidUSKCN0ZT201 (accessed on 12 August 2022).

- 3D Printed Car Parts. 3DPrint.com. Available online: https://3dprint.com/tag/3d-printed-car-parts/ (accessed on 12 August 2022).

- Savastano, M.; Amendola, C.; D’Ascenzo, F.; Massaroni, E. 3-D Printing in the Spare Parts Supply Chain: An Explorative Study in the Automotive Industry. In Digitally Supported Innovation. Lecture Notes in Information Systems and Organisation; Caporarello, L., Cesaroni, F., Giesecke, R., Missikoff, M., Eds.; Springer: Cham, Switzerland, 2016; Volume 18. [Google Scholar] [CrossRef] [Green Version]

- Montero, J.; Paetzold, K.; Bleckmann, M.; Holtmannspoetter, J. Re-design and re-manufacturing of discontinued spare parts implementing additive manufacturing in the military field. In Proceedings of the DESIGN 2018 15th International Design Conference, Dubrovnik, Croatia, 21–24 May 2018; pp. 1269–1278. [Google Scholar] [CrossRef]

- Subeshan, B.; Abdulaziz, A.; Khan, Z.; Uddin, M.N.; Rahman, M.M.; Asmatulu, E. Reverse Engineering of Aerospace Components Utilizing Additive Manufacturing Technology. In TMS 2022 151st Annual Meeting & Exhibition Supplemental Proceedings, The Minerals, Metals & Materials Series; Springer: Cham, Switzerland, 2022; pp. 238–246. [Google Scholar] [CrossRef]

- Dwivedi, G.; Srivastava, S.K.; Srivastava, R.K. Analysis of barriers to implement additive manufacturing technology in the Indian automotive sector. Int. J. Phys. Distrib. Logist. Manag. 2017, 47, 972–991. [Google Scholar] [CrossRef]

- Grunewald, S.J. 3D Printing Will Help Mercedes-Benz Trucks Deliver Thousands of Replacement Parts on Demand. 3Dprint.com. 14 July 2016. Available online: https://3dprint.com/142207/mercedes-benz-trucks-parts (accessed on 12 August 2022).

- Lee, K.H.; Woo, H. Direct integration of reverse engineering and rapid prototyping. Comput. Ind. Eng. 2000, 38, 21–38. [Google Scholar] [CrossRef]

- Otto, K.N.; Wood, K.L. Product Design: Techniques in Reverse Engineering and New Product Development; Prentice Hall: Upper Saddle River, NJ, USA, 2006. [Google Scholar]

- Otto, K.N.; Wood, K.L. Product evolution: A reverse engineering and redesign methodology. Res. Eng. Des. 1998, 10, 226–243. [Google Scholar] [CrossRef]

- Geng, Z.; Bidanda, B. Review of reverse engineering systems–current state of the art. Virtual Phys. Prototyp. 2017, 12, 161–172. [Google Scholar] [CrossRef]

- Buonamici, F.; Carfagni, M.; Furferi, R.; Governi, L.; Lapini, A.; Volpe, Y. Reverse engineering modeling methods and tools: A survey. Comput.-Aided Des. Appl. 2018, 15, 443–464. [Google Scholar] [CrossRef]

- Paulic, M.; Irgolic, T.; Balic, J.; Cus, F.; Cupar, A.; Brajlih, T.; Drstvensek, I. Reverse engineering of parts with optical scanning and additive manufacturing. Procedia Eng. 2014, 69, 795–803. [Google Scholar] [CrossRef] [Green Version]

- Bacciaglia, A.; Ceruti, A.; Liverani, A. Photogrammetry and additive manufacturing based methodology for decentralized spare Part Production in automotive industry. In Intelligent Human Systems Integration 2020. IHSI 2020. Advances in Intelligent Systems and Computing; Ahram, T., Karwowski, W., Vergnano, A., Leali, F., Taiar, R., Eds.; Springer: Cham, Switzerland, 2020; Volume 1131, pp. 796–802. [Google Scholar] [CrossRef]

- Petruccioli, A.; Gherardini, F.; Leali, F. Assessment of close-range photogrammetry for the low cost development of 3D models of car bodywork components. Int. J. Interact. Des. Manuf. 2022, 16, 703–713. [Google Scholar] [CrossRef]

- Chang, M.; Park, S.C. Reverse engineering of a symmetric object. Comput. Ind. Eng. 2008, 55, 311–320. [Google Scholar] [CrossRef]

- Rathore, N.; Jain, P.K. Reverse Engineering Applications in Manufacturing Industries: An Overview. In DAAAM International Scientific Book 2014; DAAAM International: Vienna, Austria, 2014; pp. 567–576. [Google Scholar] [CrossRef]

- Wang, J.; Gu, D.; Yu, Z.; Tan, C.; Zhou, L. A framework for 3D model reconstruction in reverse engineering. Comput. Ind. Eng. 2012, 63, 1189–1200. [Google Scholar] [CrossRef]

- ISO/ASTM 52900:2021; Additive Manufacturing-General Principles–Fundamentals and Vocabulary. International Organization for Standardization: Geneva, Switzerland, 2021. Available online: https://www.iso.org/obp/ui/#iso:std:iso-astm:52900:ed-2:v1:en (accessed on 24 October 2022).

- Gibson, I.; Rosen, D.; Stucker, B. Additive Manufacturing Technologies: 3D Printing, Rapid Prototyping, and Direct Digital Manufacturing; Springer: New York, NY, USA, 2015. [Google Scholar] [CrossRef]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.; Hui, D. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Compos. Part B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Gao, W.; Zhang, Y.; Ramanujan, D.; Ramani, K.; Chen, Y.; Williams, C.; Wang, C.; Shin, Y.; Zhang, S.; Zavattieri, P. The status, challenges, and future of additive manufacturing in engineering. CAD Comput. Aided Des. 2015, 66, 65–89. [Google Scholar] [CrossRef]

- Thompson, M.; Moroni, G.; Vaneker, T.; Fadel, G.; Campbell, R.; Gibson, I.; Bernard, A.; Schulz, J.; Graf, P.; Ahuja, B.; et al. Design for additive manufacturing: Trends, opportunities, considerations, and constraints. CIRP Ann. Manuf. Technol. 2016, 65, 737–760. [Google Scholar] [CrossRef] [Green Version]

- Mehrpouya, M.; Dehghanghadikolaei, A.; Fotovvati, B.; Vosooghnia, A.; Emamian, S.S.; Gisario, A. The potential of additive manufacturing in the smart factory industrial 4.0: A review. Appl. Sci. 2019, 9, 3865. [Google Scholar] [CrossRef] [Green Version]

- Barbieri, L.; Calzone, F.; Muzzupappa, M. Form and function: Functional optimization and additive manufacturing. In Advances on Mechanics, Design Engineering and Manufacturing II. Lecture Notes in Mechanical Engineering; Cavas-Martínez, F., Eynard, B., Fernández Cañavate, F., Fernández-Pacheco, D., Morer, P., Nigrelli, V., Eds.; Springer: Cham, Switzerland, 2019; pp. 649–658. [Google Scholar] [CrossRef]

- Dilberoglu, U.M.; Gharehpapagh, B.; Yaman, U.; Dolen, M. The Role of Additive Manufacturing in the Era of Industry 4.0. Procedia Manuf. 2017, 11, 545–554. [Google Scholar] [CrossRef]

- McKnight, M. Generative Design: What it is? How is it being used? Why it’s a game changer. KnE Eng. 2017, 2, 176–181. [Google Scholar] [CrossRef] [Green Version]

- McCormack, J.P.; Dorin, A.; Innocent, T.C. Generative design: A paradigm for design research. In Future Ground; Redmond, J., Durling, D., de Bono, A., Eds.; Monash University: Melbourne, Australia, 2005; Volume 2. [Google Scholar]

- Taborda, L.L.L.; Maury, H.; Pacheco, J. Design for additive manufacturing: A comprehensive review of the tendencies and limitations of methodologies. Rapid Prototyp. J. 2021, 27, 918–966. [Google Scholar] [CrossRef]

- Wiberg, A.; Persson, J.; Ölvander, J. Design for additive manufacturing–a review of available design methods and software. Rapid Prototyp. J. 2019, 25. [Google Scholar] [CrossRef] [Green Version]

- Vaneker, T.; Bernard, A.; Moroni, G.; Gibson, I.; Zhang, Y. Design for additive manufacturing: Framework and methodology. CIRP Ann. 2020, 69, 578–599. [Google Scholar] [CrossRef]

- ISO/ASTM 52911-1:2019(E); Additive Manufacturing—Design—Part 1: Laser-Based Powder Bed Fusion of Metals, ISO, the International Organization for Standardization. ASTM International: West Conshohocken, PA, USA, 2019. Available online: https://standards.iteh.ai/catalog/standards/cen/dfc92d06-505b-4f52-9800-ac3b026a9318/en-iso-astm-52911-1-2019 (accessed on 24 October 2022).

- Briard, T.; Segonds, F.; Zamariola, N. G-DfAM: A methodological proposal of generative design for additive manufacturing in the automotive industry. Int. J. Interact. Des. Manuf. 2020, 14, 875–886. [Google Scholar] [CrossRef]

- ASTM F2792-12a; Standard Terminology for Additive Manufacturing Technologies. ASTM International: West Conshohocken, PA, USA, 2012.

- ISO/ASTM 52900:2015; Additive Manufacturing–General Principles–Terminology, ISO, the INTERNATIONAL Organization for Standardization. ASTM International: West Conshohocken, PA, USA, 2015.

- Shanmugam, R.; Ramoni, M.; Chandran, J.; Mohanavel, V.; Pugazhendhi, L. A Review on Significant Classification of Additive Manufacturing. J. Phys. Conf. Ser. IOP Publ. 2021, 2027, 012026. [Google Scholar] [CrossRef]

- Martínez-García, A.; Monzón, M.; Paz, R. Chapter 12-Standards for additive manufacturing technologies: Structure and impact. In Handbooks in Advanced Manufacturing, Additive Manufacturing; Juan, P., Antonio, R.J., Paulo, D., Eds.; Elsevier: Amsterdam, The Netherlands, 2021; pp. 395–408. ISBN 9780128184110. [Google Scholar] [CrossRef]

- Pérez, M.; Carou, D.; Rubio, E.M.; Teti, R. Current Advances in Additive Manufacturing, Procedia CIRP; Elsevier: Amsterdam, The Netherlands, 2020; Volume 88, pp. 439–444. ISSN 2212-8271. [Google Scholar] [CrossRef]

- Holmström, J.; Holweg, M.; Khajavi, S.; Partanen, J. The direct digital manufacturing (r)evolution: Definition of a research agenda. Oper. Manag. Res. 2016, 9, 1–10. [Google Scholar] [CrossRef]

- Tofail, S.A.M.; Koumoulos, E.P.; Bandyopadhyay, A.; Bose, S.; O’Donoghue, L.; Charitidis, C. Additive manufacturing: Scientific and technological challenges, market uptake and opportunities. Mater. Today 2018, 21, 22–37. [Google Scholar] [CrossRef]

- Calignano, F.; Manfredi, D.; Ambrosio, E.P.; Biamino, S.; Lombardi, M.; Atzeni, E.; Salmi, A.; Minetola, P.; Iuliano, L.; Fino, P. Overview on Additive Manufacturing Technologies. IEEE 2017, 105, 593–612. [Google Scholar] [CrossRef]

- Razavykia, A.; Brusa, E.; Delprete, C.; Yavari, R. An Overview of Additive Manufacturing Technologies-A Review to Technical Synthesis in Numerical Study of Selective Laser Melting. Materials 2020, 13, 3895. [Google Scholar] [CrossRef]

- Mendible, G.A.; Saleh, N.; Barry, C.; Johnston, S.P. Mechanical properties and crystallinity of polypropylene injection molded in polyjet and aluminum tooling. Rapid Prototyp. J. 2022, 28, 686–694. [Google Scholar] [CrossRef]

- Morar, D.; Kemper, H.; Lasi, H. Challenges in Processing Digital and Physical Parts in Additive Manufacturing: An Exploration. In Proceedings of the 2017 Portland International Conference on Management of Engineering and Technology (PICMET), IEEE, Portland, OR, USA, 9–13 July 2017; pp. 1–9. [Google Scholar] [CrossRef]

- Bridget O’Neal, B. 3D Printing Plays a Role as Elvis Presley’s Long-Lost BMW 507 Is Returned to Original Condition–And to the USA. 3DPrint.com. 5 August 2016. Available online: https://3dprint.com/145105/3d-printing-elvis-bmw-507/ (accessed on 12 August 2022).

- Watkin, H. Unique Pininfarina Jaguar XK120 Rejuvenated with 3D Printing. All3DP.com. 23 August 2017. Available online: https://all3dp.com/unique-pininfarina-bodied-xk120-jaguar-rejuvenated-3d-printing/ (accessed on 12 August 2022).

- BMW, Elvis’ BMW 507–A Legend Revived. Available online: https://www.bmw.com/en/automotive-life/bmw507-elvis.html (accessed on 12 August 2022).

- Pebble Beach Concours d’Elegance, Celebrating 70 Years with Cars at Pebble Beach. Available online: https://pebblebeachconcours.net/wp-content/uploads/2021/04/Corrected_-Pebble-Beach-Concours-Honors-Its-Historic-Ties-to-Racing.pdf (accessed on 12 August 2022).

- Hamill, S. 3D Printed Car Parts: The Savior of Classic Cars. 3Dsourced.com 26 June 2021. Available online: https://www.3dsourced.com/feature-stories/3d-printed-car-parts-classic-car-restoration/ (accessed on 12 August 2022).

- Wiese, M.; Thiede, S.; Herrmann, C. Rapid manufacturing of automotive polymer series parts: A systematic review of processes, materials and challenges. Addit. Manuf. 2020, 36, 101582. [Google Scholar] [CrossRef]

- Gryp Youngtimers Parts, Ferrari-328-Hood Release Control-Raw Finish. Available online: https://www.gryp-3d.com/gb/ferrari-328/85-commande-d-ouverture-de-capot.html (accessed on 12 August 2022).

- Porsche. Porsche Classic Supplies Classic Parts from a 3D Printer. 12 February 2018. Available online: https://newsroom.porsche.com/en/company/porsche-classic-3d-printer-spare-parts-sls-printer-production-cars-innovative-14816.html (accessed on 12 August 2022).

- Mercedes. “Future Meets Classic”: Next Generation of Genuine Mercedes-Benz Replacement Parts from the 3D Printer. Mercedes-Benz Group Media. 22 November 2018. Available online: https://group-media.mercedes-benz.com/marsMediaSite/en/instance/ko/Future-meets-Classic-Next-generation-of-genuine-Mercedes-Benz-replacement-parts-from-the-3D-printer.xhtml?oid=41898228 (accessed on 12 August 2022).

- SOLIZE corporation. SOLIZE and HP Enable Sustainable 3D Production of Replacement NISMO Heritage Parts. 16 March 2021. Available online: https://www.solize.com/en/news/2021/0316/ (accessed on 12 August 2022).

- Blupointscan. Dino Seatbelt Cover. Available online: https://www.blupointscan.com/ferrari-dino (accessed on 12 August 2022).

- Everett, H. Car SOS TV Show Uses 3D Printing and Scanning to Restore Classic Car. 3DPrintingIndustry.com. 28 August 2021. Available online: https://3dprintingindustry.com/news/car-sos-tv-show-uses-3d-printing-and-scanning-to-restore-classic-car-195222/ (accessed on 12 August 2022).

- 3D Printing. 3D Printed Car Parts Bring Back the Classics. 3DPrinting.com. 7 August 2019. Available online: https://3dprinting.com/automotive/3d-printed-car-parts-bring-back-the-classics/ (accessed on 12 August 2022).

- HP Press Center. Eagle Uses HP Jet Fusion 3D Printer for Premium Quality Jaguar Car Parts. 10 August 2020. Available online: https://press.hp.com/us/en/blogs/2020/eagle-uses-hp-jet-fusion-3d-printer-for-premium-quality-jaguar-c.html (accessed on 12 August 2022).

- El Kashouty, M.F.; Rennie, A.E.; Ghazy, M.; Aziz, A.A.E. Selective laser melting for improving quality characteristics of a prism shaped topology injection mould tool insert for the automotive industry. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2021, 235, 7021–7032. [Google Scholar] [CrossRef]

- Çalışkan, C.İ.; Özer, G.; Koç, E.; Sarıtaş, U.S.; Yıldız, C.F.; Çiçek, Ö.Y. Efficiency Research of Conformal Channel Geometries Produced by Additive Manufacturing in Plastic Injection Mold Cores (Inserts) Used in Automotive Industry. In 3D Printing and Additive Manufacturing; Mary Ann Liebert: Larchmont, NY, USA, 2021. [Google Scholar] [CrossRef]

- Cicconi, P.; Mandolini, M.; Santucci, F.; Germani, M. Designing die inserts by additive approach: A test case. Procedia CIRP 2021, 100, 702–707. [Google Scholar] [CrossRef]

- EOS GmbH and Innovia, a.s. Accelerate Production and Reduce Maintenance: Czech Tool Manufacturer Relies on Additive Manufacturing for Complex Customer Projects. Available online: https://www.eos.info/01_parts-and-applications/case_studies_applications_parts/_case_studies_pdf/en_cases/cs_m_tooling_innomia_en.pdf (accessed on 12 August 2022).

- Vasco, J.; Barreiros, F.M.; Nabais, A.; Reis, N. Additive manufacturing applied to injection moulding: Technical and economic impact. Rapid Prototyp. J. 2019, 25, 1241–1249. [Google Scholar] [CrossRef]

- Kazmer, D.O. Injection Mold Design Engineering; Hanser-Gardner Publications: Munich, Germany, 2007. [Google Scholar]

- Kalami, H.; Urbanic, R.J. Design and fabrication of a low-volume, high-temperature injection mould leveraging a ‘rapid tooling’ approach. Int. J. Adv. Manuf. Technol. 2019, 105, 3797–3813. [Google Scholar] [CrossRef]

- ACO Mold. Rapid Injection Moulding. InjectionMoulding.org. Available online: http://www.injectionmoulding.org/rapid-injection-moulding.html (accessed on 12 August 2022).

- Volpato, N.; Solis, D.; Costa, C.A. An analysis of Digital ABS as a rapid tooling material for polymer injection moulding. Int. J. Mater. Prod. Technol. 2016, 52, 3–16. [Google Scholar] [CrossRef]

- Whlean, C.; Sheahan, C. Using Additive Manufacturing to Produce Injection Moulds Suitable for Short Series Production. Procedia Manuf. 2019, 38, 60–68. [Google Scholar] [CrossRef]

- Burggräf, P.; Bergweiler, G.; Abrams, J.A.; Dunst, A. Additive Surface Graining in Prototype Tooling for Injection Molding. J. Manuf. Mater. Process. 2022, 6, 54. [Google Scholar] [CrossRef]

- Saboori, A.; Aversa, A.; Marchese, G.; Biamino, S.; Lombardi, M.; Fino, P. Application of Directed Energy Deposition-Based Additive Manufacturing in Repair. Appl. Sci. 2019, 9, 3316. [Google Scholar] [CrossRef]

- Rahito, W.D.A.; Azman, A.H. Additive manufacturing for repair and restoration in remanufacturing: An overview from object design and systems perspectives. Processes 2019, 7, 802. [Google Scholar] [CrossRef] [Green Version]

- Josten, A.; Höfemann, M. Arc-welding based additive manufacturing for body reinforcement in automotive engineering. Weld World 2020, 64, 1449–1458. [Google Scholar] [CrossRef]

- Taheri, H.; Shoaib, M.R.B.M.; Koester, L.W.; Bigelow, T.A.; Collins, P.C.; Bond, L.J. Powder based additive manufacturing—A review of types of defects, generation mechanisms, detection, property evaluation and metrology. Int. J. Addit. Subtract. Mater. Manuf. 2017, 1, 172–209. [Google Scholar] [CrossRef]

- Zhang, J.; Song, B.; Wei, Q.; Bourell, D.; Shi, Y. A review of selective laser melting of aluminum alloys: Processing. J. Mater. Sci. Technol. 2019, 35, 270–284. [Google Scholar] [CrossRef]

- Ramoni, M.; Shanmugam, R.; Thangapandian, N.; Vishnuvarthanan, M. Challenges in Additive Manufacturing for Metals and Alloys. In Innovations in Additive Manufacturing; Springer International Publishing: Berlin/Heidelberg, Germany, 2022. [Google Scholar]

- Dalpadulo, E.; Pini, F.; Leali, F. Components residual stress and deformation reduction: An integrated process design for additive manufacturing. In Proceedings of the ASME 2021 International Mechanical Engineering Congress and Exposition, New York, NY, USA, 1–5 November 2021. [Google Scholar] [CrossRef]

- Cooper, D.; Thornby, J.; Blundell, N.; Henrys, R.; Williams, M.A.; Gibbons, G. Design and manufacture of high performance hollow engine valves by Additive Layer Manufacturing. Mater. Des. 2015, 69, 44–55. [Google Scholar] [CrossRef]

- Metal-AM. First Metal Additively Manufactured Spare Parts Produced at Mercedes-Benz Trucks, metal-am.com. 4 August 2017. Available online: https://www.metal-am.com/first-metal-additively-manufactured-spare-part-produced-mercedes-benz-trucks/ (accessed on 12 August 2022).

- Stratasys. DMLS for Auto Parts: Jay Leno’s Take. 13 November 2018. Available online: https://www.stratasys.com/en/stratasysdirect/resources/articles/3d-printed-car-parts-dmls-jay-leno/ (accessed on 12 August 2022).

- Keane, P. Classic Car Carburetor Replica by Tecron & Markforged. 3dprinting.com. 24 July 2020. Available online: https://3dprinting.com/automotive/classic-car-carburetor-replica-by-tecron-markforged/ (accessed on 12 August 2022).

- Markforged. How 3D Printing Drives Change in the Automotive Industry. Available online: https://markforged.com/it/resources/blog/how-3d-printing-drives-change-in-the-automotive-industry (accessed on 12 August 2022).

- Metal-AM, Sauber’s F1 Technology Used in Production of Additively Manufactured Classic Car Parts, metal-am.com. 9 June 2021. Available online: https://www.metal-am.com/saubers-f1-technology-used-in-production-of-additively-manufactured-classic-car-parts/ (accessed on 12 August 2022).

- Koehler, H.; Partes, K.; Seefeld, T.; Vollertsen, F. Laser reconditioning of crankshafts: From lab to application. Phys. Procedia 2010, 5, 387–397. [Google Scholar] [CrossRef] [Green Version]

- Lyalyakin, V.P.; Kostukov, A.; Denisov, V.A. Special features of reconditioning the housing of a Caterpillar diesel oil pump by gas-dynamic spraying. Weld. Int. 2016, 30, 68–70. [Google Scholar] [CrossRef]

- Liu, Z.; Jiang, Q.; Li, T.; Dong, S.; Yan, S.; Zhang, H.; Xu, B. Environmental benefits of remanufacturing: A case study of cylinder heads remanufactured through laser cladding. J. Clean. Prod. 2016, 133, 1027–1033. [Google Scholar] [CrossRef]

- Gray, J.; Depcik, C. Review of additive manufacturing for internal combustion engine components. SAE Int. J. Engines 2020, 13, 617–632. [Google Scholar] [CrossRef]

- Chhabra, M.; Singh, R. Rapid casting solutions: A review. Rapid Prototyp. J. 2011, 17, 328–350. [Google Scholar] [CrossRef]

- Hackney, P.; Wooldridge, R. Optimisation of Additive Manufactured Sand Printed Mould Material for Aluminium Castings. Procedia Manuf. 2017, 11, 457–465. [Google Scholar] [CrossRef]

- Mognol, P.; Rivette, M.; Jégou, L.; Lesprier, T. A first approach to choose between HSM, EDM and DMLS processes in hybrid rapid tooling. Rapid Prototyp. J. 2007, 13, 7–16. [Google Scholar] [CrossRef]

- Hackney, P.; Wooldridge, R. Characterisation of direct 3D sand printing process for the production of sand cast mould tools. Rapid Prototyp. J. 2017, 23, 7–15. [Google Scholar] [CrossRef]

- Clarke, C. 103 Year Old Delage Type-S Grand Prix Car Brought Back to Life with 3D Scanning and Printing. 3DPrintingIndustry.com, 28 March 2017. Available online: https://3dprintingindustry.com/news/103-year-old-delage-type-s-grand-prix-car-brought-back-life-3d-scanning-printing-109314/ (accessed on 12 August 2022).

- 3Ders. World’s Largest 3D Sand Printer Gives 1912 Brush Car a New Lease of Life. Available online: https://www.3ders.org/articles/20141112-world-largest-3d-sand-printer-gives-1912-brush-car-a-new-lease-of-life.html (accessed on 12 August 2022).

- Wang, W.; Conley, J.G.; Stoll, H.W. Rapid tooling for sand casting using laminated object manufacturing process. Rapid Prototyp. J. 1999, 5, 134–141. [Google Scholar] [CrossRef]

- Pereira, A.; Perez, J.A.; Dieguez, J.L.; Pelaez, G.; Ares, J.E. Design and manufacture of casting pattern plates by rapid tooling. Arch. Mater. Sci. 2008, 29, 63–67. [Google Scholar]

- Rare Parts, Catalogue. Available online: http://www.rarepartsclub.com/parts-catalog.html (accessed on 12 August 2022).

- Parandoush, P.; Lin, D. A review on additive manufacturing of polymer-fiber composites. Compos. Struct. 2017, 182, 36–53. [Google Scholar] [CrossRef]

- Ning, F.; Cong, W.; Qiu, J.; Wei, J.; Wang, S. Additive manufacturing of carbon fiber reinforced thermoplastic composites using fused deposition modeling. Compos. Part B Eng. 2015, 80, 369–378. [Google Scholar] [CrossRef]

- Valino, A.D.; Dizon, J.R.C.; Espera, A.H., Jr.; Chen, Q.; Messman, J.; Advincula, R.C. Advances in 3D printing of thermoplastic polymer composites and nanocomposites. Prog. Polym. Sci. 2019, 98, 101162. [Google Scholar] [CrossRef]

- Krassenstein, B. ORNL 3D Prints Working Shelby Cobra Replica—President Obama Approves. 3dprint.com. 10 January 2015. Available online: https://3dprint.com/36433/3d-printed-shelby-cobra/ (accessed on 12 August 2022).

- Hassen, A.A.; Noakes, M.; Nandwana, P.; Kim, S.; Kunc, V.; Vaidya, U.; Love, L.; Nycz, A. Scaling Up metal additive manufacturing process to fabricate molds for composite manufacturing. Addit. Manuf. 2020, 32, 101093. [Google Scholar] [CrossRef]

- Stratasys, Application Customer Story: Champion Motorsports. Available online: https://stratasysstorage01.file.core.windows.net/ssys-websites-files-prod/Public1/Resources/Case%20Studies/FDM/Applications/Champion%20Motorsports%20-%20EN%20FDM%20Case%20Study.pdf?sv=2017-04-17&sr=f&sig=mXC0nVV1DiZCp1kaDujck8UFVRDBD7eQuqPL%2FbAq224%3D&st=2022-08-18T10%3A45%3A30Z&se=2023-08-19T10%3A45%3A30Z&sp=rwl (accessed on 12 August 2022).

- Mason, H. Hybrid 3D printing/Machining Center Enables Custom Vehicle Restoration Project. 6 September 2021. Available online: https://www.compositesworld.com/articles/hybrid-3d-printingmachining-center-enables-custom-vehicle-restoration-project (accessed on 12 August 2022).

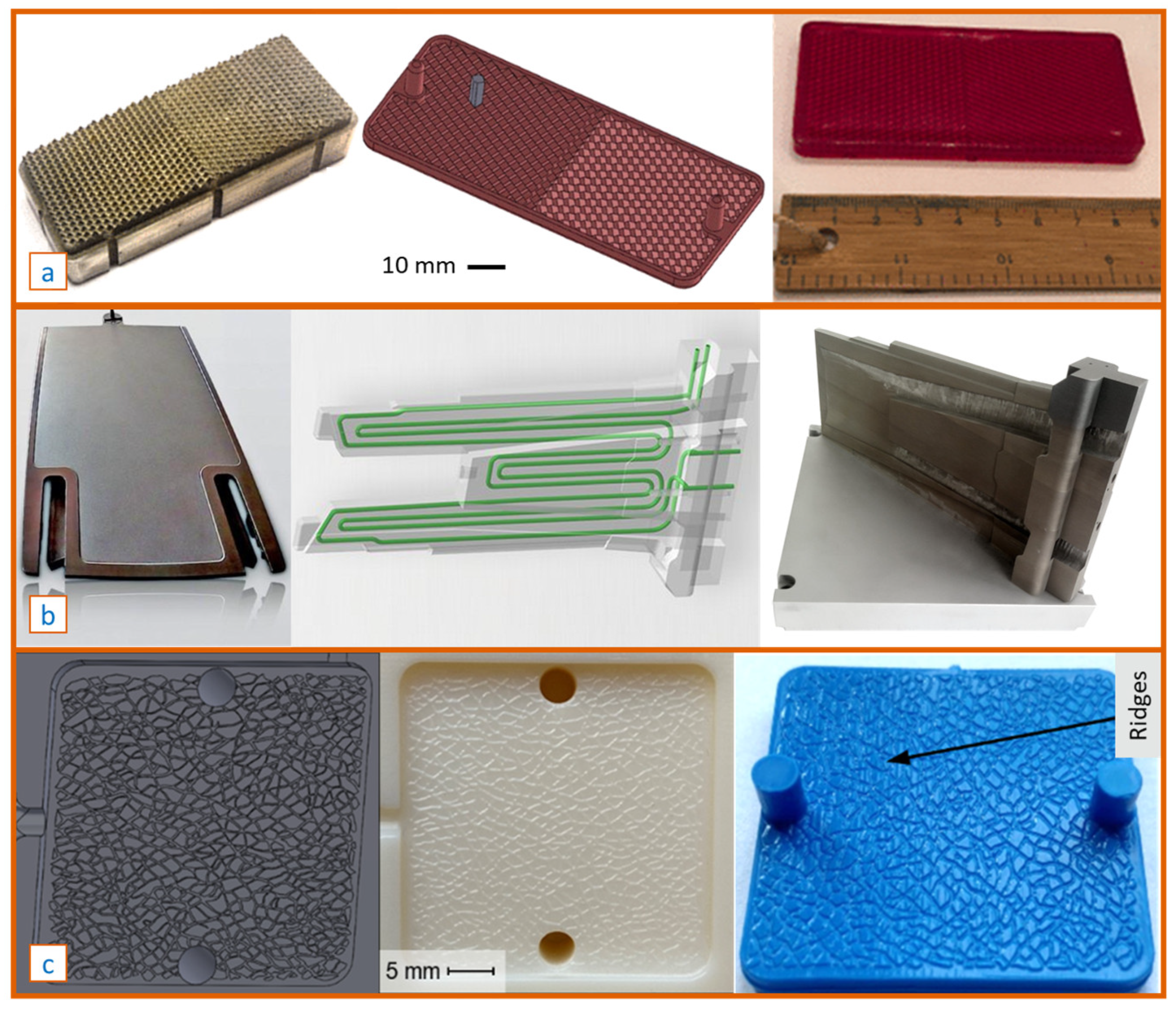

| Spare Part | Material | AM Process |

|---|---|---|

| Car volume buttons [43] | Polyamide 2200 (PA2200) | PBF—Direct (SLS) |

| Hood-release handle [81] | UV-resistant ABS | ME—Direct (FDM) |

| Crank arm [82] | Polymer | PBF—Direct (SLS) |

| Filler-cap seal [82] | Polymer | PBF—Direct (SLS) |

| Sliding sunroof rollers [83] | Polyamide 12 | PBF—Direct (SLS) |

| Spark-plug holder [83] | Polyamide 12 | PBF—Direct (SLS) |

| Plastic harness protector [84] | Polyamide 11 powder | PBF—Direct (MJF) |

| Seat-belt cover [85] | ABS | ME—Direct (FDM) |

| Central console [86] | Polymer | ME—Direct (FDM) |

| Custom front grille [87] | Polymer | ME—Direct (FDM) |

| Heating air ducts [88] | Polyamide | PBF—Direct (MJF) |

| IM prism-shaped tool insert [89] > (headlamp reflector) | Stainless steel 316 L > (polystyrene) | PBF—Indirect (SLM) > (injection moulding) |

| IM conformal-cooling insert [92] > (armrest) | Maraging steel 1.2709 > (polymer) | PBF—Indirect (SLM) > (injection moulding) |

| IM tool inserts [93] > (parking sensor housing) | Maraging steel CL 50WS > (polybutylene terephthalate (PBT)) | PBF—Indirect (SLM) > (injection moulding) |

| IM polymer mould [99] > (grain textured surfaces) | Simulated polypropylene material (Rigur) > (polypropylene) | MJ—Indirect (PolyJet) > (injection moulding) |

| Bracket [82] | Tool steel | PBF—Direct (SLM) |

| Mirror base [83] | Aluminium alloy | PBF—Direct (SLM) |

| Thermostat cover [108] | AlSi10Mg | PBF—Direct (SLM) |

| Pilot burner [109] | Inconel 718 | PBF—Direct (DMLS) |

| Carburettor body [110] | 17-4 PH stainless steel | ME—Direct (Metal X) |

| Gearbox housing [112] | AlSi10Mg | PBF—Direct (MetalFAB1) |

| Sand mould and cores [121] > (engine block) | Quartz sand > (cast iron) | BJ—Indirect (3DSP) > (metal casting) |

| Sand mould and cores [122] > (one-cylinder car engine) | Sand + foundry-grade resin > (cast iron) | BJ—Indirect (3DSP) > (metal casting) |

| Wax master model [125] > (door handle) | Wax > (solid brass) | VP—Indirect (wax SLA) > (investment casting) |

| Wax master model [125] > (fan) | Wax > (aluminium) | VP—Indirect (wax SLA) > (investment casting) |

| Wax master model [125] > (door and trunk key) | Wax > (solid brass) | VP—Indirect (wax SLA) > (investment casting) |

| Shelby Cobra replica [129] | ABS plastic and carbon fibre | ME—Direct (BAAM) |

| Core for composite lamination [131] > (Porsche 997 turbo inlet ducts) | Stratasys ST-130 (sacrificial-tooling material) > (carbon fibre prepreg) | ME—Indirect (FDM) > (lamination) |

| 3D-printed mould [132] > (composite body of a Maserati 3200 GT restomod) | 40% carbon fibre-filled polyamide 6 > (carbon fibre prepreg) | ME—Indirect (LFAM) > (lamination) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dalpadulo, E.; Petruccioli, A.; Gherardini, F.; Leali, F. A Review of Automotive Spare-Part Reconstruction Based on Additive Manufacturing. J. Manuf. Mater. Process. 2022, 6, 133. https://doi.org/10.3390/jmmp6060133

Dalpadulo E, Petruccioli A, Gherardini F, Leali F. A Review of Automotive Spare-Part Reconstruction Based on Additive Manufacturing. Journal of Manufacturing and Materials Processing. 2022; 6(6):133. https://doi.org/10.3390/jmmp6060133

Chicago/Turabian StyleDalpadulo, Enrico, Andrea Petruccioli, Francesco Gherardini, and Francesco Leali. 2022. "A Review of Automotive Spare-Part Reconstruction Based on Additive Manufacturing" Journal of Manufacturing and Materials Processing 6, no. 6: 133. https://doi.org/10.3390/jmmp6060133

APA StyleDalpadulo, E., Petruccioli, A., Gherardini, F., & Leali, F. (2022). A Review of Automotive Spare-Part Reconstruction Based on Additive Manufacturing. Journal of Manufacturing and Materials Processing, 6(6), 133. https://doi.org/10.3390/jmmp6060133