Freeform Hybrid Manufacturing: Binderjet, Structured Light Scanning, Confocal Microscopy, and CNC Machining †

Abstract

:1. Introduction

- Enhancement of optical performance or the same optical performance as a compact system is maintained, such as an expanded field of view and aberration-free surfaces.

- Quantitative reduction in optical components of systems, reducing the overall cost.

- Simplified assembly because of a few optical components. For example, freeform surfaces fabricated on a single monolith.

- Miniaturization of optical systems.

- Reduction in the weight of the optical system and a more compact size.

- Improvements in the capabilities of optical designers and innovation in optics.

In-situ or series combination of an additive manufacturing process and secondary energy sources in which physical mechanisms are fundamentally altered/controlled to affect the resulting properties of the material and/or part [20].

Alignment fiducials (also) enable more precise locating of the surface during the manufacturing process.

2. Materials and Methods

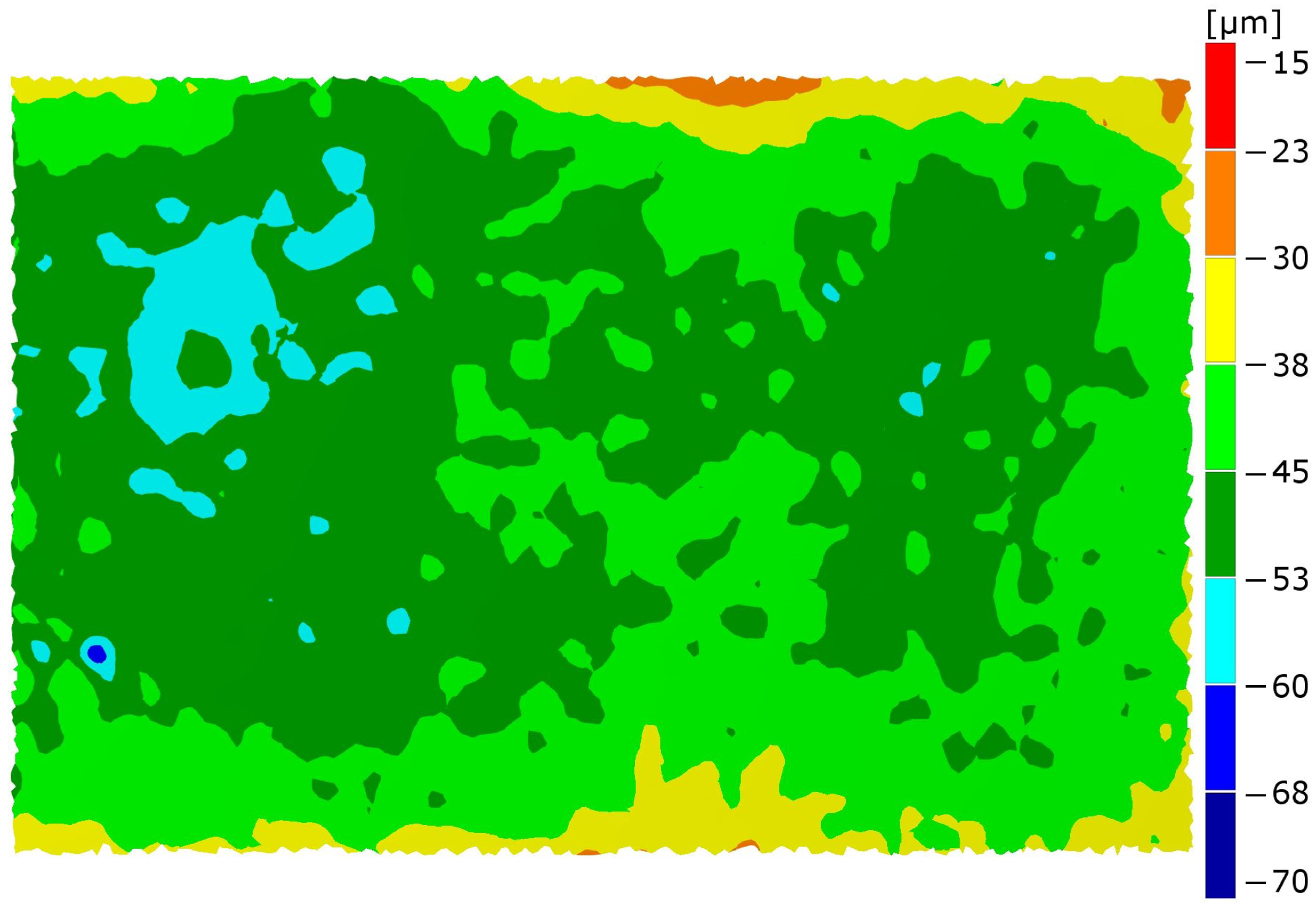

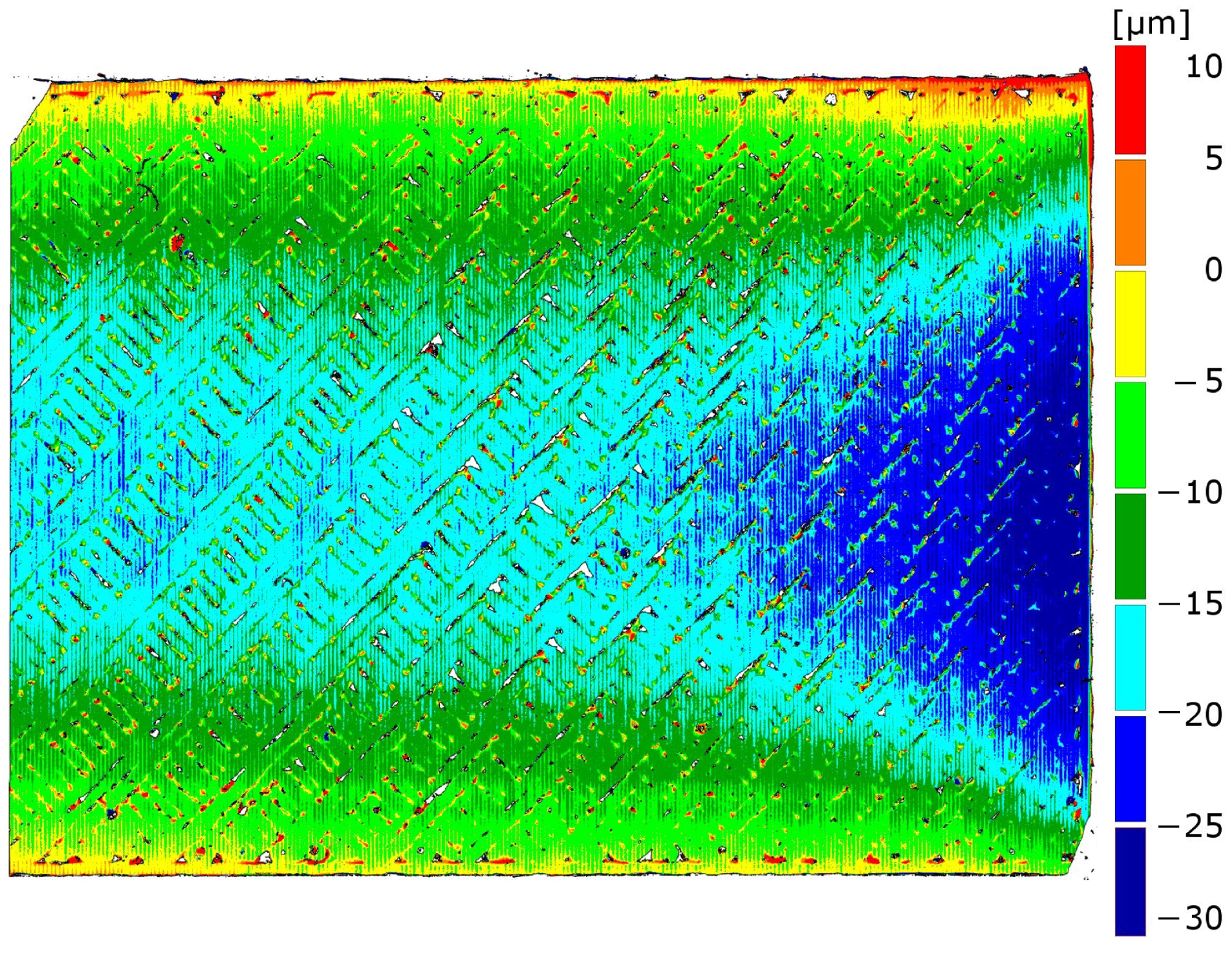

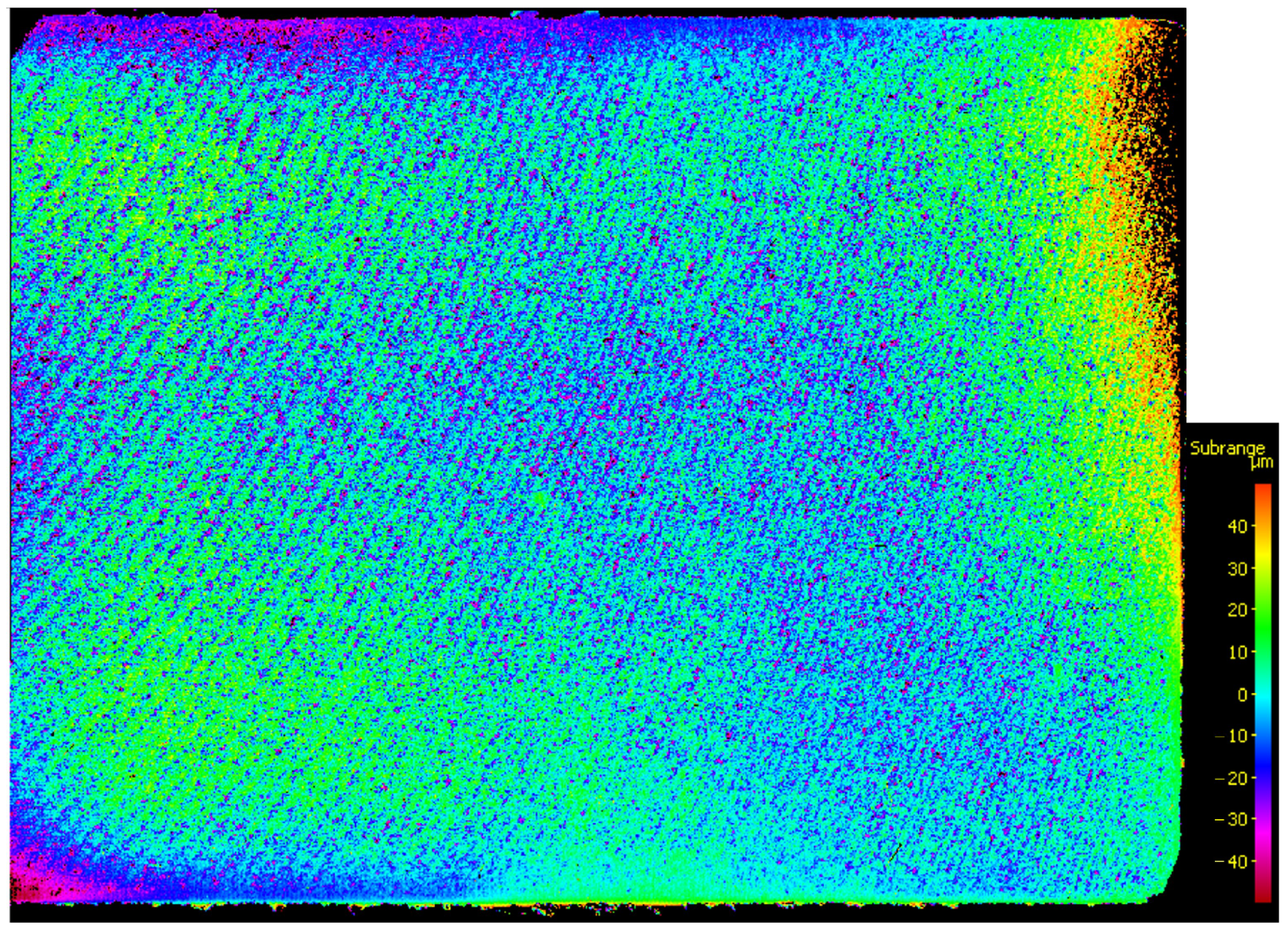

3. Results

4. Discussion

5. Conclusions

- Hybrid manufacturing of freeform surfaces on BJAM SiC samples using structured light scanning for stock model generation and WCS definition and traditional three-axis milling is possible, although final part accuracy requires additional study.

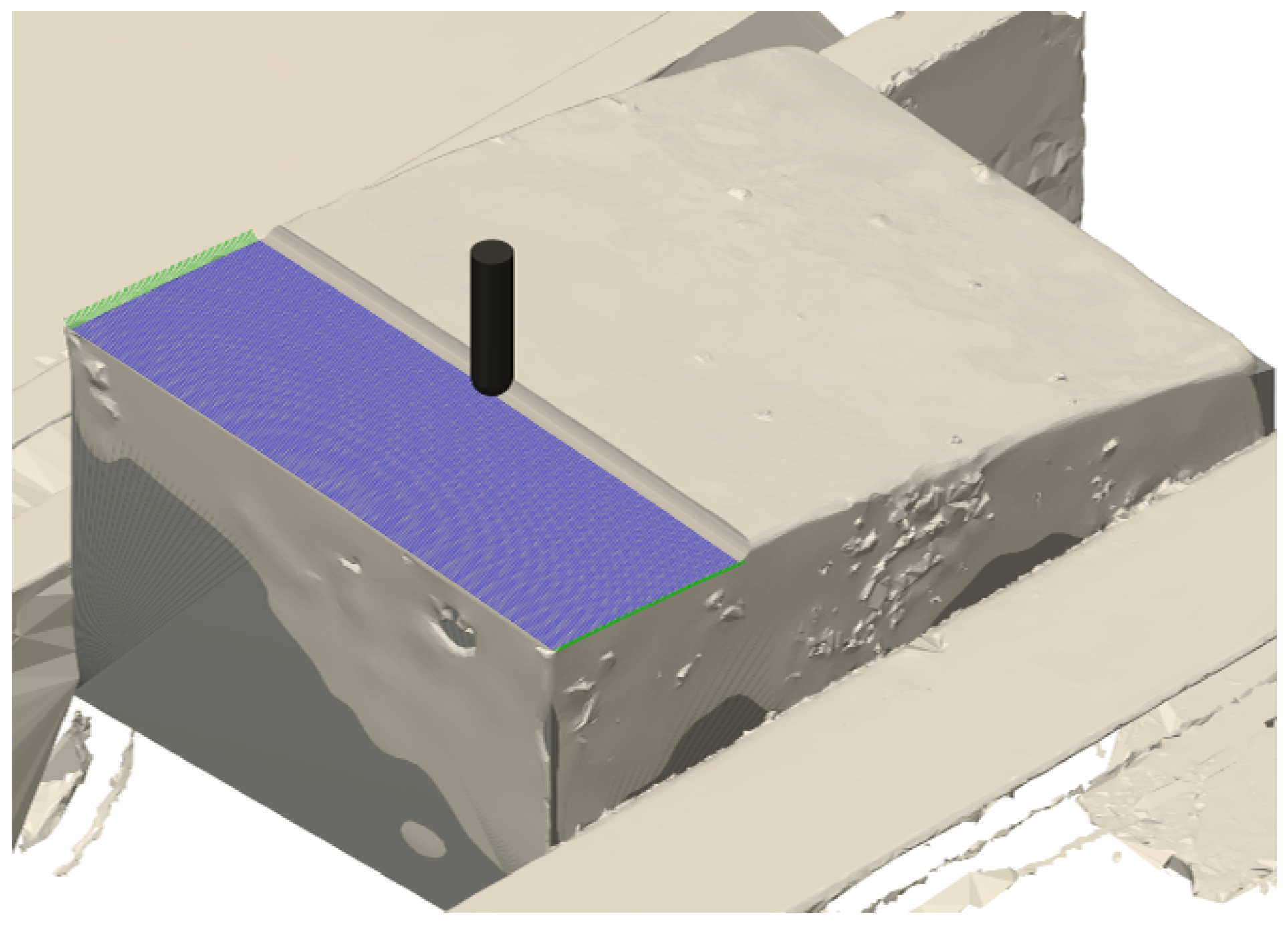

- The workpiece clamping system (a vise in this case) can provide fiducials for WCS definition and alignment in a machine tool. The strategy includes both the clamping system and part in the structured light scan to enable the coordinate system to be established independently of the part design.

- The ball end milling of a BJAM SiC sample infiltrated with cyanoacrylate was not able to properly remove layer lines from the surface resulting in poor surface finish.

- The surface finish of the machined BJAM SiC sample was worse than a FFF ABS sample machined using the same parameters and tool paths. Smaller particles or further post-processing may be required for hybrid manufacturing of SiC samples depending on the application.

- Infiltration of BJAM SiC samples can impact machining results. In this work, it is proposed that cyanoacrylate curing time can affect the final geometry of the preform.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| SiC | Silicon carbide |

| BJAM | Binder jet additive manufacturing |

| AM | Additive manufacturing |

| CNC | Computer numerical control |

| WAAM | Wire arc additive manufacturing |

| CAD | Computer-aided design |

| CS | Coordinate system |

| WCS | Work coordinate system |

| CAM | Computer-aided manufacturing |

| FFF | Fused filament fabrication |

| ABS | Acrylonitrile butadiene styrene |

References

- Blalock, T.; Medicus, K.; Nelson, J.D. Fabrication of freeform optics. In Optical Manufacturing and Testing XI; SPIE: Bellingham, WA, USA, 2015; Volume 9575, pp. 74–83. [Google Scholar]

- Fang, F.; Zhang, X.; Weckenmann, A.; Zhang, G.; Evans, C. Manufacturing and measurement of freeform optics. CIRP Ann. 2013, 62, 823–846. [Google Scholar] [CrossRef]

- Kumar, S.; Tong, Z.; Jiang, X. Advances in the design and manufacturing of novel freeform optics. Int. J. Extrem. Manuf. 2022, 4, 032004. [Google Scholar] [CrossRef]

- Wills, S. Freeform optics: Notes from the revolution. Opt. Photonics News 2017, 28, 34–41. [Google Scholar] [CrossRef]

- Brunelle, M.; Yuan, J.; Medicus, K.; Nelson, J.D. Importance of fiducials on freeform optics. In Proceedings of the Optifab 2015, Rochester, NY, USA, 12–15 October 2015; Volume 9633, pp. 325–332. [Google Scholar]

- Wang, S.; Cheung, B.; Ren, M. Uncertainty analysis of a fiducial-aided calibration and positioning system for precision manufacturing of optical freeform optics. Meas. Sci. Technol. 2020, 31, 065012. [Google Scholar] [CrossRef]

- Horvath, N.; Honeycutt, A.; Davies, M.A. Grinding of additively manufactured silicon carbide surfaces for optical applications. CIRP Ann. 2020, 69, 509–512. [Google Scholar] [CrossRef]

- Koyanagi, T.; Terrani, K.; Harrison, S.; Liu, J.; Katoh, Y. Additive manufacturing of silicon carbide for nuclear applications. J. Nucl. Mater. 2021, 543, 152577. [Google Scholar] [CrossRef]

- Petrie, C.M.; Schrell, A.M.; Leonard, D.N.; Yang, Y.; Jolly, B.C.; Terrani, K.A. Embedded sensors in additively manufactured silicon carbide. J. Nucl. Mater. 2021, 552, 153012. [Google Scholar] [CrossRef]

- Gilmer, D.; Han, L.; Hong, E.; Siddel, D.; Kisliuk, A.; Cheng, S.; Brunermer, D.; Elliott, A.; Saito, T. An in-situ crosslinking binder for binder jet additive manufacturing. Addit. Manuf. 2020, 35, 101341. [Google Scholar] [CrossRef]

- Gilmer, D.B.; Han, L.; Lehmann, M.L.; Siddel, D.H.; Yang, G.; Chowdhury, A.U.; Doughty, B.; Elliott, A.M.; Saito, T. Additive manufacturing of strong silica sand structures enabled by polyethyleneimine binder. Nat. Commun. 2021, 12, 5144. [Google Scholar] [CrossRef]

- Sachs, E.; Cima, M.; Williams, P.; Brancazio, D.; Cornie, J. Three dimensional printing: Rapid tooling and prototypes directly from a CAD model. J. Manuf. Sci. Eng. 1992, 114, 481–488. [Google Scholar] [CrossRef]

- Richardson, D.; Schumacher, A.; Rogers, A.; Petrie, C. Large-Scale Additive Manufacturing of Silicon Carbide with Process Monitoring; Technical Report; Oak Ridge National Lab. (ORNL): Oak Ridge, TN, USA, 2022. [Google Scholar]

- Mostafaei, A.; Elliott, A.M.; Barnes, J.E.; Li, F.; Tan, W.; Cramer, C.L.; Nandwana, P.; Chmielus, M. Binder jet 3D printing—Process parameters, materials, properties, modeling, and challenges. Prog. Mater. Sci. 2021, 119, 100707. [Google Scholar] [CrossRef]

- Ziaee, M.; Crane, N.B. Binder jetting: A review of process, materials, and methods. Addit. Manuf. 2019, 28, 781–801. [Google Scholar] [CrossRef]

- Terrani, K.; Jolly, B.; Trammell, M. 3D printing of high-purity silicon carbide. J. Am. Ceram. Soc. 2020, 103, 1575–1581. [Google Scholar] [CrossRef]

- Fleisher, A.; Zolotaryov, D.; Kovalevsky, A.; Muller-Kamskii, G.; Eshed, E.; Kazakin, M.; Popov, V., Jr. Reaction bonding of silicon carbides by Binder Jet 3D-Printing, phenolic resin binder impregnation and capillary liquid silicon infiltration. Ceram. Int. 2019, 45, 18023–18029. [Google Scholar] [CrossRef]

- Cramer, C.L.; Elliott, A.M.; Kiggans, J.O.; Haberl, B.; Anderson, D.C. Processing of complex-shaped collimators made via binder jet additive manufacturing of B4C and pressureless melt infiltration of Al. Mater. Des. 2019, 180, 107956. [Google Scholar] [CrossRef]

- Dvorak, J.; Gilmer, D.; Zameroski, R.; Cornelius, A.; Schmitz, T. Fabrication of freeform silicon carbide components by hybrid manufacturing. In Proceedings of the American Society for Precision Engineering Annual Meeting, Bellevue, WA, USA, 10–14 October 2022. [Google Scholar]

- Webster, S.; Lin, H.; Carter, F.M., III; Ehmann, K.; Cao, J. Physical mechanisms in hybrid additive manufacturing: A process design framework. J. Mater. Process. Technol. 2021, 291, 117048. [Google Scholar] [CrossRef]

- Wippermann, A.; Gutowski, T.; Denkena, B.; Dittrich, M.A.; Wessarges, Y. Electrical energy and material efficiency analysis of machining, additive and hybrid manufacturing. J. Clean. Prod. 2020, 251, 119731. [Google Scholar] [CrossRef]

- Zhu, Z.; Dhokia, V.G.; Nassehi, A.; Newman, S.T. A review of hybrid manufacturing processes–state of the art and future perspectives. Int. J. Comput. Integr. Manuf. 2013, 26, 596–615. [Google Scholar] [CrossRef]

- Chu, W.S.; Kim, C.S.; Lee, H.T.; Choi, J.O.; Park, J.I.; Song, J.H.; Jang, K.H.; Ahn, S.H. Hybrid manufacturing in micro/nano scale: A review. Int. J. Precis. Eng. Manuf. Green Technol. 2014, 1, 75–92. [Google Scholar] [CrossRef]

- Cornelius, A.; Dvorak, J.; Jacobs, L.; Penney, J.; Schmitz, T. Combination of structured light scanning and external fiducials for coordinate system transfer in hybrid manufacturing. J. Manuf. Process. 2021, 68, 1824–1836. [Google Scholar] [CrossRef]

- Cornelius, A.; Jacobs, L.; Lamsey, M.; McNeil, L.; Hamel, W.; Schmitz, T. Hybrid manufacturing of Invar mold for carbon fiber layup using structured light scanning. Manuf. Lett. 2022, 33, 133–142. [Google Scholar] [CrossRef]

- Dvorak, J.; Cornelius, A.; Corson, G.; Zameroski, R.; Jacobs, L.; Penney, J.; Schmitz, T. A machining digital twin for hybrid manufacturing. Manuf. Lett. 2022, 33, 786–793. [Google Scholar] [CrossRef]

- Mali, R.A.; Gupta, T.; Ramkumar, J. A comprehensive review of free-form surface milling—Advances over a decade. J. Manuf. Process. 2021, 62, 132–167. [Google Scholar] [CrossRef]

- Masood, A.; Siddiqui, R.; Pinto, M.; Rehman, H.; Khan, M.A. Tool path generation, for complex surface machining, using point cloud data. Procedia CIRP 2015, 26, 397–402. [Google Scholar] [CrossRef]

- Smith, S.; Woody, B.; Miller, J. Improving the accuracy of large scale monolithic parts using fiducials. CIRP Ann. 2005, 54, 483–486. [Google Scholar] [CrossRef]

- Srinivasan, H.; Harrysson, O.L.; Wysk, R.A. Automatic part localization in a CNC machine coordinate system by means of 3D scans. Int. J. Adv. Manuf. Technol. 2015, 81, 1127–1138. [Google Scholar] [CrossRef]

- Woody, B.A.; Scott Smith, K.; Hocken, R.J.; Miller, J.A. A technique for enhancing machine tool accuracy by transferring the metrology reference from the machine tool to the workpiece. J. Manuf. Sci. Eng. 2007, 129, 636–643. [Google Scholar] [CrossRef]

- Xu, J.; Xi, N.; Zhang, C.; Shi, Q.; Gregory, J. Real-time 3D shape inspection system of automotive parts based on structured light pattern. Opt. Laser Technol. 2011, 43, 1–8. [Google Scholar] [CrossRef]

- Mendricky, R. Determination of measurement accuracy of optical 3D scanners. MM Sci. J. 2016, 2016, 1565–1572. [Google Scholar] [CrossRef]

- Boehm, J. Accuracy investigation for structured-light based consumer 3D sensors. Photogramm. Fernerkund. Geoinf. 2014, 2014, 117–127. [Google Scholar] [CrossRef]

- Dickin, F.; Pollard, S.; Adams, G. Mapping and correcting the distortion of 3D structured light scanners. Precis. Eng. 2021, 72, 543–555. [Google Scholar] [CrossRef]

- Eiríksson, E.R.; Wilm, J.; Pedersen, D.B.; Aanæs, H. Precision and accuracy parameters in structured light 3-D scanning. Int. Arch. Photogramm. Remote Sens. Spat. Inf. Sci. 2016, 5, W8. [Google Scholar] [CrossRef]

- Li, Y.; Chen, H.; Xi, N. Automatic programming for robotic grinding using real time 3D measurement. In Proceedings of the 2017 IEEE 7th Annual International Conference on CYBER Technology in Automation, Control, and Intelligent Systems (CYBER), Honolulu, HI, USA, 31 July–4 August 2017; pp. 803–808. [Google Scholar]

- Palousek, D.; Omasta, M.; Koutny, D.; Bednar, J.; Koutecky, T.; Dokoupil, F. Effect of matte coating on 3D optical measurement accuracy. Opt. Mater. 2015, 40, 1–9. [Google Scholar] [CrossRef]

- Freeform Lens: Optics: Freeform Optical Shapes. 2021. Available online: https://www.optimaxsi.com/capabilities/freeform-optics/#1516206949479-392f52b9-e81e (accessed on 4 October 2022).

- Schmitz, T.L.; Smith, K.S. Machining Dynamics: Frequency Response to Improved Productivity, 2nd ed.; Springer: New York, NY, USA, 2014. [Google Scholar]

- Kim, H.; Schmitz, T. Bivariate uncertainty analysis for impact testing. Meas. Sci. Technol. 2007, 18, 3565. [Google Scholar] [CrossRef]

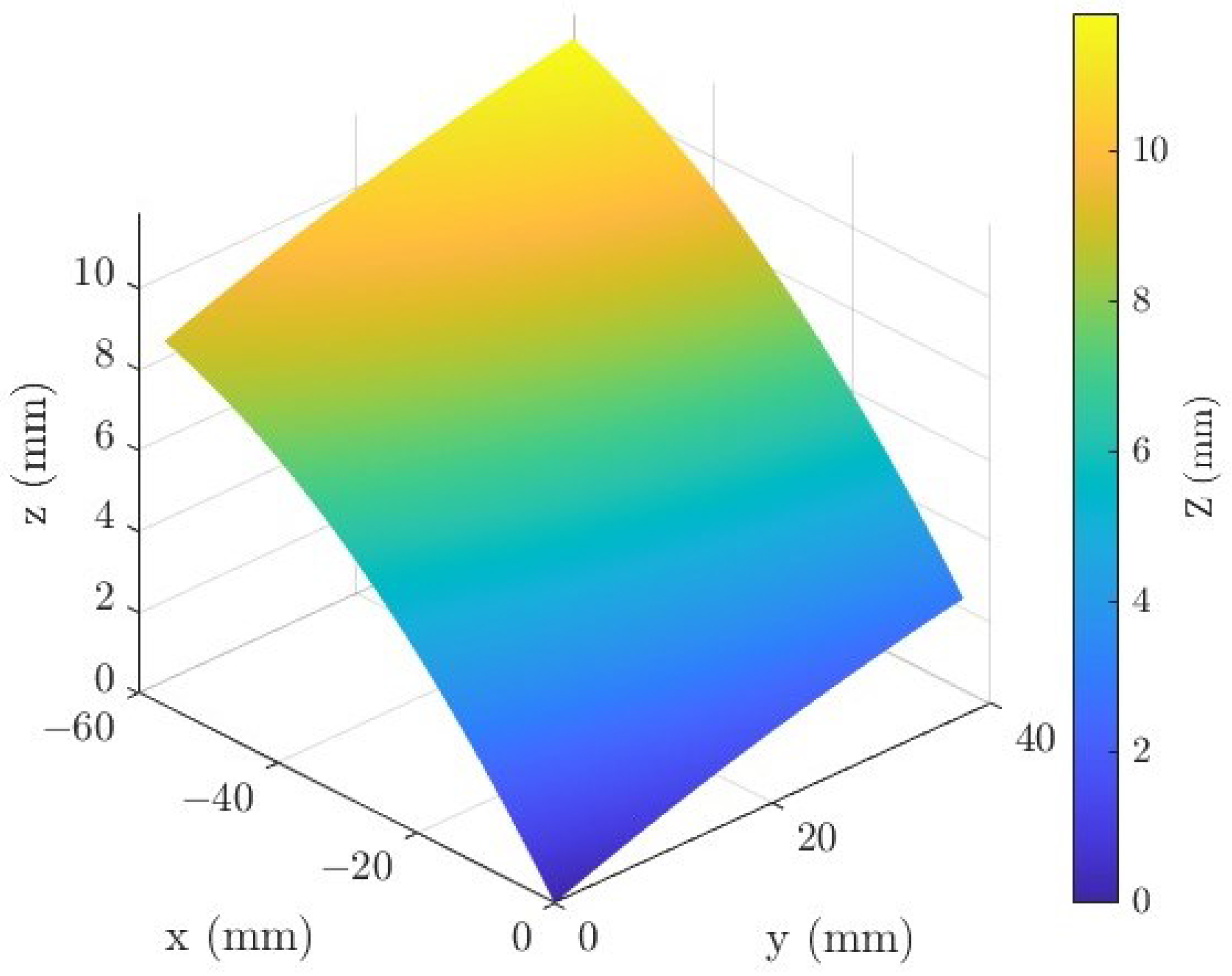

| X (mm) | Y (mm) | ||

|---|---|---|---|

| 18.75 to 75, 0.5 increment | −75 to −37.5, 0.5 increment |

| Parameter | 50% Saturation |

|---|---|

| Layer thickness (µm) | 100 |

| Y Droplet spacing (µm) | 34.4 |

| X Droplet spacing (µm) | 36.3 |

| Powder packing rate (%) | 40 |

| Last drop volume (pL) | 37.4 |

| Dry time between layers (s) | 15 |

| Roller speed (rpm) | 400 |

| Roller speed (mm/s) | 40 |

| SiC Ra before Machining μm | SiC Ra Post Machining μm | FFF Ra Post Machining μm |

|---|---|---|

| 34.6 | 9.7 | 2.08 |

| 31.1 | 9.5 | 1.95 |

| 30.1 | 9.3 | 2.29 |

| 38.9 | 8.9 | 2.39 |

| 38.1 | 7.7 | 2.68 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dvorak, J.; Gilmer, D.; Zameroski, R.; Cornelius, A.; Schmitz, T. Freeform Hybrid Manufacturing: Binderjet, Structured Light Scanning, Confocal Microscopy, and CNC Machining. J. Manuf. Mater. Process. 2023, 7, 79. https://doi.org/10.3390/jmmp7020079

Dvorak J, Gilmer D, Zameroski R, Cornelius A, Schmitz T. Freeform Hybrid Manufacturing: Binderjet, Structured Light Scanning, Confocal Microscopy, and CNC Machining. Journal of Manufacturing and Materials Processing. 2023; 7(2):79. https://doi.org/10.3390/jmmp7020079

Chicago/Turabian StyleDvorak, Jake, Dustin Gilmer, Ross Zameroski, Aaron Cornelius, and Tony Schmitz. 2023. "Freeform Hybrid Manufacturing: Binderjet, Structured Light Scanning, Confocal Microscopy, and CNC Machining" Journal of Manufacturing and Materials Processing 7, no. 2: 79. https://doi.org/10.3390/jmmp7020079

APA StyleDvorak, J., Gilmer, D., Zameroski, R., Cornelius, A., & Schmitz, T. (2023). Freeform Hybrid Manufacturing: Binderjet, Structured Light Scanning, Confocal Microscopy, and CNC Machining. Journal of Manufacturing and Materials Processing, 7(2), 79. https://doi.org/10.3390/jmmp7020079