Analysis of Tempering Effects on LDS-MID and PCB Substrates for HF Applications

Abstract

1. Introduction

2. Materials and Methods

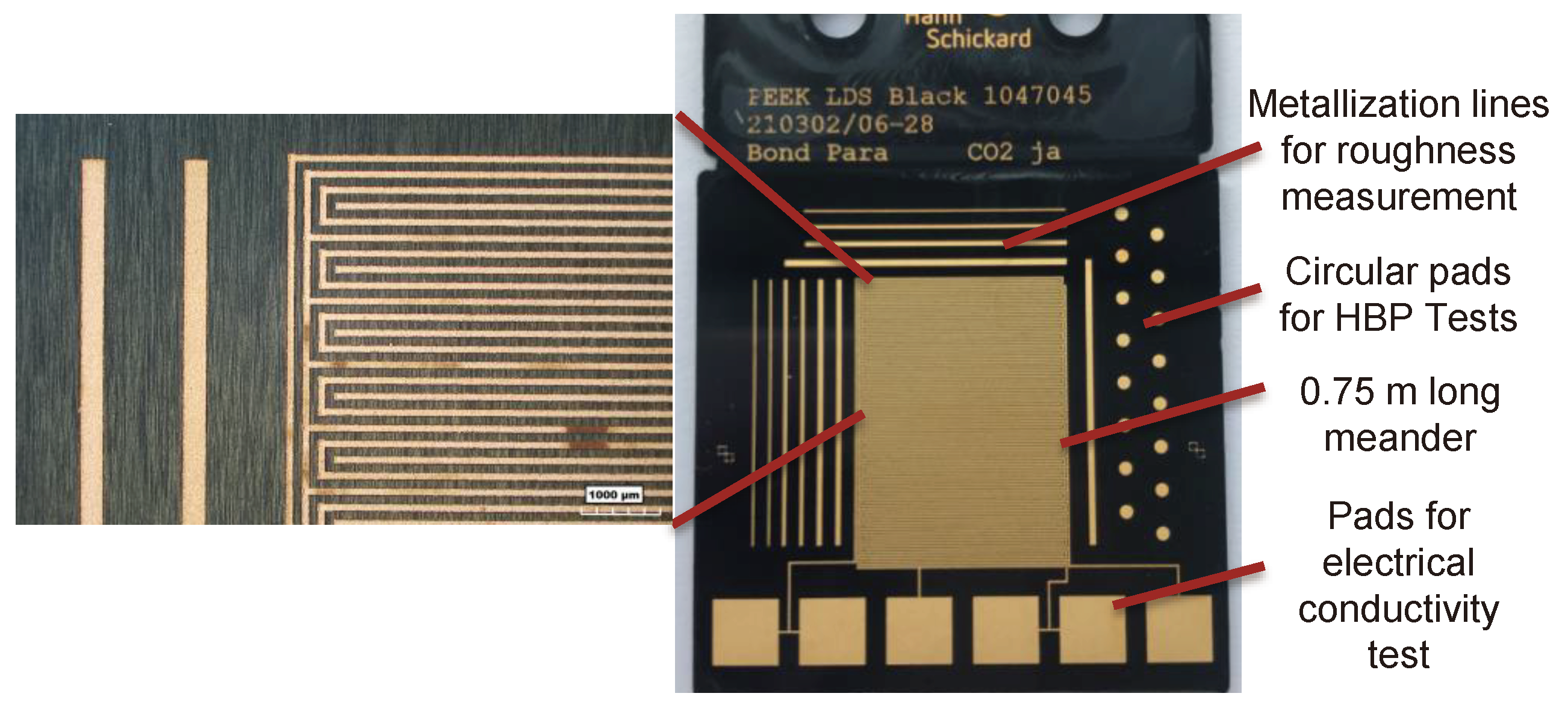

2.1. Substrate Materials and Layout

2.2. Metallization and Surface Finishes

2.3. Setup of Tempering Experiments

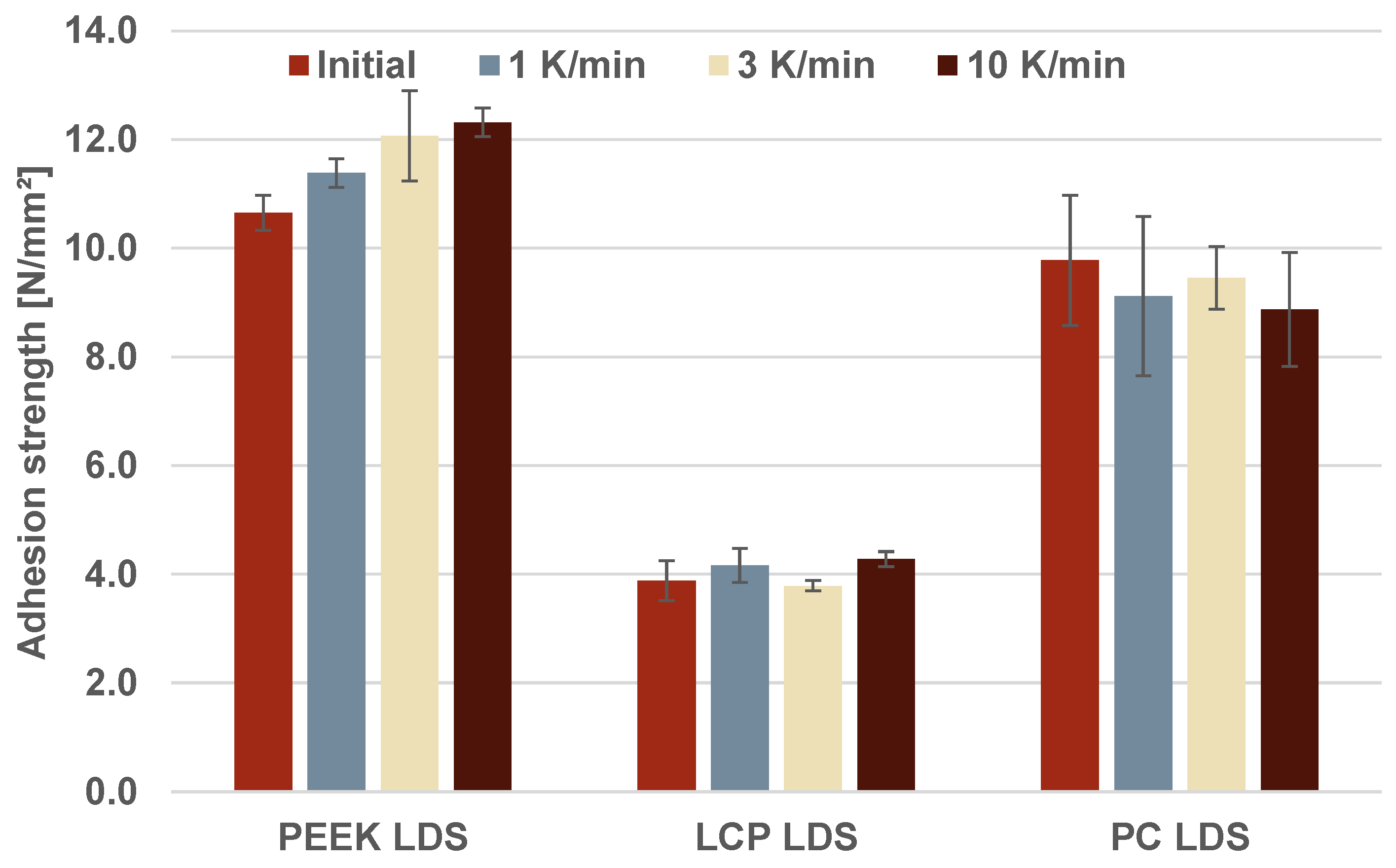

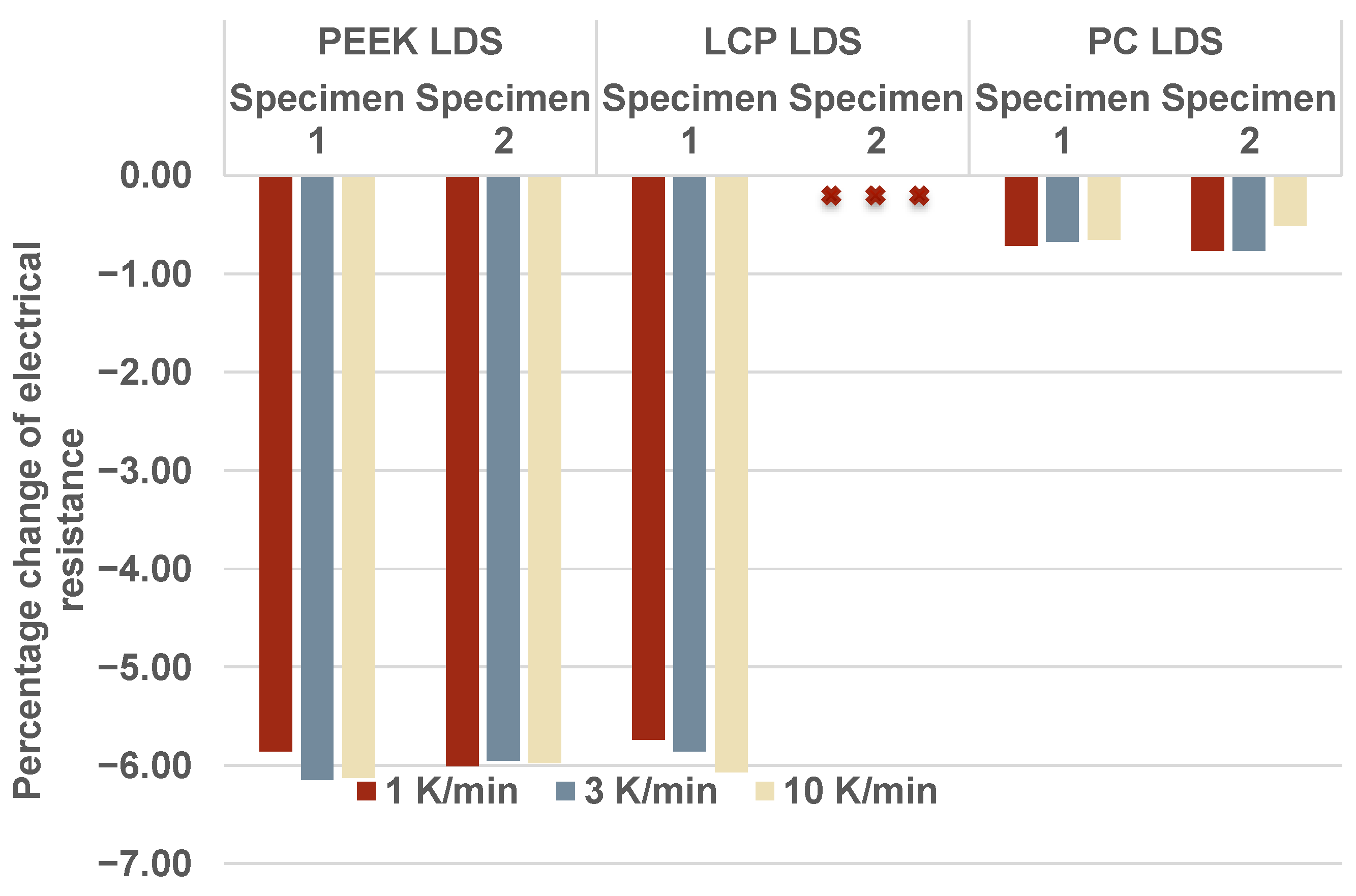

- Experiment 1 was carried out to investigate the effects of different heating rates on the LDS-MID substrates. The heating was performed at three different heating rates of 1 K/min, 3 K/min, and 10 K/min. The materials LCP LDS and PEEK LDS were held at 200 °C for two hours and the PC LDS was hold at 90 °C for four hours. The investigated surface finish was Ni/Au and the experiment was conducted in a vacuum. The temperature of 200 °C was chosen to match the temperature used in [16]. A value of 90 °C for PC LDS was chosen to be slightly higher than its glass transition temperature.

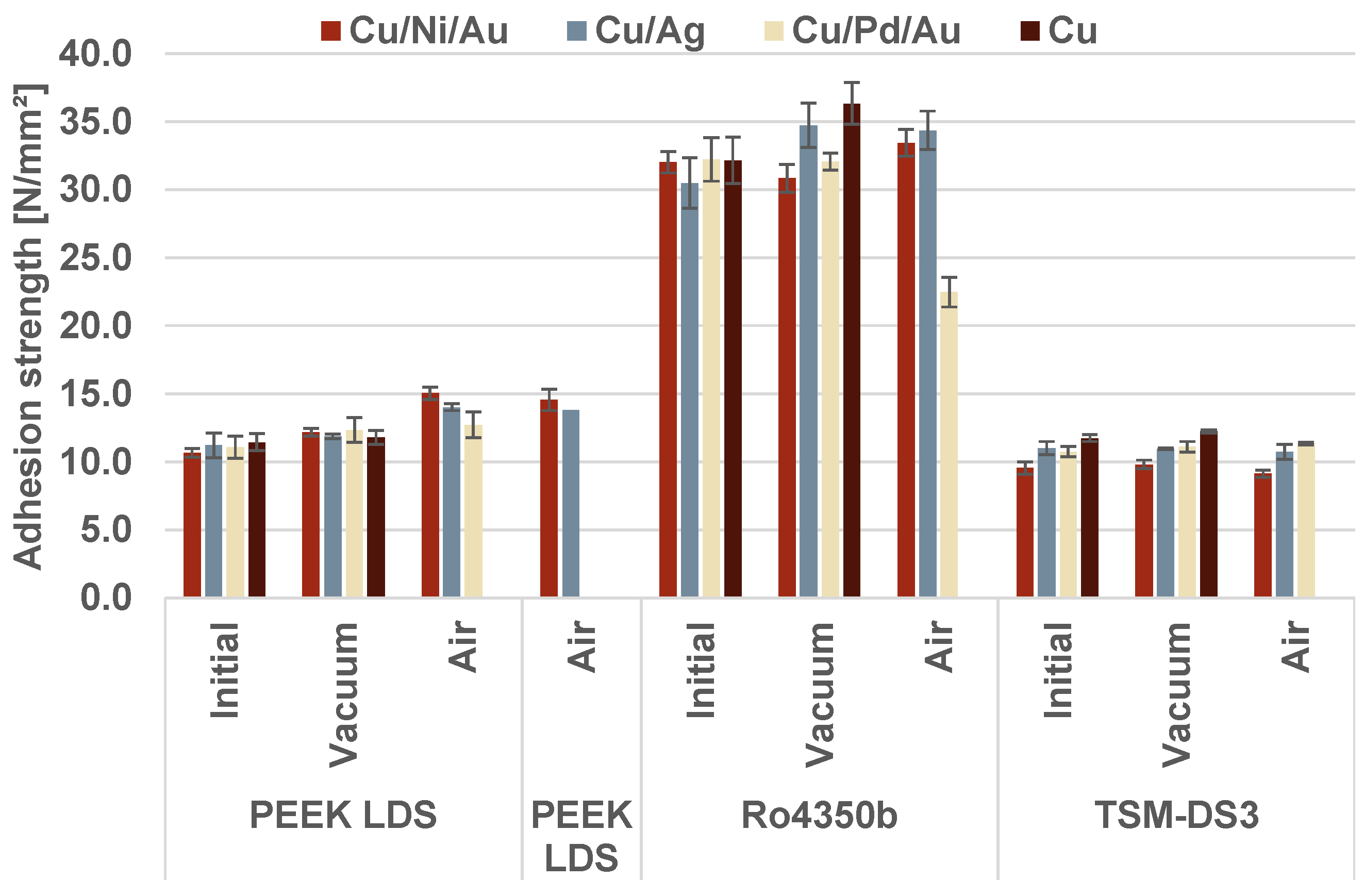

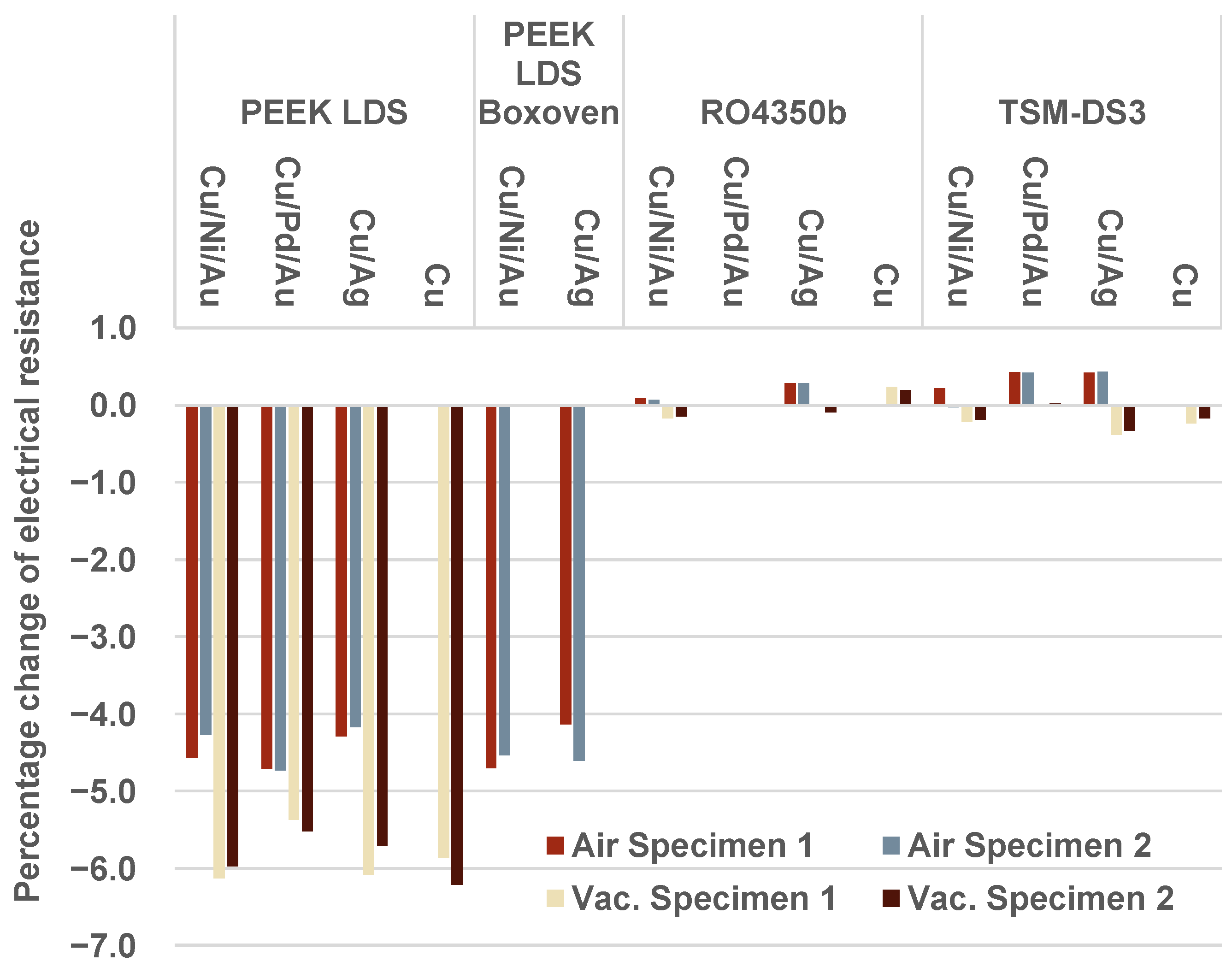

- Experiment 2 investigated the influence of tempering on different surface finishes. Pure copper metallization was used as well as copper metallization with Ni/Au, Ag and Pd/Au finishes on PEEK LDS, RO4350b and TSM-DS3 substrates. The heating rate was set to 10 K/min and the temperature was held at 200 °C for up to two hours. The presence of air during tempering was compared to tempering in a vacuum. Additionally, a box oven was used to temper PEEK LDS specimens with Ni/Au and Ag surface finish at 200 °C. The samples were placed directly into the oven, preheated to 200 °C, and removed after 2 h.

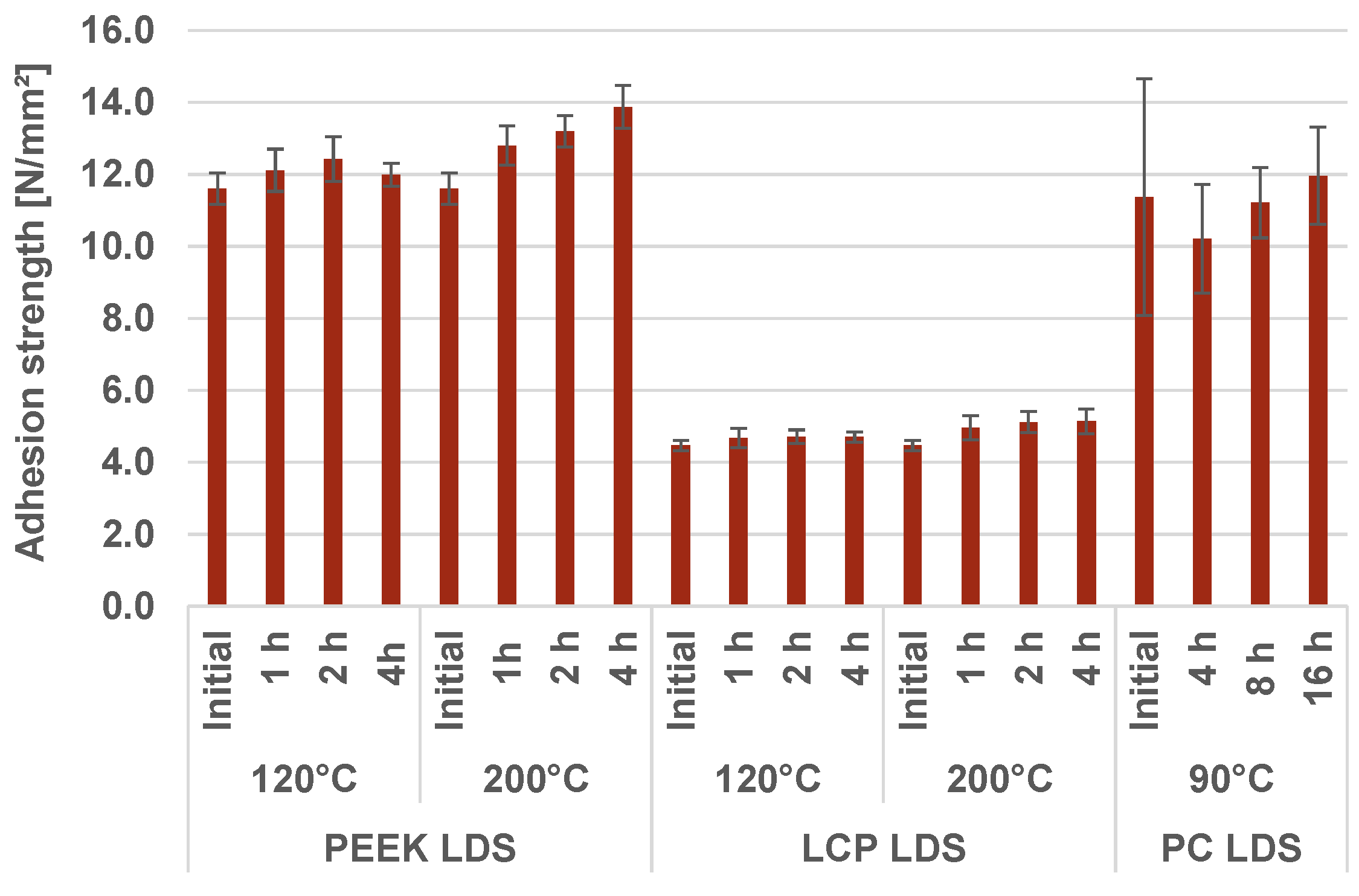

- Experiment 3 investigated the effect of longer tempering time and lower temperature on LDS-MID materials. The specimen were metallized with copper and Pd/Au surface finish. LCP LDS and PEEK LDS substrates were tempered for two, four and eight hours at temperatures of 120 °C and 200 °C, respectively. The PC LDS substrates were tempered for four, eight and sixteen hours at 90 °C. The heating rates for all substrates were set to 10 K/min.

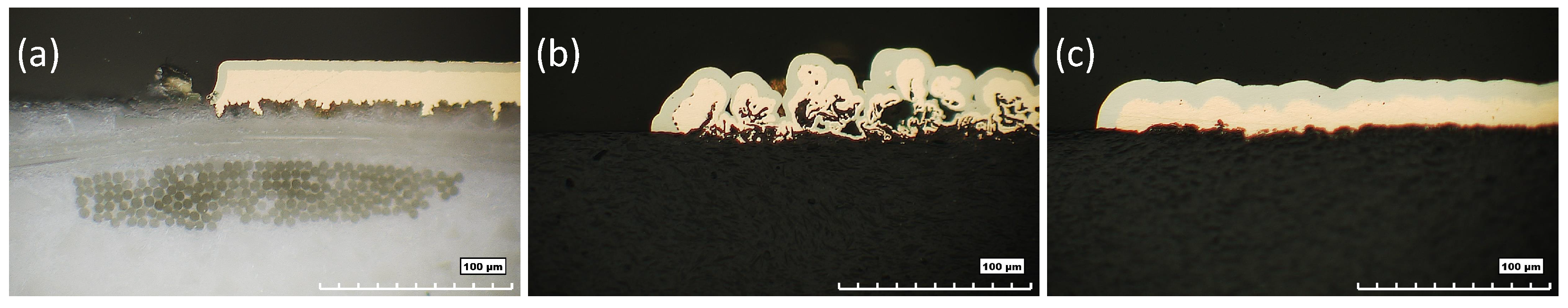

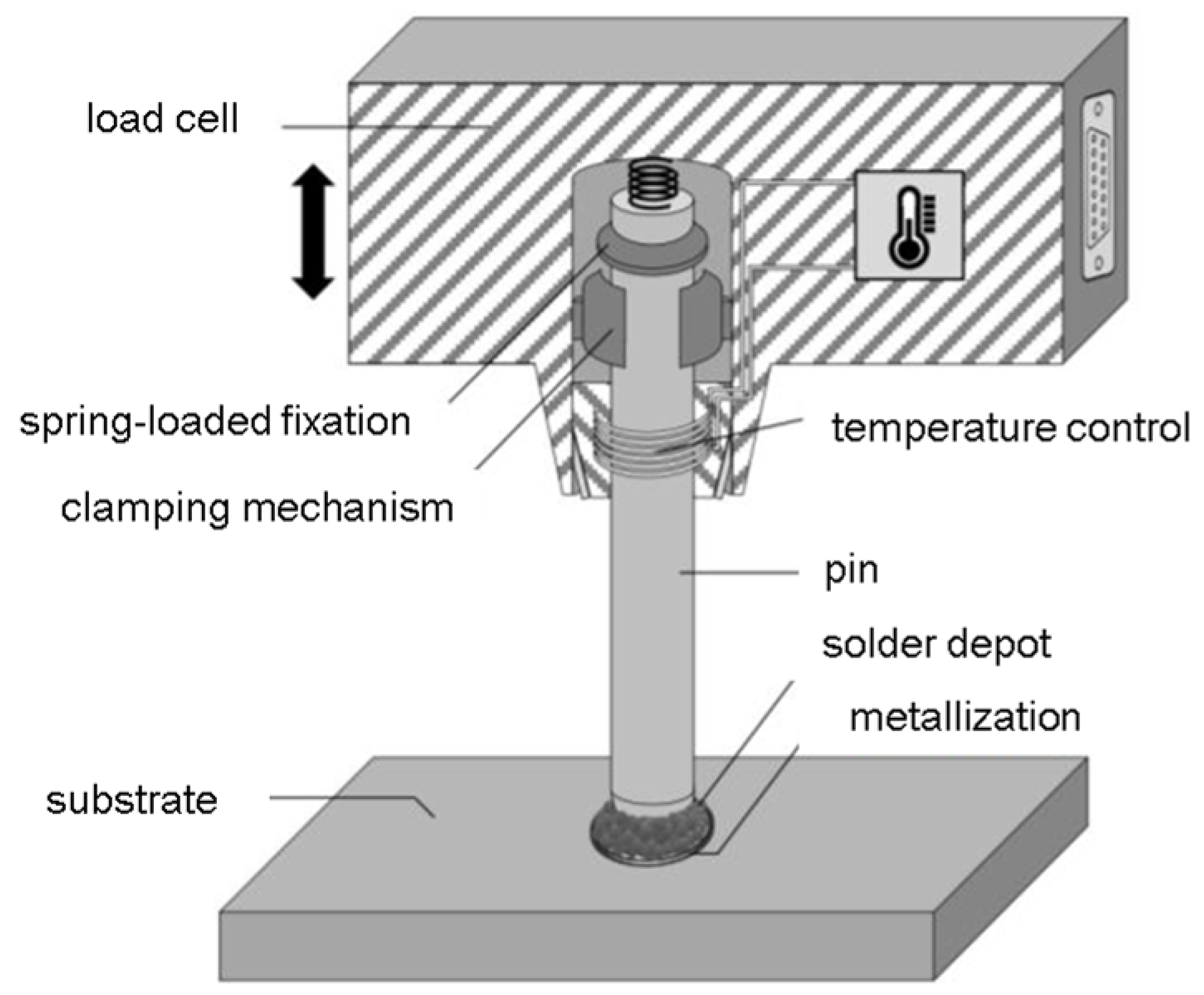

2.4. Characterization of Adhesion Strength by Hot-Bump-Pull Test

2.5. Dielectric Characterization by Capacitance Cell Measurement

2.6. Measurement of Electrical Resistance

3. Results

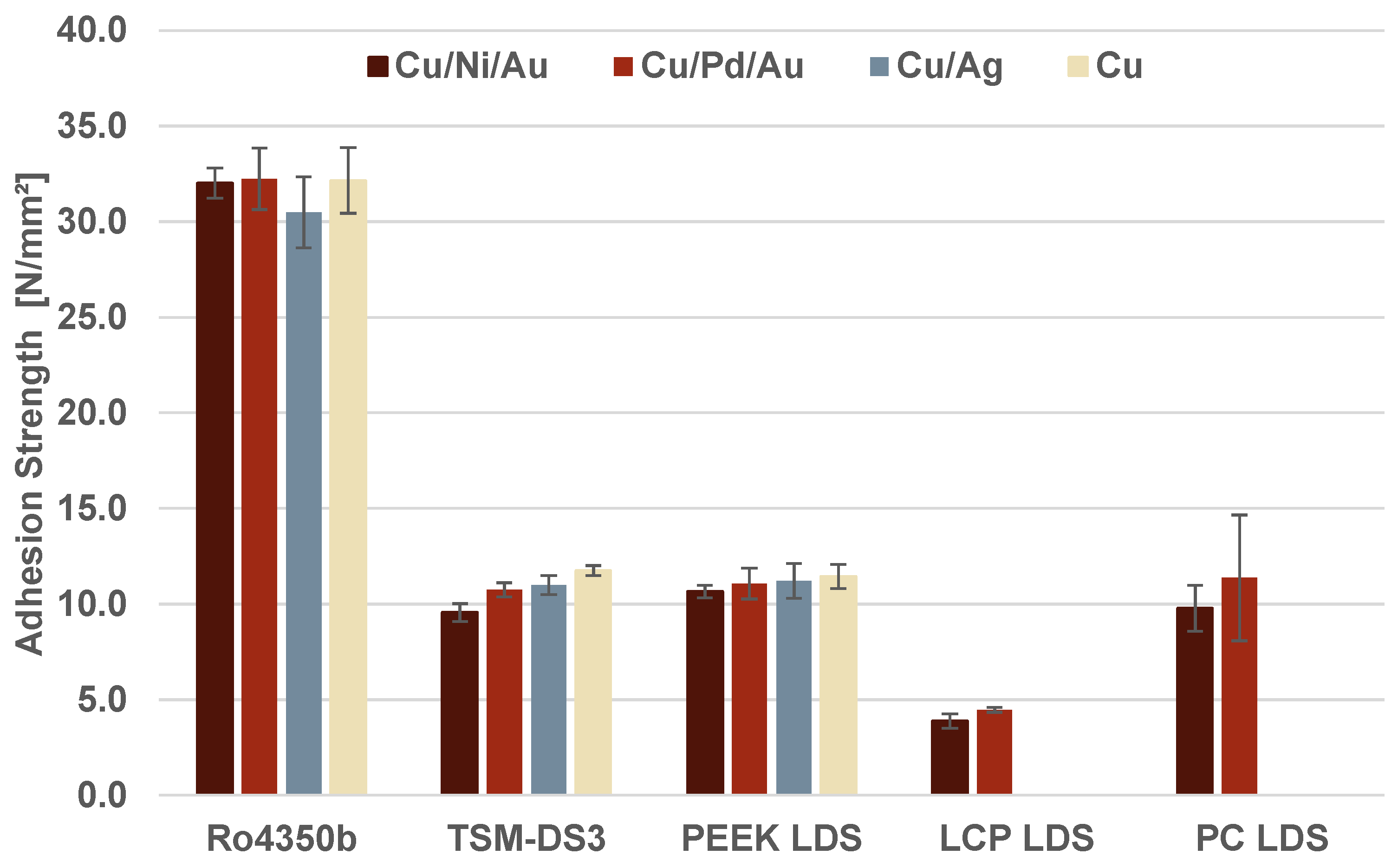

3.1. Initial Characterization of Adhesion Strength

3.2. Initial Characterization of Electrical Resistance

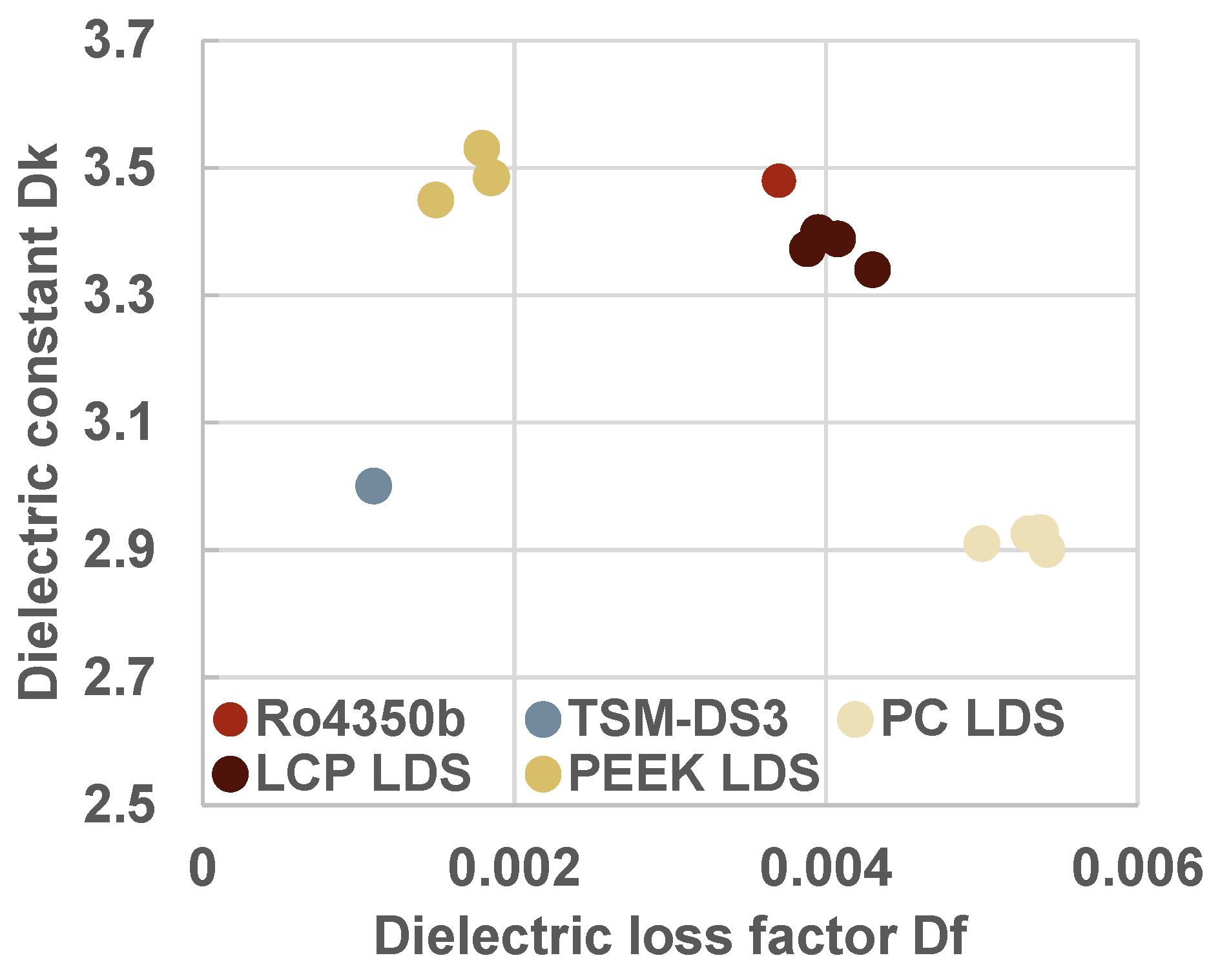

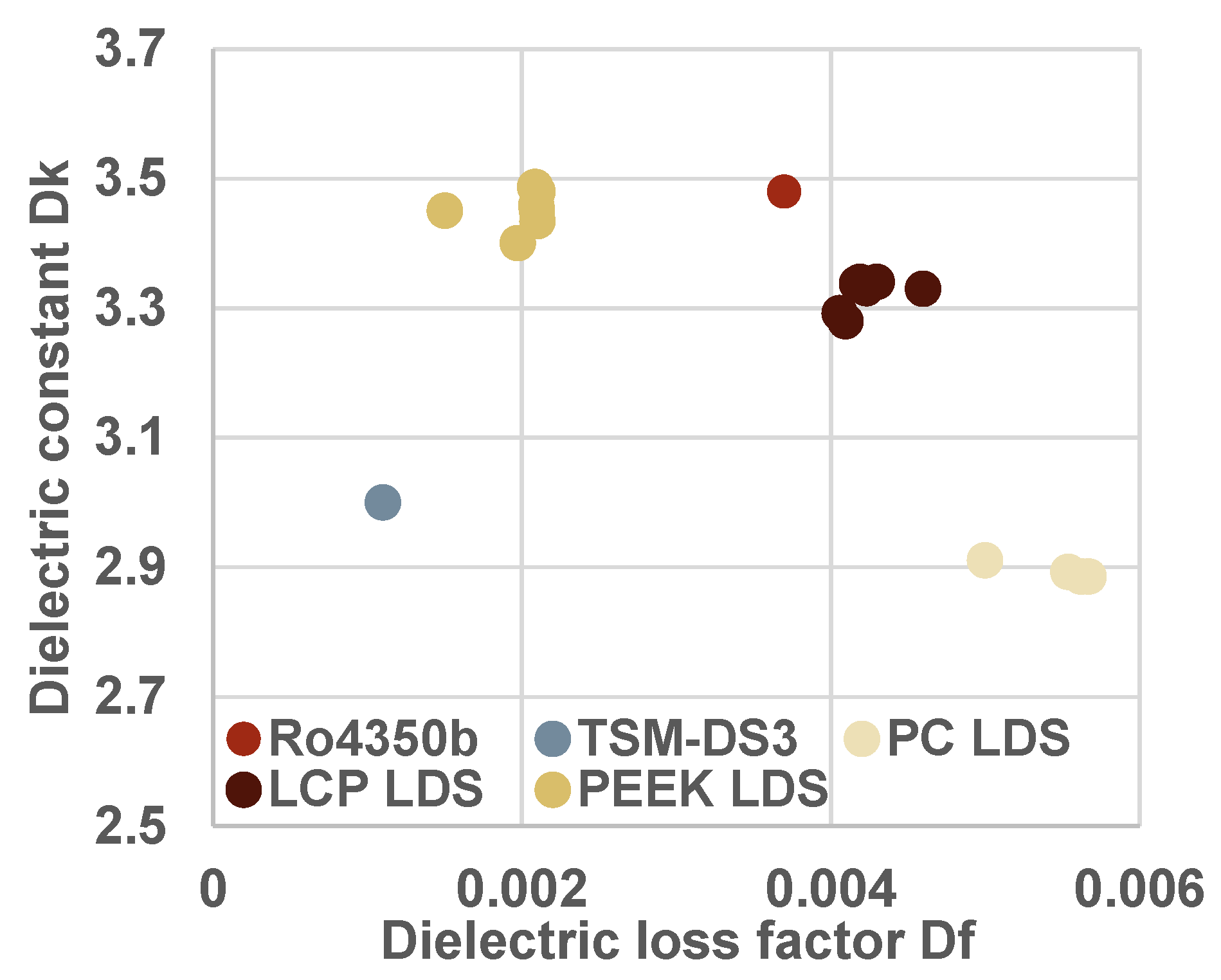

3.3. Initial Characterization of Dielectric Properties

3.4. Experiment 1: Effects of Different Heating Rates

3.5. Experiment 2: Effects of Different Metallization Surface Finishes and Tempering Atmosphere

3.6. Experiment 3: Effects of Different Tempering Times and Temperatures

4. Discussion

5. Conclusions

- Tempering of high temperature capable LDS-MID substrates can increase the adhesion strength of the metallization and lower the electrical resistance significantly.

- Tempering in air seems to be more beneficial as it increases the adhesion strength of the metallization much more than tempering in a vacuum as seen in experiment two. As delamination is high risk in many applications, the reliability of given devices will benefit therefor more from tempering in air.

- Tempering in a vacuum seemed to decrease the electrical resistance of the metallization on PEEK LDS substrates slightly stronger compared to tempering in air.

- The decrease in electrical resistance is mainly influenced by the tempering temperature and an increase in tempering time from one to four hours did not further decrease the electrical resistance.

- Tempering of PC LDS substrates reduced the electrical resistance of the metallization only marginally as the used temperature is to low to induce major changes in the metallization

- Tempering of PC LDS substrates did not improve the adhesion strength of the metallization but lowered the standard deviation. In experiment three the standard deviation of the measurements decreased from 3.3 m to values between 1.0 m to 1.5 m.

- Tempering of the HF PCB substrates did not affect the electrical resistance or adhesion strength of the metallization.

- The dielectrical properties of the LDS-MID materials were not influenced by the tempering processes.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| LCP | Liquid crystal polymer |

| PEEK | Poly-ether-ether-ketone |

| PC | Polycarbonate |

| PTFE | Polytetrafluoroethylene |

| Dk | Permittivity |

| Df | Dielectric loss factor |

| HF | High frequency |

| LDS | Laser direct structuring |

| MID | Mechatronic integrated devices |

| 5G | Fifth-generation technology standard for broadband cellular networks |

| PCB | Printed circuit boards |

| 3D | Three dimensional |

References

- Liu, D.; Pfeiffer, U.; Grzyb, J.; Gaucher, B. Advanced Millimeter-Wave Technologies: Antennas, Packaging and Circuits; John Wiley & Sons: Hoboken, NJ, USA, 2009. [Google Scholar]

- Elisabeth, S. Advanced RF packaging technology trends, from WLP and 3D integration to 5G and mmWave applications. In Proceedings of the 2019 International Wafer Level Packaging Conference (IWLPC), San Jose, CA, USA, 22–24 October 2019; pp. 1–5. [Google Scholar]

- 3dFortify Inc. Millimeter-Wave Hits the Mainstream, along with All the Challenges of High Frequency Design & Fabrication. Available online: https://www.microwavejournal.com/articles/36990-millimeter-wave-hits-the-mainstream-along-with-all-the-challenges-of-high-frequency-design-and-fabrication?page=2 (accessed on 6 March 2023).

- Franke, J. Three-Dimensional Molded Interconnect Devices (3D-MID); Carl Hanser Verlag: Munich, Germany, 2014. [Google Scholar]

- Eberhardt, W.; Weser, S. Cleaning Processes for Laser Based Fine Pitch Molded Interconnect Devices. In Proceedings of the 10th International Congress MID 2012, Nuremberg-Fuerth, Germany, 19–20 September 2012. [Google Scholar]

- Kildal, S.S.; Pfuhl, N.; Flamini, R.; Biscontini, B. Molded interconnect device (MID) design for base station antenna elements. In Proceedings of the 2016 IEEE International Symposium on Antennas and Propagation (APSURSI), Fajardo, PR, USA, 26 June–1 July 2016; pp. 1845–1846. [Google Scholar]

- Chen, Y.; Zhang, C.; Lu, Y.; Yang, W.W.; Huang, J. Compact dual-polarized base station antenna array using laser direct structuring technique. IEEE Antennas Wirel. Propag. Lett. 2020, 20, 78–82. [Google Scholar] [CrossRef]

- Molex-LLC. RHCP LDS SMT GPS Antenna. Available online: https://www.molex.com/molex/products/family/gnssgps{_}antennas (accessed on 6 March 2023).

- Glise, A.; Quéré, Y.; Maalouf, A.; Rius, E.; Castel, V.; Laur, V.; Sauvage, R. LDS Realization of High-Q SIW Millimeter Wave Filters with Cyclo-Olefin Polymers. Appl. Sci. 2018, 8, 2230. [Google Scholar] [CrossRef]

- Laur, V.; Mattei, J.L.; Vérissimo, G.; Queffelec, P.; Lebourgeois, R.; Ganne, J.P. Application of Molded Interconnect Device technology to the realization of a self-biased circulator. J. Magn. Magn. Mater. 2016, 404, 126–132. [Google Scholar] [CrossRef]

- Friedrich, A.; Geck, B.; Fengler, M.; Fischer, A. 24 GHz dielectric filled waveguide fed horn antenna using 3D-LDS MID technology. In Proceedings of the Microwave Conference (EuMC), 2016 46th European, London, UK, 4–6 October 2016; pp. 739–742. [Google Scholar]

- Friedrich, A.; Geck, B.; Fengler, M. LDS manufacturing technology for next generation radio frequency applications. In Proceedings of the 2016 12th International Congress Molded Interconnect Devices (MID), Wuerzburg, Germany, 28–29 September 2016; pp. 1–6. [Google Scholar] [CrossRef]

- Friedrich, A.; Fengler, M.; Geck, B.; Manteuffel, D. 60 GHz 3D integrated waveguide fed antennas using laser direct structuring technology. In Proceedings of the 2017 11th European Conference on Antennas and Propagation (EUCAP), Paris, France, 19–24 March 2017; pp. 2507–2510. [Google Scholar] [CrossRef]

- Seewald, S.; Manteuffel, D. Integration of a 28 GHz Beamforming Module into a Handset Device Using LDS-MID Technology. In Proceedings of the 2021 IEEE International Symposium on Antennas and Propagation and USNC-URSI Radio Science Meeting, Singapore, 4–10 December 2021. [Google Scholar]

- Seewald, S.; Manteuffel, D.; Wolf, M.; Barth, M.; Eberhardt, W.; Zimmermann, A. Low-Loss 3D-Coplanar Line Structure for Millimeter Wave Applications Using Laser Direct Structuring Technology. In Proceedings of the 2021 International Conference on Electromagnetics in Advanced Applications (ICEAA), Honolulu, HI, USA, 9–13 August 2021; p. 85. [Google Scholar]

- Nakahara, S.; Mak, C.; Okinaka, Y. Effect of Low-Temperature (100–200 °C) Annealing on the Ductility of Electroless Copper. J. Electrochem. Soc. 1991, 138, 1421. [Google Scholar] [CrossRef]

- Wheeler, H. Formulas for the Skin Effect. Proc. IRE 1942, 30, 412–424. [Google Scholar] [CrossRef]

- Mak, C.; Nakahara, S.; Okinaka, Y.; Trop, H.; Taylor, J. Annealing Behavior of Fine-Grained Electroless Copper Deposits. J. Electrochem. Soc. 1993, 140, 2363. [Google Scholar] [CrossRef]

- Koo, H.C.; Lightsey, C.; Kohl, P.A. Affect of Anneal Temperature on All-Copper Flip-Chip Connections Formed via Electroless Copper Deposition. IEEE Trans. Compon. Packag. Manuf. Technol. 2011, 2, 79–84. [Google Scholar] [CrossRef]

- Chen, L.; Crnic, M.; Lai, Z.; Liu, J. Process development and adhesion behavior of electroless copper on liquid crystal polymer (LCP) for electronic packaging application. IEEE Trans. Electron. Packag. Manuf. 2002, 25, 273–278. [Google Scholar] [CrossRef]

- Eisch, J.; Laskowski, J.; Bielinski, J.; Bolesławski, M. The deposition and adhesion of copper films on smooth polymer surfaces. J. Mater. Sci. Lett. 1995, 14, 146–147. [Google Scholar] [CrossRef]

- Okinaka, Y.; Nakahara, S. Hydrogen embrittlement of electroless copper deposits. J. Electrochem. Soc. 1976, 123, 475. [Google Scholar] [CrossRef]

- Okinaka, Y.; Straschil, H. The effect of inclusions on the ductility of electroless copper deposits. J. Electrochem. Soc. 1986, 133, 2608. [Google Scholar] [CrossRef]

- Lin, J.H.; Lee, T.L.; Hsieh, W.J.; Lin, C.C.; Kou, C.S.; Shih, H.C. Interfacial mechanism studies of electroless plated Cu films on a-Ta: N layers catalyzed by PIII. J. Vac. Sci. Technol. A Vac. Surfaces Film. 2002, 20, 733–740. [Google Scholar] [CrossRef][Green Version]

- Porta, G.M.; Foust, D.F.; Burrell, M.C.; Karas, B.R. Vacuum metallization of polyetherimide: Interfacial chemistry and adhesion. Polym. Eng. Sci. 1992, 32, 1021–1027. [Google Scholar] [CrossRef]

- Lee, C.H.; Kim, J.J. Self-annealing effect of electrolessly deposited copper thin films based on Co (ii)–ethylenediamine as a reducing agent. J. Vac. Sci. Technol. B Microelectron. Nanometer Struct. Process. Meas. Phenom. 2004, 22, 180–184. [Google Scholar] [CrossRef]

- Mitsubishi Engineering Plastics Corp. XANTAR LDS 3760® LDS 3760; Mitsubishi Engineering Plastics Corp: Tokyo, Japan, 2017. [Google Scholar]

- Ensinger GmbH. TECACOMP® LCP LDS Black 4107; Ensinger GmbH: Nufringen, Germany, 2016. [Google Scholar]

- Ensinger GmbH. TECACOMP® PEEK LDS Black 1047045; Ensinger GmbH: Nufringen, Germany, 2019. [Google Scholar]

- Rogers Corp. RO4000 Series High Frequency Circuit Materials Data Sheet; Rogers Corp: Chandler, AZ, USA, 2022. [Google Scholar]

- AGC Inc. TSM-DS3 Dimensionally Stable Low Loss Laminate; AGC Inc.: Tokyo, Japan, 2022. [Google Scholar]

- Kuhn, T. Qualität und Zuverlässigkeit Laserdirektstrukturierter Mechatronisch Integrierter Baugruppen (LDS-MID); FAU University Press: Erlangen, Germany, 2020. [Google Scholar]

- Hsu, H.H.; Lin, K.H.; Lin, S.J.; Yeh, J.W. Electroless copper deposition for ultralarge-scale integration. J. Electrochem. Soc. 2001, 148, C47. [Google Scholar] [CrossRef]

- Aithal, R.K.; Yenamandra, S.; Gunasekaran, R.; Coane, P.; Varahramyan, K. Electroless copper deposition on silicon with titanium seed layer. Mater. Chem. Phys. 2006, 98, 95–102. [Google Scholar] [CrossRef]

- Celanese Corp. Vectra® LCP Design Guide; Celanese Corp: Dallas, TX, USA, 2013. [Google Scholar]

- Monson, L.; Moon, S.I.; Extrand, C. Permeation resistance of poly (ether ether ketone) to hydrogen, nitrogen, and oxygen gases. J. Appl. Polym. Sci. 2013, 127, 1637–1642. [Google Scholar] [CrossRef]

| Substrate Material | Acronym | Technology | Matrix Material | Heat Distortion Temperature (°C) | Melting Temperature (°C) |

|---|---|---|---|---|---|

| Rogers Ro4350b | Ro4350b | HF-PCB | Thermoset | >280 | - |

| Taconic TSM-DS 3 | TSM-DS 3 | HF-PCB | PTFE | - | 321–344 |

| Xantar 3760 LDS | PC LDS | LDS-MID | PC | 103 | - |

| Tecacomp LCP LDS black 4107 | LCP LDS | LDS-MID | LCP | 274 | 320 |

| Tecacomp PEEK LDS black 1047045 | PEEK LDS | LDS-MID | PEEK | 255 | 343 |

| Substrate Material | Pre-Heating Phase | Peak Phase | Start of Pull Force | ||

|---|---|---|---|---|---|

| Temp. (°C) | Dwell Time (s) | Temp. (°C) | Dwell Time (s) | Temp. (°C) | |

| RO4350b TSM-DS3 PC LDS LCP LDS | 140 | 2 | 160 | 6 | 50 |

| PEEK LDS | 140 | 8 | 180 | 8 | 50 |

| Ro4350b | TSM-DS3 | PEEK LDS | LCP LDS | PC LDS | ||

|---|---|---|---|---|---|---|

| Transmission line width | (µm) | 104 | 104 | 65 | 69 | 83 |

| Transmission line height | (µm) | 17 | 15 | 11 | 13 | 11 |

| Cross section area | (µm²) | 1768 | 1560 | 715 | 897 | 913 |

| RO4350b (@10 GHz) | TSM-DS3 (@10 GHz) | PC LDS (@1 GHz) | LCP LDS (@1 GHz) | PEEK LDS (@1 GHz) | |

|---|---|---|---|---|---|

| Dk | 3.48 | 3.0 | 2.9 | 3.3 | 3.4 |

| Df | 0.0037 | 0.0014 | 0.006 | 0.005 | 0.0025 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wolf, M.; Werum, K.; Guenther, T.; Schleeh, L.; Eberhardt, W.; Zimmermann, A. Analysis of Tempering Effects on LDS-MID and PCB Substrates for HF Applications. J. Manuf. Mater. Process. 2023, 7, 139. https://doi.org/10.3390/jmmp7040139

Wolf M, Werum K, Guenther T, Schleeh L, Eberhardt W, Zimmermann A. Analysis of Tempering Effects on LDS-MID and PCB Substrates for HF Applications. Journal of Manufacturing and Materials Processing. 2023; 7(4):139. https://doi.org/10.3390/jmmp7040139

Chicago/Turabian StyleWolf, Marius, Kai Werum, Thomas Guenther, Lisa Schleeh, Wolfgang Eberhardt, and André Zimmermann. 2023. "Analysis of Tempering Effects on LDS-MID and PCB Substrates for HF Applications" Journal of Manufacturing and Materials Processing 7, no. 4: 139. https://doi.org/10.3390/jmmp7040139

APA StyleWolf, M., Werum, K., Guenther, T., Schleeh, L., Eberhardt, W., & Zimmermann, A. (2023). Analysis of Tempering Effects on LDS-MID and PCB Substrates for HF Applications. Journal of Manufacturing and Materials Processing, 7(4), 139. https://doi.org/10.3390/jmmp7040139