3.1. Cutting Forces

As mentioned previously, one of the parameters used for the analysis of the machining process was that of the cutting forces. This kind of data is quoted as being one important parameter to be monitored because it is one of the ways that material machinability could be evaluated, owing to the relation that the magnitude of cutting forces has with the tool wear, heat generation, accuracy, and quality of the final products [

24].

As there are different aspects of the cutting forces to be analyzed, for a better organization of the present section, this discussion was divided into different subsections, containing observations for the shapes of cutting graphs, maximum cutting forces, and machining stability of both samples.

3.1.1. Surface Deformation Effects on Cutting Forces

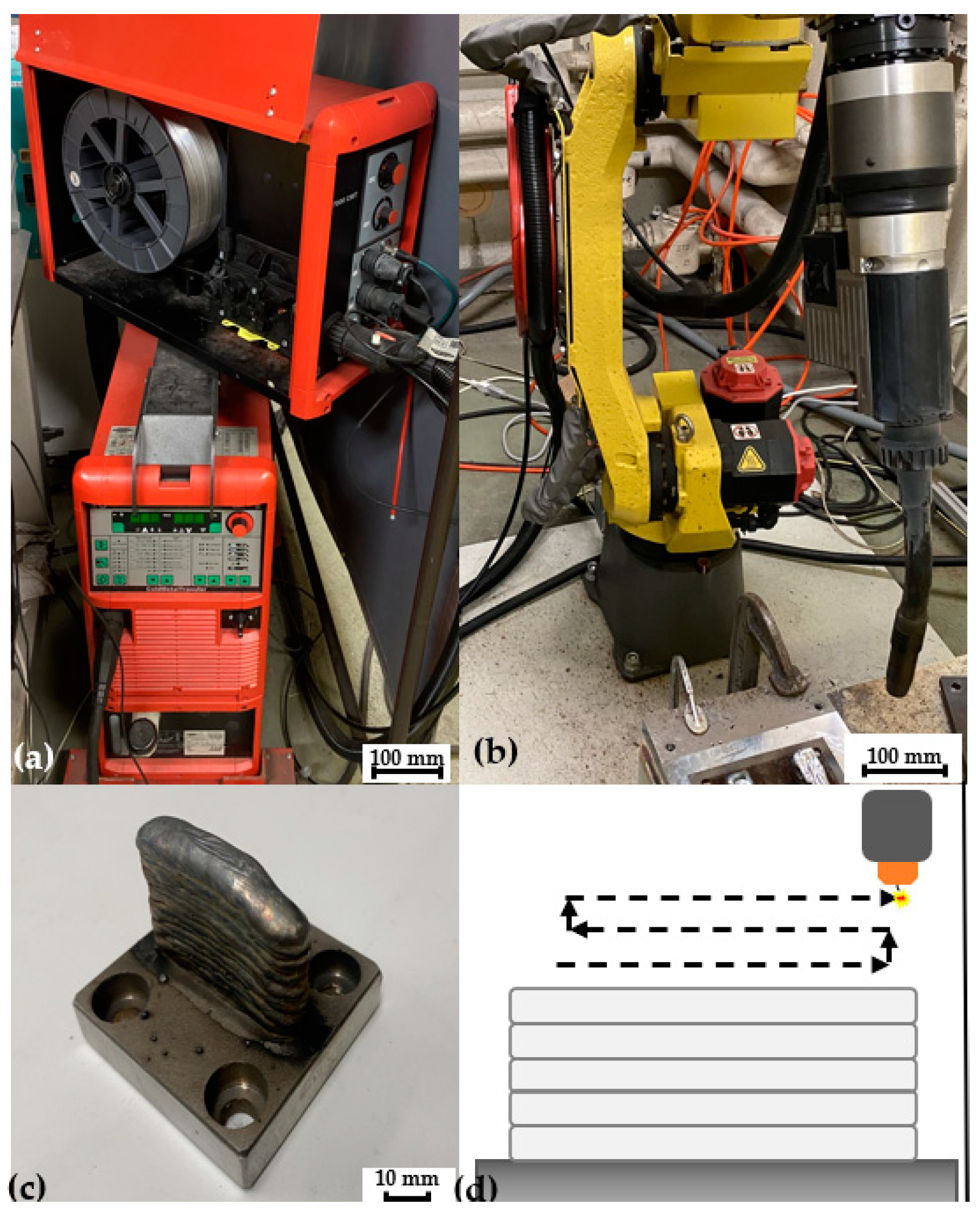

To evaluate the maximum cutting forces, only the last machining pass for each height was analyzed, with the idea of only assessing the machining of a flat surface. Owing to the surface deformation of the WAAM samples, as shown in

Figure 1c, the amount of material being cut (cutting depth) may vary, resulting in differences in the cutting forces. To exemplify this variation in the cutting forces owing to the deformation of the samples,

Figure 7 presents one graph representing the cutting forces for the first machining pass on the second height (12 mm) for case (a).

Figure 7 represents the cutting forces for the X-, Y-, and Z-axes for the second layer (12 mm of height from the top) and first machining pass, with a cutting depth of 0.3 mm. This graph shows the variations owing to the deformation of the samples manufactured using the WAAM technique.

These variances are explained by the differences in the amount of material removed by the machining step, with the sample distortions being more significant than the radial depth of the cut (0.3 mm) in that dimension, meaning that the actual radial depth of the cut would keep changing throughout the cutting procedure, explaining the variances of the cutting forces. This directly influences the first cutting passes’ results, making the comparison process more difficult. Accordingly, it was decided to leave this step out of the present study.

Although not present in this paper and not the objective of this study, it is important to mention that the machining of these irregularities present throughout the workpieces could represent some problems for the post-processing step. The abrupt increase and decrease in the depth of the cut cause these variations in cutting forces, and these changes could be responsible for causing unwanted wear and even tool breakage during the cutting procedure, making the machining of additive manufacturing samples even harder.

In the case of this research, however, the endmills were checked for possible excessive wear and breakage before the analysis of the cutting forces, and although some wear was present in all cases, including for the annealed samples, it was considered to be minimum, especially when taking into account the difficulty in machining Inconel 718; it was discarded that the deformation and its impact in the machining process played an important role in the results that will be further discussed in the posterior topics.

One example of pictures of cutting tools after machining for each type of material (WAAM (a), AMS5662 (b)) is present in

Figure 8, highlighting the area of wear by a red circle, that was considered of low impact to the cutting procedure.

Another important observation to be made is regarding the stability of the cutting procedure. Being a new kind of setup and a different kind of sample to be machined, it was deemed important to consider the possibility that problems, such as chatter vibration, would occur during the cutting process; with that, a set of experiments were performed to check that possibility with the aid of an accelerometer. The setup of the experiments is shown in

Figure 9.

The data to be gathered from this kind of experiment would be both cutting forces from the dynamometer and frequency from the accelerometer. While the dynamometer showcases data in the form of cutting forces (N), the accelerometer and software only yield data in frequency after a fast Fourier transform (FFT) analysis. The idea behind this experiment is to check the vibration signals (frequency) and compare them with the natural frequency of vibration of the system; the deviations from the range of the natural frequency could be deemed as anomalies, such as chatter vibrations.

The natural frequencies that would be acting as standard for the vibration signals gathered were calculated using the equations previously proposed for a cantilever beam presented below [

25].

where

E is the Young modulus of the material,

M is the mass,

I is the moment of inertia,

Y is the displacement,

L is the beam length,

β is the constant for cantilever beam vibration, and

ω is the natural frequency.

From Equations (1) and (2), it was obtained that the first harmonic for the system in question is 153 Hz, meaning that when vibrations from this range are obtained from the accelerometer, it is assumed that the vibration is the natural frequency for the system and not from some kind of abnormality. One example of the results of cutting forces and frequency of vibration, called Case 1, is shown in

Figure 10.

It is possible to observe from

Figure 10, that, although the cutting forces present a variable nature, due to the geometry of the cutting samples, which could increase the possibility of unwanted vibrations, the vibration signals are primarily located in the range of 150 Hz, highlighted by the circle in red, the natural frequency of the system that was calculated previously, meaning no possible anomalies had been observed during the cutting process.

Although there are some different factors that could affect the cutting process and induce unwanted vibrations, it is assumed that the data acquisition and clamping system used throughout this research are not causes for unwanted vibrations, and with that, the testing procedure could proceed.

3.1.2. Maximum Cutting Forces

With the considerations stated in the previous topic in mind and for a better understanding of the influences of the different characteristics of the products owing to their manufacturing processes and the cutting conditions in the milling of Inconel 718 products, the maximum values for the X- and Y-axes for the last machining pass at each height are plotted in a graph in

Figure 11.

From

Figure 11, it can be seen that the cutting force values for the X-axis do not present significant differences, making it possible to consider the same overall maximum value for all cases. Moreover, these values do not increase significantly after multiple cutting passes, indicating that, even though this material is hard to cut, the degree of tool wear was minimal.

However, when considering the Y-axis, a different trend can be perceived; the WAAM sample (case (a)) presents higher values overall. Even though the values themselves do not differ greatly, they were higher for all cases and could even be thought of as significant when considering the fact that the two cases are composed of the same kind of alloy.

When analyzing the cutting forces, is difficult to draw any conclusion comparing the maximum values for cutting forces alone. Due to the nature of the machining process, it is possible that different fluctuations occur, and with that, the maximum cutting force value would not be a good representation of the process as a whole. For that, the analysis of the graphs of the cutting forces could complement this step, and for that, in the next topic, this kind of analysis is performed.

3.1.3. Machining Pass Analysis

For the next research stage, the last machining pass of the second height (12 mm from the top) at a depth of 2.1 mm was studied. The cutting data collected using the dynamometer were plotted as two graphs, one for each parameter (a, and b), and these results are presented in

Figure 12.

By comparing

Figure 7 and

Figure 12, the influences of the deformations of the sample caused by the additive manufacturing process on the cutting forces become more evident, with

Figure 12 showing a more even shape across the cutting process for all cases. This demonstrates that the material removal is constant throughout the procedure for the last cutting pass, indicating the removal of a flat surface. The authors also visually confirmed this by observing the samples before each machining pass.

Even though the surface of the AM products is flat, because no machining is performed on the sides and tops of the samples, the material is still irregular on the sides of the sample. These differences can be observed by the sudden diminishing trend in the cutting forces detected when the cutting procedure is nearing its end; this is noted on all axes but is more accentuated on the X- and Y-axes.

When further comparing both materials, the WAAM samples seem to present a higher variation, with higher peaks of the cutting forces overall, as opposed to the annealed sample, which had almost a “linear” shape for each of the graphs after its peaks. It is also interesting to note that the Y axis presented more variations in the cutting forces when compared to the X axis for case (a), having an elevated presence of peaks, making the graph for this axis appear more irregular than that of the other axes.

What was mentioned previously, regarding the analysis of the maximum cutting forces (

Figure 11), is better observed in

Figure 12; that is, while the annealed sample presented almost no variability in the cutting force values, the WAAM workpieces, especially for the Y-axis presented peaks that were not consistent with the shape of the graph, presenting instability that likely affected the maximum cutting force values.

Another point worth mentioning is that, although being a side-milling operation, the Z-axis was not expected to have major differences in their profile, for case (a); the variation in Z-axis cutting forces is more significant when compared to case (b), indicating some sort of instability in the cutting procedure.

3.1.4. Single-Cycle Cutting Forces

To further understand the cutting forces’ stabilities, as shown in

Figure 12, the corresponding discussion is presented. In this study, the graphs of a single cycle (0.075 s), that is, a 360° rotation of the cutting tool of a specific cutting route, were observed to obtain more profound insights. To acquire a more accurate representation of the side-milling step, the last pass of a particular height was analyzed in a manner similar to the previous evaluations to observe the cutting of a more even surface and avoid surface deformations influencing the analysis.

Figure 13 presents one graph of each studied case (a, b) for the second height.

From

Figure 13, different characteristics of the machining processes can be observed. First, the graphs present a visible distance between the cutting and non-cutting intervals, that is, between the periods in which there is actual contact with the edge of the blade for the process of material removal (higher values of cutting forces) and those in which the material removal (cutting) process is not present (cutting forces close to zero Newtons).

The above-mentioned characteristic is observed because there are only two flutes on the endmill, causing the cutting force profile to be composed of two different cutting peaks. It is also important to mention that not only the material and the number of flutes of the endmill are influences in the cutting force values, but also different kinds of parameters like the cutting tool geometry are also important factors that one should look for when observing the cutting force procedure.

Regarding this aspect, it has been reported that for side milling, an increase in the helix angle of a cutting tool will decrease the peak cutting forces [

26]. The rake angle also plays an integral part in the cutting force differences. Thus, changing the rake angles of cutters can directly influence the surface finishes of samples [

27].

Regarding the values themselves, although the WAAM results in

Figure 13 present lower cutting forces, they present slightly higher maximum cutting forces, as observed in

Figure 11. Although a single cycle picked at random might have lower values, there are peaks of cutting forces causing disturbances in the process throughout the whole procedure, as was already discussed in this paper.

3.1.5. Simulation Procedure (Material Analysis)

It was chosen to perform an additional procedure to identify the best differences in the cutting forces. Focusing on the cutting force values for both the AM and annealed samples for one tooth of the endmill, it was determined that performing a simulation was the best option.

Considering the differences in the cutting forces presented in this study, it can be seen that the Z-axis does not show much variability. This is expected because the research in question is being performed as side-milling operations. With this in mind, the cutting force values for the Z-axis were not simulated.

For the simulation process, the endmilling process was modeled using a mechanistic model [

28]. The cutting forces (

F) were derived using the previously proposed equations and processes described below.

With “

q = (

x,

y,

z)” and “

fi”, the feed rate of the experiment can be simulated. By integrating Equation (1) in terms of the entry and exit angles (

θst and

θex), Equations (4) and (5) corresponding to the X- and Y-axes, respectively, can be obtained as follows:

When following the modeling process and focusing on Equations (4) and (5) for the cutting forces on the X- and Y-axes, the feed rate, entry and exit angles, number of teeth for the cutting tool (N), and width of the cut (a) are already known. However, there is still a need to acquire data for the calculation of the shearing force cutting coefficients and plowing force cutting coefficients for the tangential (Ktc) and radial (Krc) directions. Thus, different machining steps were performed with varying feed rates for both the annealed and WAAM samples.

The average values of the cutting forces were plotted in different graphs from the data acquired from the machining experiments. The values for

Ktc,

Kte,

Krc, and

Kre were derived from a linear regression. The simulation was performed, and a graph representing the cutting forces from a single cutting tooth for both the WAAM and annealed samples is shown in

Figure 14.

As shown in

Figure 14, the simulated values, particularly for the WAAM sample (a), share high similarity with the experimental results. Even though the values for the annealed sample are not as similar, they are still considered satisfactory by the authors.

When comparing the cases among themselves as opposed to the maximum cutting force graph seen in

Figure 11, and similar to the results in

Figure 12, the annealed sample presents lower values, especially for the Y-axis. This indicates that the machinability might be better for the annealed sample and reinforces the idea that certain problems might have occurred during the machining process of this type of sample.

When considering the shape of the simulated graphs, for both simulated and experimental data for the different samples, it is possible to observe that although the WAAM samples presented a higher variability overall, presenting especially in the peak of the graphs a “wavy” appearance of the cutting forces, in contrast with the other graphs that present a more “straight” form. And although those variations are higher when compared with the annealed case, it is considered not as significant when compared with the difference in values for cutting forces themselves.

The possible causes for those instabilities or oscillations on the cutting forces on the WAAM samples are better explained in

Section 3.3 where the differences in the materials and their influence on the machining process are further explored.

3.1.6. Average Resultant Cutting Forces (Material Analysis)

To further evaluate the machinability of both samples, another graph was produced. For that, the average resultant cutting forces for both kinds of samples, WAAM and annealed, were calculated for five different feed rates (80, 120, 160, 200, and 240 mm/min), and were plotted into a graph. The graph of the resultant cutting forces for each feed per tooth is presented in

Figure 15.

When analyzing

Figure 15, the trend that was observed previously from the cutting force analysis contained in this topic is more easily perceived. That is, the cutting forces for the WAAM samples presented higher values than those of the annealed samples, for all analyzed parameters.

The presence of higher cutting forces could be a hindrance to the machining process for different kinds of reasons. First, although not observed for the machining of the samples in question, this increase in forces is linked with chatter vibration and faster tool wear, possibly causing early breakage of tools and decreasing the surface quality of the samples.

From the productivity standpoint, when lower cutting forces are involved, more “aggressive” parameters such as higher feed per tooth could be selected, increasing the material removal rate, and consequently being able to increase productivity without having negative effects on the machining procedure.

It is interesting to also observe that when considering the values of cutting forces for each axis, the differences between the two kinds of samples are not considered great, but when those “small” differences add up for the three axes, the resultant cutting forces present a significant difference for each feed per tooth.

A related point to consider when analyzing the cutting forces is that for both kinds of samples, there is a growth in the overall values of resultant forces as the feed rate increases. This trend is explained by the fact that the chip load per tooth increases as the feed rate rises; that is, the amount of material being removed by the cutting tool blade is increased, requiring more force for the material removal; similar results are found in the literature for the milling of Inconel 718 [

29].

Even though a growth trend was observed for the cutting forces with the increase in the feed rate, extrapolating this tendency of growth for different parameters such as cutting speed might lead to erroneous conclusions. And even though the optimization of those parameters was not the focus of this research, it is deemed necessary to better explore these kinds of differences between the materials.

Another critical aspect of the machining analysis is the finished products themselves. However, the instabilities of the cutting forces suggested that differences in surface quality could occur and could only be assessed after a thorough examination. For this reason, the next section presents an evaluation of the surfaces of the machined samples.

3.2. Surface Quality

To assess the surface quality of the samples after machining, two steps were performed. The first step was to analyze the visual aspects of the pieces, and the second was a surface roughness measurement process.

3.2.1. Surface Appearance

To evaluate the appearance of the samples, pictures were first taken at a macro level with a regular digital camera as shown in

Figure 15 and then with the aid of a microscope as shown in

Figure 16. The photographs were taken with the aim of noticing different aspects of the samples, such as feed marks and possible imperfections owing to chatter vibrations.

In performing only the side-milling process, certain irregularities, such as the deformations at the top and sides of the WAAM sample (cases (a)), were not removed, as mentioned in the previous section. However, when evaluating the machined area itself, it can be seen that flat surfaces with no significant apparent distortions are achieved in all cases.

Moreover, the staircase aspect of the samples is well discerned with the differences between the heights visible to the naked eye, indicating that no significant deformation has occurred. However, when considering the deformations and possible imperfections on the surfaces of the machined samples, a more precise conclusion can be drawn only with higher magnification.

Figure 17 presents pictures of the sample surfaces after machining at a higher magnification as taken using a USB microscope.

Figure 17 shows clear differences between the machined surfaces. It can be seen that the cutter marks are not as visible as in the first picture. In addition, this case presents different irregularities on the surface, indicating a possible instability in the cutting process. Case (b), however, has a more stable surface and exhibits no significant irregularities. The cutter marks presented in the last case also appear less spaced, possibly indicating better results in terms of surface roughness.

The authors hypothesize that these differences in stability and apparent variabilities in the surface can be explained (as in the cutting forces topic) by the anisotropy and differences in microstructures between the samples. The less stable cutting with possible variations on the removed chips causes the surface to have a worse overall visual aspect.

Regarding the microstructure, different research explores the possibility of this kind of property influencing the surface profile. For instance, when comparing samples with different grain sizes, it was described that the material removal process was affected by this characteristic, having the grain size determining the uniformity of deformation, and possibly affecting the surface profiles [

30].

When considering additive manufactured samples and, more specifically, workpieces with microstructure composed of dendritic structures, investigations regarding differences in this kind of microstructure, achieved by changing the chemical composition, concluded that the machining of more homogenous microstructures achieved better surface profiles, owing to better stability in the material removal process, due to this more homogeneous microstructure [

31].

In other words, the idea behind this instability is that the deformation process that occurs during the metal cutting is constantly being disturbed due to the microstructure and its differences. The resistance that is offered by the material during cutting might change due to those differences, and with that, the “easiness” for the material to be removed changes as well, and the machining process becomes unstable. Reflecting, then, on the results that are shown in this paper, this process and differences are further explored in

Section 3.3.

Another aspect that can directly influence the surface quality of the parts is the wear of the cutting tools. Unfortunately, this characteristic is not further discussed herein due to the differences in the material removed (cutting length and volume).

In the next topic, a more thorough examination of the surface quality and surface roughness is presented.

3.2.2. Surface Roughness Analysis

As mentioned previously, to evaluate the surface quality of the machined samples beyond the visual aspects, the surface roughness values of the machined products were measured according to the International Organization for Standardization 4288 [

32]. A contact-based measurement system comprising a profilometer (Kosaka Laboratory Surfcorder ET 200), equipment with reproducibility of 1 σ 0.3 nm or less and resolution of 0.1 nm for Z and 0.1 μm for X, was used to acquire the values for Ra (average of the profile measurements), Rz (the sum of the values for the highest peak and depth), and RSm (the average of the profile widths) [

33]. The tests were performed 10 times in different locations for each case, with the movement of the stylus being performed in the direction of the milling, having the stylus traveling 4.8 mm, with an evaluation length of 4 mm and 0.8 mm of sampling length.

The parameters to be analyzed were chosen based on the idea that the Ra and Rz measurements are the most used values for roughness analyses in industrial environments [

34]; the RSm values were also used for observations. The average results of these tests are presented in

Table 4. In addition, the values for the average surface roughness (Ra) are shown in

Figure 18 in the form of a graph for easier visualization.

Different sample characteristics are observed in the surface roughness tests after the machining. First, when comparing the WAAM and annealed materials, the latter achieves better results, with lower average surface roughness values and lower variations in the valley peaks and depths. This indicates that the annealed samples are “easier to cut” than the WAAM samples. In addition, the best surface quality overall, as evaluated by the surface roughness tests, was achieved in case (b), i.e., the annealed sample.

Although the differences between the measured surface roughness averages from (a) to (b) might not be considered significant variations (especially when considering actual product applications), together with the other aspects of machinability discussed herein, this type of disparity is another indicator of the machinability differences between the two different types of samples.

Also important to mention is that even though the AMS5662 sample presents higher values for Vickers microhardness, the results from both the surface roughness average and visual aspect are worse for the WAAM sample, in opposition to what is to be expected considering this parameter alone. As discussed previously, the instability of the cutting process for WAAM is thought to be the main reason behind those differences.

A further point worth discussing is that even though it was discoursed previously that the tools after cutting presented no excessive damage, and the volume of material removed was considered small, considering the difficulty of machining the Inconel 718 alloy for both wrought and AM, the tool wear could be a hindrance to the cutting procedure, affecting the results for roughness and cutting forces as well.

The causes of the machinability distinctions for the WAAM and AMS5662 samples were initially only considered to arise from the influences of the microstructure and anisotropic characteristics, but further explanations were considered necessary. Thus, the next subsection introduces a more thorough explanation of the machinability differences between the two types of materials, focusing on the microstructures and anisotropy but also exploring different possibilities, such as the mechanical properties’ influences on the machining procedure.

3.3. Material-Affected Machinability

In

Section 2.2, certain differences between both types of materials were discussed. Among those variations, grain size was quoted as one of the main distinctions. As this characteristic was hypothesized by the authors as having a possible impact on machinability comparisons, the influence of this characteristic on the same type of alloy was already one focus of this study.

When researching the different effects of the grain size in the post-processing of Inconel 718, it was reported that workpieces with larger grain sizes are linked to higher cutting forces and a higher degree of wear, as affected by the relationship between the grain size, undeformed chip thickness, and anisotropic properties [

35].

Although the boundary density may be weaker for large grain sizes, the deformation occurring during the machining process is highly irregular. As there are fewer neighboring grains able to act as a bond, irregular deformation is not inhibited and causes disturbances in the process.

In the present study, the samples differed in regard to grain size, and the microstructures of the WAAM Inconel 718 were uneven. The differences in the size and directionality of the grains could cause variations in the cutting forces not observed in the wrought samples.

Another point mentioned previously is the anisotropy characteristic of the WAAM samples. The highly textured microstructures of AM workpieces, mainly owing to the dendritic formations, as opposed to the uniformity of the grains of AMS5662, could lead to constant changes in the required cutting forces for the material removal process.

These dendritic formations are not exclusive to AM samples; this type of microstructure has also been reported in Inconel 718 samples manufactured by casting. Even though the casting procedure does not repeat the cyclic nature of the thermal history of AM, the increase in temperature for melting and sudden decrease in temperature as the sample material is hardened are responsible for the formation of this type of microstructure.

Although there are differences between the AM and cast material properties, because they share the same type of microstructure and there are examples of research regarding the machining of this type of product, it was considered that an analogy could be drawn.

Similar to the comparison between the machining of different grain sizes and results from the present research, the machining of large dendritic structures (as-cast) and fine-equiaxed-grain structures had different cutting forces from the machining of the dendritic structures and presented higher values. These differences were explained to be caused by irregular deformations owing to the sizes of the dendritic structures [

36].

Another peculiar aspect of the dendrites that differentiates them from the usual equiaxial grain structure is the fact that in the grains that present this kind of structure, not only the dendrites are present, but structures that are usually called interdendritic regions occur. These structures that show an absence of dendritic formations are also present in the WAAM Inconel 718.

It is explained that the dendritic and interdendritic regions share differences in micromechanical properties, owing primarily to the chemical composition differences between the two regions [

37].

Those variations in micromechanical properties, like microhardness, could affect the machining process, as those variations are quoted as having a strong relation to the abrasion resistance, influencing aspects like tool wear and surface quality [

38].

Those changes that happen throughout the whole sample being cut could represent minor fluctuations in the cutting forces, causing unwanted instability during the cutting procedure. Also, although not explored in the present research, this instability could increase the wear of the cutting tools.

With these minor fluctuations of material removal mechanisms, the variations found on the cutting forces graphs are explained and, together with the previously mentioned points, represent one of the possible causes for the machinability differences encountered in this research.

Other authors also explore the possibility of the additive-manufacturing-deposition-induced microstructure directly affecting the machining process. For the particular case of the Inconel 718 and its microstructure, which is composed of columnar dendrites, not only the relation between cutting and dendritic directionality was studied, concluding that the machining process and its results are different with the different dendrites’ direction [

39] but also trying to improve the machining stability by performing different deposition strategies to change this directionality and consequently the relation between dendrites and cutting tool [

40].

Although in this topic, the focus of the explanations regarding the differences in machinability between the two different kinds of materials was given to the differences in microstructure and anisotropy, it is important to mention that other properties might influence the milling procedure as well.

Material hardness is one of those already discussed in the present paper. And even though it might influence the machining procedure and tool life, the AMS5662 presents higher values of hardness than those of the WAAM Inconel 718 manufactured for this research, an aspect that did not end up reflecting in the results obtained. However, when considering the peculiarities of the AM products, it is also important to mention that for both wrought and WAAM Inconel 718, there is a presence of MC carbide deposits, which are abrasive material deposits that could negatively influence the machining process [

41], for both types of samples.

Another property that, along with the hardness, is quoted as having a direct effect on the cutting forces is the tensile strength. It is known that the high values for both hardness and tensile strengths are associated with low machinability, which affects the cutting forces [

42]. As explained previously, the AMS5662 presents higher tensile and yield strength for this kind of property. This difference in the strength of the materials could also be quoted as being one more aspect that could have been influential in causing the difference in cutting forces and machinability overall.

Another aspect of the manufacturing process that could hinder the machining process and the products themselves is the appearance of different defects that could happen throughout the deposition process. Porosity is quoted as one of the main concerns in the production by AM [

43]; this kind of structure could lead to the initiation of cracks, which could be formed for different reasons, such as the lack of fused material, trapped gases, and even contaminants [

44].

Apart from the structural defects that the pores could be directly linked, it is explained that these kinds of structures directly influence the machining process, making the cutting procedure more difficult, linking the increase in porosity with the higher instability of the cutting forces, higher surfacer roughness, and faster tool wear [

45]. Even though this kind of formation could also appear in WAAM samples, due to it usually not being considered a problem for this specific kind of production process for most alloys [

13], its influence was considered negligible and is not present in the discussions of the present paper.

Also not present in the discussions, in an isolated manner, is the anisotropic behavior of the WAAM Inconel 718. Although quoted as being a possible influence on the machining process, the effect of the anisotropy of this kind of product was not explored. To set apart the effects of this kind of property without the influence of the other characteristics of the sample was not achieved by the authors.

As explained in this topic, there are different characteristics that could make the machining process differ among the samples, and isolating the effect of each property would be a difficult task, mainly considering the effect of the microstructure on the different mechanical properties.

With that, although it is hypothesized that the microstructure and anisotropy played an important role in the effects of the material removal process, further research is deemed necessary to try and understand the possible different effects of those characteristics on the material removal process.