Effects of Oil Concentration in Flood Cooling on Cutting Force, Tool Wear and Surface Roughness in GTD-111 Nickel-Based Superalloy Slot Milling

Abstract

:1. Introduction

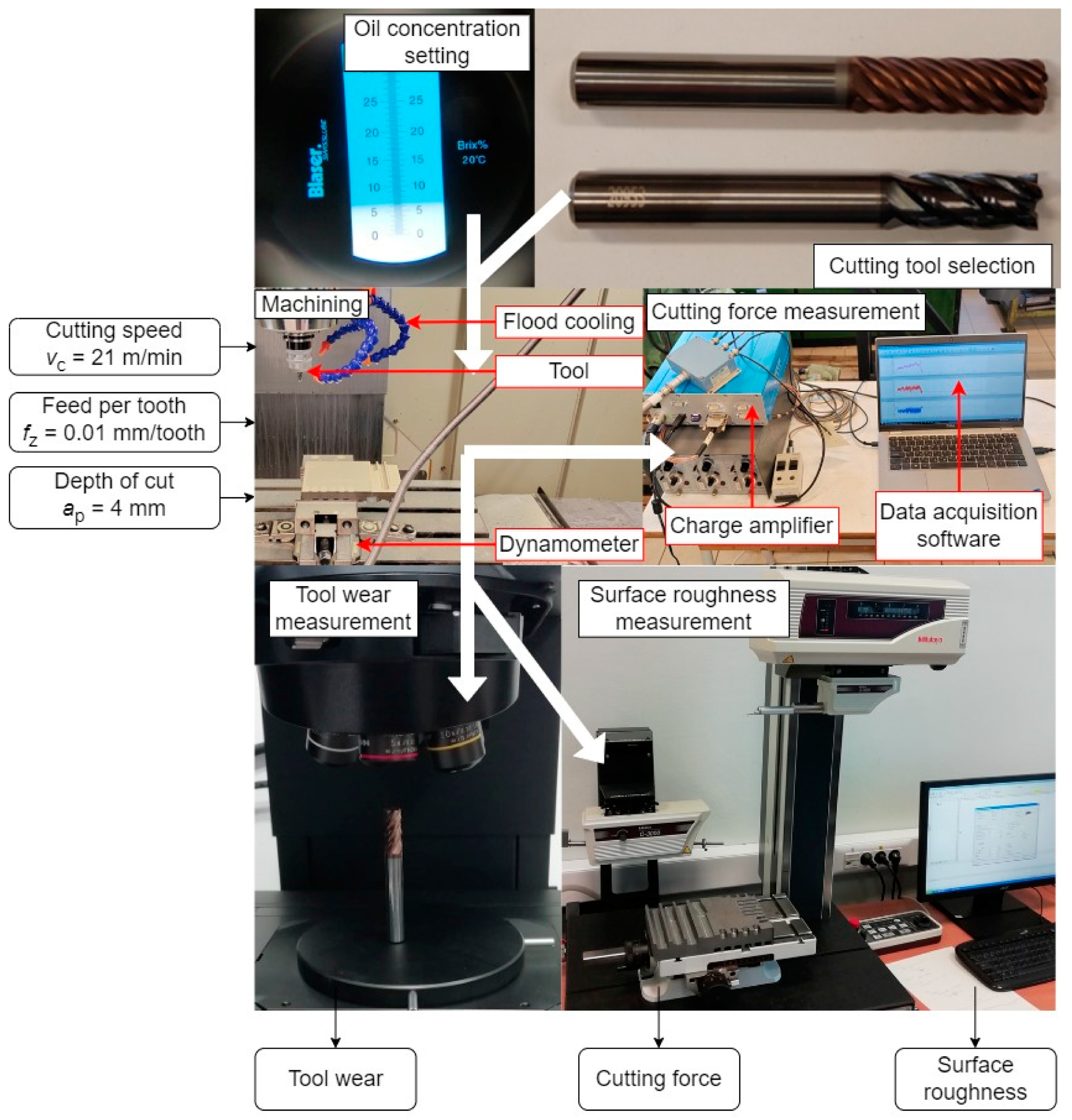

2. Materials and Methods

2.1. Experimental Procedure

2.2. Material

3. Results

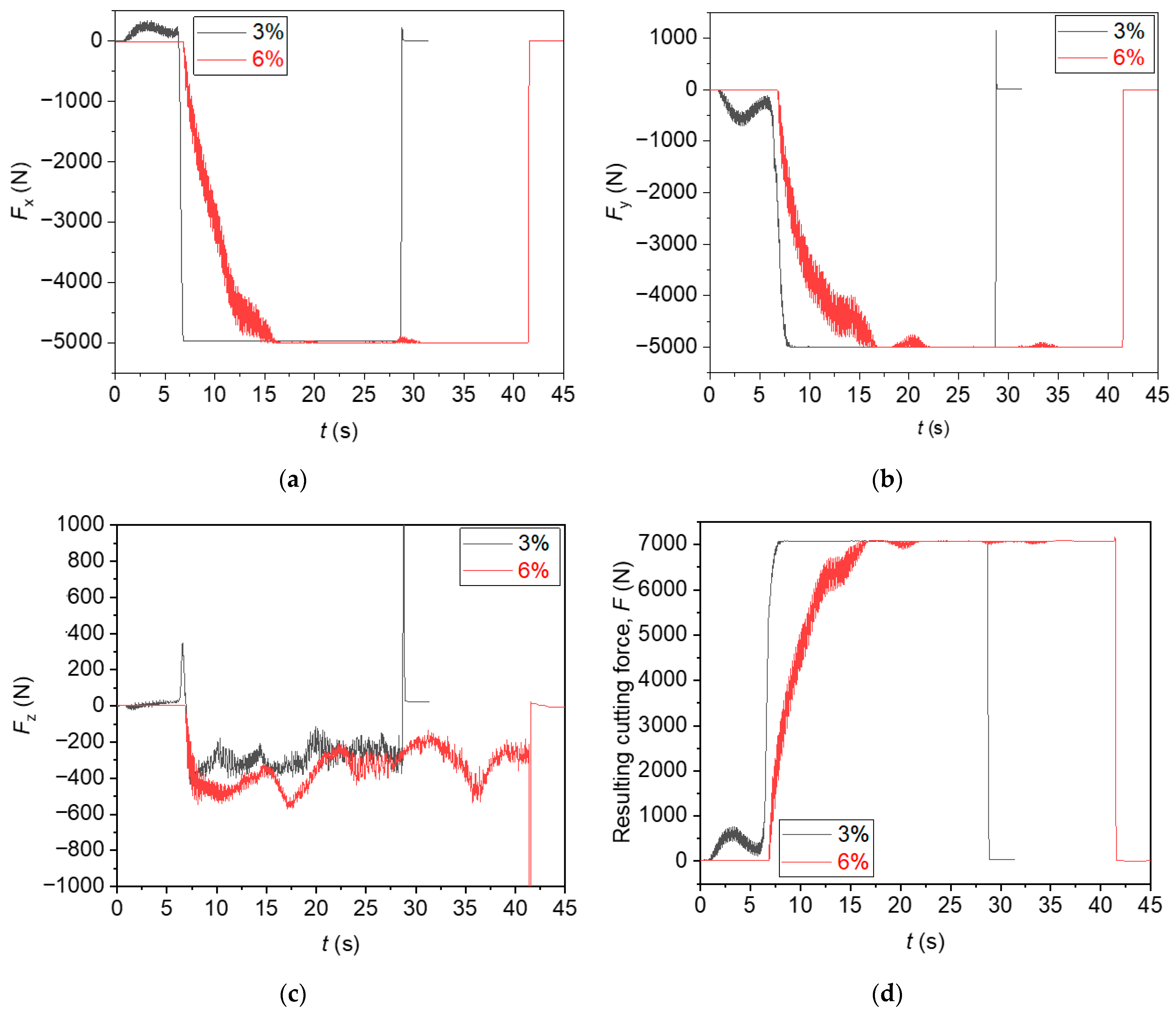

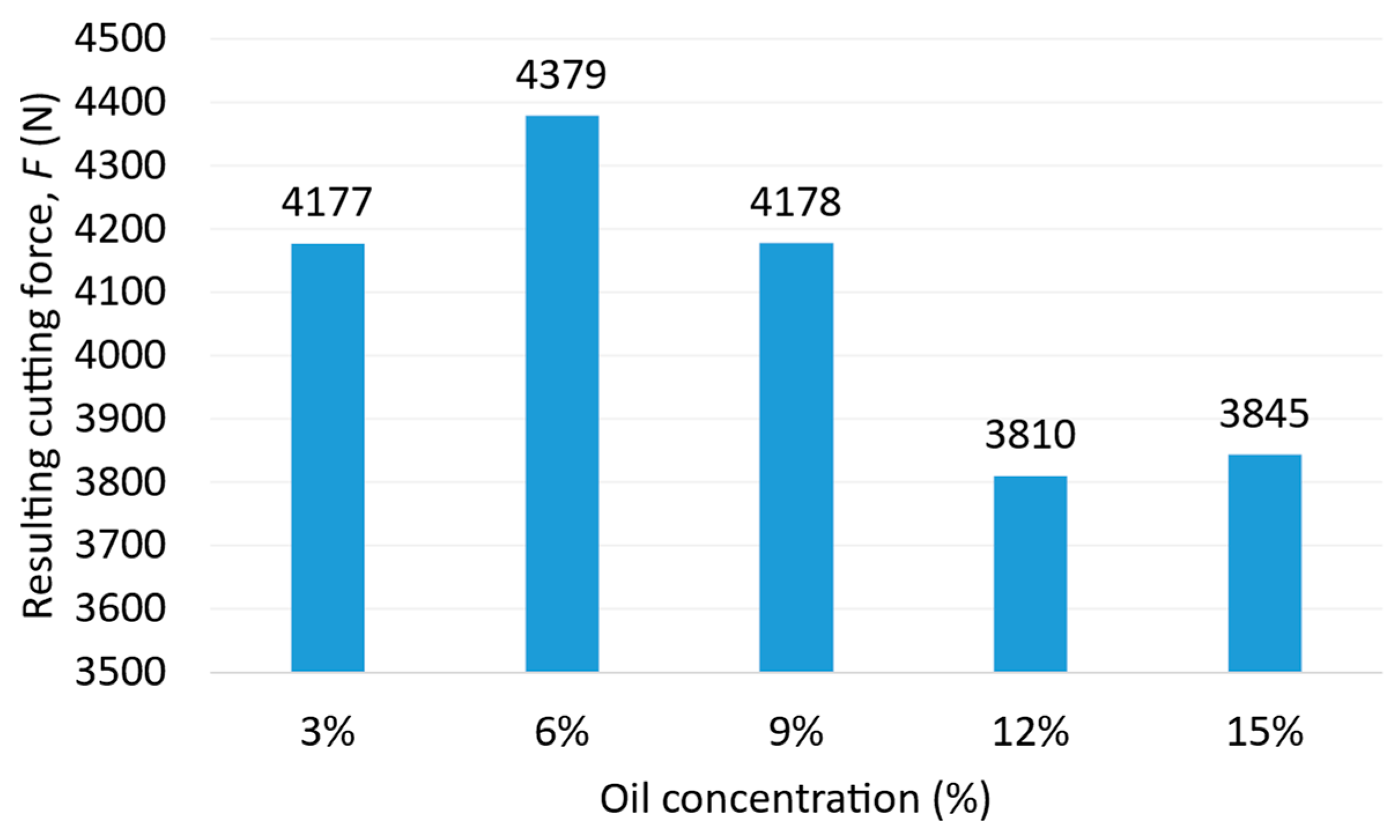

3.1. Cutting Force

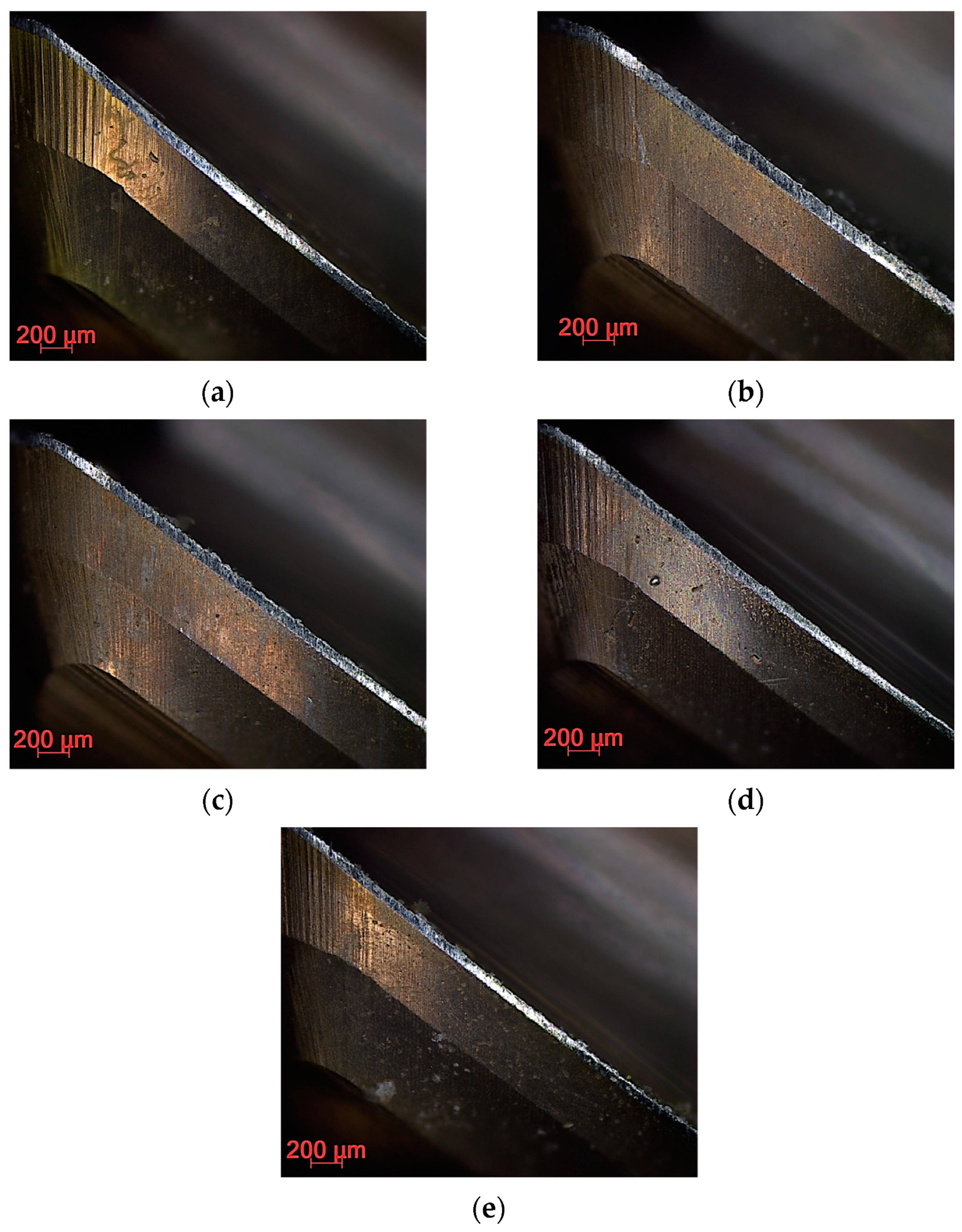

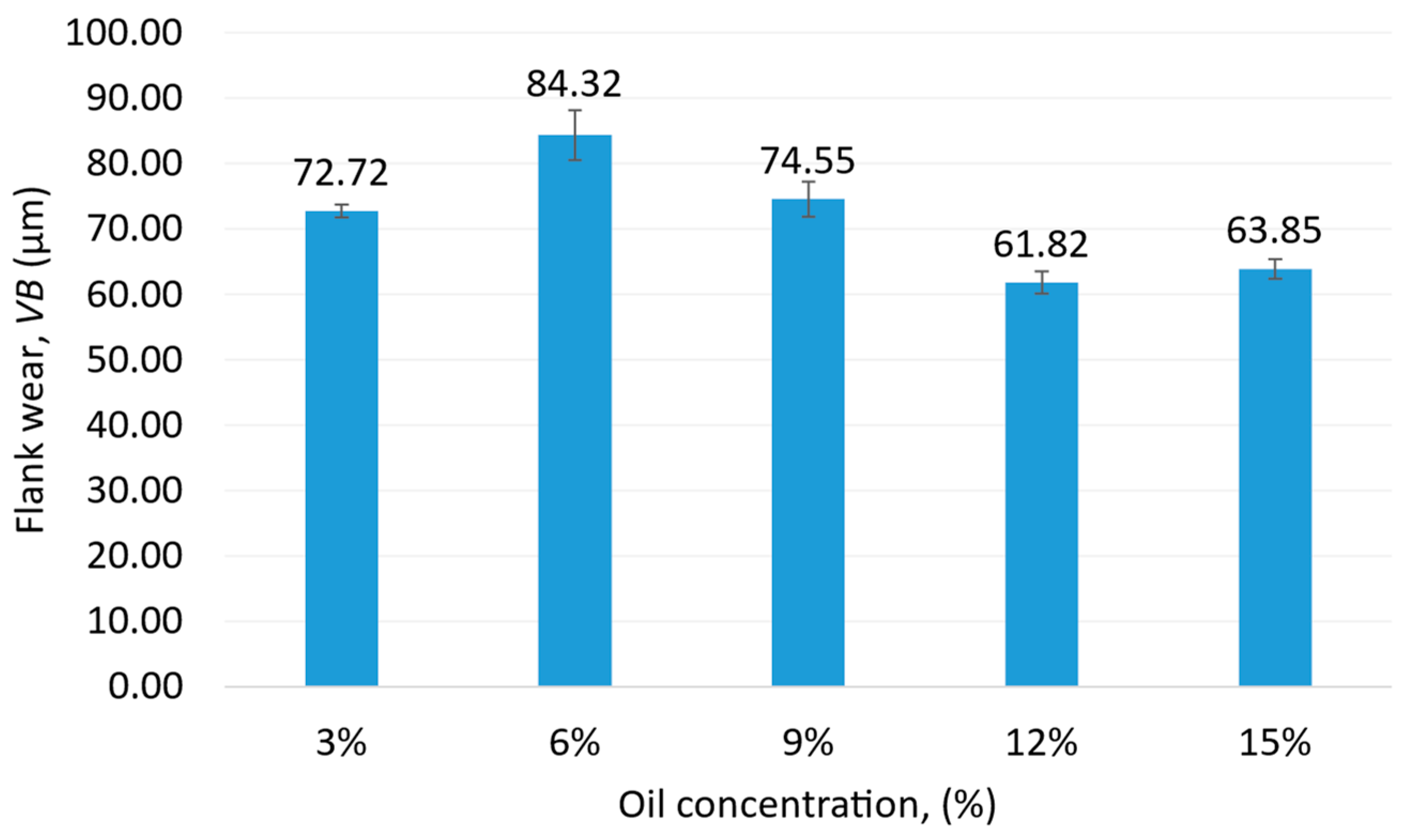

3.2. Tool Wear

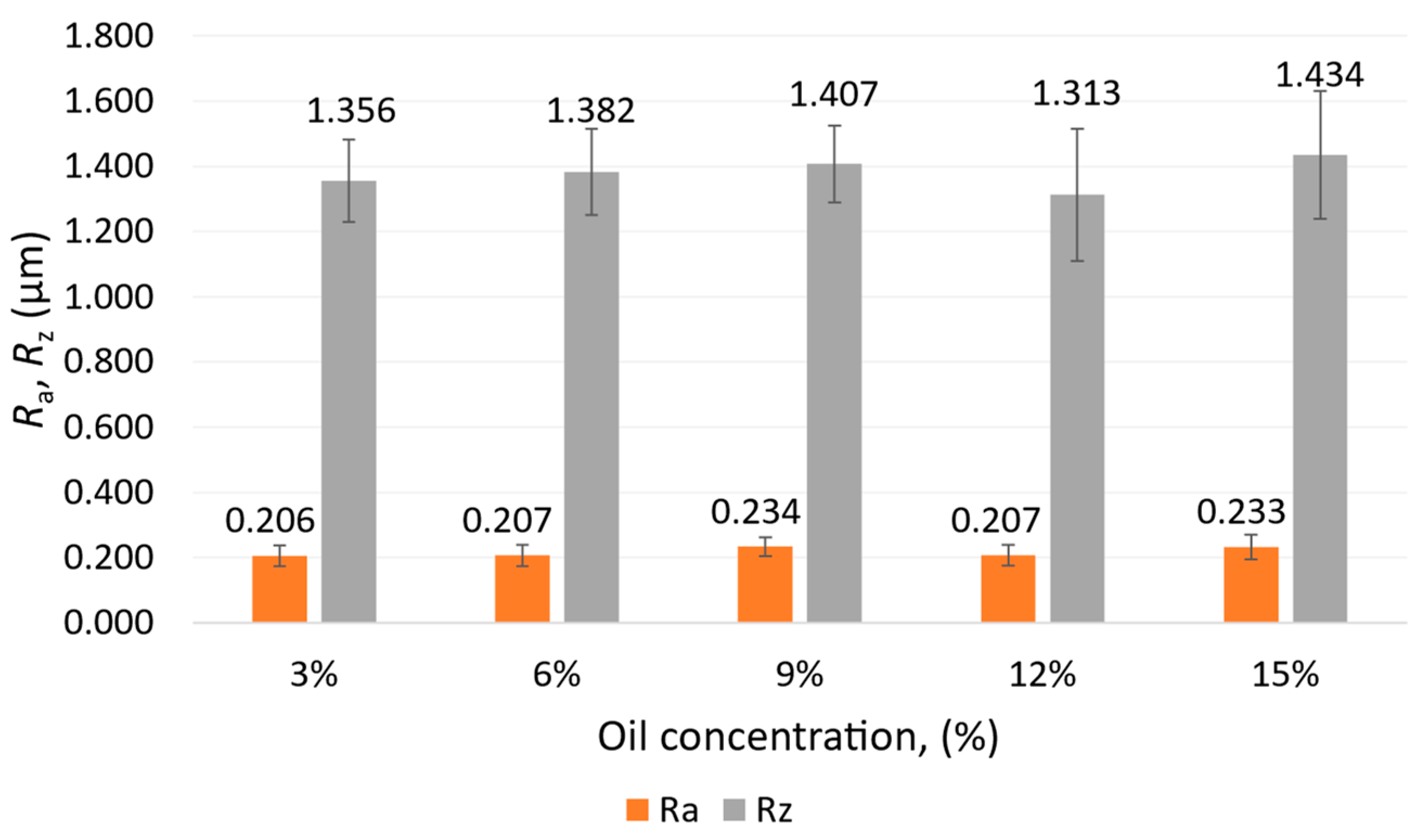

3.3. Surface Roughness

4. Conclusions

- The lowest cutting force at a 12% oil concentration of flood cooling, and the highest at the oil concentration of 6%, was observed. With the same noise filtering method, the highest fluctuation in the force signal is observed at 6% oil concentration, which is due to the higher vibration during machining.

- Consistent with the trend in cutting force, the lowest wear was measured at an oil concentration of 12%, and the highest at 6%. Vibrations during machining have a negative impact on both tool wear and tool life.

- The dispersion of the wear of five tool edges was calculated for an emulsion concentration of 6%, which shows that in this case, the wear of the edges was the most uneven, which accelerates the failure.

- The surface roughness is not influenced by the oil concentration content of the flood cooling; it is influenced by the cutting parameters and tool geometry.

- Increasing the oil concentration fundamentally decreases tool wear because in water-based emulsions, there is more oil available to lubricate the contact surface between the workpiece and the tool. This leads to a reduction in the abrasive effect of the metal carbides present in the material, as the surfaces can slide against each other more easily. Additionally, friction decreases, resulting in lower heat generation in the machining zone, thereby subjecting the tool to a reduced heat load. The choice of oil concentration has an even more significant effect at greater depth of cut, as shown in Figure 3 and Figure 4.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kónya, G.; Kovács, Z.F. The Comparison of Effects of Liquid Carbon Dioxide and Conventional Flood Cooling on the Machining Conditions During Milling of Nickel-based Superalloys. Period. Polytech. Mech. Eng. 2023, 67, 190–196. [Google Scholar] [CrossRef]

- Kun, K.; Kodácsy, J.; Vaczkó, D.; Kovács, Z.F. Machinability of Ni-based Superalloys by Indexable End Mills. Acta Mater. Transylvanica 2019, 2, 49–54. [Google Scholar] [CrossRef]

- Guimaraes, M.C.R.; Fogagnolo, J.B.; Paiva, J.M.; Veldhuis, S.; Diniz, A.E. The impact of the cutting parameters and tool condition on surface integrity when milling Inconel 625. J. Mater. Res. Technol. 2023, 25, 1944–1958. [Google Scholar] [CrossRef]

- Halim, N.H.A.; Haron, C.H.C.; Ghani, J.A. Sustainable Machining of Hardenes Inconel 718: A Comparative Study. Int. J. Precis. Eng. Manuf. 2020, 21, 1375–1387. [Google Scholar] [CrossRef]

- Ratnam, C.; Kumar, K.A.; Murthy, B.S.N.; Rao, K.V. An experimental study on boring of Inconel 718 and multi response optimization of machining parameters using Response Surface Methodology. Mater. Today Proc. 2018, 5, 27123–27129. [Google Scholar] [CrossRef]

- Faraz, M.I.; Petru, J. Evaluation of Machining Variables on Machinability of Nickel Alloy Inconel 718 Using Coated Carbide Tools. Machines 2024, 12, 4. [Google Scholar] [CrossRef]

- Özbek, O.; Saruhan, H. The effect of vibration and cutting zone temperature on surface roughness and tool wear in eco-friendly MQL turning of AISI D2. J. Mater. Res. Technol. 2020, 9, 2762–2772. [Google Scholar] [CrossRef]

- Xue, K.; Chen, P.; Liu, W.; Zou, B.; Li, L.; Chen, W.; Wang, X.; Xu, Z. Geometric Structures for Sialon Ceramic Solid End Mills and Its Performance in High-Speed Milling of Nickel-Based Superalloys. Coatings 2023, 13, 1483. [Google Scholar] [CrossRef]

- Zhang, J.; Du, J.; Li, B.; Su, G. Investigation on White Layer Formation in Dry High-Speed Milling of Nickel-Based Superalloy GH4169. Machines 2023, 11, 406. [Google Scholar] [CrossRef]

- Bilgin, M.; Karabulut, Ş.; Karakoç, H.; Kayır, Y.; Sarıkaya, M. An experimental investigation on machining-induced surface/subsurface characteristics of nickel based Inc-718 alloy: A novel hybrid approach in milling process. Tribol. Int. 2024, 191, 109120. [Google Scholar] [CrossRef]

- Grzesik, W.; Niesłony, P.; Habrat, W.; Sieniawski, J.; Laskowski, P. Investigation of tool wear in the turning of Inconel 718 superalloy in terms of process performance and productivity enhancement. Tribol. Int. 2018, 118, 337–346. [Google Scholar] [CrossRef]

- Zhu, D.; Zhang, X.; Ding, H. Tool wear characteristics in machining of nickel-based superalloys. Int. J. Mach. Tools Manuf. 2013, 64, 60–77. [Google Scholar] [CrossRef]

- Soriano Gonzalez, L.; Medina Aguirre, F.; Soo, S.L.; Hood, R.; Novovic, D. Influence of Size Effect in Milling of a Single-Crystal Nickel-Based Superalloy. Micromachines 2023, 14, 313. [Google Scholar] [CrossRef] [PubMed]

- Ezugwu, E.O. Key improvements in the machining of difficult-to-cut aerospace superalloys. Int. J. Mach. Tools Manuf. 2005, 45, 1353–1367. [Google Scholar] [CrossRef]

- Molaiekiya, F.; Aliakbari Khoei, A.; Aramesh, M.; Veldhuis, S.C. Machined surface integrity of inconel 718 in high-speed dry milling using SiAlON ceramic tools. Int. J. Adv. Manuf. Technol. 2021, 112, 1941–1950. [Google Scholar] [CrossRef]

- Singh, A.; Ghosh, S.; Aravindan, S. State of art for sustainable machining of nickel-based alloys using coated and uncoated tools and machining of high strength materials using surface modified cutting tools. Tribol. Int. 2022, 170, 107517. [Google Scholar] [CrossRef]

- Kónya, G.; Szabó, N.; Kovács, Z.F. Investigation of the Machinability of GTD-111 Type Nickel-Base Superalloy During Face Milling. Acta Mater. Transylvanica 2023, 6, 23–28. [Google Scholar]

- Seleznev, A.; Pinargote, N.W.S.; Smirnov, A. Ceramic Cutting Materials and Tools Suitable for Machining High-Temperature Nickel-Based Alloys: A Review. Metals 2021, 11, 1385. [Google Scholar] [CrossRef]

- Jacso, A.; Szalay, T.; Sikarwar, B.S.; Phanden, R.K.; Singh, R.K.; Ramkumar, J. Investigation of conventional and ANN-based feed rate scheduling methods in trochoidal milling with cutting force and acceleration constraints. Int. J. Adv. Manuf. Technol. 2023, 127, 487–506. [Google Scholar] [CrossRef]

- Jacso, A.; Sikarwar, B.S.; Phanden, R.K.; Singh, R.K.; Ramkumar, J.; Sahu, G.N. Optimisation of tool path shape in trochoidal milling using B-spline curves. Int. J. Adv. Manuf. Technol. 2022, 121, 3801–3816. [Google Scholar] [CrossRef]

- Líska, J.; Kun, K.; Kovács, Z. Attendants at MMC Composite Milling. In Advances in Manufacturing Engineering and Materials II; Hloch, S., Klichová, D., Pude, F., Krolczyk, G.M., Chattopadhyaya, S., Eds.; Springer International Publishing: Cham, Switzerland, 2021; pp. 332–342. [Google Scholar]

- Monaca, A.; Axinte, D.A.; Liao, Z.; M’Saoubi, R.; Hardy, M.C. Towards understanding the thermal history of microstructural surface deformation when cutting a next generation powder metallurgy nickel-base superalloy. Int. J. Mach. Tools Manuf. 2021, 168, 103765. [Google Scholar] [CrossRef]

- Móricz, L.; János, Z.V. Investigation of ductile/brittle chip formation zone in the context of manufactured geometry with different CAM paths strategies. IFAC-PapersOnLine 2022, 55, 2300–2305. [Google Scholar]

- Patel, T.; Khanna, N.; Yadav, S.; Shah, P.; Sarikaya, M.; Singh, D.; Gupta, M.K. Machinability analysis of nickel-based superalloy Nimonic 90: A comparison between wet and LCO2 as a cryogenic coolant. Int. J. Adv. Manuf. Technol. 2021, 113, 3613–3628. [Google Scholar] [CrossRef]

- Guo, C.; Chen, X.; Li, Q.; Ding, G.; Yue, H.; Zhang, J. Milling optimization of GH4169 nickel–based superalloy under minimal quantity lubrication condition based on multi-objective particle swarm optimization algorithm. Int. J. Adv. Manuf. Technol. 2022, 123, 3983–3994. [Google Scholar] [CrossRef]

- Korkmaz, M.E.; Gupta, M.K.; Boy, M.; Yaşar, N.; Krolczyk, G.M.; Günay, M. Influence of duplex jets MQL and nano-MQL cooling system on machining performance of Nimonic 80A. J. Manuf. Process. 2021, 69, 112–124. [Google Scholar] [CrossRef]

- Pereira, O.; Celaya, A.; Urbikaín, G.; Rodríguez, A.; Fernández-Valdivielso, A.; de Lacalle, L.N.L. CO2 cryogenic milling of Inconel 718: Cutting forces and tool wear. J. Mater. Res. Technol. 2020, 9, 8459–8468. [Google Scholar] [CrossRef]

- Wang, F.; Wang, Y. Comparison of cryogenic cooling strategy effects on machinability of milling nickel-based alloy. J. Manuf. Process. 2021, 66, 623–635. [Google Scholar] [CrossRef]

- Villarrazo, N.; Caneda, S.; Pereira, O.; Rodríguez, A.; de Lacalle, L.N.L. The Effects of Lubricooling Ecosustainable Techniques on Tool Wear in Carbon Steel Milling. Materials 2023, 16, 2936. [Google Scholar] [CrossRef]

- Wu, X.; Zhu, W.; Chen, J. Tool wear mechanisms in laser-assisted milling of Nickel-based superalloys. J. Braz. Soc. Mech. Sci. Eng. 2021, 43, 151. [Google Scholar] [CrossRef]

- Zhang, H.; Yan, R.; Deng, B.; Lin, J.; Yang, M.; Peng, F. Investigation on surface integrity in laser-assisted machining of Inconel 718 based on in-situ observation. Procedia CIRP 2022, 108, 129–134. [Google Scholar] [CrossRef]

- Parida, A.K.; Maity, K. Experimental investigation on tool life and chip morphology in hot machining of Monel-400. Eng. Sci. Technol. Int. J. 2018, 21, 371–379. [Google Scholar] [CrossRef]

- Parida, A.K.; Maity, K. Numerical and experimental analysis of specific cutting energy in hot turning of Inconel 718. Measurement 2018, 133, 361–369. [Google Scholar] [CrossRef]

- Kim, E.J.; Lee, C.M. A Study on the Optimal Machining Parameters of the Induction Assisted Milling with Inconel 718. Materials 2019, 12, 233. [Google Scholar] [CrossRef] [PubMed]

- Baili, M.; Wagner, V.; Dessein, G.; Sallaberry, J.; Lallement, D. An Experimental Investigation of Hot Machining with Induction to Improve Ti-5553 Machinability. Appl. Mech. Mater. 2011, 62, 67–76. [Google Scholar] [CrossRef]

- Gupta, M.K.; Niesłony, P.; Korkmaz, M.E.; Kuntoğlu, M.; Królczyk, G.M.; Günay, M.; Sarikaya, M. Comparison of Tool Wear, Surface Morphology, Specific Cutting Energy and Cutting Temperature in Machining of Titanium Alloys Under Hybrid and Green Cooling Strategies. Int. J. Precis. Eng. Manuf.-Green Technol. 2023, 10, 1393–1406. [Google Scholar] [CrossRef]

- Kovács, Z.F.; Viharos, Z.J.; Kodácsy, J. Improvements of surface tribological properties by magnetic assisted ball burnishing. Surf. Coat. Technol. 2022, 437, 128317. [Google Scholar] [CrossRef]

- Pimenov, D.Y.; da Silva, L.R.R.; Machado, A.R.; França, P.H.P.; Pintaude, G.; Unune, D.R.; Kuntoğlu, M.; Krolczyk, G.M. A comprehensive review of machinability of difficult-to-machine alloys with advanced lubricating and cooling techniques. Tribol. Int. 2024, 196, 109677. [Google Scholar] [CrossRef]

- Liao, Y.S.; Lin, H.M. Mechanism of minimum quantity lubrication in high-speed milling of hardened steel. Int. J. Mach. Tools Manuf. 2007, 47, 1660–1666. [Google Scholar] [CrossRef]

- Li, M.; Yu, T.; Yang, L.; Li, H.; Zhang, R.; Wang, W. Parameter optimization during minimum quantity lubrication milling of TC4 alloy with graphene-dispersed vegetable-oil-based cutting fluid. J. Clean. Prod. 2019, 209, 1508–1522. [Google Scholar] [CrossRef]

- Karmiris-Obratanski, P.; Karkalos, N.E.; Kudelski, R.; Markopoulos, A.P. Experimental study on the effect of the cooling method on surface topography and workpiece integrity during trochoidal end milling of Incoloy 800. Tribol. Int. 2022, 176, 107899. [Google Scholar] [CrossRef]

- Singh, R.; Sharma, V. Machining induced surface integrity behavior of nickel-based superalloy: Effect of lubricating environments. J. Mater. Process. Technol. 2022, 307, 117701. [Google Scholar] [CrossRef]

- Sharma, A.K.; Singh, R.K.; Dixit, A.M.; Tiwari, A.K. Characterization and experimental investigation of Al2O3 nanoparticle based cutting fluid in turning of AISI 1040 steel under minimum quantity lubrication (MQL). Mater. Today Proc. 2016, 3, 1899–1906. [Google Scholar]

- Said, Z.; Gupta, M.; Hegab, H.; Arora, N.; Khan, A.M.; Jamil, M.; Bellos, E. A comprehensive review on minimum quantity lubrication (MQL) in machining processes using nano-cutting fluids. Int. J. Adv. Manuf. Technol. 2019, 105, 2057–2086. [Google Scholar] [CrossRef]

- Wang, C.; Li, K.; Chen, M.; Liu, Z. Evaluation of minimum quantity lubrication effects by cutting force signals in face milling of Inconel 182 overlays. J. Clean. Prod. 2015, 108, 145–157. [Google Scholar] [CrossRef]

- Çakīr, O.; Yardimeden, A.; Ozben, T.; Kilickap, E. Selection of cutting fluids in machining processes. J. Achiev. Mater. Manuf. Eng. 2007, 25, 99–102. [Google Scholar]

- Adler, D.; Hii, W.-S.; Michalek, D.; Sutherland, J. Examining the role of cutting fluids in machining and efforts to address associated environmental/health concerns. Mach. Sci. Technol. 2006, 10, 23–58. [Google Scholar] [CrossRef]

- Khanna, N.; Shah, P.; Chetan. Comparative analysis of dry, flood, MQL and cryogenic CO2 techniques during the machining of 15-5-PH SS alloy. Tribol. Int. 2020, 146, 106196. [Google Scholar]

- Peralta Álvarez, M.E.; Marcos Bárcena, M.; Aguayo González, F. On the sustainability of machining processes. Proposal for a unified framework through the triple bottom-line from an understanding review. J. Clean. Prod. 2017, 142, 3890–3904. [Google Scholar] [CrossRef]

- Lawal, S.; Choudhury, I.; Nukman, Y. Application of vegetable oil-based metalworking fluids in machining ferrous metals—A review. Int. J. Mach. Tools Manuf. 2012, 52, 1–12. [Google Scholar] [CrossRef]

- Xu, X.; Huang, S.; Wang, M.; Yao, W. A study on process parameters in end milling of AISI-304 stainless steel under electrostatic minimum quantity lubrication conditions. Int. J. Adv. Manuf. Technol. 2017, 90, 979–989. [Google Scholar] [CrossRef]

- Gajrani, K.K.; Suvin, P.S.; Kailas, S.V.; Sankar, M.R. Hard machining performance of indigenously developed green cutting fluid using flood cooling and minimum quantity cutting fluid. J. Clean. Prod. 2019, 206, 108–123. [Google Scholar] [CrossRef]

- Hadad, M.; Hadi, M. An investigation on surface grinding of hardened stainless steel S34700 and aluminum alloy AA6061 using minimum quantity of lubrication (MQL) technique. Int. J. Adv. Manuf. Technol. 2013, 68, 2145–2158. [Google Scholar] [CrossRef]

- Debnath, S.; Reddy, M.M.; Yi, Q.S. Environmental friendly cutting fluids and cooling techniques in machining: A review. J. Clean. Prod. 2014, 83, 33–47. [Google Scholar] [CrossRef]

- Sen, B.; Mia, M.; Krolczyk, G.; Mandal, U.K.; Mondal, S.P. Eco-friendly cutting fluids in minimum quantity lubrication assisted machining: A review on the perception of sustainable manufacturing. Int. J. Precis. Eng. Manuf.-Green Technol. 2021, 8, 249–280. [Google Scholar] [CrossRef]

- Singh, T.; Singh, P.; Dureja, J.S.; Dogra, M.; Singh, H.; Bhatti, M.S. A review of near dry machining/minimum quantity lubrication machining of difficult to machine alloys. Int. J. Mach. Mach. Mater. 2016, 18, 213. [Google Scholar] [CrossRef]

- da Silva, L.R.R.; Ruzzi, R.S.; Teles, V.C.; Sales, W.F.; Guesser, W.L.; Machado, A.R. Analysis of the coefficient of friction at the workpiece-tool interface in milling of high strength compacted graphite cast irons. Wear 2019, 426–427, 1646–1657. [Google Scholar] [CrossRef]

- Behera, B.C.; Alemayehu, H.; Ghosh, S.; Rao, P.V. A comparative study of recent lubri-coolant strategies for turning of Ni-based superalloy. J. Manuf. Process. 2017, 30, 541–552. [Google Scholar] [CrossRef]

- Kaynak, Y.; Gharibi, A.; Yılmaz, U.; Köklü, U.; Aslantaş, K. A comparison of flood cooling, minimum quantity lubrication and high pressure coolant on machining and surface integrity of titanium Ti-5553 alloy. J. Manuf. Process. 2018, 34, 503–512. [Google Scholar] [CrossRef]

- Kónya, G.; Kovács, Z.F. Experimental investigation of the effects of cooling-lubricating methods on the slot milling process of GTD-111 type nickel-based superalloy. J. Manuf. Process. 2024, 119, 98–108. [Google Scholar] [CrossRef]

- Bao, X.; Yao, P.; Xu, J.; Mei, Z.; Li, Y.; Yang, J.; Wang, Q.; Chen, Z.; Qu, S. Effect of tool geometry and cutting parameters on surface quality and chip morphology of amorphous electroless nickel-phosphorus alloy in ultra-precision turning. Int. J. Adv. Manuf. Technol. 2023, 126, 2461–2478. [Google Scholar] [CrossRef]

- Peta, K.; Bartkowiak, T.; Rybicki, M.; Galek, P.; Mendak, M.; Wieczorowski, M.; Brown, C.A. Scale-dependent wetting behavior of bioinspired lubricants on electrical discharge machined Ti6Al4V surfaces. Tribol. Int. 2024, 194, 109562. [Google Scholar] [CrossRef]

| Cutting Speed vc (m/min) | Feed per Tooth fz (mm/tooth) | Depth of Cut ap (mm) | Oil Concentration (wt. %) |

|---|---|---|---|

| 21 | 0.01 | firstly, 8 mm after breaking after the whole experiment, 4 mm | 3; 6; 9; 12; 15 |

| Ni (wt. %) | C (wt. %) | Cr (wt. %) | Co (wt. %) | Al (wt. %) | Ti (wt. %) | W (wt. %) | Mo (wt. %) | Ta (wt. %) | B (wt. %) |

|---|---|---|---|---|---|---|---|---|---|

| 62.37 | 0.06 | 13.7 | 9.0 | 2.8 | 4.7 | 3.5 | 1.4 | 2.4 | 0.05 |

| Tensile Strength Rm (MPa) | Stretch A5 (%) | Contraction Z (%) | Hardness HRC |

|---|---|---|---|

| 1310 | 8 | 5 | 41.4 |

| Density ρ (kg/m3) | Thermal Conductivity at 20 °C λ (W/m·K) | Specific Heat at 20 °C c (J/kg·K) |

|---|---|---|

| 8000 | 12.56 | 0.452 × 103 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kónya, G.; Kovács, Z.F. Effects of Oil Concentration in Flood Cooling on Cutting Force, Tool Wear and Surface Roughness in GTD-111 Nickel-Based Superalloy Slot Milling. J. Manuf. Mater. Process. 2024, 8, 119. https://doi.org/10.3390/jmmp8030119

Kónya G, Kovács ZF. Effects of Oil Concentration in Flood Cooling on Cutting Force, Tool Wear and Surface Roughness in GTD-111 Nickel-Based Superalloy Slot Milling. Journal of Manufacturing and Materials Processing. 2024; 8(3):119. https://doi.org/10.3390/jmmp8030119

Chicago/Turabian StyleKónya, Gábor, and Zsolt F. Kovács. 2024. "Effects of Oil Concentration in Flood Cooling on Cutting Force, Tool Wear and Surface Roughness in GTD-111 Nickel-Based Superalloy Slot Milling" Journal of Manufacturing and Materials Processing 8, no. 3: 119. https://doi.org/10.3390/jmmp8030119

APA StyleKónya, G., & Kovács, Z. F. (2024). Effects of Oil Concentration in Flood Cooling on Cutting Force, Tool Wear and Surface Roughness in GTD-111 Nickel-Based Superalloy Slot Milling. Journal of Manufacturing and Materials Processing, 8(3), 119. https://doi.org/10.3390/jmmp8030119