Ensuring Melt Track Width Consistency and Crack-Free Conditions Using Interpass-Temperature-Dependent Process Parameters for Wire-Arc-Directed Energy-Deposited Inconel 718

Abstract

1. Introduction

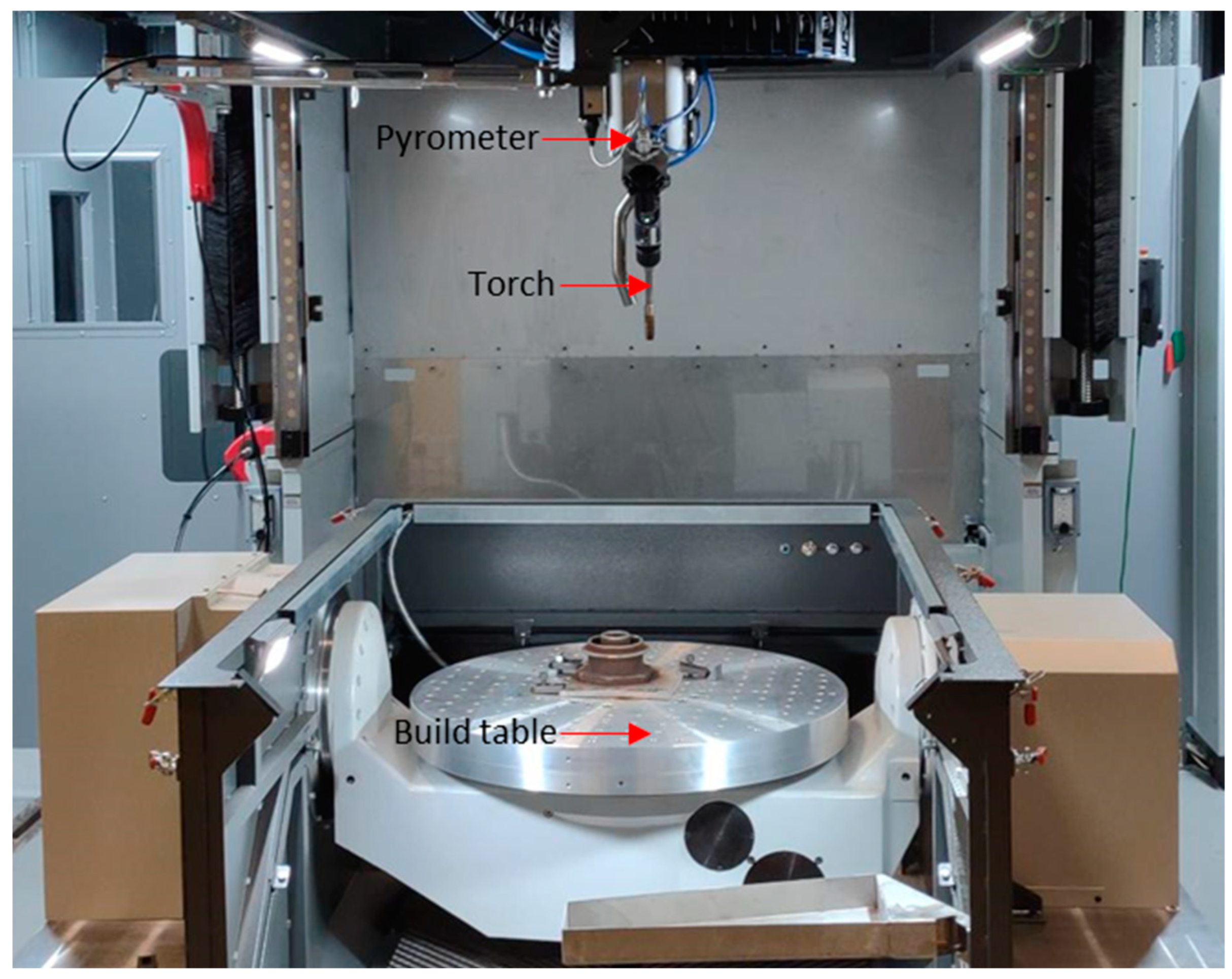

2. Materials and Methods

3. Results

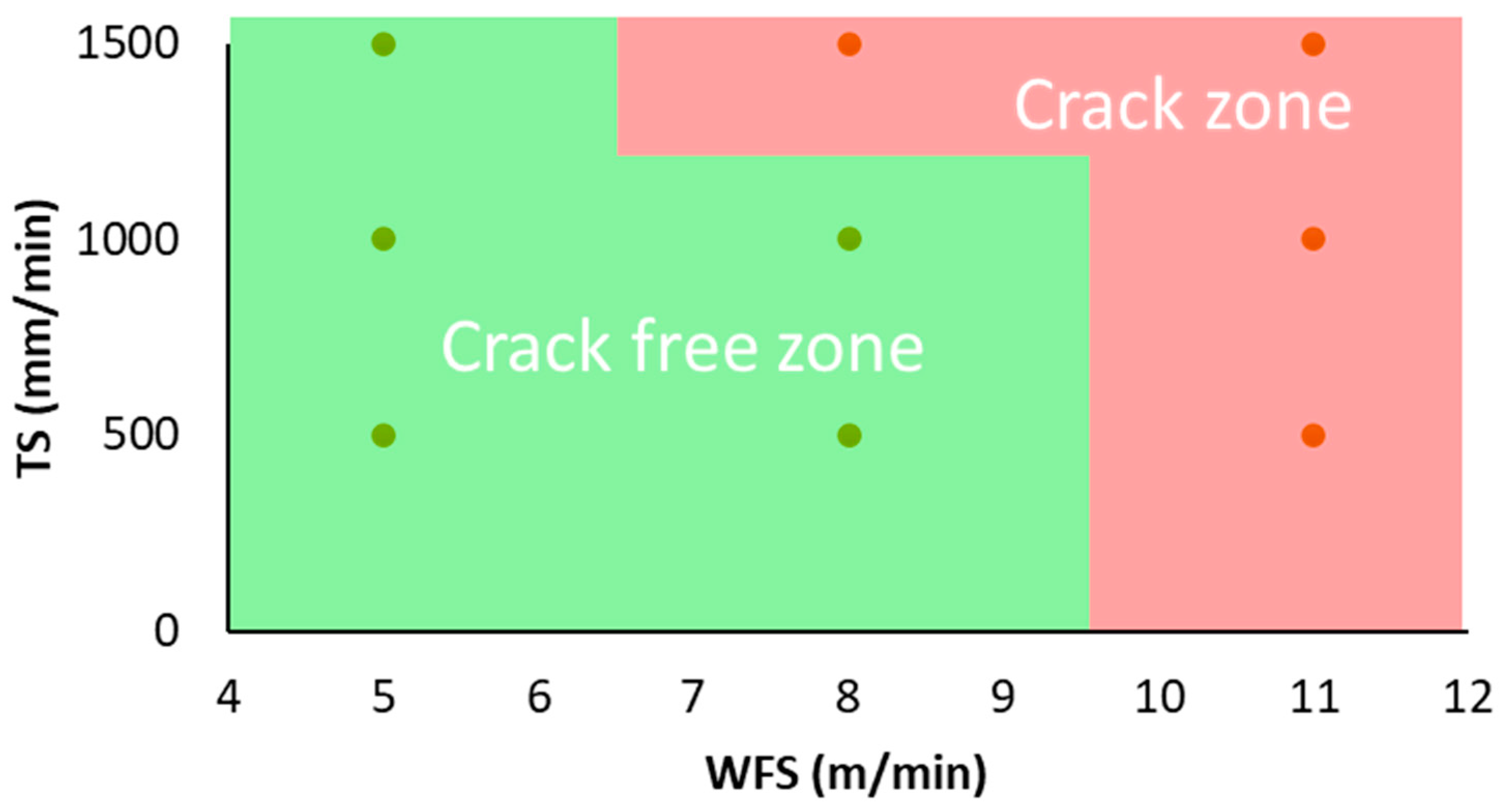

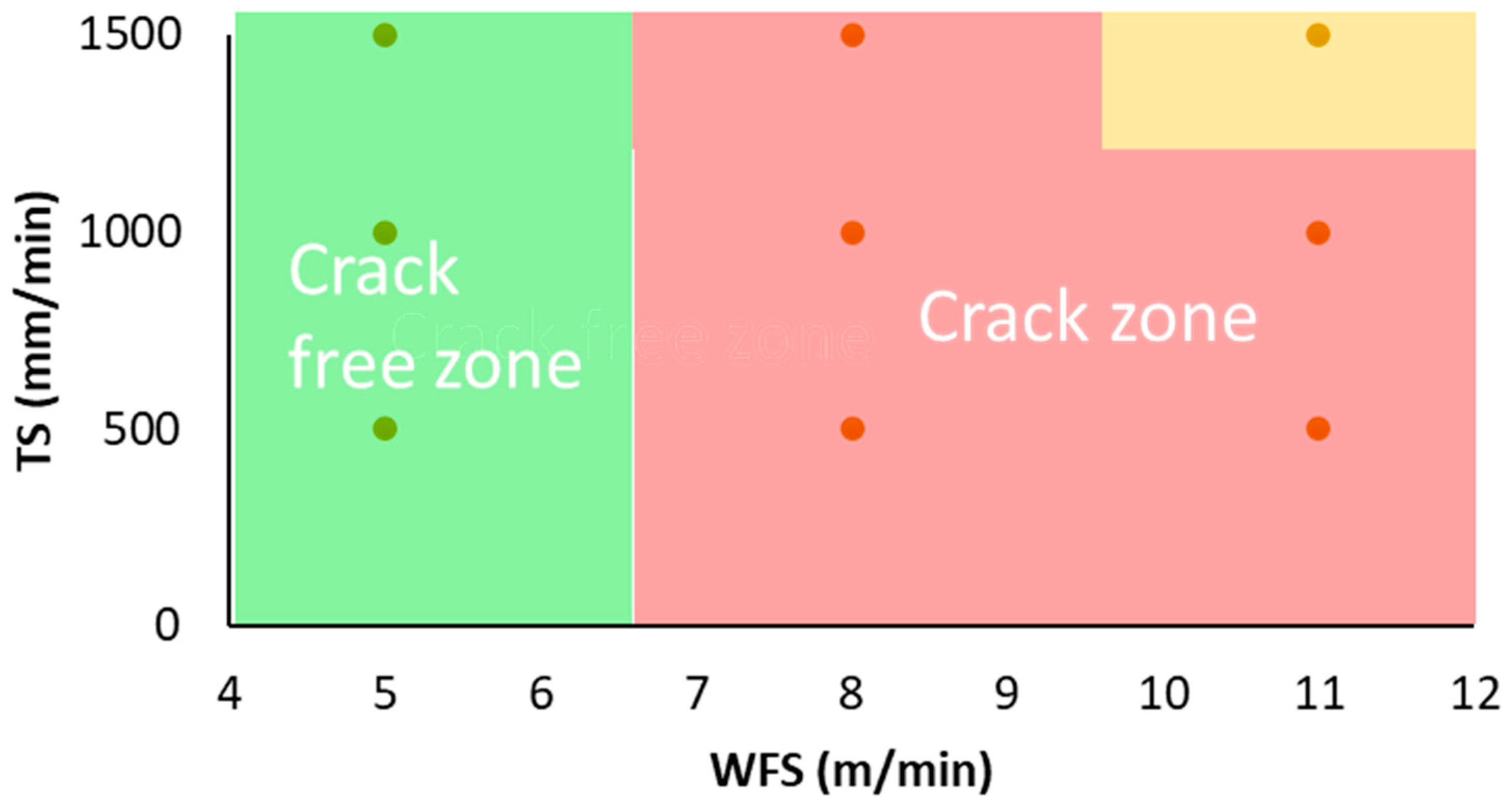

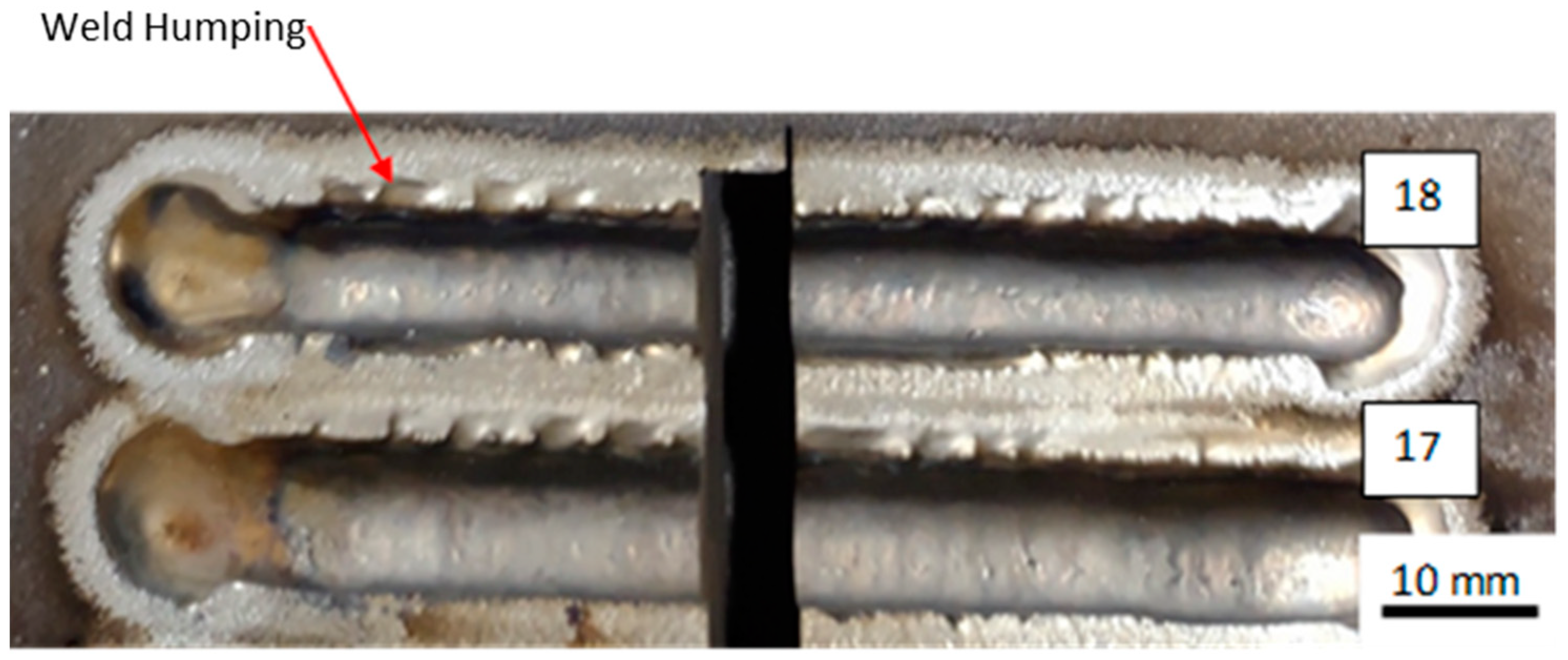

3.1. Process Parameter Development Results

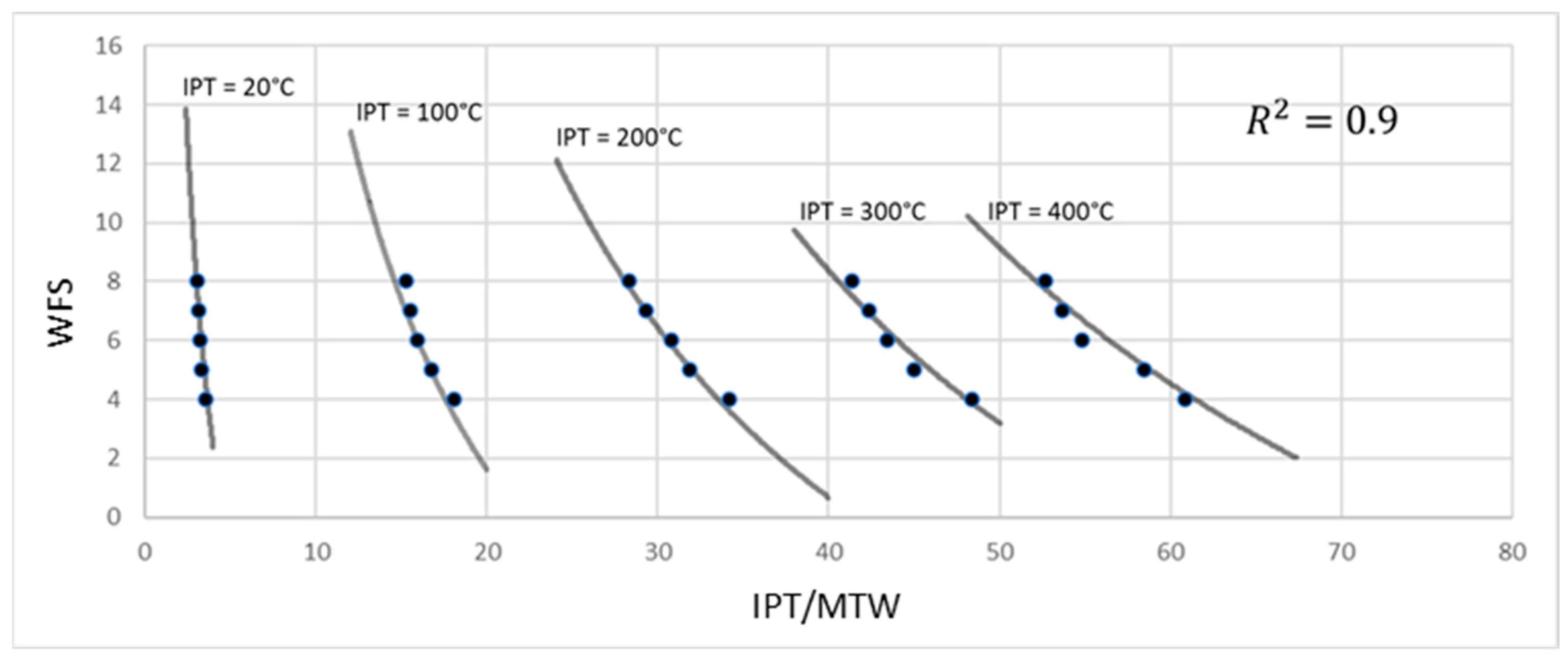

3.2. Linear Regression Model

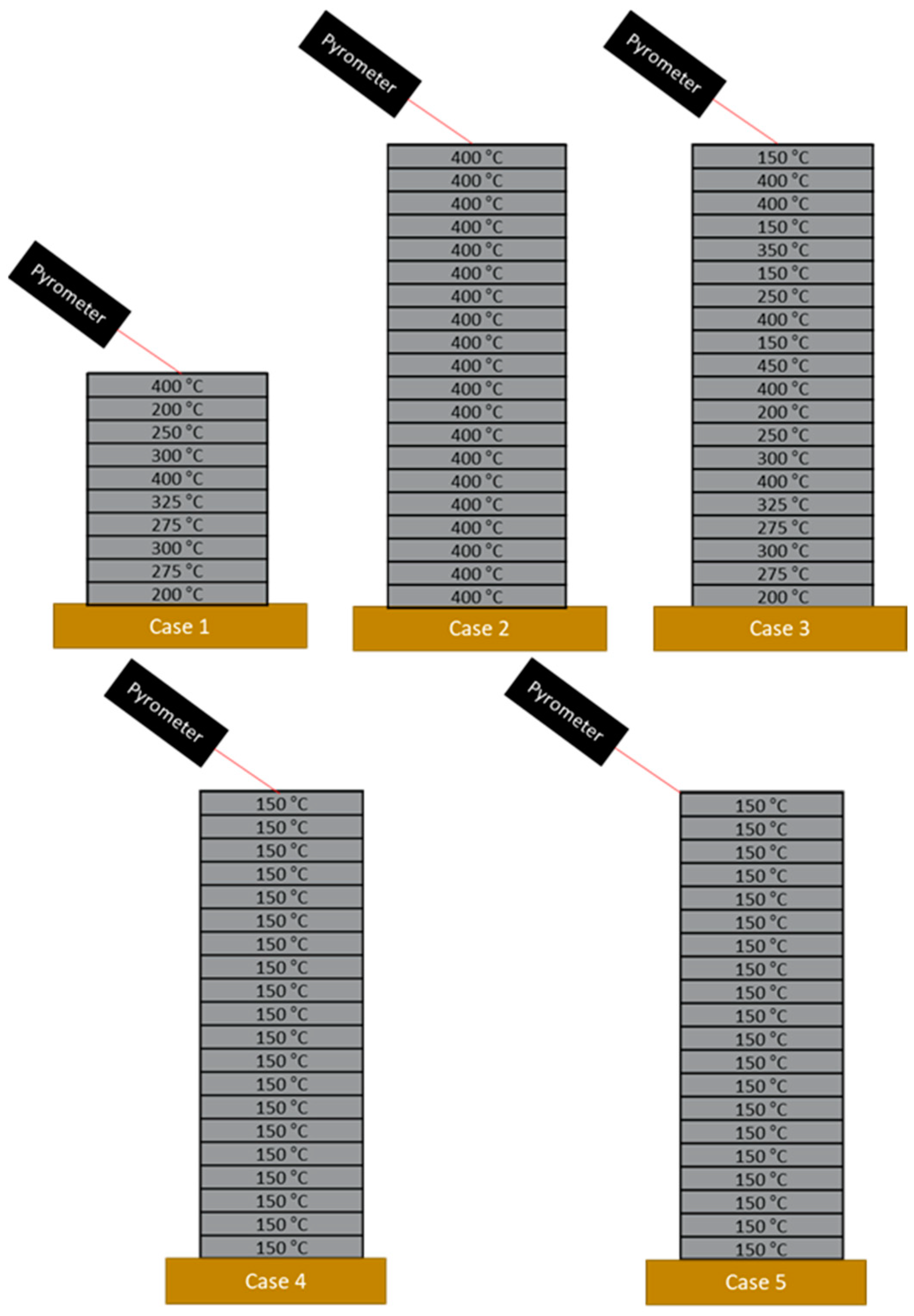

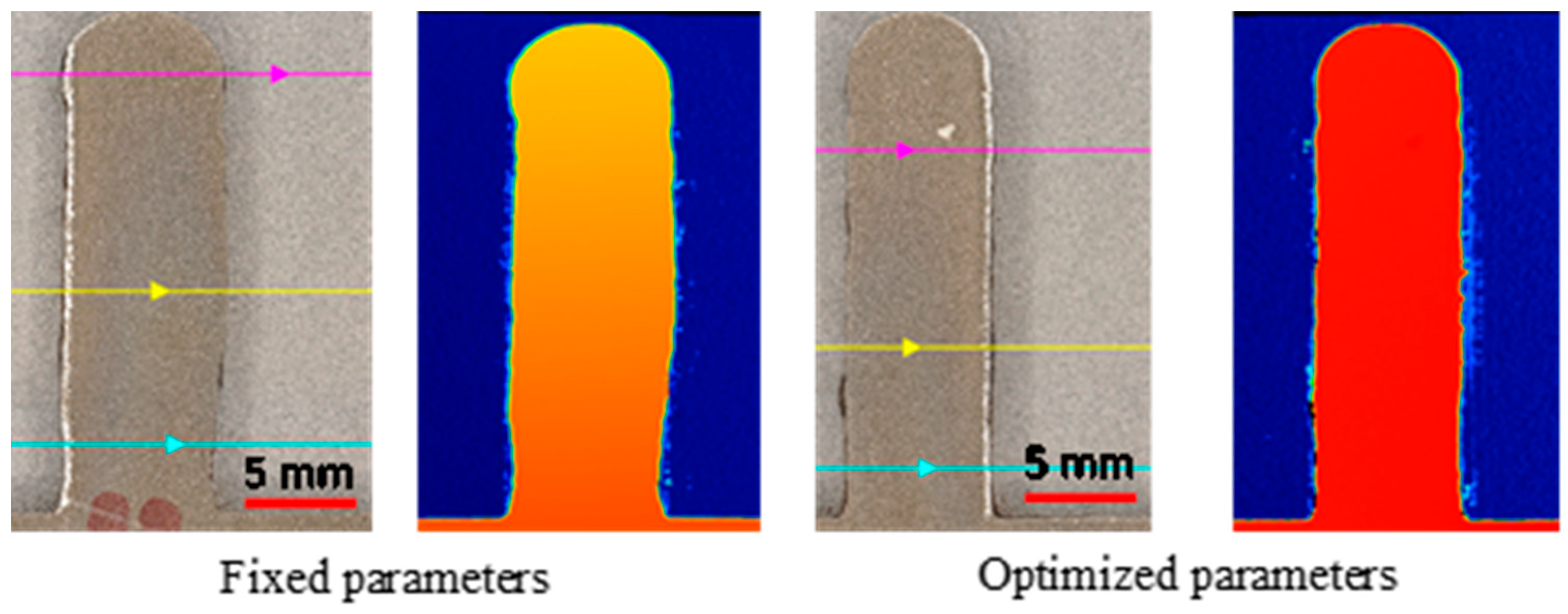

3.3. Test Cases

4. Discussion

5. Conclusions

- (1)

- The process window for Inconel 718 is well-defined, allowing for crack-free deposition at varying IPTs (Up to 350 °C).

- (2)

- Cracking can be avoided by using a lower WFS (<8 m/min), irrespective of the TS.

- (3)

- A linear regression model effectively correlates TS, WFS, IPT, and melt track width. Although more complex models could potentially offer better performance, the linear model provides easily interpretable results that offer insights into process physics (R2: 0.9).

- (4)

- The study demonstrates that using parameters derived from the linear regression model can achieve the desired melt track widths efficiently (3% error), reducing the number of experiments, material consumption, machining time, and associated costs.

- (5)

- The location for temperature checks using a pyrometer must be selected with prior knowledge of the thermal conditions that the part will experience during printing. Failure to do this might result in sections of the part exceeding the maximum IPT threshold.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wu, B.; Pan, Z.; Ding, D.; Cuiuri, D.; Li, H.; Xu, J.; Norrish, J. A review of the wire arc additive manufacturing of metals: Properties, defects and quality improvement. J. Manuf. Process. 2018, 35, 127–139. [Google Scholar] [CrossRef]

- Yi, H.; Yang, L.; Jia, L.; Huang, Y.; Cao, H. Porosity in wire-arc directed energy deposition of aluminum alloys: Formation mechanisms, influencing factors and inhibition strategies. Addit. Manuf. 2024, 84, 104108. [Google Scholar]

- Ryan, E.M.; Sabin, T.J.; Watts, J.F.; Whiting, M.J. The influence of build parameters and wire batch on porosity of wire and arc additive manufactured aluminium alloy 2319. J. Mater. Process. Technol. 2018, 262, 577–584. [Google Scholar] [CrossRef]

- Long, J.; Wang, M.; Zhao, W.; Zhang, X.; Wei, Y.; Ou, W. High-power wire arc additive manufacturing of stainless steel with active heat management. Sci. Technol. Weld. Join. 2022, 27, 256–264. [Google Scholar] [CrossRef]

- Gornyakov, V.; Ding, J.; Sun, Y.; Williams, S. Understanding and designing post-build rolling for mitigation of residual stress and distortion in wire arc additively manufactured components. Mater. Des. 2022, 213, 110335. [Google Scholar] [CrossRef]

- Zhang, L.N.; Ojo, O.A. Corrosion behavior of wire arc additive manufactured Inconel 718 superalloy. J. Alloys Compd. 2020, 829, 154455. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, K.; Huang, J.; Hosseini, S.R.E.; Li, Z. Characterization of heat affected zone liquation cracking in laser additive manufacturing of Inconel 718. Mater. Des. 2016, 90, 586–594. [Google Scholar] [CrossRef]

- Seow, C.E.; Zhang, J.; Coules, H.E.; Wu, G.; Jones, C.; Ding, J.; Williams, S. Effect of crack-like defects on the fracture behaviour of Wire + Arc Additively Manufactured nickel-base Alloy 718. Addit. Manuf. 2020, 36, 101578. [Google Scholar] [CrossRef]

- Srinivasan, G.; Bhaduri, A.K.; Shankar, V.; Raj, B. Evaluation of hot cracking susceptibility of some austenitic stainless steels and a nickel-base alloy. Weld. World 2008, 52, 4–17. [Google Scholar] [CrossRef]

- Gu, J.; Bai, J.; Ding, J.; Williams, S.; Wang, L.; Liu, K. Design and cracking susceptibility of additively manufactured Al-Cu-Mg alloys with tandem wires and pulsed arc. J. Mater. Process. Technol. 2018, 262, 210–220. [Google Scholar] [CrossRef]

- Artaza, T.; Bhujangrao, T.; Suárez, A.; Veiga, F.; Lamikiz, A. Influence of heat input on the formation of laves phases and hot cracking in plasma arc welding (PAW) additive manufacturing of inconel 718. Metals 2020, 10, 771. [Google Scholar] [CrossRef]

- Thavamani, R.; Balusamy, V.; Nampoothiri, J.; Subramanian, R.; Ravi, K.R. Mitigation of hot cracking in Inconel 718 superalloy by ultrasonic vibration during gas tungsten arc welding. J. Alloys Compd. 2018, 740, 870–878. [Google Scholar] [CrossRef]

- Ye, X.; Hua, X.; Wang, M.; Lou, S. Controlling hot cracking in Ni-based Inconel-718 superalloy cast sheets during tungsten inert gas welding. J. Mater. Process. Technol. 2015, 222, 381–390. [Google Scholar] [CrossRef]

- Selvi, S.; Vishvaksenan, A.; Rajasekar, E. Cold metal transfer (CMT) technology—An overview. Defence Technol. 2018, 14, 28–44. [Google Scholar] [CrossRef]

- Coniglio, N.; Cross, C.E. Effect of weld travel speed on solidification cracking behavior. Part 1: Weld metal characteristics. Int. J. Adv. Manuf. Technol. 2020, 107, 5011–5023. [Google Scholar] [CrossRef]

- Radhakrishna, C.; Rao, K.P. The formation and control of Laves phase in superalloy 718 welds. J. Mater. Sci. 1997, 32, 1977–1984. [Google Scholar] [CrossRef]

- Li, R.; Xiong, J. Influence of interlayer dwell time on stress field of thin-walled components in WAAM via numerical simulation and experimental tests. Rapid Prototyp. J. 2019, 25, 1433–1441. [Google Scholar] [CrossRef]

- Teng, S.; Dehgahi, S.; Henein, H.; Wolfe, T.; Qureshi, A. Effect of surface texture, viewing angle, and surface condition on the emissivity of wire arc directed energy deposition manufactured 7075 nano treated aluminum alloy. Int. J. Adv. Manuf. Technol. 2023, 126, 2175–2189. [Google Scholar] [CrossRef]

- da Silva, L.J.; Souza, D.M.; de Araújo, D.B.; Reis, R.P.; Scotti, A. Concept and validation of an active cooling technique to mitigate heat accumulation in WAAM. Int. J. Adv. Manuf. Technol. 2020, 107, 2513–2523. [Google Scholar] [CrossRef]

- Reisgen, U.; Sharma, R.; Mann, S.; Oster, L. Increasing the manufacturing efficiency of WAAM by advanced cooling strategies. Weld. World 2020, 64, 1409–1416. [Google Scholar] [CrossRef]

- Scotti, F.M.; Teixeira, F.R.; da Silva, L.J.; de Araújo, D.B.; Reis, R.P.; Scotti, A. Thermal management in WAAM through the CMT Advanced process and an active cooling technique. J. Manuf. Process. 2020, 57, 23–35. [Google Scholar] [CrossRef]

- Xian, G.; Cheepu, M.; Yu, J.; Cho, S.M.; Yeom, J.T.; Choi, Y.S.; Kang, N. Enhancing Tensile Properties of Wire-Arc Additively Manufactured Ti-6Al-4 V Deposits Via Cryogenic Vaporised Ar Shielding/Cooling. Met. Mater. Int. 2023, 29, 501–514. [Google Scholar] [CrossRef]

- Xia, C.; Pan, Z.; Zhang, S.; Polden, J.; Wang, L.; Li, H.; Xu, Y.; Chen, S. Model predictive control of layer width in wire arc additive manufacturing. J. Manuf. Process. 2020, 58, 179–186. [Google Scholar] [CrossRef]

- Wang, Y.; Xu, X.; Zhao, Z.; Deng, W.; Han, J.; Bai, L.; Liang, X.; Yao, J. Coordinated monitoring and control method of deposited layer width and reinforcement in WAAM process. J. Manuf. Process. 2021, 71, 306–316. [Google Scholar] [CrossRef]

- Li, Y.; Li, X.; Zhang, G.; Horváth, I.; Han, Q. Interlayer closed-loop control of forming geometries for wire and arc additive manufacturing based on fuzzy-logic inference. J. Manuf. Process. 2021, 63, 35–47. [Google Scholar] [CrossRef]

- Ščetinec, A.; Klobčar, D.; Bračun, D. In-process path replanning and online layer height control through deposition arc current for gas metal arc based additive manufacturing. J. Manuf. Process. 2021, 64, 1169–1179. [Google Scholar] [CrossRef]

- Manikandan, S.G.K.; Sivakumar, D.; Kamaraj, M. Welding the Inconel 718 Superalloy: Reduction of Micro-Segregation and Laves Phases; Elsevier: Amsterdam, The Netherlands, 2019. [Google Scholar] [CrossRef]

- Zhao, C.; Fezzaa, K.; Cunningham, R.W.; Wen, H.; De Carlo, F.; Chen, L.; Rollett, A.D.; Sun, T. Real-time monitoring of laser powder bed fusion process using high-speed X-ray imaging and diffraction. Sci. Rep. 2017, 7, 3602. [Google Scholar] [CrossRef] [PubMed]

- Zhang, C.; Qiu, Z.; Zhu, H.; Wang, Z.; Muránsky, O.; Ionescu, M.; Pan, Z.; Xi, J.; Li, H. On the effect of heat input and interpass temperature on the performance of inconel 625 alloy deposited using wire arc additive manufacturing–cold metal transfer process. Metals 2022, 12, 46. [Google Scholar] [CrossRef]

- Xu, C.; Guo, N.; Zhang, X.; Jiang, H.; Tan, Y.; Zhou, L. Influence of welding speed on weld pool dynamics and welding quality in underwater wet FCAW. J. Manuf. Process. 2020, 55, 381–388. [Google Scholar] [CrossRef]

- Koppu, A.K.; Lautre, N.K.; Motwani, A.; Hajare, D. CMT-WAAM deposition strategies for thin overhanging disc of SS308LSi and investigation of mechanical and microstructural characteristics. Proc. Inst. Mech. Eng. C J. Mech. Eng. Sci. 2024. [Google Scholar] [CrossRef]

| Specimen | WFS (m/min) | TS (mm/min) | IPT (°C) |

|---|---|---|---|

| 1 | 5 | 500 | 150 |

| 2 | 5 | 1000 | 150 |

| 3 | 5 | 1500 | 150 |

| 4 | 8 | 500 | 150 |

| 5 | 8 | 1000 | 150 |

| 6 | 8 | 1500 | 150 |

| 7 | 11 | 500 | 150 |

| 8 | 11 | 1000 | 150 |

| 9 | 11 | 1500 | 150 |

| 10 | 5 | 500 | 350 |

| 11 | 5 | 1000 | 350 |

| 12 | 5 | 1500 | 350 |

| 13 | 8 | 500 | 350 |

| 14 | 8 | 1000 | 350 |

| 15 | 8 | 1500 | 350 |

| 16 | 11 | 500 | 350 |

| 17 | 11 | 1000 | 350 |

| 18 | 11 | 1500 | 350 |

| 19 | 5 | 1000 | 450 |

| 20 | 5 | 1000 | 550 |

| Specimen | WFS (m/min) | TS (mm/min) | IPT (°C) | Melt Track Width (mm) |

|---|---|---|---|---|

| 1 | 4 | 480 | 20 | 5.62 |

| 2 | 5 | 600 | 20 | 6.05 |

| 3 | 6 | 720 | 20 | 6.25 |

| 4 | 7 | 840 | 20 | 6.40 |

| 5 | 8 | 960 | 20 | 6.48 |

| 6 | 4 | 480 | 100 | 5.54 |

| 7 | 5 | 600 | 100 | 5.97 |

| 8 | 6 | 720 | 100 | 6.28 |

| 9 | 7 | 840 | 100 | 6.46 |

| 10 | 8 | 960 | 100 | 6.56 |

| 11 | 4 | 480 | 200 | 5.86 |

| 12 | 5 | 600 | 200 | 6.28 |

| 13 | 6 | 720 | 200 | 6.50 |

| 14 | 7 | 840 | 200 | 6.83 |

| 15 | 8 | 960 | 200 | 7.07 |

| 16 | 4 | 480 | 300 | 6.21 |

| 17 | 5 | 600 | 300 | 6.67 |

| 18 | 6 | 720 | 300 | 6.90 |

| 19 | 7 | 840 | 300 | 7.09 |

| 20 | 8 | 960 | 300 | 7.25 |

| 21 | 4 | 480 | 300 | 6.58 |

| 22 | 5 | 600 | 400 | 6.84 |

| 23 | 6 | 720 | 400 | 7.30 |

| 24 | 7 | 840 | 400 | 7.45 |

| 25 | 8 | 960 | 400 | 7.59 |

| Interpass (°C) | Width (mm) | WFS (m/min) | TS (mm/min) |

|---|---|---|---|

| 100 | 7 | 8.54 | 1025.29 |

| 125 | 7 | 8.31 | 996.81 |

| 150 | 7 | 8.07 | 968.34 |

| 175 | 7 | 7.83 | 939.86 |

| 200 | 7 | 7.59 | 911.38 |

| 225 | 7 | 7.36 | 882.91 |

| 250 | 7 | 7.12 | 854.43 |

| 275 | 7 | 6.88 | 825.95 |

| 300 | 7 | 6.65 | 797.48 |

| 325 | 7 | 6.41 | 769.00 |

| 350 | 7 | 6.17 | 740.52 |

| 375 | 7 | 5.93 | 712.05 |

| 400 | 7 | 5.70 | 683.57 |

| Case 1 | Case 2 | Case 3 | Standard Deviation among All Cases | ||

|---|---|---|---|---|---|

| IPT-specific optimized parameters | Track width | 6.75 ± 0.001 mm | 6.80 ± 0.058 mm | 6.86 ± 0.018 mm | 0.05 mm |

| Printing time | 5 min 10 s | 8 min 26 s | 13 min 47 s | ||

| Fixed parameters | Track width | 6.96 ± 0.3075 mm | 7.31 ± 0.302 mm | 7.86 ± 0.538 mm | 0.40 mm |

| Printing time | 4 min 29 s | 9 min 35 s | 12 min 43 s |

| Pyrometer reading at center | Width | 6.81 ± 0.129 mm |

| Printing time | 20 min 25 s | |

| Pyrometer reading at edge | Width | 7.07 ± 0.456 mm |

| Printing time | 15 min 46 s |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jimenez, X.A.; Song, J.; Fu, Y.; To, A.C. Ensuring Melt Track Width Consistency and Crack-Free Conditions Using Interpass-Temperature-Dependent Process Parameters for Wire-Arc-Directed Energy-Deposited Inconel 718. J. Manuf. Mater. Process. 2024, 8, 140. https://doi.org/10.3390/jmmp8040140

Jimenez XA, Song J, Fu Y, To AC. Ensuring Melt Track Width Consistency and Crack-Free Conditions Using Interpass-Temperature-Dependent Process Parameters for Wire-Arc-Directed Energy-Deposited Inconel 718. Journal of Manufacturing and Materials Processing. 2024; 8(4):140. https://doi.org/10.3390/jmmp8040140

Chicago/Turabian StyleJimenez, Xavier A., Jie Song, Yao Fu, and Albert C. To. 2024. "Ensuring Melt Track Width Consistency and Crack-Free Conditions Using Interpass-Temperature-Dependent Process Parameters for Wire-Arc-Directed Energy-Deposited Inconel 718" Journal of Manufacturing and Materials Processing 8, no. 4: 140. https://doi.org/10.3390/jmmp8040140

APA StyleJimenez, X. A., Song, J., Fu, Y., & To, A. C. (2024). Ensuring Melt Track Width Consistency and Crack-Free Conditions Using Interpass-Temperature-Dependent Process Parameters for Wire-Arc-Directed Energy-Deposited Inconel 718. Journal of Manufacturing and Materials Processing, 8(4), 140. https://doi.org/10.3390/jmmp8040140