Effect of Different Annealing Methods on ULTEM 9085 Parts Manufactured by Material Extrusion

Abstract

1. Introduction

2. Methodology

2.1. Material and Manufacturing Process

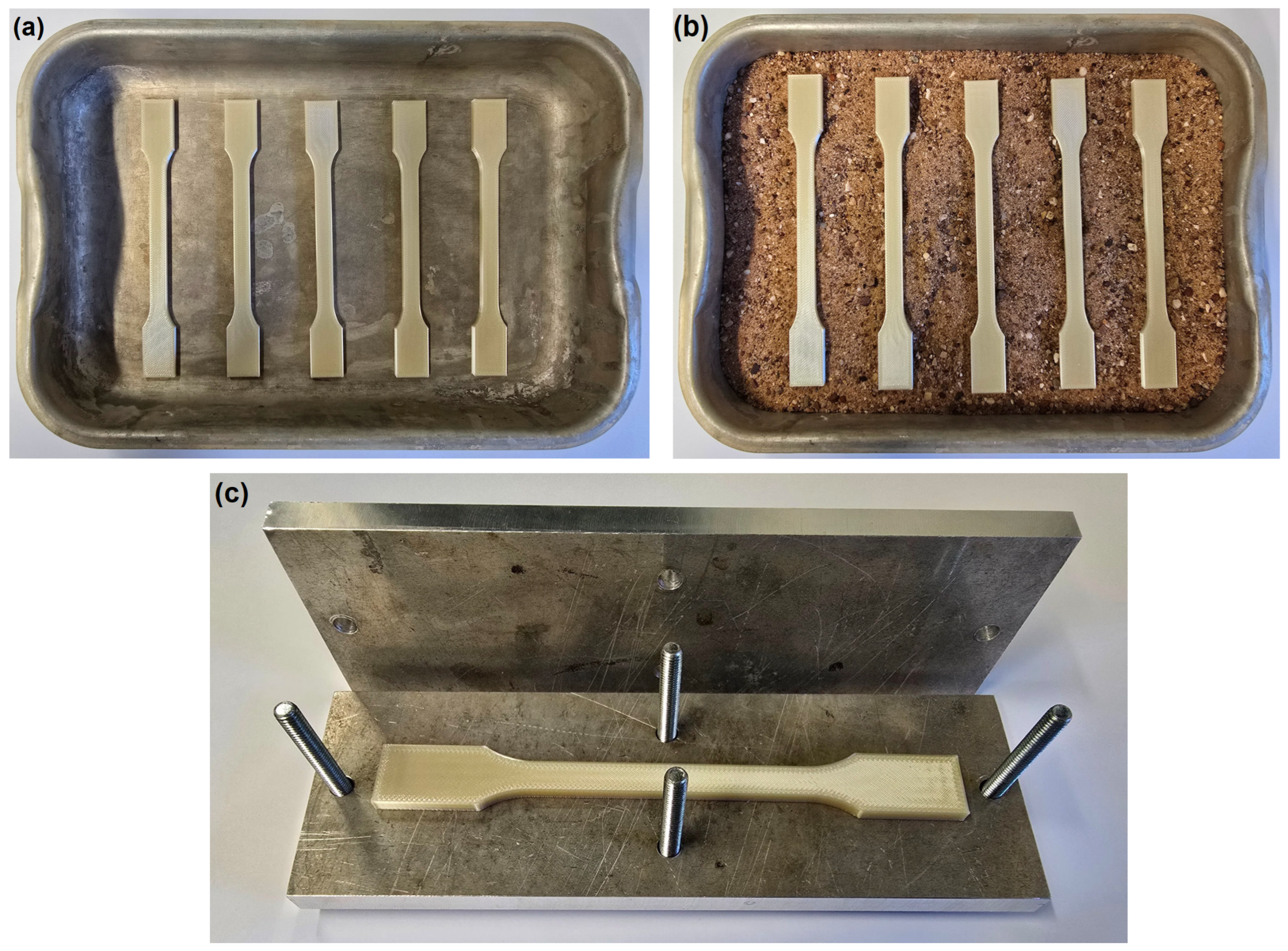

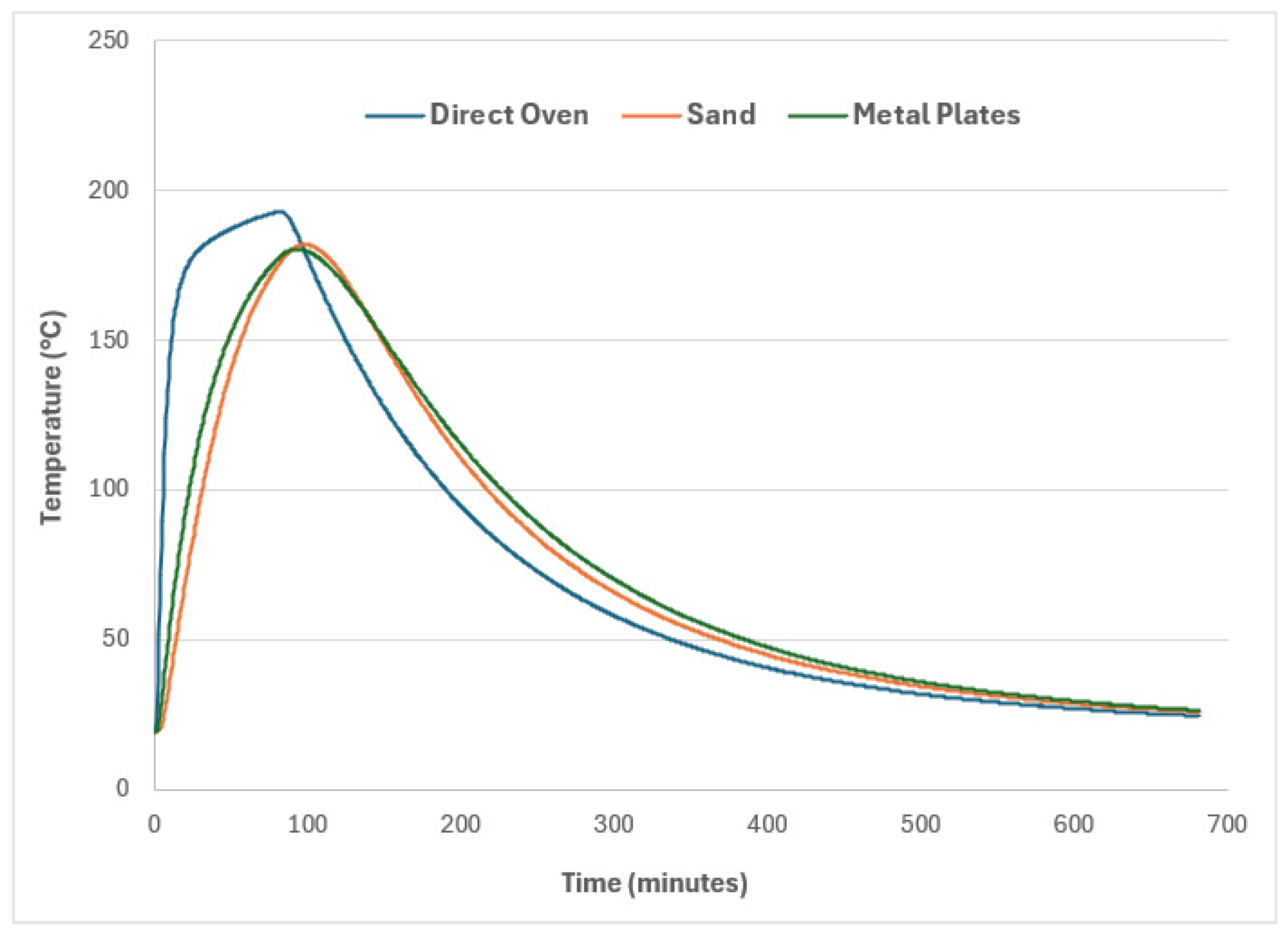

2.2. Annealing Methods

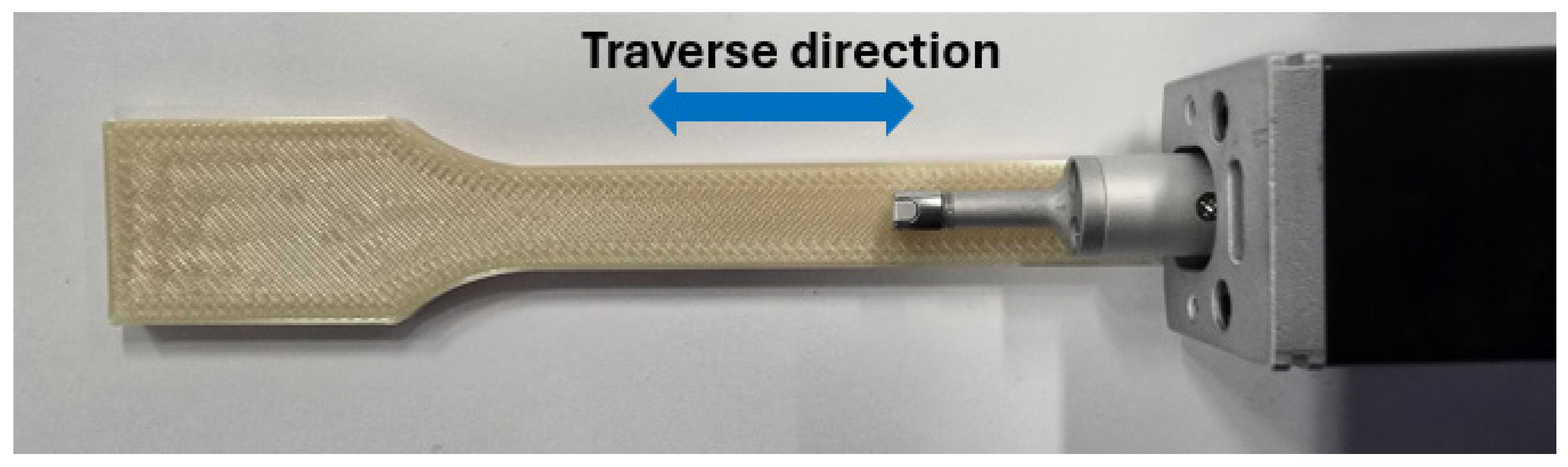

2.3. Measurements and Experimental Testing

3. Results and Discussion

3.1. Dimensional Analysis

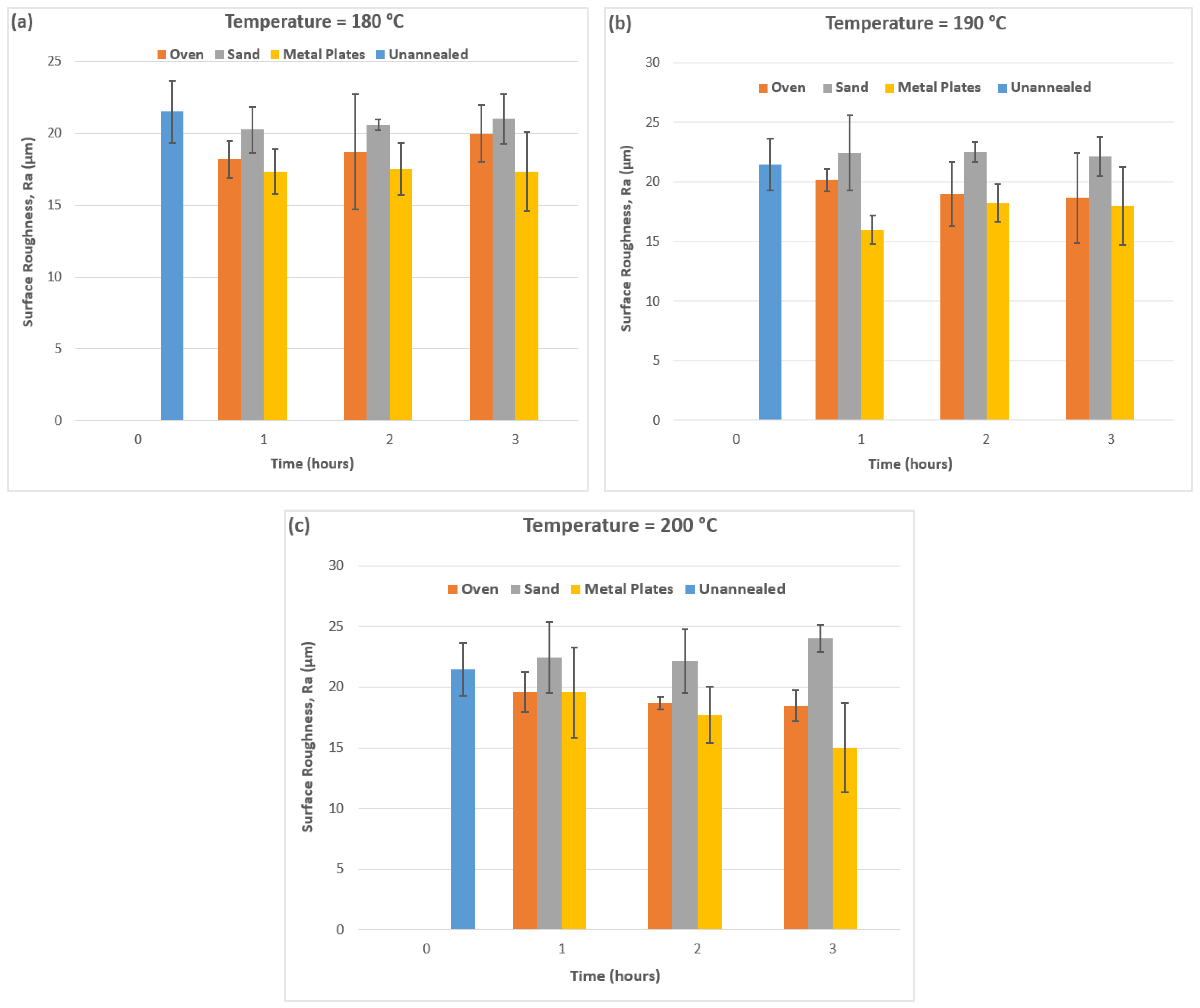

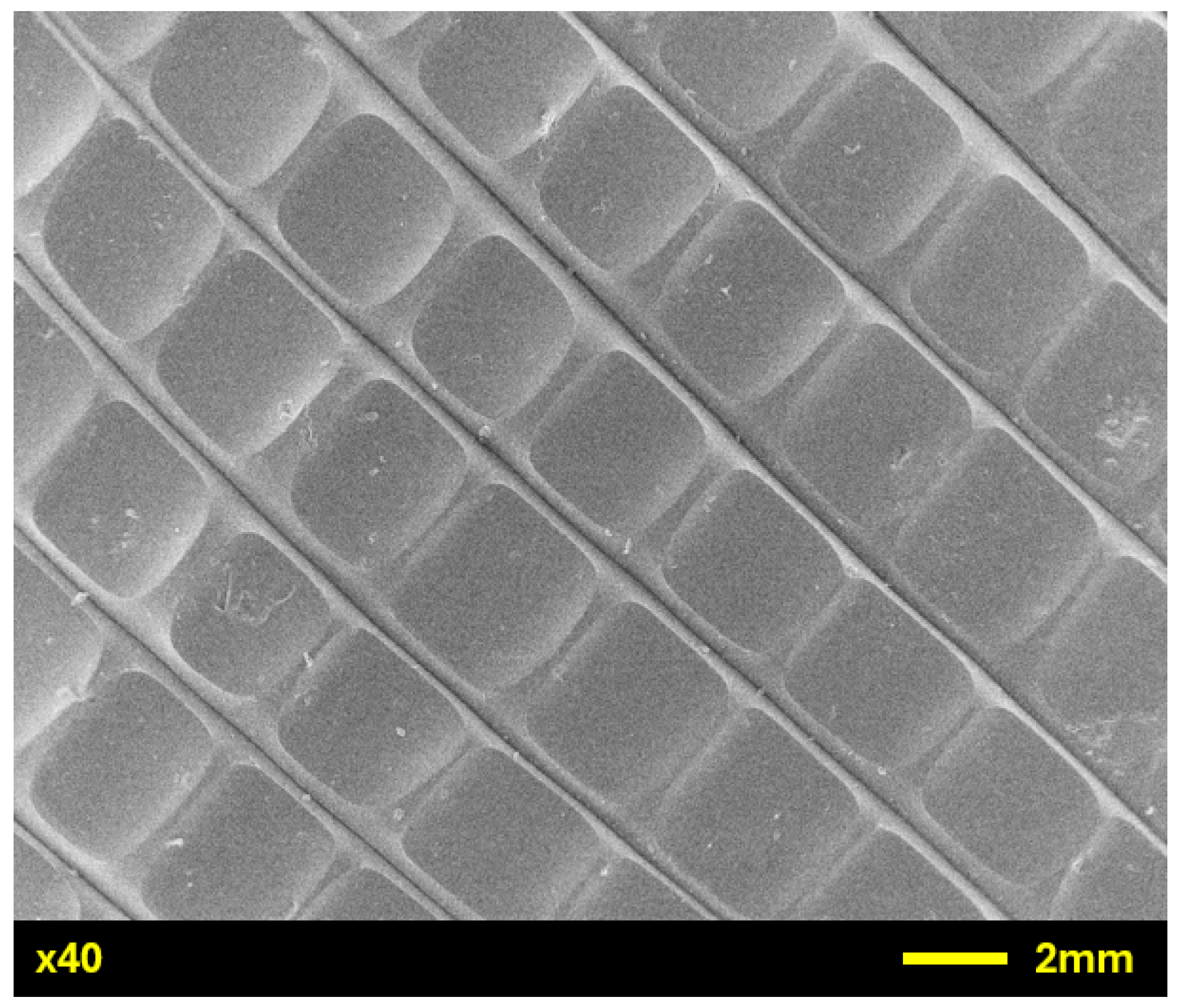

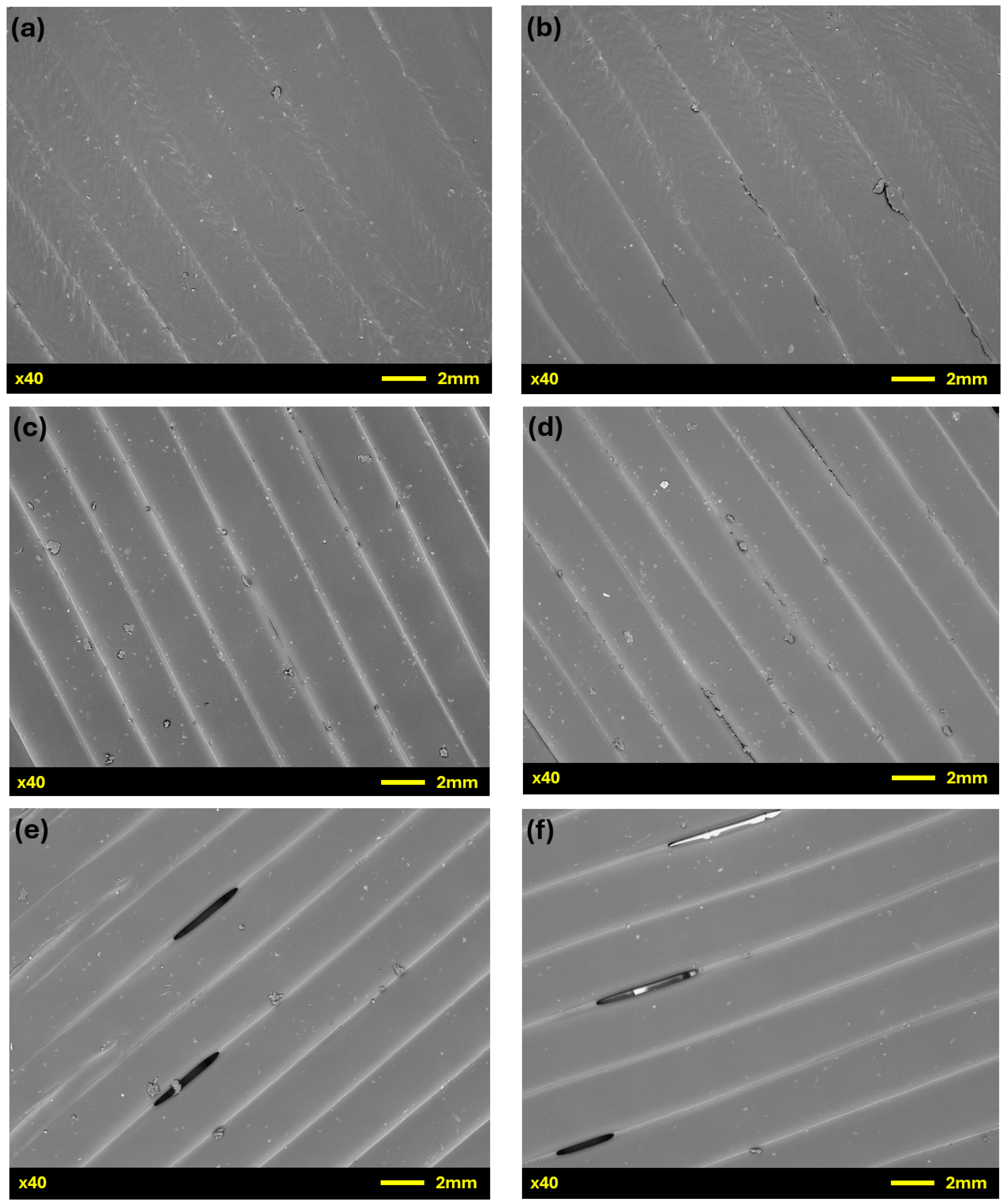

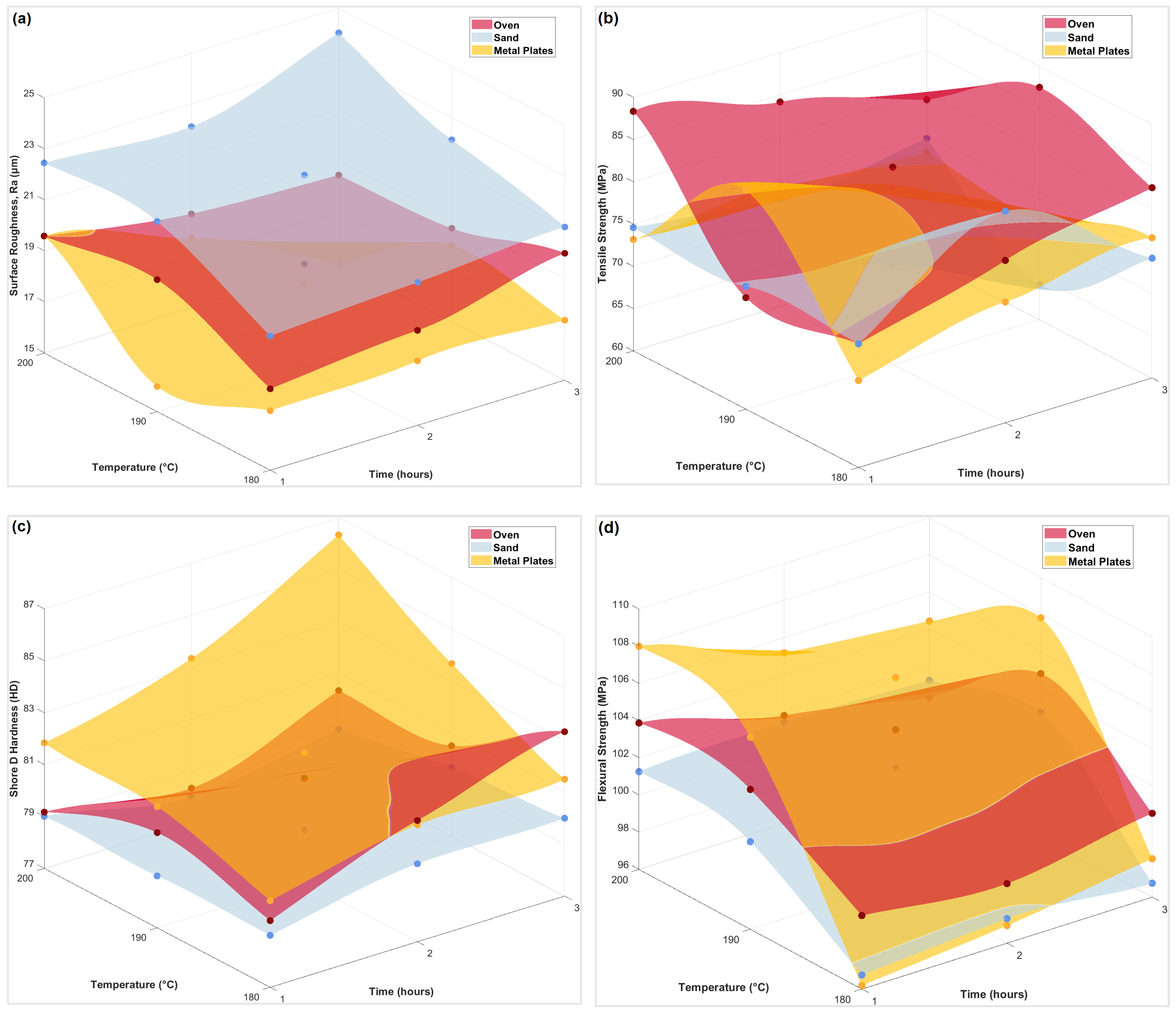

3.2. Surface Roughness Analaysis

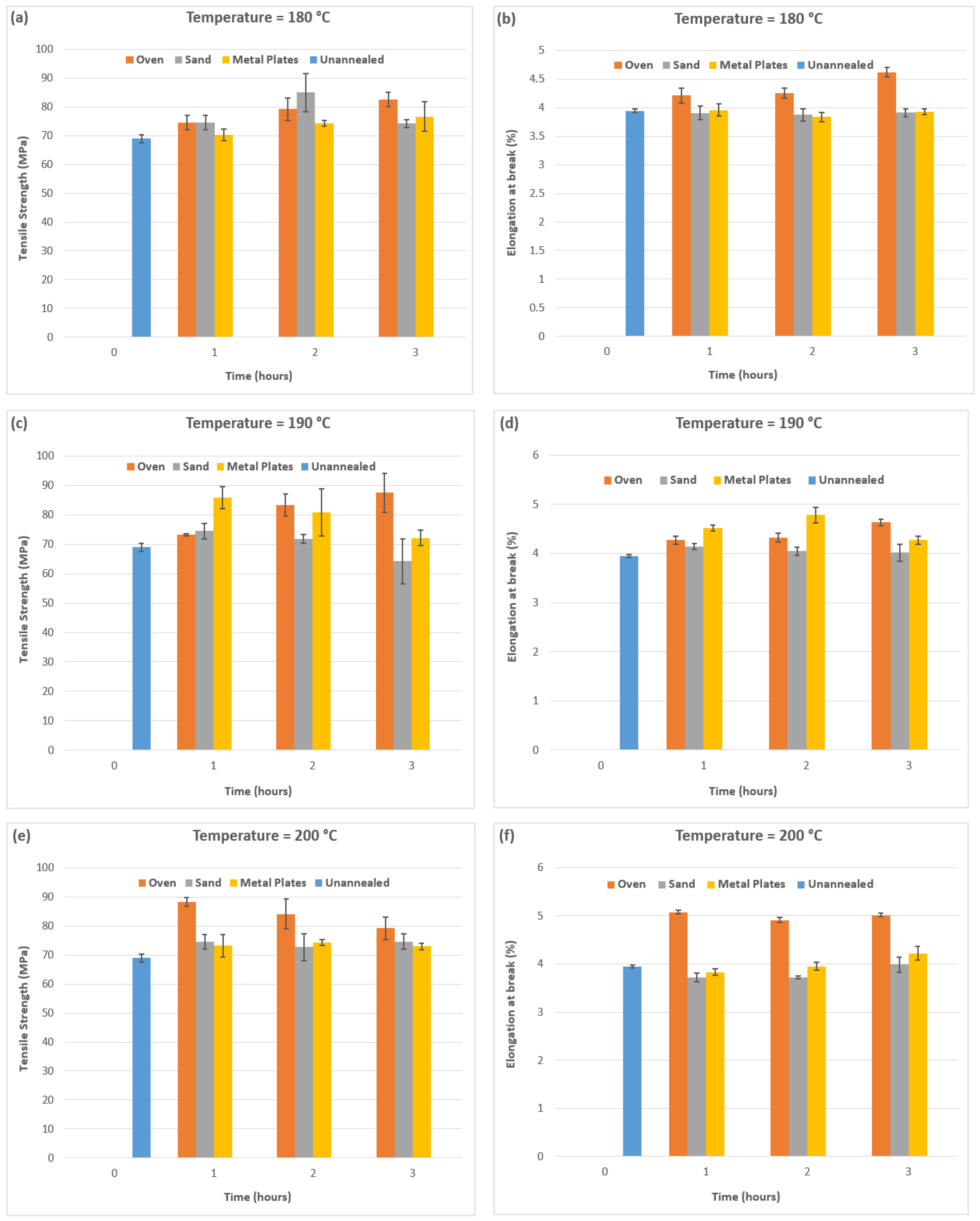

3.3. Tensile Testing

3.4. Hardness Testing

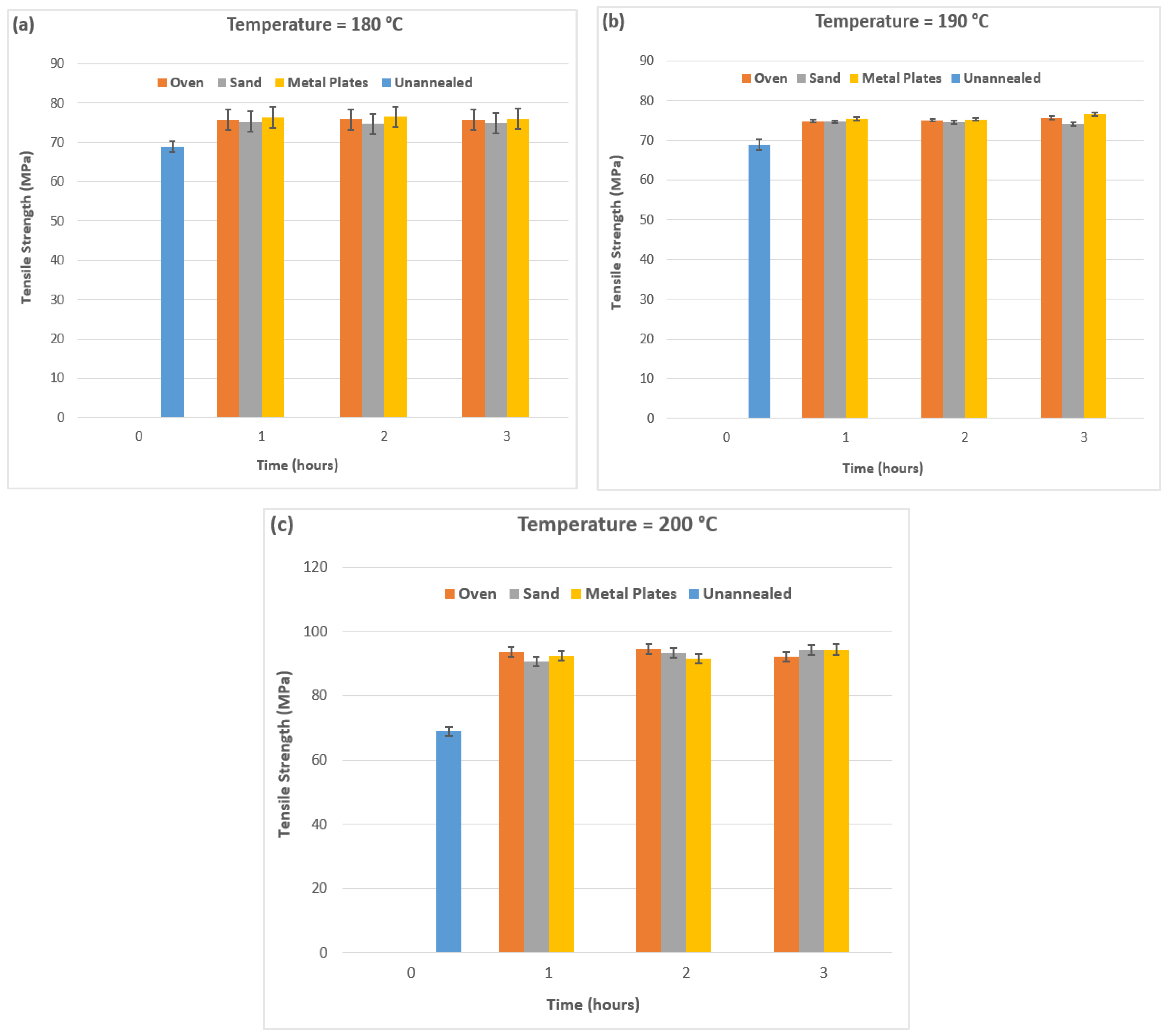

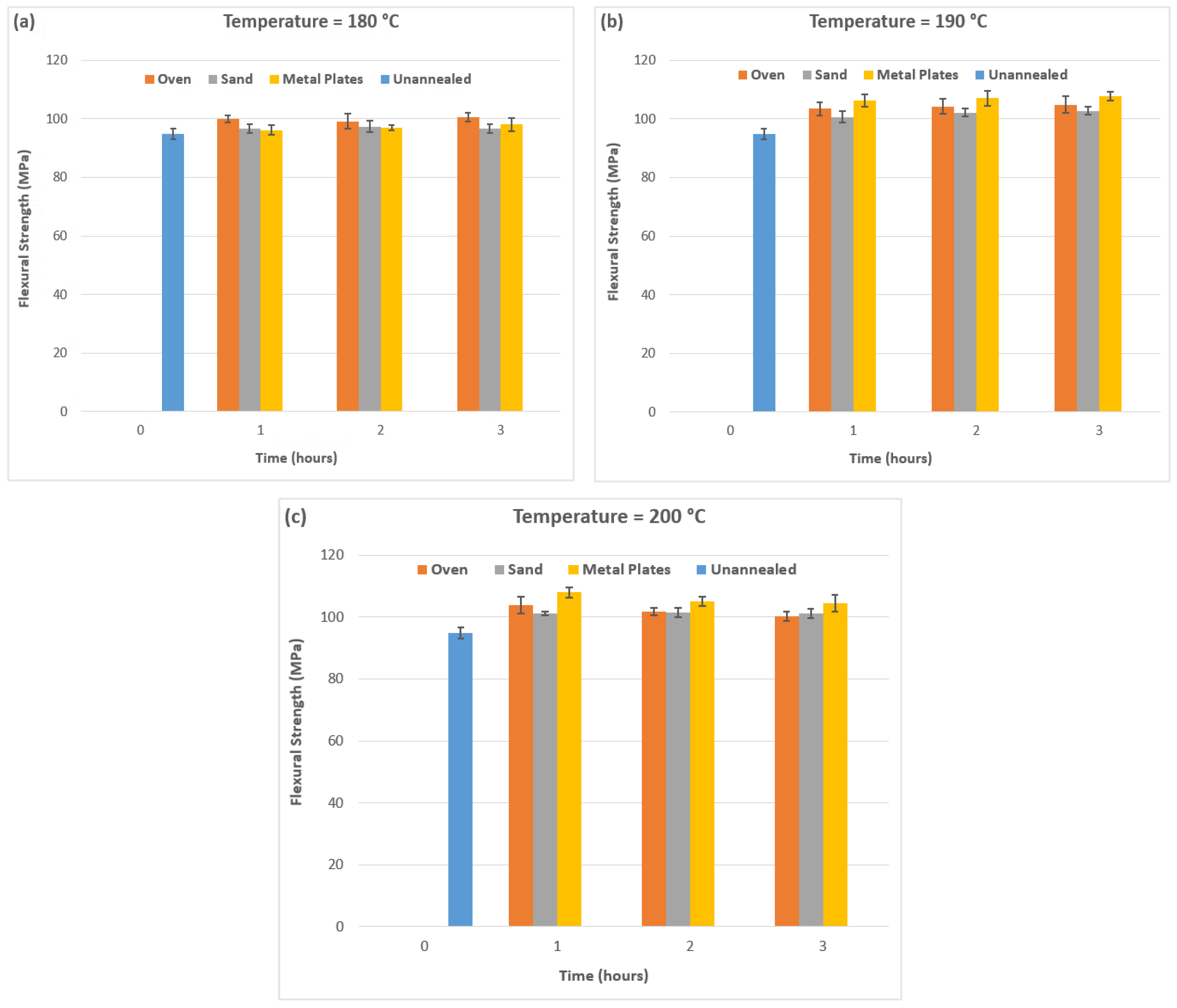

3.5. Flexural Testing

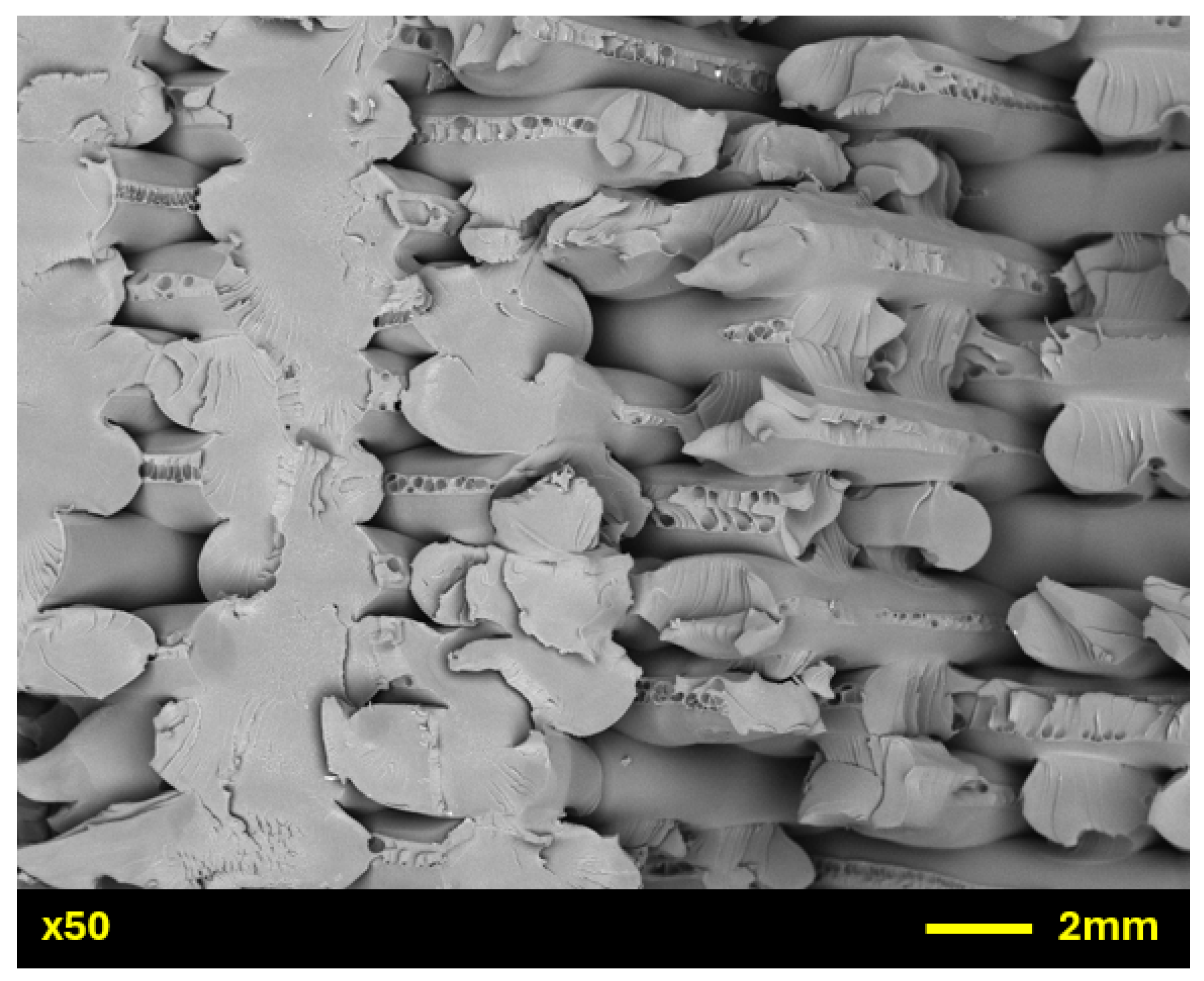

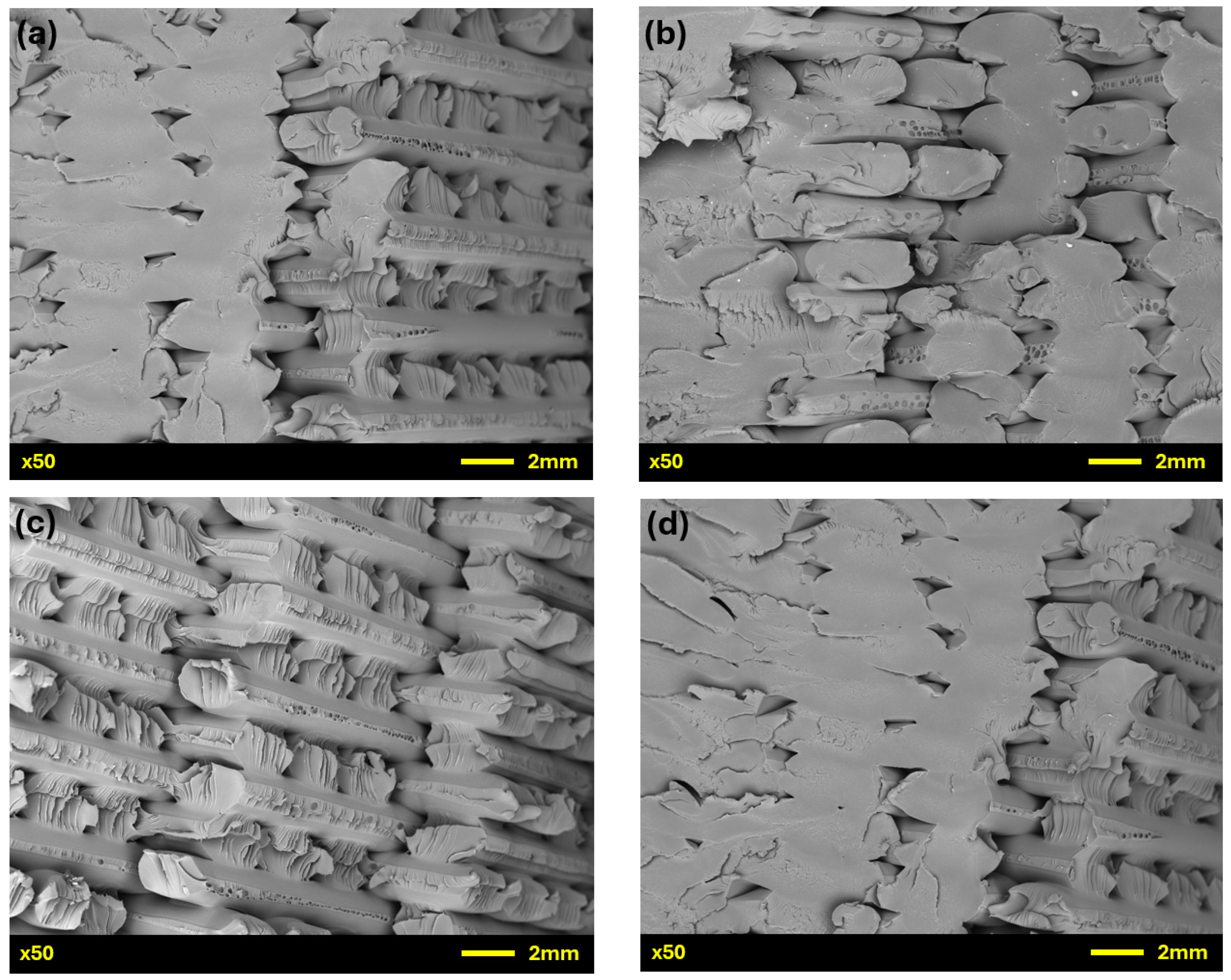

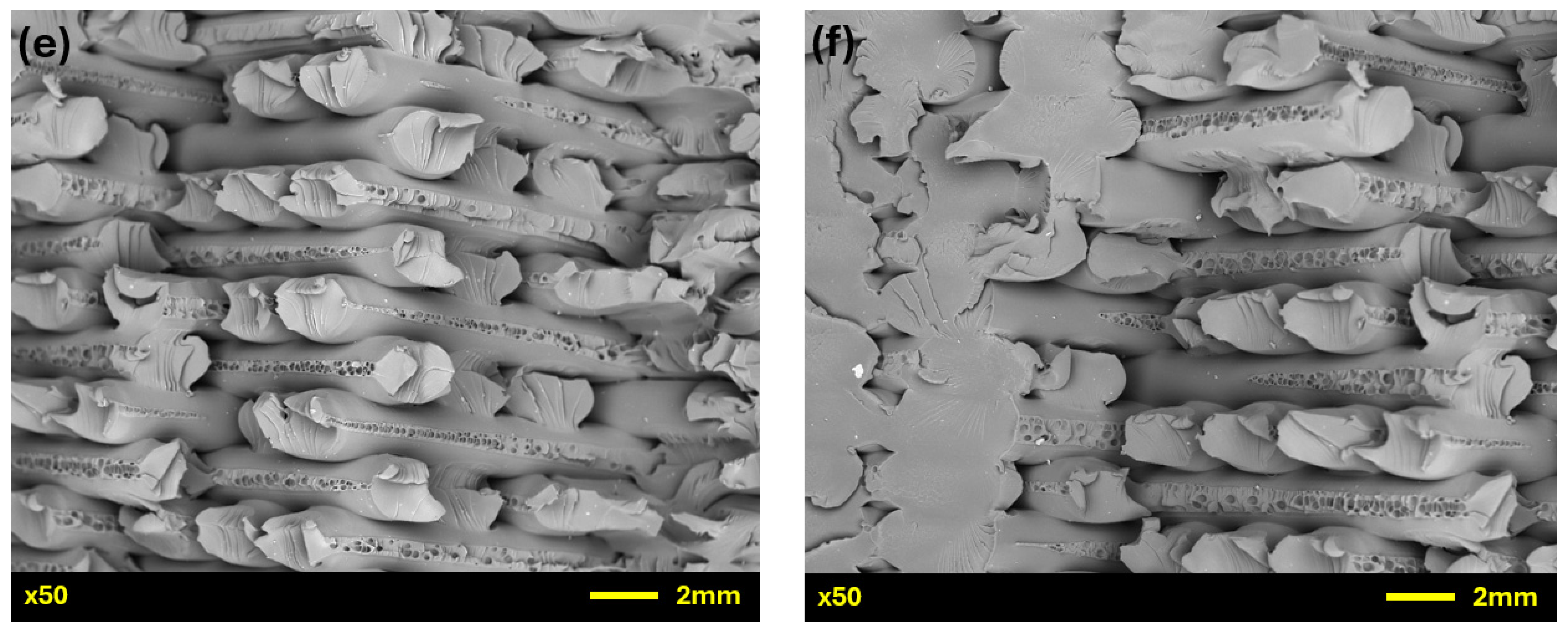

3.6. Microstructural Analysis

4. Material Quality Characterization

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Islam, M.A.; Mobarak, M.H.; Rimon, M.I.H.; Al Mahmud, M.Z.; Ghosh, J.; Ahmed, M.M.S.; Hossain, N. Additive manufacturing in polymer research: Advances, synthesis, and applications. Polym. Test. 2024, 132, 108364. [Google Scholar] [CrossRef]

- Srivastava, M.; Rathee, S. Additive manufacturing: Recent trends, applications and future outlooks. Prog. Addit. Manuf. 2022, 7, 261–287. [Google Scholar] [CrossRef]

- Leal, R.; Barreiros, F.M.; Alves, L.; Romeiro, F.; Vasco, J.C.; Santos, M.; Marto, C. Additive manufacturing tooling for the automotive industry. Int. J. Adv. Manuf. Technol. 2017, 92, 1671–1676. [Google Scholar] [CrossRef]

- Butt, J.; Onimowo, D.A.; Gohrabian, M.; Sharma, T.; Shirvani, H. A desktop 3D printer with dual extruders to produce customised electronic circuitry. Front. Mech. Eng. 2018, 13, 528–534. [Google Scholar] [CrossRef]

- First Metal Part 3D Printed in Space. Available online: https://phys.org/news/2024-09-metal-3d-space.html#:~:text=Additive%20manufacturing%20in%20space%20will,relying%20on%20resupplies%20and%20redundancies (accessed on 15 September 2024).

- ISO/ASTM 52900:2021; Additive Manufacturing—General Principles—Fundamentals and Vocabulary. International Organization for Standardization: Geneva, Switzerland, 2021.

- Oleff, A.; Küster, B.; Stonis, M.; Overmeyer, L. Process monitoring for material extrusion additive manufacturing: A state-of-the-art review. Prog. Addit. Manuf. 2021, 6, 705–730. [Google Scholar] [CrossRef]

- Park, S.I.; Rosen, D.W.; Choi, S.K.; Duty, C.E. Effective mechanical properties of lattice material fabricated by material extrusion additive manufacturing. Addit. Manuf. 2014, 1, 12–23. [Google Scholar]

- Jiang, J.; Xu, X.; Stringer, J. Optimization of process planning for reducing material waste in extrusion based additive manufacturing. Robot. Comput. Manuf. 2019, 59, 317–325. [Google Scholar] [CrossRef]

- Butt, J.; Bhaskar, R.; Mohaghegh, V. Analysing the effects of layer heights and line widths on FFF-printed thermoplastics. Int. J. Adv. Manuf. Technol. 2022, 121, 7383–7411. [Google Scholar] [CrossRef]

- Butt, J.; Bhaskar, R.; Mohaghegh, V. Investigating the effects of extrusion temperatures and material extrusion rates on FFF-printed thermoplastics. Int. J. Adv. Manuf. Technol. 2021, 117, 2679–2699. [Google Scholar] [CrossRef]

- Kechagias, J.; Chaidas, D.; Vidakis, N.; Salonitis, K.; Vaxevanidis, N. Key parameters controlling surface quality and dimensional accuracy: A critical review of FFF process. Mater. Manuf. Process. 2022, 37, 963–984. [Google Scholar] [CrossRef]

- Cicala, G.; Ognibene, G.; Portuesi, S.; Blanco, I.; Rapisarda, M.; Pergolizzi, E.; Recca, G. Comparison of Ultem 9085 Used in Fused Deposition Modelling (FDM) with Polytherimide Blends. Materials 2018, 11, 285. [Google Scholar] [CrossRef] [PubMed]

- Shelton, T.E.; Willburn, Z.A.; Hartsfield, C.R.; Cobb, G.R.; Cerri, J.T.; Kemnitz, R.A. Effects of thermal process parameters on mechanical interlayer strength for additively manufactured Ultem 9085. Polym. Test. 2020, 81, 106255. [Google Scholar] [CrossRef]

- Padovano, E.; Galfione, M.; Concialdi, P.; Lucco, G.; Badini, C. Mechanical and thermal behavior of ULTEM® 9085 fabricated by fused-deposition modeling. Appl. Sci. 2020, 10, 3170. [Google Scholar] [CrossRef]

- Butt, J.; Bhaskar, R. Investigating the effects of annealing on the mechanical properties of FFF-printed thermoplastics. J. Manuf. Mater. Process. 2020, 4, 38. [Google Scholar] [CrossRef]

- Zhang, Y.; Moon, S.K. The effect of annealing on additive manufactured ULTEM™ 9085 mechanical properties. Materials 2021, 14, 2907. [Google Scholar] [CrossRef]

- de Bruijn, A.C.; Gómez-Gras, G.; Pérez, M.A. Thermal annealing as a post-process for additively manufactured Ultem 9085 parts. Procedia Comput. Sci. 2022, 200, 1308–1317. [Google Scholar] [CrossRef]

- de Bruijn, A.C.; Gómez-Gras, G.; Fernández-Ruano, L.; Farràs-Tasias, L.; Pérez, M.A. Optimization of a combined thermal annealing and isostatic pressing process for mechanical and surface enhancement of Ultem FDM parts using Doehlert experimental designs. J. Manuf. Process. 2023, 85, 1096–1115. [Google Scholar] [CrossRef]

- Glaskova-Kuzmina, T.; Dejus, D.; Jātnieks, J.; Aniskevich, A.; Sevcenko, J.; Sarakovskis, A.; Zolotarjovs, A. Effect of post-printing cooling conditions on the properties of ULTEM printed parts. Polymers 2023, 15, 324. [Google Scholar] [CrossRef]

- ULTEM™ 9085 Resin. Available online: https://www.stratasys.com/uk/materials/materials-catalog/fdm-materials/ULTEM-9085-resin/ (accessed on 16 September 2024).

- BS EN ISO 527-2:2012; Plastics—Determination of Tensile Properties–Part 2: Test Conditions for Moulding and Extrusion Plastics. British, European and International Standard: London, UK, 2012.

- BS EN ISO 868:2003; Plastics and Ebonite–Determination of Indentation Hardness by Means of a Durometer (Shore Hardness). British, European and International Standard: London, UK, 2018.

- BS EN ISO 178:2019; Plastics—Determination of Flexural Properties. British, European and International Standard: London, UK, 2019.

- Mitutoyo: SJ-210—Portable Surface Roughness Tester. Available online: https://www.mitutoyo.com/products/form-measurement-machine/surface-roughness/sj-210-portable-surface-roughness-tester-2/ (accessed on 16 September 2024).

- ISO 21920-2:2021; Geometrical Product Specifications (GPS)—Surface Texture: Profile—Part 2: Terms, Definitions and Surface Texture Parameters. International Organization for Standardization (ISO): Geneva, Switzerland, 2021.

- Hart, K.R.; Dunn, R.M.; Sietins, J.M.; Mock, C.M.H.; Mackay, M.E.; Wetzel, E.D. Increased fracture toughness of additively manufactured amorphous thermoplastics via thermal annealing. Polymer 2018, 144, 192–204. [Google Scholar] [CrossRef]

- Rane, R.; Kulkarni, A.; Prajapati, H.; Taylor, R.; Jain, A.; Chen, V. Post-process effects of isothermal annealing and initially applied static uniaxial loading on the ultimate tensile strength of fused filament fabrication parts. Materials 2020, 13, 352. [Google Scholar] [CrossRef]

- Alsoufi, M.S.; Elsayed, A.E. How surface roughness performance of printed parts manufactured by desktop FDM 3D printer with PLA+ is influenced by measuring direction. Am. J. Mech. Eng. 2017, 5, 211–222. [Google Scholar]

- Garg, A.; Bhattacharya, A.; Batish, A. On surface finish and dimensional accuracy of FDM parts after cold vapor treatment. Mater. Manuf. Process. 2016, 31, 522–529. [Google Scholar] [CrossRef]

- Parrington, R.J. Fractography of metals and plastics. Pract. Fail. Anal. 2002, 2, 16–19. [Google Scholar] [CrossRef]

| Annealing Time (h) | Annealing Temperature (°C) |

|---|---|

| 1 | 180 |

| 1 | 190 |

| 1 | 200 |

| 2 | 180 |

| 2 | 190 |

| 2 | 200 |

| 3 | 180 |

| 3 | 190 |

| 3 | 200 |

| Annealing Methods | Time (h) | Temperature (°C) | Δ Length (%) (±SD) | Δ Width (%) (±SD) | Δ Thickness (%) (±SD) |

|---|---|---|---|---|---|

| Direct oven | 1 | 180 | −0.524 (0.22) | −0.106 (0.01) | 1.245 (0.02) |

| 1 | 190 | −0.995 (0.32) | −0.153 (0.03) | 1.895 (0.02) | |

| 1 | 200 | −1.937 (0.15) | −1.226 (0.04) | 3.317 (0.03) | |

| 2 | 180 | −0.455 (0.24) | 0 (0) | 1.656 (0.06) | |

| 2 | 190 | −1.1 (0.31) | −0.076 (0.01) | 2.369 (0.07) | |

| 2 | 200 | −1.942 (0.15) | −1.688 (0.06) | 3.309 (0.09) | |

| 3 | 180 | −0.567 (0.21) | −0.114 (0.03) | 1.176 (0.05) | |

| 3 | 190 | −1.135 (0.23) | −0.46 (0.05) | 2.432 (0.04) | |

| 3 | 200 | −1.469 (0.25) | −0.543 (0.05) | 3.095 (0.08) | |

| Sand | 1 | 180 | −0.128 (0.12) | 0 (0) | 0.943 (0.01) |

| 1 | 190 | −0.725 (0.15) | −0.153 (0.03) | 1.654 (0.04) | |

| 1 | 200 | −0.843 (0.21) | −0.536 (0.05) | 1.418 (0.05) | |

| 2 | 180 | −0.322 (0.16) | −0.076 (0.01) | 0 (0) | |

| 2 | 190 | −0.731 (0.19) | −0.306 (0.04) | 1.176 (0.06) | |

| 2 | 200 | −1.381 (0.27) | −1.61 (0.05) | 2.117 (0.09) | |

| 3 | 180 | −0.362 (0.35) | −0.076 (0.01) | 0.235 (0.01) | |

| 3 | 190 | −0.761 (0.28) | −0.23 (0.02) | 0.705 (0.02) | |

| 3 | 200 | −1.171 (0.38) | −1.911 (0.06) | 2.619 (0.07) | |

| Metal plate | 1 | 180 | −0.304 (0.14) | 0.306 (0.04) | −1.654 (0.05) |

| 1 | 190 | −0.433 (0.12) | 0.229 (0.03) | −2.576 (0.08) | |

| 1 | 200 | −0.362 (0.18) | 0.613 (0.04) | −3.301 (0.09) | |

| 2 | 180 | −0.403 (0.22) | 0.306 (0.02) | −1.891 (0.04) | |

| 2 | 190 | −0.357 (0.28) | 0.460 (0.02) | −1.869 (0.04) | |

| 2 | 200 | −0.333 (0.39) | 0.304 (0.02) | −2.863 (0.06) | |

| 3 | 180 | −0.374 (0.31) | 0.298 (0.01) | −1.184 (0.04) | |

| 3 | 190 | −0.316 (0.39) | 0.766 (0.04) | −2.843 (0.08) | |

| 3 | 200 | −0.292 (0.42) | 1.377 (0.05) | −3.739 (0.09) |

| Annealing Method | Annealing Temperature (°C) | Annealing Time (h) | Surface Roughness (μm) | Tensile Strength (MPa) | Hardness (HD) | Flexural Strength (MPa) |

|---|---|---|---|---|---|---|

| Direct oven | 190 | 3 | 18.6 | 87.5 | 80.5 | 104.8 |

| Metal plate | 190 | 1 | 15.9 | 85.8 | 81.6 | 106.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Butt, J.; Afsharnia, H.; Alam Khan, M.A.; Mohaghegh, V. Effect of Different Annealing Methods on ULTEM 9085 Parts Manufactured by Material Extrusion. J. Manuf. Mater. Process. 2024, 8, 258. https://doi.org/10.3390/jmmp8060258

Butt J, Afsharnia H, Alam Khan MA, Mohaghegh V. Effect of Different Annealing Methods on ULTEM 9085 Parts Manufactured by Material Extrusion. Journal of Manufacturing and Materials Processing. 2024; 8(6):258. https://doi.org/10.3390/jmmp8060258

Chicago/Turabian StyleButt, Javaid, Habib Afsharnia, Md Ashikul Alam Khan, and Vahaj Mohaghegh. 2024. "Effect of Different Annealing Methods on ULTEM 9085 Parts Manufactured by Material Extrusion" Journal of Manufacturing and Materials Processing 8, no. 6: 258. https://doi.org/10.3390/jmmp8060258

APA StyleButt, J., Afsharnia, H., Alam Khan, M. A., & Mohaghegh, V. (2024). Effect of Different Annealing Methods on ULTEM 9085 Parts Manufactured by Material Extrusion. Journal of Manufacturing and Materials Processing, 8(6), 258. https://doi.org/10.3390/jmmp8060258