Microstructure, Physical-Mechanical, and Magnetic Characteristics of a Butt-Welded Joint Obtained by Rotary Friction Welding Technology of Bimetallic Pipe

Abstract

1. Introduction

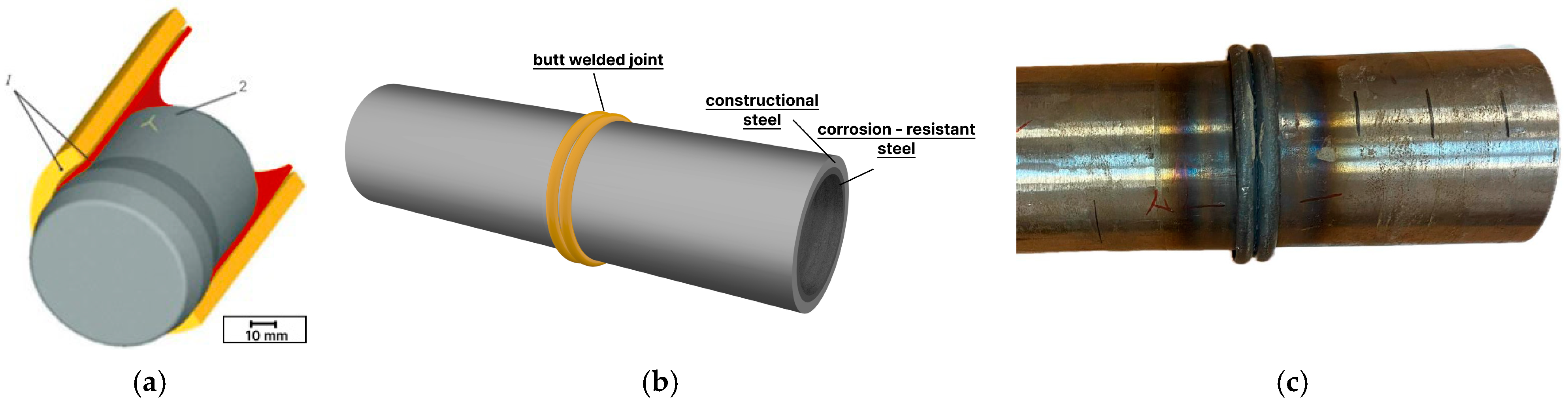

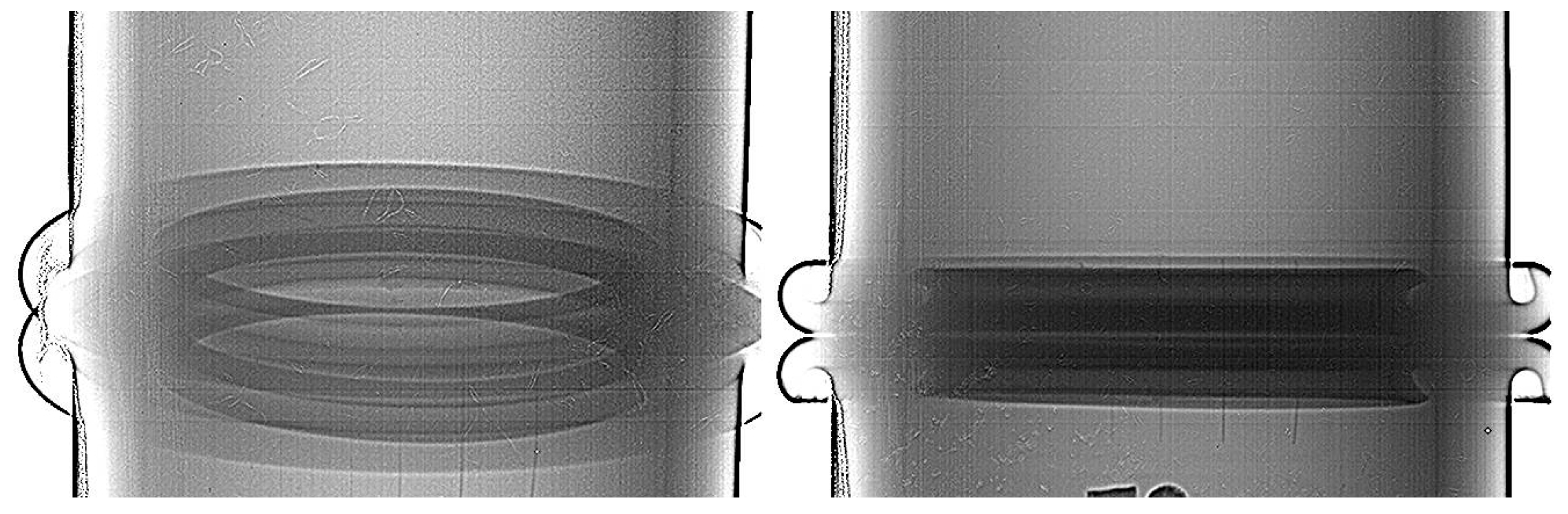

2. Materials and Methods

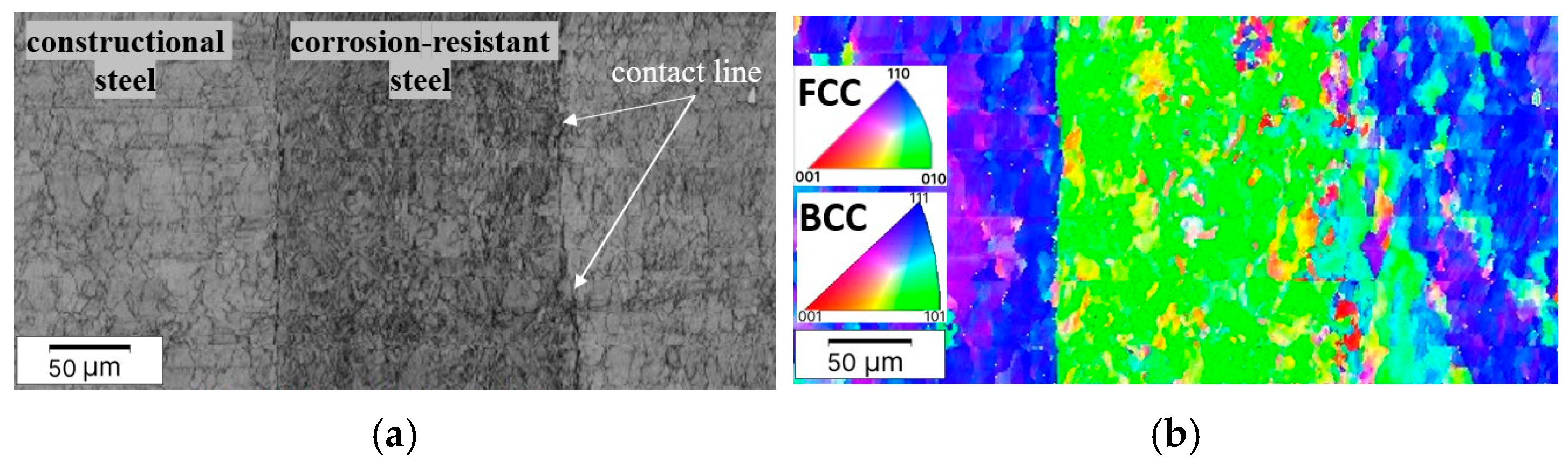

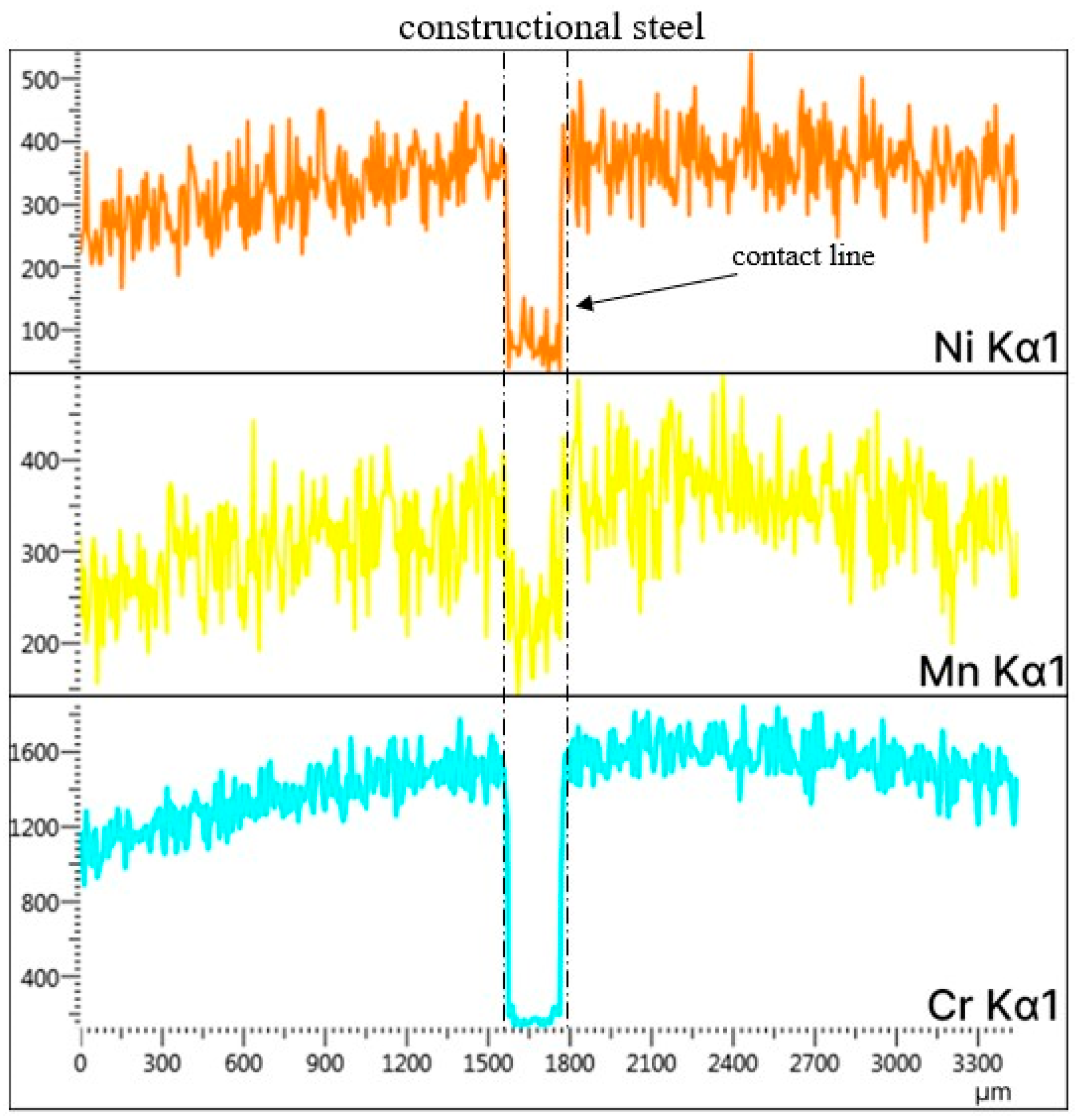

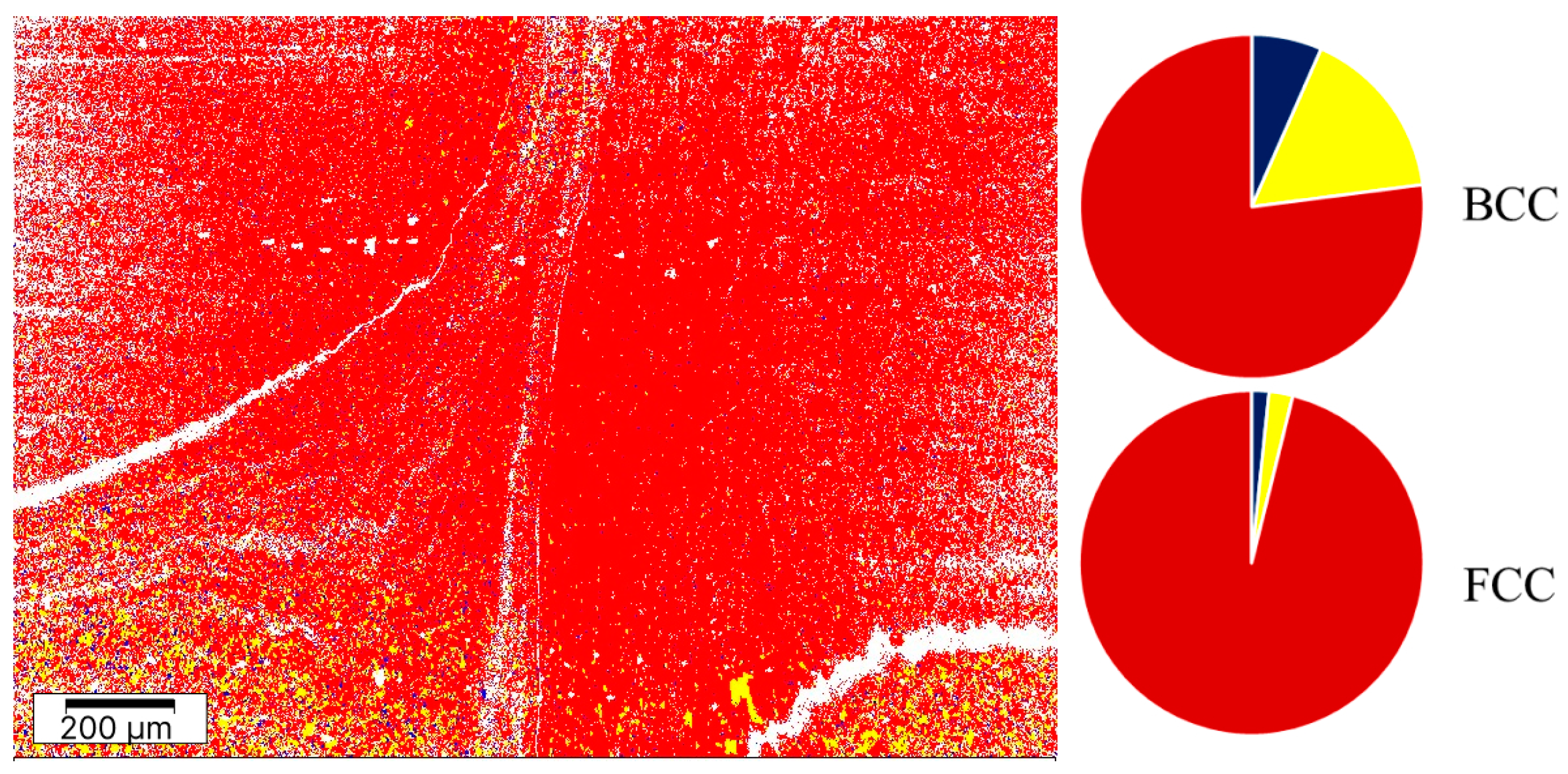

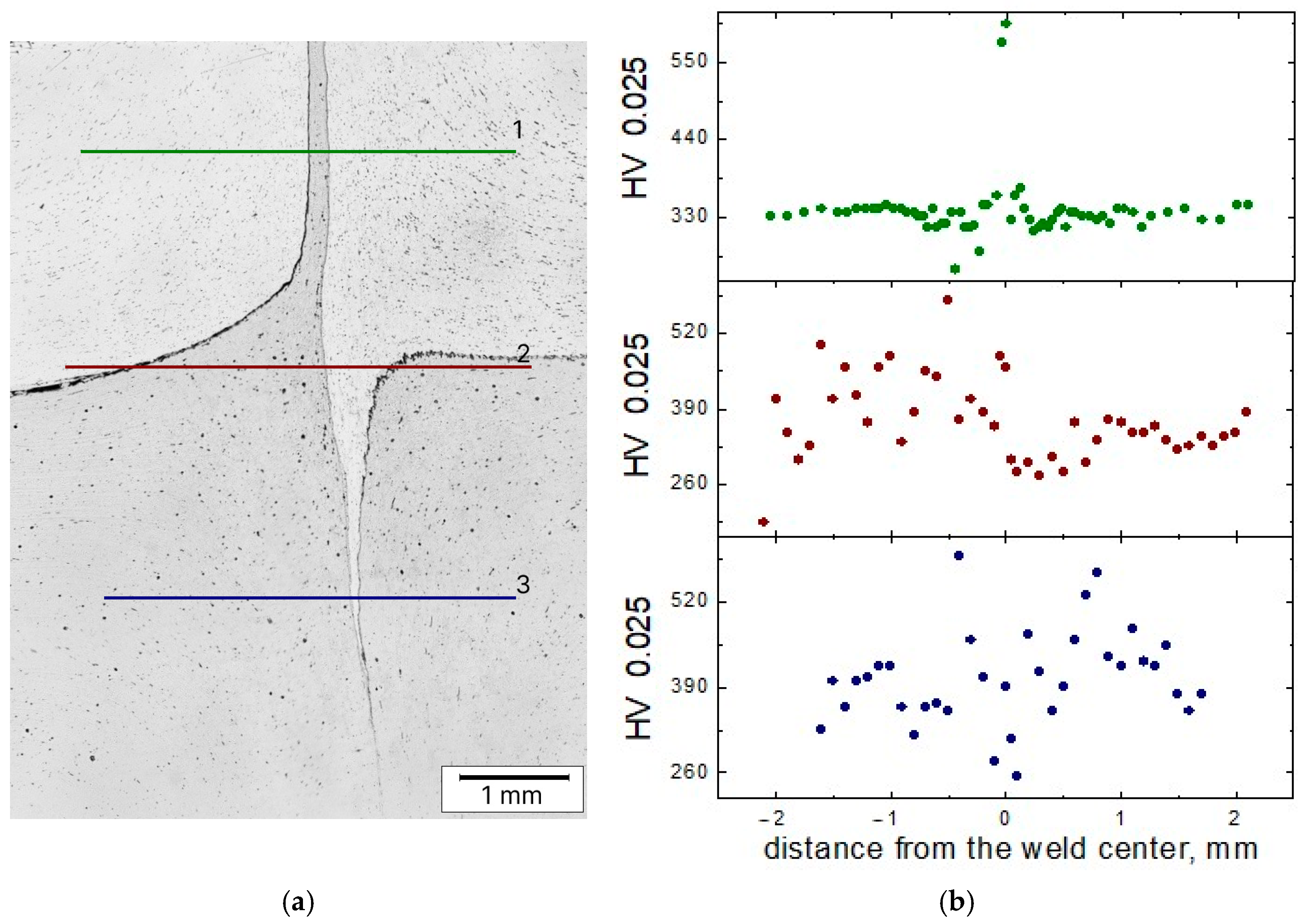

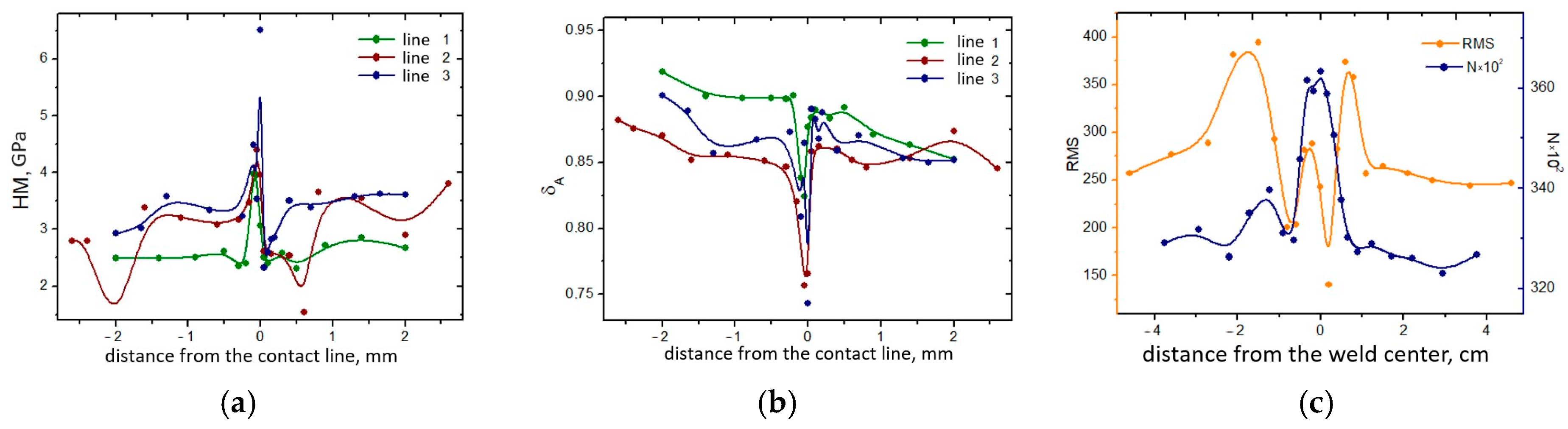

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, C.; Bi, Z.Y.; Zhang, W.P.; Yang, Y.B.; Han, Z.C. Research status on double-metal composite pipe at home and abroad. Welded Pipe Tube 2015, 38, 7–12. [Google Scholar]

- Spence, M.A.; Roscoe, C.V. Bi-metal CRA-lined pipe employed for North sea field development. Oil Gas J. 1999, 97, 80–88. [Google Scholar]

- Smith, L. Engineering with clad steel. In NiDI, Technical Series; Nickel Development Institute: Birmingham, UK, 1996; No. 10064; pp. 1–19. [Google Scholar]

- Li, F.G.; Li, X.J.; Li, W.W.; Wang, F.S.; Li, X.M. Failure Analysis and Solution to Bimetallic Lined Pipe. Mater. Sci. Forum 2020, 993, 1265–1269. [Google Scholar] [CrossRef]

- Li, F.G.; Li, X.J.; Li, W.W.; Li, X.M.; Chang, Z.L.; Feng, Q. Study on Welding Techniques of 316 L Lined Bimetallic Pipe. Mater. Sci. Forum 2019, 944, 944–949. [Google Scholar] [CrossRef]

- Uday, M.B.; Ahmad Fauzi, M.N.; Zuhailawati, H.; Ismail, A.B. Advances in friction welding process: A review. Sci. Technol. Weld. Join. 2010, 15, 534–558. [Google Scholar] [CrossRef]

- Mishra, R.S.; Mahoney, M.W. Friction Stir Welding and Processing; ASM International: Materials Park, OH, USA, 2007; p. 360. [Google Scholar]

- Neumann, A.; Schober, D. Reibschweißen von Metallen; Verlag Technik GmbH: Berlin, Germany, 1991; ISBN 3-87155-124-4. [Google Scholar]

- Grünauer, H. Reibschweißen von Metallen; VDE Verlag: Ehningen bei Böblingen, Germany, 1987; ISBN 3-8169-0117-4. [Google Scholar]

- Sathija, P.; Aravindan, S.; Noorul Haq, A. Effect of Friction Welding Parameters on Mechanical and Metallurgical Properties of Ferritic Stainless Steel. Int. J. Adv. Manuf. Technol. 2007, 31, 1076–1082. [Google Scholar] [CrossRef]

- Tan, C.; Zhou, K.; Ma, W.; Min, L. Interfacial characteristic and mechanical performance of maraging steel-copper functional bimetal produced by selective laser melting based hybrid manufacture. Mater. Des. 2018, 155, 77–85. [Google Scholar] [CrossRef]

- Sebastian, R.; Singh, A.K.; Paliwal, M.; Gautam, A. Investigation of the interface between SLM processed nickel alloy on a cast iron substrate. Prog. Addit. Manuf. 2018, 4, 131–142. [Google Scholar]

- Fu, Y.; Liu, J.; Huang, W.; Liu, Y. Interfacial characterization and bonding performance of additively manufactured GH4169/cast iron bimetal. Addit. Manuf. 2024, 93, 104429. [Google Scholar] [CrossRef]

- Li, L.; Xiao, J.; Han, B.; Wang, X. Microstructure and mechanical properties of welded joints of L415/316L bimetal composite pipe using post internal-welding process. Int. J. Press. Vess. Piping 2020, 179, 104026. [Google Scholar]

- Ramesh, N.R.; Senthil Kumar, V.S. Experimental erosion-corrosion analysis of friction stir welding of AA 5083 and AA 6061 for sub-sea applications. Appl. Ocean Res. 2020, 98, 102121. [Google Scholar] [CrossRef]

- Li, L.; Yu, T.; Xia, J.; Gao, Y.; Han, B.; Gao, Z. Failure analysis of L415/316L composite pipe welded joint. Eng. Fail. Anal. 2024, 158, 107981. [Google Scholar] [CrossRef]

- Falahati Naqibi, M.; Elyasi, M.; Jamshidi Aval, H.; Mirnia, M.J. Theoretical and experimental studies on fabrication of two-layer aluminum−copper pipe by friction stir additive manufacturing. Trans. Nonferr. Met. Soc. China 2021, 31, 3643–3658. [Google Scholar] [CrossRef]

- Selvamani, S.T.; Palanikumar, K. Optimizing the friction welding parameters to attain maximum tensile strength in AISI 1035 grade carbon steel rods. Measurement 2014, 53, 10–21. [Google Scholar] [CrossRef]

- Shanjeevi, C.; Satish Kumar, S.; Sathiya, P. Evaluation of Mechanical and Metallurgical Properties of Dissimilar Materials by Friction Welding. Int. Conf. Des. Manuf. 2013, 64, 1514–1523. [Google Scholar] [CrossRef]

- Kirik, I.; Ozdemir, N. Effect of Process Parameters on the Microstructure and Mechanical properties of Friction-Welded joints of AISI 1040/ AISI 304L Steels. Mater. Technol. 2015, 5, 825–832. [Google Scholar] [CrossRef]

- Caligulu, U.; Yalcinoz, M.; Kati, N.; Balalan, Z.; Islak, S. The Effects of Rotation Speed and Friction Time for Joining of AISI 4340—2205 Steels by Friction Welding. Metallofiz. Noveishie Tekhnol. 2015, 5, 665–681. [Google Scholar]

- Sarsilmaz, F.; Kirik, I.; Batı, S. Microstructure and mechanical properties of armor 500/AISI2205 steel joint by friction welding. J. Manuf. Process. 2017, 28, 131–136. [Google Scholar] [CrossRef]

- Khidhir, G.I. Efficiency of Dissimilar Friction Welded SAF 2205 Duplex Stainless Steel and 1045 Medium Carbon Steel Joints. Int. J. Metall. Met. Phys. 2021, 6, 065. [Google Scholar]

- Mishra, N.K.; Manikandan, S.G.K.; Shrivastava, A. Interfacial inhomogeneous plastic deformation during rotary friction welding of dissimilar AA2219-SS321 joint combination with AA6061 interlayer. J. Adv. Join. Process. 2024, 10, 100245. [Google Scholar] [CrossRef]

- Hattingh, D.G.; James, M.N.; Schwim, F.K.; Opperman, R.; Bernard, D.; Wedderburn, I. Innovative rotary friction welding of heat exchanger tube nozzles on high pressure headers. Int. J. Press. Vessel. Pip. 2024, 210, 105263. [Google Scholar] [CrossRef]

- Gotawala, N.; Shrivastava, A. Investigation of interface microstructure and mechanical properties of rotatory friction welded dissimilar aluminum-steel joints. Mater. Sci. Eng. A 2021, 825, 141900. [Google Scholar] [CrossRef]

- Mahmoud, B.M.M. Effects of Thermal and Mechanical Treatments on the Fatigue Performance of Friction Welded Joints. Ph.D. Thesis, Clausthal University of Technology, Clausthal-Zellerfeld, Germany, 2018; 179p. [Google Scholar]

- Rombaut, P. Joining of Dissimilar Materials Through Rotary Friction Welding. Master’s Thesis, Universiteit Gent, Ghent, Belgium, 2011. [Google Scholar]

- Suwanda, T.; Soenoko, R.; Irawan, Y.S.; Choiron, M.A. Temperature Cycle Analysis of A6061-AISI304 Dissimilar Metal Continuous Drive Friction Welding. East.-Eur. J. Enterp. Technol. 2020, 3, 38–43. [Google Scholar] [CrossRef]

- Seli, H.; Awang, M.; Ismail, A. Evaluation of properties and FEM model of the friction welded mild steel-Al6061-alumina. Mater. Res. 2013, 16, 453–467. [Google Scholar] [CrossRef]

- Mousavi, S.; Kelishami, A.R. Experimental and numerical analysis of the friction welding process for the 4340 steel and mild steel combinations. Weld. J. 2008, 87, 178. [Google Scholar]

- Bogatov, N.A.; Bogatov, A.A.; Salikhyanov, D.R. Use of the lining method to restore the service characteristics of pump-compressor tubing that has exhausted its original service life. Metallurgist 2015, 58, 1006–1010. [Google Scholar] [CrossRef]

- Bogatov, N.A. Method of Making Pump-Compressor Tubing. Patent No. 2344266 RF, IPC E21V17/01, 20 September 2007. [Google Scholar]

- Koning, A.C.; Nakasugi, H.; Li, P. TFP and TFT back in town (Tight Fit CRA lined Pipe and Tubing). Stainl. Steel World 2003, 1–12. Available online: https://www.kuroki.co.jp/ktp/pdf/PublishedPaper_KurokiPaperForStainlessSteel.pdf (accessed on 25 November 2024).

- Yoshida, T.; Matsui, S.; Atsuta, T.; Itoga, K. Corrosion problems of pipeline and a solution. In Proceedings of the 12th Annual Offshore Technology Conference (OTC), Houston, TX, USA, 5–8 May 1980; p. 3891. [Google Scholar]

- Yoshida, T.; Matsuda, S.; Matsui, S.; Atsuta, T.; Toma, S.; Itoga, K. The development of corrosionresistant tubing. In Proceedings of the 13th Annual Offshore Technology Conference (OTC), Houston, TX, USA, 4–7 May 1981; p. 4153. [Google Scholar]

- Sahin, M. Characterization of properties in plastically deformed austenitic-stainless steels joined by friction Welding. Mater. Design 2009, 30, 135–144. [Google Scholar] [CrossRef]

- Sahin, M. Evaluation of the joint-interface properties of austenitic-stainless steels (AISI 304) joined by friction welding. Mater. Design 2007, 28, 2244–2250. [Google Scholar] [CrossRef]

- Zdemira, N.O.; Sarsılmaz, F.; Hascalık, A. Effect of rotational speed on the interface properties of friction- welded AISI 304L to 4340 steel. Mater. Design 2007, 28, 301–307. [Google Scholar]

- Larikov, L.N.; Rybov, V.R.; Falchenko, V.M. Diffusion Processes in the Solid Phase During Welding; Mashinostroinie: Moscow, Russia, 1975; 192p. [Google Scholar]

- Lobanov, M.L.; Pyshmintsev, I.Y.; Urtsev, V.N.; Danilov, S.V.; Urtsev, A.A.; Redikultsev, A.A. Texture inheritance on phase transition in low-carbon, low-alloy pipe steel after thermomechanical controlled processing. Steel Trans. 2017, 60, 710–716. [Google Scholar] [CrossRef]

- Genevois, C.; Deschamps, A.; Denquin, A. Characterisation of the microstructural evolution during friction stir welding of aluminium alloys: A comparative study of 5251 and 2024 alloys. In Proceedings of the 5th International Symposium on Friction Stir Welding, Metz, France, 14–16 September 2004; p. 11. [Google Scholar]

- Priymak, E.Y.; Yakovleva, I.L.; Tereshchenko, N.A.; Morozova, A.N.; Stepanchukova, A.V. Evolution of the structure and mechanism of the formation of welded joints of medium-carbon steels upon rotary friction welding. Phys. Met. Metallogr. 2019, 120, 1091–1096. [Google Scholar] [CrossRef]

- Gorkunov, E.S.; Zadvorkin, S.M.; Putilova, E.A.; Savrai, R.A. Effect of the structure and stress state on the magnetic properties of metal in different zones of welded pipes of large diameter. Phys. Met. Metallogr. 2014, 115, 949–956. [Google Scholar] [CrossRef]

- Saraev, Y.N.; Bezborodov, V.P.; Putilova, E.A. Effect of heat input pulse on the structure and properties of welded joints of steels ferritic-pearlitic class, operating under low-frequency temperature-force loading. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2015; p. 012014. [Google Scholar]

- Gorkunov, E.S.; Povolotskaya, A.M.; Tueva, E.A.; Goruleva, L.S.; Zadvorkin, S.M. Determination of the magnetic properties of separate zones of welds and the width of welded joints based on magnetic measurements. Russ. J. Nondestruct. Test. 2011, 47, 577–586. [Google Scholar] [CrossRef]

- Gorkunov, E.S.; Zadvorkin, S.M.; Putilova, E.A.; Bakunova, A.A. Quality control of heat treatment of oil and gas pipes using magnetic structuroscopy. Inorg. Mater. 2016, 52, 1483–1488. [Google Scholar] [CrossRef]

- Gorkunov, E.S. Magnetic Structural-Phase Analysis as Applied to Diagnosing and Evaluating the Lifetime of Products and Structural Components. Part 1. Diagn. Resour. Mech. Mater. Struct. 2015, 1, 6–40. [Google Scholar] [CrossRef]

| Alloying Elements, wt. % | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Steel | C | Si | Mn | S | Cr | Ni | Mo | Cu | Ti |

| Constructional | 0.35 | 0.50 | 1.55 | 0.01 | 0.14 | 0.17 | 0.03 | 0.21 | - |

| Corrosion-resistant | 0.08 | 0.76 | 1.09 | 0.02 | 16.58 | 9.82 | 0.2 | 0.23 | 0.59 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Putilova, E.; Kryucheva, K.; Kamantsev, I.; Priymak, E. Microstructure, Physical-Mechanical, and Magnetic Characteristics of a Butt-Welded Joint Obtained by Rotary Friction Welding Technology of Bimetallic Pipe. J. Manuf. Mater. Process. 2024, 8, 271. https://doi.org/10.3390/jmmp8060271

Putilova E, Kryucheva K, Kamantsev I, Priymak E. Microstructure, Physical-Mechanical, and Magnetic Characteristics of a Butt-Welded Joint Obtained by Rotary Friction Welding Technology of Bimetallic Pipe. Journal of Manufacturing and Materials Processing. 2024; 8(6):271. https://doi.org/10.3390/jmmp8060271

Chicago/Turabian StylePutilova, Evgeniia, Kristina Kryucheva, Ivan Kamantsev, and Elena Priymak. 2024. "Microstructure, Physical-Mechanical, and Magnetic Characteristics of a Butt-Welded Joint Obtained by Rotary Friction Welding Technology of Bimetallic Pipe" Journal of Manufacturing and Materials Processing 8, no. 6: 271. https://doi.org/10.3390/jmmp8060271

APA StylePutilova, E., Kryucheva, K., Kamantsev, I., & Priymak, E. (2024). Microstructure, Physical-Mechanical, and Magnetic Characteristics of a Butt-Welded Joint Obtained by Rotary Friction Welding Technology of Bimetallic Pipe. Journal of Manufacturing and Materials Processing, 8(6), 271. https://doi.org/10.3390/jmmp8060271