Increasing the Impact Toughness of Cellulose Fiber Reinforced Polypropylene Composites—Influence of Different Impact Modifiers and Production Scales

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

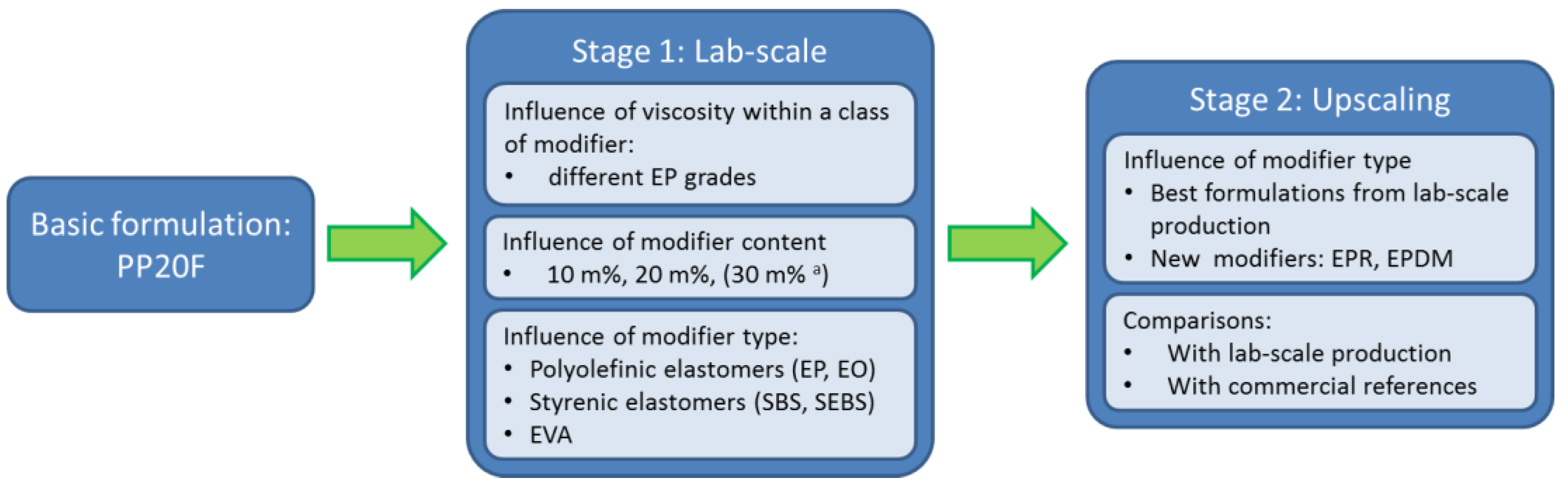

2.2. Sample Preparation

2.3. Characterization Methods

3. Results

3.1. Fiber Reinforcement of the Neat PP

3.2. Characterization of the Compounds from the Laboratory-Scale Production

3.2.1. Influence of the Viscosity of the Impact Modifier

3.2.2. Effects of Different Types of Impact Modifiers

3.3. Upscaling and Comparison with Commercial Reference Materials

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Sobczak, L.; Lang, R.W.; Haider, A. Polypropylene Composites with Natural Fibers and Wood—General Mechanical Property Profiles. Compos. Sci. Technol. 2012, 72, 550–557. [Google Scholar] [CrossRef]

- Tranninger, M.; Gahleitner, M.; Gubo, R.; Haider, A.; Sobczak, L. Low Weight and Sustainability for Vehicles. Kunstst. Int. 2014, 11, 51–53. [Google Scholar]

- Partanen, A.; Carus, M. Successful Biocomposites in Toys, Furniture and Consumer Goods. In Proceedings of the Biocomposites Conference Cologne, Cologne, Germany, 6–7 December 2017. [Google Scholar]

- Sobczak, L.; Brüggemann, O.; Putz, R.F. Polyolefin Composites with Natural Fibers and Wood—Modification of the Fiber/Filler-Matrix Interaction. J. Appl. Polym. Sci. 2013, 127, 1–17. [Google Scholar] [CrossRef]

- Franco-Marquès, E.; Méndez, J.A.; Pèlach, M.A.; Vilaseca, F.; Bayer, J.; Mutjè, P. Influence of coupling agents in the preparation of polypropylene composites reinforced with recycled fibers. Chem. Eng. J. 2011, 166, 1170–1178. [Google Scholar] [CrossRef]

- Rana, A.K.; Mandal, A.; Bandyopadhyay, S. Short jute fiber reinforced polypropylene composites: Effect of compatibiliser, impact modifier and fiber loading. Compos. Sci. Technol. 2003, 63, 801–806. [Google Scholar] [CrossRef]

- Keener, T.J.; Stuart, R.K.; Brown, T.K. Maleated coupling agents for natural fiber composites. Compos. Part A 2004, 35, 357–362. [Google Scholar] [CrossRef]

- Niu, P.; Liu, B.; Wei, X.; Wang, X.; Yang, J. Study on mechanical properties and thermal stability of polypropylene/hemp fiber composites. J. Reinf. Plast. Compos. 2011, 30, 36–44. [Google Scholar] [CrossRef]

- Sobczak, L.; Welser, R.; Brüggemann, O.; Haider, A. Polypropylene (PP)-based wood polymer composites—Performance of five commercial maleic anhydride grafted PP coupling agents. J. Thermoplast. Compos. Mater. 2014, 27, 439–463. [Google Scholar] [CrossRef]

- Panthapulakkal, S.; Sain, M.; Law, S. Effect of coupling agents on rice-husk-filled HDPE extruded profiles. Polym. Int. 2005, 54, 137–142. [Google Scholar] [CrossRef]

- Bera, M.; Alagirusamy, R.; Das, A. A study on interfacial properties of jute-PP composites. J. Reinf. Plast. Compos. 2010, 29, 3155–3161. [Google Scholar] [CrossRef]

- Dubnikova, I.L.; Berezina, S.M.; Antonov, A.V. Effect of rigid particle size on the toughness of filled polypropylene. J. Appl. Polym. Sci. 2004, 94, 1917–1926. [Google Scholar] [CrossRef]

- Pretschuh, C.; Sobczak, L.; Salaberger, D.; Jerabek, M.; Lummerstorfer, T. Impact Performance in PP with PVA Fiber Reinforcement. In Proceedings of the ECCM17—17th European Conference on Composite Materials, Munich, Germany, 26–30 June 2016. [Google Scholar]

- Pretschuh, C.; Jerabek, M.; Renner, K.; Salaberger, D.; Lummerstorfer, T. Impact strength improvement of PP based WPC by hybridization with PP impregnated pet fiber. In Proceedings of the ECCM18—18th European Conference on Composite Materials, Athens, Greece, 24–28 June 2018. [Google Scholar]

- van der Wal, A.; Nijhof, R.; Gaymans, R.J. Polypropylene–rubber blends 2 The effect of the rubber content on the deformation and impact behaviour. Polymer 1999, 40, 6031–6044. [Google Scholar] [CrossRef]

- van der Wal, A.; Verheul, A.J.J.; Gaymans, R.J. Polypropylene–rubber blends 4 The effect of the rubber particle size on the fracture behaviour at low and high test speed. Polymer 1999, 40, 6057–6065. [Google Scholar] [CrossRef]

- Tam, W.Y.; Cheung, T.; Li, R.K.Y. An investigation on the impact fracture characteristics of EPR toughened polypropylene. Polym. Test. 1996, 15, 363–380. [Google Scholar] [CrossRef]

- Shanks, R.; Kong, I. Thermoplastic Elastomers. In Thermoplastic Elastomers; El-Sonbati, A.Z., Ed.; InTech: Rijeka, Croatia, 2012; pp. 137–154. [Google Scholar]

- Abreu, F.O.M.S.; Forte, M.M.C.; Liberman, S.A. SBS and SEBS block copolymers as impact modifiers for polypropylene compounds. J. Appl. Polym. Sci. 2005, 95, 254–263. [Google Scholar] [CrossRef]

- Park, B.D.; Balatinecz, J.J. Mechanical properties of wood-fiber/toughened isotactic polypropylene composites. Polym. Compos. 1997, 18, 79–89. [Google Scholar] [CrossRef]

- Oksman, K.; Clemons, C.M. Mechanical Properties and morphology of impact modified polypropylene-wood flour composites. J. Appl. Polym. Sci. 1998, 67, 1503–1513. [Google Scholar] [CrossRef]

- Lopez Manchado, M.A.; Arroyo, M.; Biagiotti, J.; Kenny, J.M. Enhancement of mechanical properties and interfacial adhesion of PP/EPDM/flax fiber composites using maleic anhydride as a compatibilizer. J. Appl. Polym. Sci. 2003, 90, 2170–2178. [Google Scholar] [CrossRef]

- Anuar, H.; Zuraida, A. Improvement in mechanical properties of reinforced thermoplastic elastomer composite with kenaf bast fibre. Compos. Part B 2011, 42, 462–465. [Google Scholar] [CrossRef]

- Svoboda, P.; Svobodova, D.; Slobodian, P.; Ougizawa, T.; Inoue, T. Crystallization kinetics of polypropylene/ethylene-octene copolymer blends. Polym. Test. 2009, 28, 215–222. [Google Scholar] [CrossRef]

- McLennaghan, A. Ethylene-1-octene Polyolefin Elastomers. The materials of choice for modifying Polypropylene. Kautsch. Gummi Kunstst. 2001, 54, 540–545. [Google Scholar]

- Ghahri, S.; Najafi, S.K.; Mohebby, B.; Tajvidi, M. Impact strength improvement of wood flour-recycled polypropylene composites. J. Appl. Polym. Sci. 2012, 124, 1074–1080. [Google Scholar] [CrossRef]

- UPM. Biocomposites: Datasheet UPM ForMi EXP. 2014. Available online: https://www.upmformi.com/injection-moulding/downloads/Pages/default.aspx (accessed on 15 December 2017).

- Gahleitner, M.; Hauer, A.; Bernreitner, K.; Ingolic, E. PP-based Model Compounds as Tools for the Development of High-impact-ethylene-propylene Copolymers. Int. Polym. Proc. 2002, 17, 318–324. [Google Scholar] [CrossRef]

- Grein, C.; Bernreitner, K.; Hauer, A.; Gahleitner, M.; Neissl, W. Impact modified isotatic polypropylene with controlled rubber intrinsic viscosities: Some new aspects about morphology and fracture. J. Appl. Polym. Sci. 2003, 87, 1702–1712. [Google Scholar] [CrossRef]

- D’Orazio, L.; Cecchin, G. Isotactic polypropylene/ethylene- co -propylene blends. Effects of composition on rheology, morphology and properties of injection moulded samples. Polymer 2001, 42, 2675–2684. [Google Scholar] [CrossRef]

- Wu, S. Phase structure and adhesion in polymer blends: A criterion for rubber toughening. Polymer 1985, 26, 1855–1863. [Google Scholar] [CrossRef]

- Tang, W.; Tang, J.; Yuan, H.; Jin, R. Crystallization behavior and mechanical properties of polypropylene random copolymer/poly(ethylene-octene) blends. J. Appl. Polym. Sci. 2011, 122, 461–468. [Google Scholar] [CrossRef]

- Yu, T.C.; Metzler, D.K. Metallocene Plastomers as Polypropylene Impact Modifiers. In Handbook of Polypropylene and Polypropylene Composites, 2nd ed.; Karian, H.G., Ed.; Revised and Expanded; Marcel Dekker: New York, NY, USA; Basel, Switzerland, 2003; pp. 200–250. [Google Scholar]

- Gahleitner, M.; Kastner, E.; Siebert, H.; Stadlbauer, M. Low Emission Polymer Composition. U.S. Patent 8344069 B2, 1 January 2013. [Google Scholar]

- Wang, J.; Lilja, J.; Horill, T.; Gahleitner, M.; Denifl, P.; Leinonen, T. Low Emission Propylene Homopolymer with High Melt Flow. U.S. Patent 9751962 B2, 5 September 2017. [Google Scholar]

- Ter Woort, C.; Koscher, E.; Vandoorne, P. Blend for Use in Automobile Application. U.S. Patent 9434835 B2, 6 September 2013. [Google Scholar]

| Code | Density (g/cm³) | Hardness Shore A | MFR(2.16 kg; 190/230 °C) (g/10 min) | Additional Material Information |

|---|---|---|---|---|

| Only laboratory scale production | ||||

| EP1 | 0.865 | A 71 | 18.5(190 °C)/48(230 °C) | 13% ethylene content |

| EP2 | 0.863 | A 64 | 8.5(190 °C)/20(230 °C) | 15% ethylene content |

| EP3 | 0.862 | A 67 | 1.5(190 °C)/3(230 °C) | 16% ethylene content |

| EO1 | 0.885 | A 84 | 30(190 °C) a | Mooney viscosity 2 MU |

| SBS | 0.94 | A 71–81 | <1(200 °C, 5 kg) [Datasheet] b | 31% styrene content |

| SEBS | 0.90 | A 47 | 1.8(190 °C)/9.4(230 °C) | 13% styrene content |

| EVA | 0.952 | A 75 | 2.5(230 °C) c | 28% VA content |

| Laboratory scale and upscaled production | ||||

| EO2 | 0.870 | A 70 | 5(190 °C)/10.8(230 °C) | Mooney viscosity 9 MU |

| EO3 | 0.857 | A 57 | 1(190 °C)/2.2(230 °C) | Mooney viscosity 25 MU |

| EO4 | 0.870 | A 51 | 0.5(190 °C)/1.4(230 °C) | Mooney viscosity 45 MU |

| Only upscaled production | ||||

| EPR | n/a | n/a | n/a d | 72% ethylene content Mooney viscosity 44 MU |

| EPDM | n/a | n/a | n/a d | 69% ethylene content 4.4% diene content Mooney viscosity 60 MU |

| Absolute Values | Specific Values (Normalized by Density) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Code | ρ | MFR | HDT-B | E | σM | acU | acN | E_sp | σM_sp | acU_sp | acN_sp |

| Unit | g/cm3 | g/10 min | °C | GPa | MPa | kJ/m2 | kJ/m2 | GJ/kg | MJ/kg | kJ m/kg | kJ m/kg |

| PP | 0.906 | 140 a | 95.8 | 1.55 | 34.7 | 40.1 | 1.1 | 1.71 | 38.3 | 44.3 | 1.2 |

| PP20F | 0.981 | 9.2 | 134.6 | 2.76 | 40.1 | 41.0 | 4.5 | 2.81 | 40.9 | 41.8 | 4.6 |

| EP1_10 | 0.978 | 7.3 | 129.4 | 2.07 | 35.6 | 39.4 | 5.3 | 2.12 | 36.4 | 40.3 | 5.4 |

| EP1_20 | 0.978 | 6.3 | 119.1 | 1.74 | 30.8 | 40.1 | 7.5 | 1.78 | 31.5 | 41.0 | 7.7 |

| EP1_30 | 0.973 | 6.0 | 104.0 | 1.32 | 24.7 | 38.6 | 9.7 | 1.36 | 25.4 | 39.7 | 10.0 |

| EP2_10 | 0.978 | 7.1 | 132.6 | 2.05 | 35.3 | 39.0 | 5.6 | 2.10 | 36.1 | 39.9 | 5.7 |

| EP2_20 | 0.978 | 4.6 | 122.9 | 1.72 | 30.4 | 41.0 | 8.1 | 1.76 | 31.1 | 41.9 | 8.3 |

| EP2_30 | 0.974 | 3.6 | 108.0 | 1.33 | 24.2 | 36.9 | 11.1 | 1.37 | 24.8 | 37.9 | 11.4 |

| EP3_10 | 0.981 | 5.1 | 136.1 | 2.19 | 36.6 | 39.3 | 6.2 | 2.23 | 37.3 | 40.1 | 6.3 |

| EP3_20 | 0.976 | 2.6 | 127.7 | 1.83 | 31.0 | 39.1 | 9.2 | 1.88 | 31.8 | 40.1 | 9.4 |

| EP3_30 | 0.972 | 2.2 | 114.3 | 1.33 | 24.3 | 36.9 | 12.8 | 1.37 | 25.0 | 38.0 | 13.2 |

| EO1_10 | 0.984 | 6.4 | - | 2.30 | 36.7 | 44.3 | 6.7 | 2.34 | 37.3 | 45.0 | 6.8 |

| EO1_20 | 0.980 | 5.2 | - | 1.83 | 31.9 | 44.5 | 8.4 | 1.87 | 32.6 | 45.4 | 8.6 |

| EO2_10 | 0.981 | 6.7 | - | 2.36 | 34.2 | 42.2 | 7.6 | 2.41 | 34.9 | 43.0 | 7.7 |

| EO2_20 | 0.977 | 4.7 | - | 2.03 | 29.4 | 38.4 | 10.2 | 2.08 | 30.1 | 39.3 | 10.4 |

| EO3_10 | 0.978 | 6.2 | - | 2.44 | 35.1 | 35.8 | 7.2 | 2.49 | 35.9 | 36.6 | 7.4 |

| EO3_20 | 0.972 | 3.5 | - | 2.09 | 29.3 | 34.4 | 10.1 | 2.15 | 30.1 | 35.4 | 10.4 |

| EO4_10 | 0.974 | 5.5 | - | 2.30 | 33.6 | 37.8 | 7.1 | 2.36 | 34.5 | 38.8 | 7.3 |

| EO4_20 | 0.979 | 3.0 | - | 2.03 | 28.8 | 36.7 | 11.6 | 2.07 | 29.4 | 37.5 | 11.8 |

| SBS_10 | 0.982 | 4.3 | - | 2.29 | 32.7 | 41.9 | 6.8 | 2.33 | 33.3 | 42.7 | 6.9 |

| SBS_20 | 0.993 | 2.4 | - | 2.12 | 28.5 | 40.9 | 9.6 | 2.13 | 28.7 | 41.2 | 9.7 |

| SBS_30 | 0.997 | 1.5 | - | 1.72 | 22.3 | 37.8 | 14.2 | 1.73 | 22.4 | 37.9 | 14.2 |

| SEBS_10 | 0.982 | 4.5 | - | 2.27 | 34.8 | 41.3 | 7.5 | 2.31 | 35.4 | 42.1 | 7.6 |

| SEBS_20 | 0.980 | 3.1 | - | 1.86 | 28.6 | 40.4 | 11.4 | 1.90 | 29.2 | 41.2 | 11.6 |

| EVA_10 | 0.990 | 5.8 | - | 2.30 | 35.1 | 39.3 | 6.2 | 2.32 | 35.5 | 39.7 | 6.3 |

| EVA_20 | 0.996 | 5.3 | - | 1.93 | 31.3 | 38.2 | 7.3 | 1.94 | 31.4 | 38.4 | 7.3 |

| Absolute Values | Specific Values (Normalized by Density) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Code | [g/cm3] | E [GPa] | M [MPa] | acU [kJ/m2] | can [kJ/m2] | E_sp [GJ/kg] | M_sp [MJ/kg] | acU_sp [kJ m/kg] | acN_sp [kJ m/kg] |

| PP20F_Lab | 0.981 | 2.76 | 40.1 | 41.0 | 4.5 | 2.81 | 40.8 | 41.8 | 4.6 |

| PP20F_Up | 0.980 | 2.82 | 41.0 | 43.4 | 5.5 | 2.88 | 41.9 | 44.4 | 5.6 |

| EO2_20_Lab | 0.977 | 2.03 | 29.4 | 38.4 | 10.2 | 2.07 | 30.1 | 39.3 | 10.4 |

| EO2_20_Up | 0.972 | 2.03 | 28.9 | 39.7 | 10.7 | 2.09 | 29.8 | 40.9 | 11.0 |

| EO3_20_Lab | 0.972 | 2.09 | 29.3 | 34.4 | 10.1 | 2.15 | 30.1 | 35.4 | 10.3 |

| EO3_20_Up | 0.973 | 2.01 | 28.3 | 41.8 | 12.2 | 2.06 | 29.1 | 42.9 | 12.5 |

| EO4_20_Lab | 0.979 | 2.04 | 28.8 | 36.7 | 11.6 | 2.08 | 29.5 | 37.5 | 11.9 |

| EO4_20_Up | 0.976 | 1.96 | 26.8 | 43.3 | 13.3 | 2.01 | 27.4 | 44.4 | 13.6 |

| EPR_20_Up | 0.973 | 2.18 | 29.4 | 36.1 | 8.7 | 2.24 | 30.3 | 37.1 | 9.0 |

| EPDM_20_Up | 0.976 | 2.13 | 28.6 | 35.2 | 8.5 | 2.18 | 29.3 | 36.0 | 8.7 |

| H_TRC | 1.062 | 1.90 | 21.4 | >160 a | 31.7 | 1.79 | 20.2 | >151 b | 29.9 |

| H_EKC | 1.020 | 1.63 | 19.4 | >160 a | 27.3 | 1.60 | 19.0 | >157 b | 26.8 |

| Formi EXP 20 b | 0.99 | 1.80 | 33 | 45 | 8.8 | 1.82 | 33.3 | 45.5 | 8.9 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mihalic, M.; Sobczak, L.; Pretschuh, C.; Unterweger, C. Increasing the Impact Toughness of Cellulose Fiber Reinforced Polypropylene Composites—Influence of Different Impact Modifiers and Production Scales. J. Compos. Sci. 2019, 3, 82. https://doi.org/10.3390/jcs3030082

Mihalic M, Sobczak L, Pretschuh C, Unterweger C. Increasing the Impact Toughness of Cellulose Fiber Reinforced Polypropylene Composites—Influence of Different Impact Modifiers and Production Scales. Journal of Composites Science. 2019; 3(3):82. https://doi.org/10.3390/jcs3030082

Chicago/Turabian StyleMihalic, Matthias, Lukas Sobczak, Claudia Pretschuh, and Christoph Unterweger. 2019. "Increasing the Impact Toughness of Cellulose Fiber Reinforced Polypropylene Composites—Influence of Different Impact Modifiers and Production Scales" Journal of Composites Science 3, no. 3: 82. https://doi.org/10.3390/jcs3030082

APA StyleMihalic, M., Sobczak, L., Pretschuh, C., & Unterweger, C. (2019). Increasing the Impact Toughness of Cellulose Fiber Reinforced Polypropylene Composites—Influence of Different Impact Modifiers and Production Scales. Journal of Composites Science, 3(3), 82. https://doi.org/10.3390/jcs3030082