3.1. Thermoelectrical Properties of Nanotube Buckypapers and Powder Packages

The first step was to characterize the thermoelectric properties of carbon nanotubes themselves (

Table 4). It is assumed that the differences in the characteristics of the CNTs will certainly be reflected in the TE performance of the composites. It should be determined whether the CNTs are n- or p-type materials indicated by a negative or positive Seebeck value, respectively.

For buckypapers (BP) of NC7000, CNS-PEG, Tuball, and HiPco, a positive Seebeck coefficient could be measured and the values were between 8.0 and 37.4 µV/K. These values are slightly lower than those reported by Nonoguchi et al. [

14] (49 µV/K) and Piao et al. [

15] (39 µV/K) for thin SWCNT (Thomas Swan & Co. LTD, Crockhall, Consett, UK) films. The Seebeck coefficient of the HiPco buckypaper (28.6 µV/K) is higher than the value of ca. 16 µV/K reported by Hewitt et al. [

6] for a buckypaper prepared from HiPco (raw material, purified by the authors). Measurements of the Seebeck coefficients on nanotube powders (P) resulted in slightly different values but of the same magnitude. This difference is assigned to a different CNT packing density of the nanotubes in the buckypaper or in the compressed nanotube packing.

As expected, after the incorporation of electron-donating nitrogen in the CNT structure [

34], a negative Seebeck coefficient of buckypapers as well as powders was determined for the laboratory synthesized nitrogen-doped MWCNTs N-A1 and N-IFW. In order to verify these results, a buckypaper made of commercially available nitrogen-doped MWCNT N400 was measured, also resulting in a negative S coefficient. The measurements made on nanotube powders resulted in negative S-values, whereby the one on MWCNTs N-IFW led to the highest negative number amount of −12.9 μV/K.

When comparing the values of the different buckypapers, SWCNTs show higher values of the Seebeck coefficients than MWCNTs. This is in accordance with the discussion in the literature and given by the semimetallic nature of MWCNTs versus the combination of chiralities in SWCNTs ranging from semiconducting to metallic [

21]. Among the SWCNTs, the buckypaper consisting of SWCNT Tuball showed a higher Seebeck coefficient of 37.4 μV/K as well as power factor of 59.2 µW/m·K

2. The difference is expected to result from the different structural characteristics of both SWCNTs. All thermoelectric values of SWCNT Tuball are much higher than the values of the other buckypapers. This order is also reflected when comparing the values measured on nanotube powders.

Next to the Seebeck coefficients, the electrical conductivity also behaves differently between the different CNT types. The buckypapers result in higher values than the CNT powder packages, SWCNTs show higher values than MWCNTs, and the highest value of more than 40,000 S/m was measured for the SWCNT Tuball buckypaper.

3.2. Thermoelectric Properties of Polymer Composites Filled with Different Kinds of Nanotubes

The thermoelectrical properties of CNT filled composites can be regarded as interplay of the thermoelectric properties and the CNT network formed in a given matrix and a possible charge transfer from the polymer matrix to the CNTs. Thus, it can be expected that the same nanotubes forming networks in different matrices can have different charge carrier behavior.

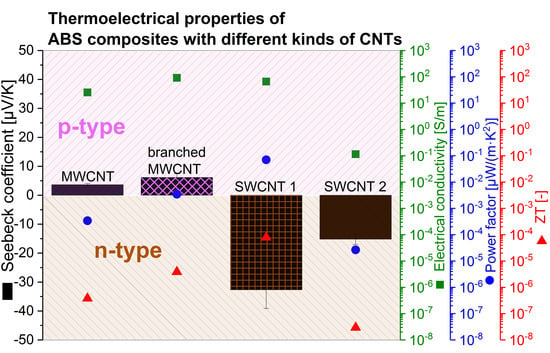

The results for composites based on different polymer matrices with 2 wt % of different CNTs are summarized in

Figure 2,

Figure 3,

Figure 4 and

Figure 5 and

Table 5. For ABS and PA6, additional results are shown for different CNT contents. It was found that all composites containing MWCNTs NC7000 or CNS-PEG exhibit a positive Seebeck coefficient whereby the S-values for polymer/CNS-PEG composites are always higher than those for composites with NC7000. This result correlates with the higher S-value of buckypaper based on CNS-PEG than the one made of NC7000.

At the same CNT content of 2 wt % in the composites, the addition of SWCNT Tuball resulted in either positive or negative Seebeck coefficients, depending on the matrix polymer. In PBT, PVDF, PP and PC, positive Seebeck coefficient values were found which exceed the values for the corresponding composites with both MWCNTs (

Figure 2 and

Figure 3). The higher magnitude of the Seebeck coefficients in the SWCNT Tuball based composites is in accordance with its highest value among all buckypapers. In ABS, PA6, PARA and PA66, negative Seebeck coefficients of relatively high magnitude (−30 to −51 μV/K) were reached. Variation of the SWCNT Tuball content, as performed in ABS and PARA, resulted in higher (less negative) values with increasing Tuball loading. Based on the positive Seebeck coefficient of the Tuball buckypaper and the previously published values for composites containing SWCNTs (in matrices different than those used here), this behavior was unexpected and not yet been described in the literature. The Tuball material is characterized by the highest electrical conductivity and the highest Seebeck coefficient of the buckypaper (equivalent to 100% CNTs). Based on that, the power factor PF of the SWCNT Tuball buckypaper showed by far the highest value.

The addition of SWCNT HiPco, only studied in ABS, PA6 and PARA resulted in negative values in ABS, but positive values in PA6 and PARA. This was proven at two different SWCNT contents, namely 2 and 4 wt %. Thereby, higher SWCNT HiPco content decreased the (positive) Seebeck coefficient in PA6 but increased it in PARA. In ABS the (negative) Seebeck coefficient gets higher (less negative) when the SWCNT content is increased.

If n-type N-MWCNTs are included in the comparison, as studied for PBT and PP, according to the n-type of those buckypapers all composites show negative Seebeck coefficients. This indicates that the n-type character of the N-MWCNTs dominates the composite TE properties even though the three polymers were p-type materials. Thereby, the achieved values are in the range between −8.2 μV/K (PBT) and −17.3 μV/K (PP) (

Table 5). A direct comparison was made between 2 wt % N-A1 and N-IFW in PP based composites whereby the tubes N-A1 resulted in more negative values (

Figure 3 left,

Table 5).

In addition, the electrical network structure of the CNTs in the composite is important for the TE properties. The comparison of the same CNT kind in different matrices shows that the TE properties are also significantly dependent on the polymer type. For example, the Seebeck for composites filled with 2 wt % NC7000 varied between 1.5 µV/K (PARA, 6.3 µV/K (PA66), 6.8 µV/K (PBT), 8.5 µV/K (PC), 9.5 µV/K (PP) up to 14.3 µV/K (PVDF) (see

Table 5). It has to be considered that the different composites may have different states of the conductive network, as the processing conditions were different which are known to significantly influence the state of the CNT dispersion and network formation [

35,

36]. In addition, the interactions between the polymer types and the CNTs are different. This results in different nanotube dispersibility and dispersion. The relationship between the amount of non-dispersed CNTs (determined using transmission light microscopy at 1 vol % loading of MWCNTs Baytubes C150 HP, Bayer Material Science, Leverkusen, Germany) and the calculated interfacial energy between CNTs and some polymers is described by Kasaliwal et al. [

36]. The comparison showed very low interfacial energy and good macrodispersion for PA66 and PC, but worse dispersion and higher interfacial energy for PP. One also may argue that the distance between the actual used CNT concentration of 2 wt % and the electrical percolation threshold concentration are different when using the various polymer matrices, so that the composites are compared at different network states.

The electrical percolation threshold reflects the state of the dispersion of conductive fillers and is generally lower with better dispersion. The electrical percolation thresholds of the studied composites with NC7000, CNS-PEG and SWCNT Tuball are summarized in

Table 6.

The trend is that the electrical percolation thresholds for composites with NC7000 are typically higher than for the other two CNT types (CNS-PEG, Tuball). Even if the percolation thresholds between the different MWCNTs in the same polymer or the same CNTs in different polymers differ strongly, it can be seen that the TE investigations presented were carried out on composite materials whose CNT concentrations were clearly above the respective electrical percolation threshold. The influence of CNT content on TE properties is discussed for selected matrices (PBT and ABS) in more detail in

Section 3.3.

Interestingly, for the composites filled with SWCNTs Tuball and HiPco, which showed positive Seebeck coefficients in the form of buckypaper, positive and negative Seebeck coefficients were measured in the composite materials depending on the polymer type. For Tuball, a positive S-value was determined if PBT, PVDF, PP or PC were the polymer matrix. For composites based on ABS, PA6, PARA or PA66 a negative value was detected. For HiPco negative values were only achieved in ABS, but positive in PA6 and PARA. It can be assumed that electron doping occurs in the interaction between SWCNTs and these polymers, but to a different extent when comparing both SWCNT types.

An explanation for this doping effect could lie in the molecular structure of the polymers that is shown for PA and ABS in

Figure 6. For the different polyamide types, the amide group which has one free electron pair at nitrogen and two free electron pairs at oxygen is considered for electron donation. In ABS, the nitrile group consisting of carbon and triple-bound nitrogen could serve as an electron supplier. Both the amide group and the nitrile group have very electron-rich regions due to the multiple bonds between the atoms and the free electron pairs. The planar spatial arrangement of the groups can also contribute to the high electron density leading to doping of the CNTs. The assumption that the amide group can play a key role in the doping of CNTs by the polymer is also supported by results from Piao et al. [

15]. The authors showed that the Seebeck coefficient of SWCNT (product of Thomas Swan Co. LTD, Consett, UK) films infiltrated with poly(vinyl pyrrolidone) (PVP) or poly(ethylene imine) (PEI) show negative Seebeck coefficients (around −40 µV/K) even though the pristine SWCNT buckypaper had a positive Seebeck coefficient (+39 µV/K). Both PVP and PEI contain molecular elements like amid groups, which also appear in PA in each repeat unit (

Figure 6). The treatment of the SWCNT network with N,N,N′,N′-tetramethyl-

p-phenylenediamine (TMPD) (structure see

Figure 6) leads also to a negative S-value with a lower magnitude of −3 µV/K [

15]. Thus, the switching from p-type buckypapers to n-type infiltrated buckypapers was achieved only with molecules containing amide or amine groups. This indicates that the SWCNT doping is connected with the electron-donating effect of these nitrogen containing groups. All other infiltrated buckypapers studied by Piao et al. [

15] led to positive S-values, whereby the molecular structures of the used polymers did not contain nitrogen groups. From this, a clear correlation can be shown with the results of the present study. Positive S-values were obtained for all polymers which do not contain an amide group in their molecular structure, namely PBT, PP, PC and PVDF. Only for the polyamides (PA6, PA66, PARA) and ABS the switching from p-type to n-type was observed using SWCNT Tuball. The different kinds of PA contain amid groups. ABS contains a nitrile group instead of an amide group. Interestingly, for SWCNT HiPco such a switching only took place in ABS, which indicates a different degree of interaction with or electron donation through the PA matrices compared to SWCNT Tuball. More investigations are needed to study the influence of the structural parameters of SWCNTs on this behavior. To our knowledge, it has not yet been researched which parameters are decisive for thermoelectric properties in general and which for the doping efficiency of polymers.

Such doping behavior of nitrogen-containing polymer matrices on CNTs was only observed in the case of SWCNTs. It is assumed that the electron donating is only effective if only one wall is involved. For MWCNTs with typically eight to 12 walls, electron donation is much less efficient and there is no conversion to n-type composites.

In addition to the Seebeck coefficient S, the power factor PF and figure of merit ZT are important for the evaluation of the TE properties of composites. The highest power factors in this screening were found for PVDF/2 wt % CNS-PEG at 0.1063 µW/m·K

2 and for PA6/5 wt % Tuball at 0.1425 µW/m·K

2. Such high PF values for melt compounded CNT polymer composites were only published by Luo et al. for a PP/4 wt % SWCNT composite with 0.066 µW/m·K

2 (PP/4 wt % SWCNT) [

10] or 0.12 µW/m·K

2 (PP/2 wt % SWCNT) [

11]. ZT values of 1.2E-4 (PVDF/2 wt % CNS-PEG) and 1.6E-4 (PA6/5 wt % Tuball) can be calculated from these PF values.

For composites based on PP, PC, and PVDF, a comparison with TE properties reported in the literature is possible. Comparing the values of PP/2 wt % Tuball composites to the reported values, in our study a slightly higher Seebeck coefficient (47.2 µV/K vs. 43 µV/K [

11]) and lower power factor (0.027 µW/m·K

2 vs. 0.12 µW/m·K

2 [

11]) were found. In addition, Luo et al. [

11] described the influence of the functionalization of Tuball on the TE properties of PP/2 wt % SWCNT composites by comparing batches of unfunctionalized Tuball materials (batches A and B) with a batch which was plasma oxidized (batch mA). The Seebeck coeffiecient varied between 23.2 μV/K (for CNTs batch A), 43 μV/K (for CNTs batch B) and 35.6 μV/K (for CNTs batch mA) and PF between 0.009 µW/m·K

2 (batch A), 0.12 µW/m·K

2 (batch B) and 0.01 µW/m·K

2 (batch mA). These TE results show that both batch and functionalization have an impact on TE results.

For PC/2 wt % CNT composites, in our study Seebeck coefficients between 8.5 and 34.8 µV/K were determined (

Figure 3 right,

Table 5). Compared to PC/2.5 wt % unfunctionalized MWCNT composites as reported by Liebscher et al. [

7] to have an S-value of 7.5 ± 0.9 µV/K, our results are higher. Furthermore, the PF values of our composites are higher compared to the reported one in reference [

7]. Comparing the S-values of CNT buckypapers and PC/CNT composites, for all three CNT types the S-values were only slightly different indicating that each composite well reflects the value of the buckypaper. This finding correlates with the results of Piao et al. [

15] on SWCNT buckypapers infiltrated with PC where the value of the buckypaper was hardly changed.

The TE results for PVDF/CNT composites can be compared with some values from the literature. Sun et al. [

4] used the same type of PVDF and MWCNTs and the same preparation method for composites, namely melt compounding using a microcompounder DSM15 but with different melt mixing conditions than in our study. The measured S-values with 10 µV/K are slightly lower than in our investigation with 14.3 µV/K. It can be concluded that when using the same raw materials (PVDF, MWCNT), sample preparation plays also a role in the TE properties. It has been known for some time that both the melt mixing conditions and the compression molding conditions strongly influence the formation of the conductive network [

35,

41,

42]. Hewitt et al. [

5] described multilayered fabrics in which the p- and n-type layers were fabricated by solution mixing of CNTs with PVDF. The authors name a similar room temperature Seebeck coefficient of 10.05 µV/K for PVDF/95 wt % p-type CNTs and of about 30 µV/K for films with 20 wt % CNT loading. When using n-type CNTs, a room temperature value of −5.04 µV/K is reported for the n-type film. In [

6], the same authors report for solution processed PVDF with SWCNT HiPco (raw material, purified by the authors), room temperature values of about 32 µV/K at 5 wt % loading and lower values at increasing SWCNT content. Comparing the S-values of the CNT buckypapers and PVDF/CNT composites, for both MWCNT types the S-value increases with incorporation in the PVDF matrix. This finding correlates with the results of polymer infiltrated SWCNT buckypaper as reported in [

15]. However, for SWCNT Tuball, in our study, the PVDF/2 wt % composite shows with 24.0 µV/K a lower Seebeck coefficient than the buckypaper (37.4 µV/K) which does not follow this line.

In order to see relations between the Seebeck coefficient and electrical conductivity, both depending on the CNT network structure,

Figure 7 plots all values measured for polymer/MWCNT composites and their buckypapers. SWCNTs and N-MWCNTs are not included in this overview. It was found that over a wide range of conductivity values the Seebeck coefficient increase slightly with conductivity (including variation of MWCNT type and content (ABS)). However, this relationship does not apply to PA6 and PA66, for which decreasing Seebeck coefficients with increasing conductivity (only variation of MWCNT type) is seen. This may be related to the previously discussed effect of the amine group electron donation, which may also be present in MWCNTs, but to a lesser extent. It is obvious that the values of all MWCNT containing composites are lower or in the range of the corresponding buckypapers with only PVDF composites having slightly higher Seebeck values in the composites. This indicates that the conductivity of the MWCNTs themselves significantly influences the behavior of the composites. Conversely, this means that CNTs with significantly higher Seebeck coefficient are required to produce composites with higher S-values. This assumption is confirmed if the composite materials with SWCNTs, which lead to positive Seebeck coefficients, are taken into account. The S-values of SWCNT buckypapers and powder packages are significantly higher compared to those of MWCNTs. The values of Seebeck coefficients of SWCNT based composites are quite higher than those based on MWCNTs. In contrast to MWCNTs, the S-values of SWCNT-containing composite materials were sometimes higher than those of the corresponding buckypapers, with the effect being most pronounced with SWCNT Tuball.

3.3. Influence of Single-Walled Carbon Nanotube (SWCNT) content on Thermoelectric (TE) Properties

Exemplarily, for three polymer matrices the influence of SWCNT content on TE properties was studied. On the one hand, p-type PBT/SWCNT Tuball composites (

Figure 8,

Table 7) are considered as p-type composites, and on the other hand, ABS/SWCNT Tuball (

Figure 9,

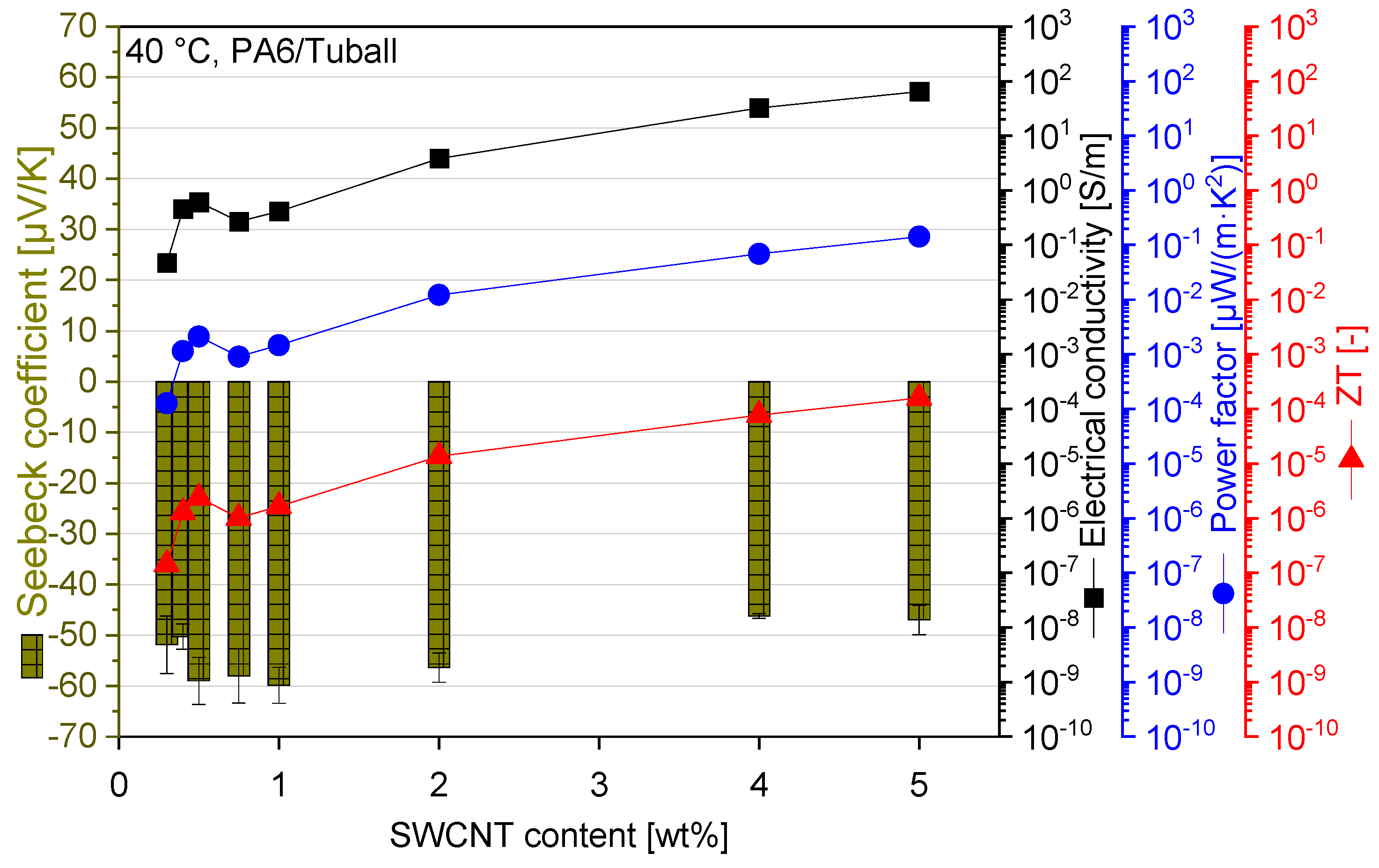

Table 8) and PA6/SWCNT Tuball (

Figure 10,

Table 9) as n-type composites.

For the PBT/SWCNT system, it was found that the Seebeck coefficient, power factor and figure of merit increase with CNT content. The S-value increases slightly from 54.3 µV/K at 0.2 wt % Tuball up to 66.4 µV/K at 5 wt % Tuball. The increasing trend implies that no maximum of the Seebeck coefficient may be obtained up to 5 wt %. In accordance with the also increasing electrical conductivity (only very slightly lower values at 5 wt % compared to 4 wt %), PF and ZT increase up to values of 0.28 µW/m·K2 and 3.1 × 10−4, respectively. The values for both parameters are the highest values described so far for melt prepared polymer/CNT composites in the literature, when excluding reported values for composites containing other additives or prepared by solvent processes.

For the n-type ABS/Tuball composites, a maximum negative Seebeck coefficient of −57.1 µV/K was found at 0.5 wt % Tuball. Especially at higher CNT content, the S-value increases up to −29.7 µV/K at 7 wt % SWCNT. However, due to the increasing electrical conductivity, the power factor and ZT value increase with the CNT content to values up to 0.14 µW/m·K2 and 1.6 × 10−4, respectively. Thereby, mainly due to the significantly lower values of conductivity in ABS/SWCNT as compared to PBT/SWCNT, the PF and ZT values were lower compared to the values of PBT/SWCNT composites.

For PA6 composites filled with 0.3–5 wt % SWCNT Tuball, the thermoelectrical measurements shows n-type behavior. The highest Seebeck coefficient was found at −59.0 µV/K for PA6/0.5 wt % SWCNT. As with ABS/Tuball composites, the S-value increases with the SWCNT content to −46 µV/K to −47 µV/K (4–5 wt % SWCNT). It has been observed in both ABS and PA6 matrices that a lower amount of SWCNTs can obviously be doped more strongly by the surrounding polymer chains, leading to a higher absolute value of the S-value than at a higher SWCNT contents. In the p-type composites based on PBT no such doping occurs and the S-values are more dependent on the conductive network formation.

For the three SWCNT composites based on PBT, ABS or PA6, maximum values of the TE results (PF, ZT) are achieved in the CNT concentration range between 4 wt % and 5 wt %. A maximum of these values at similar SWCNT concentrations was also found in PP based composites, as reported by Luo et al. [

10]. In this SWCNT concentration range, which is far above the percolation threshold concentration (compared to

Table 6), a very dense carbon nanotube network can be assumed. Electrical conductivity can be used as a measure of the density and quality of the conductive network, which approaches a limit as the CNT content increases. If the maximum conductivity is reached, then further network paths do not lead to a further increase in conductivity. It is assumed that the charge transport, which cannot be further increased by the addition of CNT, is reflected in almost constant PF and ZT values.