Remanufacturing of Woven Carbon Fibre Fabric Production Waste into High Performance Aligned Discontinuous Fibre Composites

Abstract

:1. Introduction

2. Experimental Work

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Pickering, S.J. Recycling technologies for thermoset composite materials—Current status. Compos. Part A Appl. Sci. 2006, 37, 1206–1215. [Google Scholar] [CrossRef]

- Pimenta, S.; Pinho, S.T. Recycling carbon fibre reinforced polymers for structural applications: Technology review and market outlook. Waste Manag. 2011, 31, 378–392. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Oliveux, G.; Dandy, L.O.; Leeke, G.A. Current status of recycling of fibre reinforced polymers: Review of technologies, reuse and resulting properties. Prog. Mater. Sci. 2015, 72, 61–99. [Google Scholar] [CrossRef] [Green Version]

- Meyer, L.O.; Schulte, K.; Grove-Nielsen, E. CFRP-recycling following a pyrolysis route: Process optimization and potentials. J. Compos. Mater. 2009, 43, 1121–1132. [Google Scholar] [CrossRef] [Green Version]

- Pimenta, S.; Pinho, S.T. The effect of recycling on the mechanical response of carbon fibres and their composites. Compos. Struct. 2012, 94, 3669–3684. [Google Scholar] [CrossRef] [Green Version]

- Pickering, S.J.; Turner, T.A.; Meng, F.; Morris, C.N.; Heil, J.P.; Wong, K.H.; Melendi-Espina, S. Developments in the fluidised bed process for fibre recovery from thermoset composites. In Proceedings of the 2nd Annual Composites and Advanced Materials Expo, CAMX, Dallas, TX, USA, 26–29 October 2015. [Google Scholar]

- Lester, E.; Kingman, S.; Wong, K.H.; Rudd, C.; Pickering, S.; Hilal, N. Microwave heating as a means for carbon fibre recovery from polymer composites: A technical feasibility study. Mater. Res. Bull. 2004, 39, 1549–1556. [Google Scholar] [CrossRef]

- Liu, Y.; Meng, L.; Huang, Y.; Du, J. Recycling of carbon/epoxy composites. J. Appl. Polym. Sci. 2004, 95, 1912–1916. [Google Scholar] [CrossRef]

- Lee, S.-H.; Choi, H.-O.; Kim, J.-S.; Lee, C.-K.; Kim, Y.-K.; Ju, C.-S. Circulating flow reactor for recycling of carbon fiber from carbon fiber reinforced epoxy composite. Korean J. Chem. Eng. 2011, 28, 449–454. [Google Scholar] [CrossRef]

- Feraboli, P.; Kawakami, H.; Wade, B.; Gasco, F.; Deoto, L.; Masini, A. Recyclability and reutilization of carbon fiber fabric/epoxy composites. J. Compos. Mater. 2012, 46, 1459–1473. [Google Scholar] [CrossRef]

- Das, M.; Chacko, R.; Varughese, S. An efficient method of recycling of CFRP waste using peracetic acid. Acs Sustain. Chem. Eng. 2018, 6, 1564–1571. [Google Scholar] [CrossRef]

- Li, J.; Xu, P.-L.; Zhu, Y.-K.; Ding, J.-P.; Xue, L.-X.; Wang, Y.-Z. A promising strategy for chemical recycling of carbon fiber/thermoset composites: Self-accelerating decomposition in a mild oxidative system. Green Chem. 2012, 14, 3260. [Google Scholar] [CrossRef]

- Ma, Y.; Kim, D.; Williams, T.J.; Nutt, S.R. Recycling of carbon fiber composites using chemical treatment: Reaction characterization and optimizaiton. In Proceedings of the SAMPE 2017, Seattle, WA, USA, 22–25 May 2017. [Google Scholar]

- Pinero-Hernanz, R.; Dodds, C.; Hyde, J.; Garcia-Serna, J.; Poliakoff, M.; Lester, E.; Cocero, M.J.; Kingman, S.; Pickering, S.; Wong, K.H. Chemical recycling of carbon fibre reinforced composites in nearcritical and supercritical water. Compos. Part A Appl. Sci. 2008, 39, 454–461. [Google Scholar] [CrossRef]

- Bai, Y.; Wang, Z.; Feng, L. Chemical recycling of carbon fibers reinforced epoxy resin composites in oxygen in supercritical water. Mater. Des. 2010, 31, 999–1002. [Google Scholar] [CrossRef]

- Hyde, J.R.; Lester, E.; Kingman, S.; Pickering, S.; Wong, K.H. Supercritical propanol, a possible route to composite carbon fibre recovery: A viability study. Compos. Part A Appl. Sci. Manuf. 2006, 37, 2171–2175. [Google Scholar] [CrossRef]

- Oliveux, G.; Bailleul, J.-L.; Gillet, A.; Mantaux, O.; Leeke, G.A. Recovery and reuse of discontinuous carbon fibres by solvolysis: Realignment and properties of remanufactured materials. Compos. Sci. Technol. 2017, 139, 99–108. [Google Scholar] [CrossRef] [Green Version]

- ELG Carbon Fibre Ltd. Available online: http://www.elgcf.com/home (accessed on 4 June 2020).

- CFK Valley Stade Recycling GmbH & Co. KG. Available online: https://www.cfk-recycling.de/index.php?id=5 (accessed on 4 June 2020).

- Carbon Conversions Inc. Available online: https://carbonconversions.com/ (accessed on 4 June 2020).

- Recycling Technologies—Adherent Technologies Inc. Available online: https://www.adherent-tech.com/recycling_technologies (accessed on 4 June 2020).

- Turner, T.A.; Warrior, N.A.; Pickering, S.J. Development of high value moulding compounds from recycled carbon fibres. Plast. Rubber Compos. 2010, 39, 151–156. [Google Scholar] [CrossRef]

- Fibre, P.T. Carbon Veils & Mats. Available online: https://www.tfpglobal.com/products/composite-materials (accessed on 4 June 2020).

- Wong, K.H.; Pickering, S.J.; Rudd, C.D. Recycled carbon fibre reinforced polymer composite for electromagnetic interference shielding. Compos. Part A Appl. Sci. Manuf. 2010, 41, 693–702. [Google Scholar] [CrossRef]

- Edwards, K.L. An overview of the technology of fibre-reinforced plastics for design purposes. Mater. Des. 1998, 19, 1–10. [Google Scholar] [CrossRef]

- Shah, D.U.; Schubel, P.J. On recycled carbon fibre composites manufactured through a liquid composite moulding process. J. Reinf. Plast. Comp. 2016, 35, 533–540. [Google Scholar] [CrossRef]

- Longana, M.L.; Ondra, V.; Yu, H.; Potter, K.D.; Hamerton, I. Reclaimed carbon and flax fibre composites: Manufacturing and mechanical properties. Recycling 2018, 3, 52. [Google Scholar] [CrossRef] [Green Version]

- Miyake, T.; Imaeda, S. A dry aligning method of discontinuous carbon fibers and improvement of mechanical properties of discontinuous fiber composites. Adv. Manuf. Polym. Compos. Sci. 2016, 2, 117–123. [Google Scholar] [CrossRef] [Green Version]

- Hengstermann, M.; Raithel, N.; Abdkader, A.; Hasan, M.M.B.; Cherif, C. Development of new hybrid yarn construction from recycled carbon fibers for high performance composites. Part-I: Basic processing of hybrid carbon fiber/polyamide 6 yarn spinning from virgin carbon fiber staple fibers. Text. Res. J. 2015, 86, 1307–1317. [Google Scholar] [CrossRef] [Green Version]

- Hengstermann, M.; Hasan, M.M.B.; Abdkader, A.; Cherif, C. Development of a new hybrid yarn construction from recycled carbon fibers (rCF) for high-performance composites. Part-II: Influence of yarn parameters on tensile properties of composites. Text. Res. J. 2016, 87, 1655–1664. [Google Scholar] [CrossRef] [Green Version]

- Hengstermann, M.; Hasan, M.M.B.; Scheffler, C.; Abdkader, A.; Cherif, C. Development of a new hybrid yarn construction from recycled carbon fibres for high-performance composites. Part III: Influence of sizing on textile processing and composite properties. J. Thermoplast. Compos. Mater. 2019. [Google Scholar] [CrossRef]

- Baz, S.; Ausheyks, L.; Reichert, O.; Dinkelmann, A.; Finckh, H.; Hehl, J.; Poeppel, A.; Gresser, G.T. Recycling of long carbon fibers, Part I: Development of a high aligned rCF-sliver for a binder tape manufacturing process. In Proceedings of the 18th European Conference on Composites Materials, Athens, Greece, 25–28 June 2018. [Google Scholar]

- Rimmel, O.; May, D.; Goergen, C.; Poeppel, A.; Schlimbach, J.; Mitschang, P. Recycling of long carbon fibers, Part II: Development of a binder tape manufacturing process for processing in automated tape laying. In Proceedings of the 18th European Conference on Composites Materials, Athens, Greece, 25–28 June 2018. [Google Scholar]

- Yarlagadda, S.; Deitzel, J.; Heider, D.; Tierney, J.; Jr, J.G. Tailorable universal feedstock for forming (TUFF): Overview and Performance. In Proceedings of the SAMPE 2019, Munich, Germany, 17–19 September 2019. [Google Scholar]

- Heider, D.; Tierney, J.; Henchir, M.; Gargitter, V.; Yarlagadda, S.; Jr, J.G.; Sun, J.; Sietins, J.; Knorr, D. Microstructural evaluation of aligned, Short Fiber TUFF Material. In Proceedings of the SAMPE 2019, Munich, Germany, 17–19 September 2019. [Google Scholar]

- Heider, D.; Tierney, J.; Deitzel, J.; Kubota, M.; Thiravong, J.; Gargitter, V.; Burris, W.; Morris, J.; Shevchenko, N.; Yarlagadda, S. Closed Loop Recycling of CFRP Into Highly Aligned High Performance Short Fiber Composites Using the TUFF Process. In Proceedings of the SAMPE, Charlotte, NC, USA, 20–23 May 2019. [Google Scholar]

- Yu, H.; Potter, K.D. Method and Apparatus for Aligning Discontinuous Fibres. European Patent EP2986768, 4 April 2014. [Google Scholar]

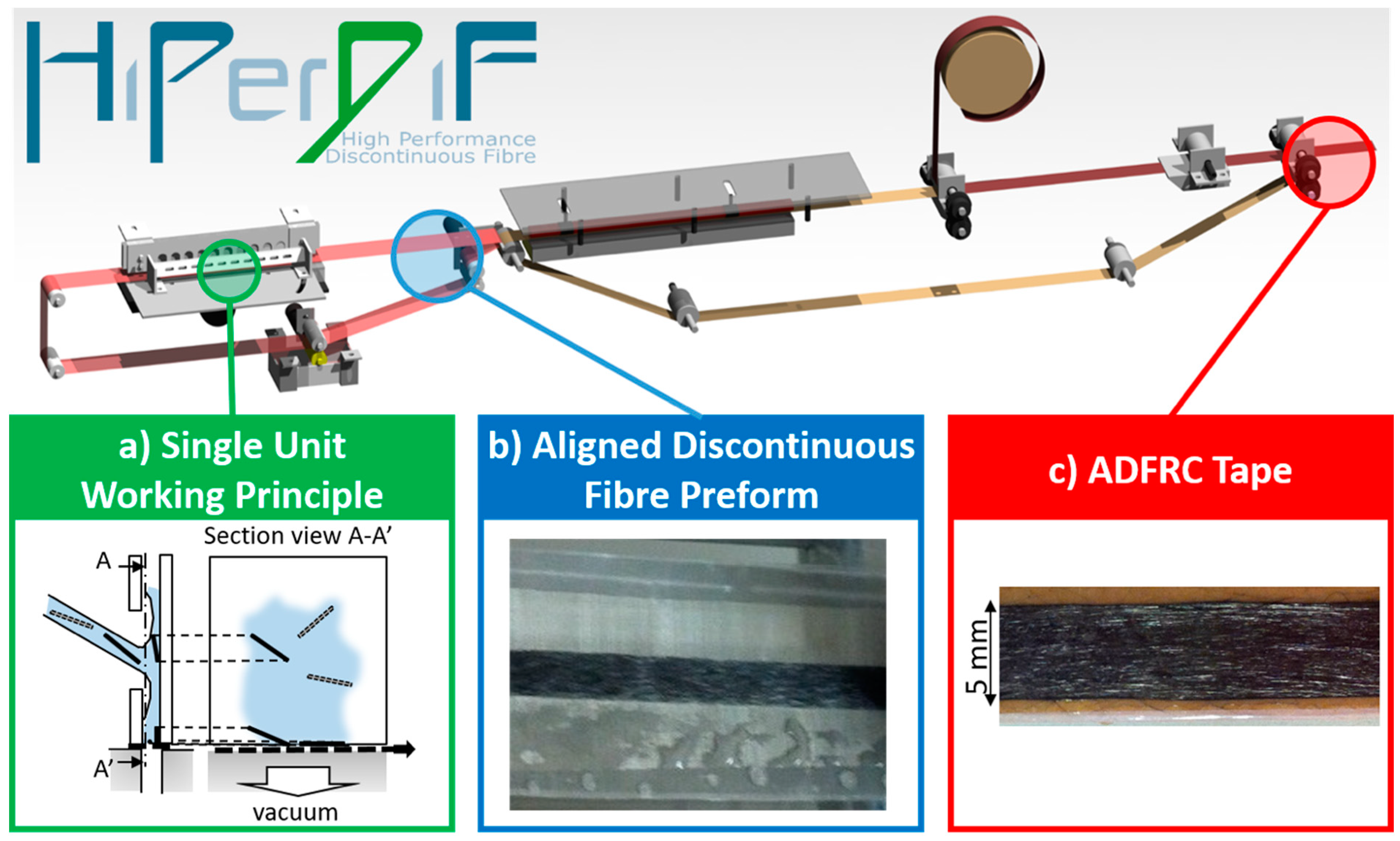

- Yu, H.; Potter, K.D.; Wisnom, M.R. A novel manufacturing method for aligned discontinuous fibre composites (High Performance-Discontinuous Fibre method). Compos. Part A Appl. Sci. Manuf. 2014, 65, 175–185. [Google Scholar] [CrossRef]

- Pozegic, R.T.; Huntley, S.; Longana, L.M.; He, S.; Bandara, M.I.R.; King, G.S.; Hamerton, I. Improving dispersion of recycled discontinuous carbon fibres to increase fibre throughput in the HiPerDiF Process. Materials 2020, 13, 1544. [Google Scholar] [CrossRef] [Green Version]

- Longana, M.L.; Yu, H.N.; Jalavand, M.; Wisnom, M.R.; Potter, K.D. Aligned discontinuous intermingled reclaimed/virgin carbon fibre composites for high performance and pseudo-ductile behaviour in interlaminated carbon-glass hybrids. Compos. Sci. Technol. 2017, 143, 13–21. [Google Scholar] [CrossRef] [Green Version]

- Longana, M.L.; Ong, N.; Yu, H.; Potter, K.D. Multiple closed loop recycling of carbon fibre composites with the HiPerDiF (High Performance Discontinuous Fibre) Method. Compos. Struct. 2016, 153, 271–277. [Google Scholar] [CrossRef] [Green Version]

- Tapper, R.J.; Longana, M.L.; Yu, H.; Hamerton, I.; Potter, K.D. Development of a closed-loop recycling process for discontinuous carbon fibre polypropylene composites. Compos. Part B: Eng. 2018, 146, 222–231. [Google Scholar] [CrossRef] [Green Version]

- Tapper, R.J.; Longana, M.L.; Hamerton, I.; Potter, K.D. A closed-loop recycling process for discontinuous carbon fibre polyamide 6 composites. Compos. Part B Eng. 2019, 179, 107418. [Google Scholar] [CrossRef]

- Longana, M.L.; Yu, H.; Hamerton, I.; Potter, K.D. Development and application of a quality control and property assurance methodology for reclaimed carbon fibers based on the HiPerDiF (High Performance Discontinuous Fibre) method and interlaminated hybrid specimens. Adv. Manuf. Polym. Compos. Sci. 2018, 4, 48–55. [Google Scholar] [CrossRef] [Green Version]

- Microtex Composites SRL. Available online: http://www.microtexcomposites.com/en/ (accessed on 4 June 2020).

- ASTM D3039/D3039M-17 Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials; ASTM International: West Conshohocken, PA, USA, 2017.

- Yu, H.; Potter, K.D.; Wisnom, M.R. A novel manufacturing method of aligned short fibre composite. In Proceedings of the 15th European Conference on Composite Materials (ECCM15), Venice, Italy, 24–28 June 2012. [Google Scholar]

- Huntley, S.; Rendall, T.; Longana, M.L.; Pozegic, T.; Potter, K.; Hamerton, I. Validation of a smoothed particle hydrodynamics model for a highly aligned discontinuous fibre composites manufacturing process. Compos. Sci. Technol. 2020, 196, 108152. [Google Scholar] [CrossRef]

- Huntley, S.; Rendall, T.; Longana, M.L.; Pozegic, T.; Potter, K.; Hamerton, I. Short fibre recycling using water jet alignment. Int. J. Comput. Fluid Dyn. 2020, in press. [Google Scholar]

| Fibre Length | Stiffness [GPa] | Strength [MPa] | Failure Strain [%] |

|---|---|---|---|

| 3 | 70 ± 5 | 841 ± 39 | 1.19 ± 0.03 |

| 3 + 6 | 66 ± 3 | 706 ± 42 | 1.07 ± 0.07 |

| 4.5 | 69 ± 4 | 769 ± 85 | 1.11 ± 0.07 |

| 3 + 4.5 + 6 | 70 ± 4 | 723 ± 74 | 1.04 ± 0.09 |

| 6 | 81 ± 5 | 783 ± 102 | 0.97 ± 0.09 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aravindan, P.; Becagli, F.; Longana, M.L.; Blok, L.G.; Pozegic, T.R.; Huntley, S.J.; Rendall, T.; Hamerton, I. Remanufacturing of Woven Carbon Fibre Fabric Production Waste into High Performance Aligned Discontinuous Fibre Composites. J. Compos. Sci. 2020, 4, 68. https://doi.org/10.3390/jcs4020068

Aravindan P, Becagli F, Longana ML, Blok LG, Pozegic TR, Huntley SJ, Rendall T, Hamerton I. Remanufacturing of Woven Carbon Fibre Fabric Production Waste into High Performance Aligned Discontinuous Fibre Composites. Journal of Composites Science. 2020; 4(2):68. https://doi.org/10.3390/jcs4020068

Chicago/Turabian StyleAravindan, Parthasarathi, Federico Becagli, Marco L. Longana, Lourens G. Blok, Thomas R. Pozegic, Samantha J. Huntley, Thomas Rendall, and Ian Hamerton. 2020. "Remanufacturing of Woven Carbon Fibre Fabric Production Waste into High Performance Aligned Discontinuous Fibre Composites" Journal of Composites Science 4, no. 2: 68. https://doi.org/10.3390/jcs4020068

APA StyleAravindan, P., Becagli, F., Longana, M. L., Blok, L. G., Pozegic, T. R., Huntley, S. J., Rendall, T., & Hamerton, I. (2020). Remanufacturing of Woven Carbon Fibre Fabric Production Waste into High Performance Aligned Discontinuous Fibre Composites. Journal of Composites Science, 4(2), 68. https://doi.org/10.3390/jcs4020068