Preliminary Mechanical Analysis of Rubber-Cement Composites Suitable for Additive Process Construction

Abstract

1. Introduction

- Reduction in injury rates by eliminating dangerous activities.

- Increasing sustainability in construction: less material waste and reduced CO2 emissions.

- Creation of high-end technology-based jobs.

- Increasing architectural freedom which would enable more sophisticated designs for engineering and aesthetic purposes.

- Enhance multi-functionality for structural/architectural elements. Thanks to this feature, construction components can be designed to tune their properties according to the type of application to which they are addressed (weight reduction, improvement of mechanical properties, acoustic damping, thermal insulation).

- Technological optimization of the printing process (automated implementation of structural reinforcements or integration of multi-deposition devices);

- Rigorous studies on the development of building units with functional morphologies;

- Study and design of novel printable materials with low environmental impact (use of eco-friendly binders or industrial wastes as mixture aggregates).

2. Materials and Methods

2.1. Material Properties and Mix Proportions

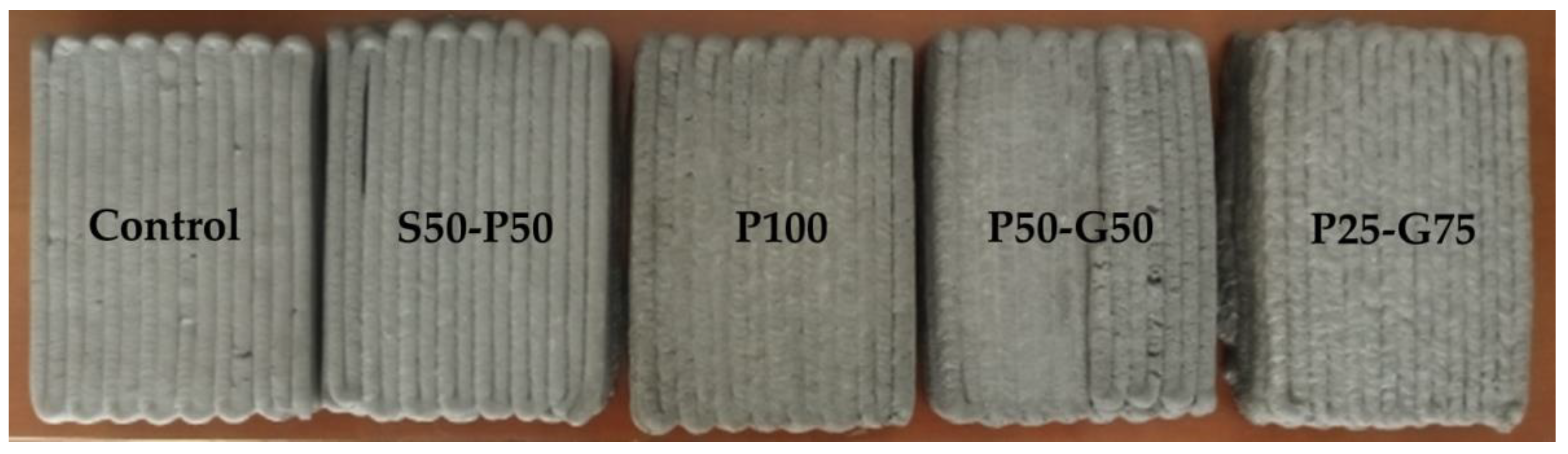

- S50-P50: 50% by volume of sand—50% by volume of RP.

- P100: 100% by volume of RP.

- P50-G50: 50% by volume of RP—50% by volume of RG.

- P25-G75: 25% by volume of RP—75% by volume of RG.

3D Printability Tests and Samples Manufacturing

- Extrudability. This can be defined as the ability of the material to be deposited regularly and without interruptions/blockages in the extrusion nozzle.

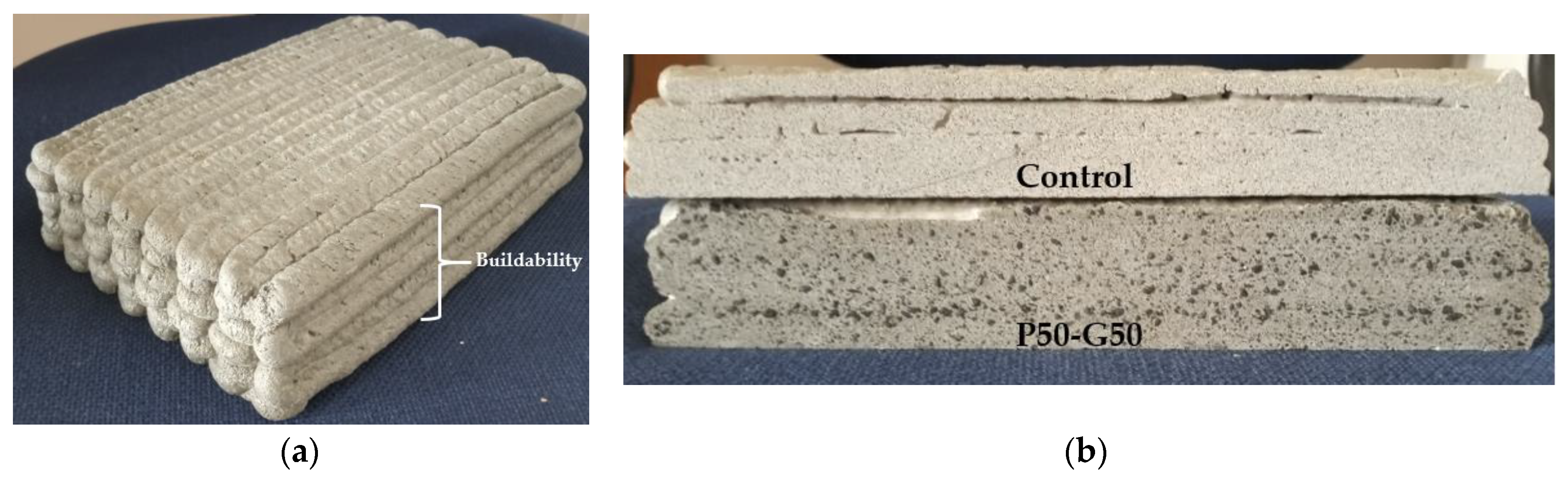

- Buildability (or shape stability). This is the material’s ability to retain its shape, as per the extruder dimension, under pressure from the upper layers without the occurrence of collapse phenomena. Five printed layers of cementitious material are the “target-condition” for defining the mix as printable.

- Inter-layer adhesion. This is related to the bond strength between the printed layers. High inter-layer adhesion implies a compact material without voids or defects between the deposited filaments. This requirement is closely related to the mechanical properties of the printed samples. The structural homogeneity of the object promotes its isotropic behavior in terms of mechanical strength.

2.2. Experimental Testing

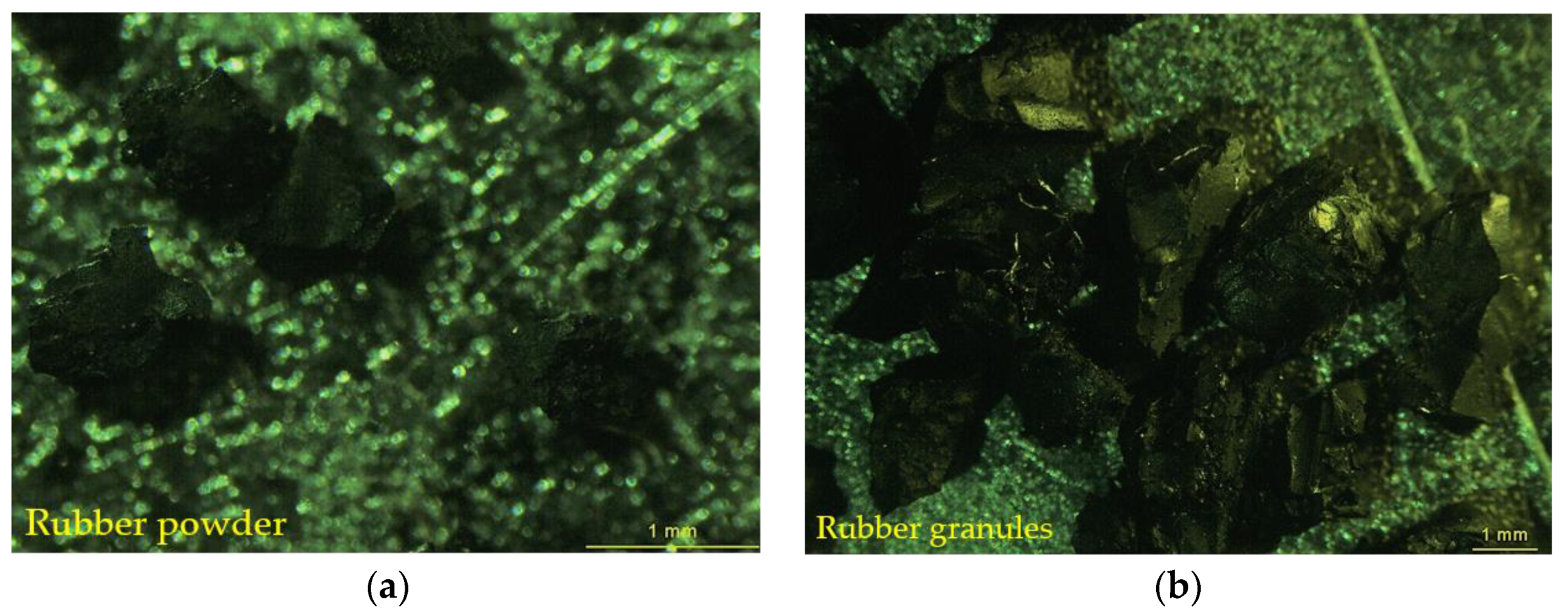

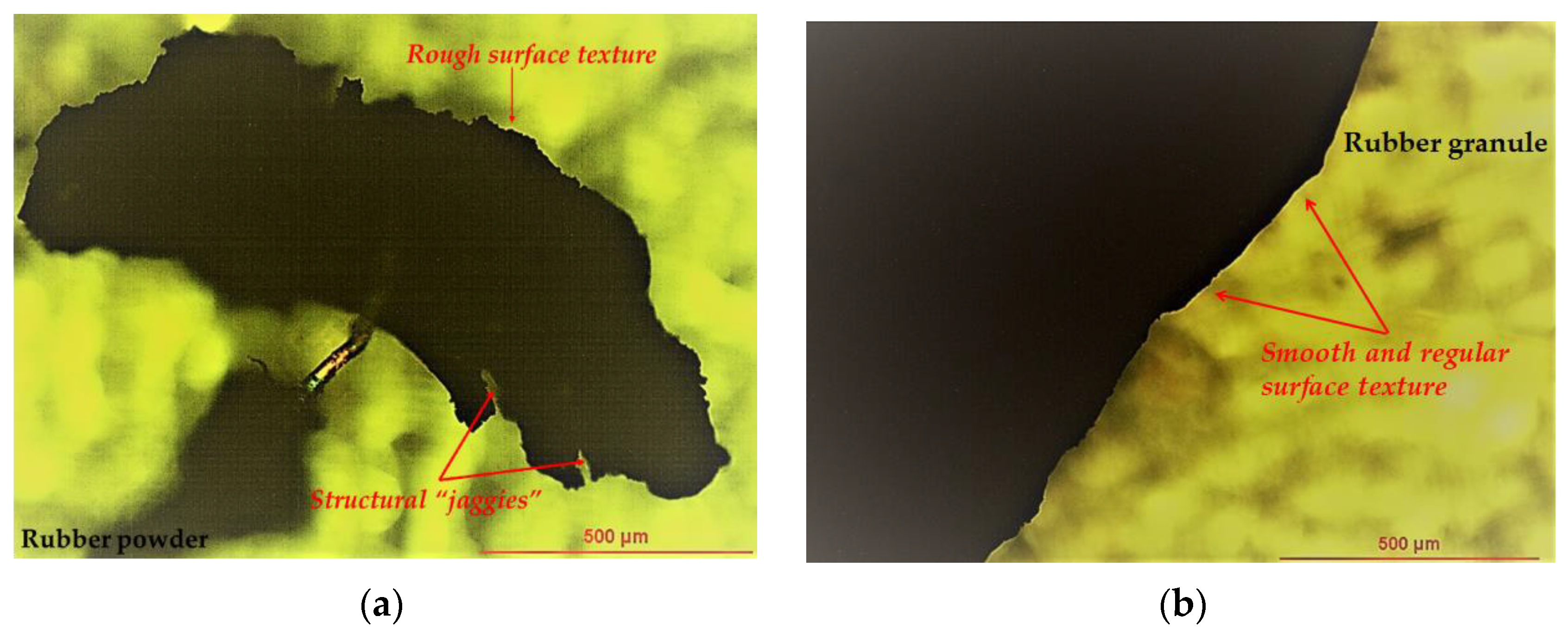

2.2.1. Microscopical Analysis on GTR and Microstructure Characterization

2.2.2. Bulk Density Evaluation

2.2.3. Mechanical Characterization: Compressive Test

2.2.4. Mechanical Characterization: Four-Point Flexural Test

3. Results and Discussion

3.1. 3D Printability Test: A Qualitative Analysis

3.2. Microscopical Analysis on GTR and Microstructure Characterization

3.3. Bulk Density Evaluation

3.4. Mechanical Characterization: Compressive Test

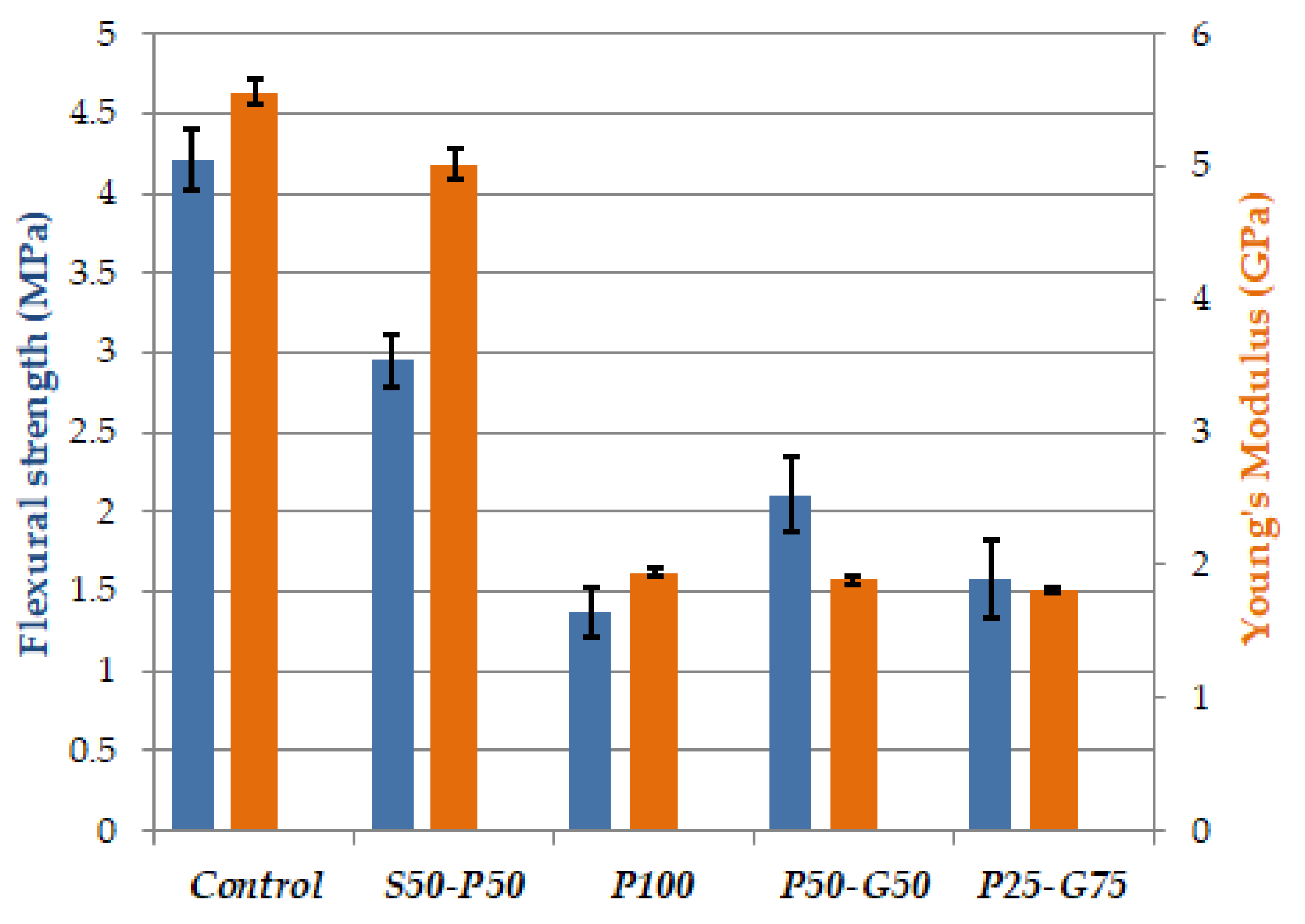

3.5. Mechanical Characterization: Four-Point Flexural Test

4. Conclusions

- The replacement of mineral aggregates by GTR particles does not alter the proper printability of cement-based mixtures. Polymer aggregates modify the surface tension of the fresh compound, increasing its fluidity and ensuring a more efficient layer-by-layer deposition process in terms of adhesion between the filaments, compaction of the hardened material, and mechanical isotropy.

- The incorporation of lightweight and hydrophobic rubber particles implies a reduction in the unit weight of the cement mortars. However, by properly combining the two polymer fractions used in this work (RP and RG), it is possible to obtain a less relevant density loss with consequent advantages in mechanical strength performances.

- Low density and poor rubber-cement interfacial bonding are the main causes of the mechanical strength loss in rubber-cement composites. However, by exploiting the synergy between fine (RP) and coarse fractions (RG), it was possible to observe better strength performances (P50-G50 mix). Partial sand-rubber replacement (S50-P50 mix) provides good mechanical requirements but could represent a less efficient strategy in terms of enhancing the tire recycling process and saving natural resources.

- More ductile behavior is observed for rubberized mortars compared to plain cement specimens under compressive and flexural testing. These can represent interesting requirements in applications where structural deformability is a primary requirement (flexible paving bricks, flexible sub-base for pavements, anti-shock barriers).

- Complete the experimental campaign on 3D printable rubber-cement mixtures, evaluating the effect of GTR fractions on the acoustic and thermal properties. The authors have already published a piece of research concerning the durability performance of the materials investigated in this work [18].

- Study and analyze potential chemical-physical treatments to improve rubber-cement adhesion properties. Compatibilizing treatments and surface modification methods are widely used in composites materials technology, where matrix reinforcement adhesion is a fundamental requirement to improve the physical-mechanical properties of the material [36,37].

- Explore the frontiers of AM and exploit its design flexibility to enhance the use of RC technology in the construction and architectural fields.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Craveiroa, F.; Duartec, J.P.; Bartoloa, H.; Bartolod, P.J. Additive manufacturing as an enabling technology for digital construction: A perspective on Construction 4.0. Autom. Constr. 2019, 103, 251–267. [Google Scholar] [CrossRef]

- Abubakar, M.; Ibrahim, Y.M.; Kado, D.; Bala, K. Contractors’ perception of the factors affecting Building Information Modelling (BIM) adoption in the Nigerian Construction Industry. In Proceedings of the 2014 International Conference on Computing in Civil and Building Engineering, Orlando, FL, USA, 23–25 June 2014; American Society of Civil Engineers (ASCE): Reston, VS, USA; pp. 167–178. [Google Scholar] [CrossRef]

- Sanjayan, J.G.; Nematollahi, B.; Xia, M.; Marchment, T. Effect of surface moisture on inter-layer strength of 3D printed concrete. Constr. Build. Mater. 2018, 172, 468–475. [Google Scholar] [CrossRef]

- Buswell, R.A.; Soar, R.; Gibb, A.G.; Thorpe, T. The potential of freeform construction processes. In Proceedings of the 16th International Symposium on Solid Freeform Fabrication, Austin, TX, USA, 1–3 August 2005; pp. 503–512. [Google Scholar]

- Nematollahi, B.; Xia, M.; Sanjayan, J. Current progress of 3D concrete printing technologies. In Proceedings of the International Symposium on Automation and Robotics in Construction, Taipei, Taiwan, 28 June–1 July 2017. [Google Scholar]

- Valente, M.; Sibai, A.; Sambucci, M. Extrusion-Based additive manufacturing of concrete products: Revolutionizing and remodeling the construction industry. J. Compos. Sci. 2019, 3, 88. [Google Scholar] [CrossRef]

- Wangler, T.; Lloret, E.; Reiter, L.; Hack, N.; Gramazio, F.; Kohler, M.; Bernhard, M.; Dillenburger, B.; Buchli, J.; Roussel, N. Digital concrete: Opportunities and challenges. RILEM Tech. Lett. 2016, 1, 67–75. [Google Scholar] [CrossRef]

- D-Shape by Enrico Dini, Chairman. Available online: https://d-shape.com/ (accessed on 19 May 2020).

- Dezeen. Available online: https://www.dezeen.com/2012/08/22/stone-spray-robot-by-anna-kulik-inder-shergill-and-petr-novikov/ (accessed on 19 May 2020).

- Salet, T.A.M.; Ahmed, Z.Y.; Laagland, H.L.M. 3D printed concrete bridge. In Proceedings of the 3rd International Conference on Progress in Additive Manufacturing (Pro-AM 2018), Singapore, 14–17 May 2018; pp. 2–9. [Google Scholar]

- XTREE. Available online: https://www.xtreee.eu/projects/ (accessed on 8 June 2020).

- Wasp. Available online: https://www.3dwasp.com/stampa-3d-ceramica-wasp-clay/ (accessed on 19 May 2020).

- Lim, J.H.; Weng, Y.; Pham, Q.C. 3D printing of curved concrete surfaces using Adaptable Membrane Formwork. Constr. Build. Mater. 2020, 232, 117075. [Google Scholar] [CrossRef]

- Mechtcherine, V.; Nerella, V.N.; Will, F.; Näther, M.; Otto, J.; Krause, M. Large-scale digital concrete construction—CONPrint3D concept for on-site, monolithic 3D-printing. Autom. Constr. 2019, 107, 102933. [Google Scholar] [CrossRef]

- ETRA. Available online: https://www.etra-eu.org/ (accessed on 8 June 2020).

- Mohammed, B.S.; Hossain, K.M.A.; Swee, J.T.E.; Wong, G.; Abdullahi, M. Properties of crumb rubber hollow concrete block. J. Clean. Prod. 2012, 23, 57–67. [Google Scholar] [CrossRef]

- Valente, M.; Sibai, A. Rubber/Crete: Mechanical properties of scrap to reuse tire-derived rubber in concrete: A review. J. Appl. Biomater. Funct. Mater. 2019, 17, 1–8. [Google Scholar] [CrossRef]

- Sambucci, M.; Marini, D.; Valente, M. Tire Recycled Rubber for More Eco-Sustainable Advanced Cementitious Aggregate. Recycling 2020, 5, 11. [Google Scholar] [CrossRef]

- Sambucci, M.; Valente, M.; Sibai, A.; Marini, D.; Quitadamo, A.; Musacchi, E. Rubber-Cement Composites for Additive Manufacturing: Physical, Mechanical and Thermo-Acoustic Characterization. In Second RILEM International Conference on Concrete and Digital Fabrication: Digital Concrete 2020; Bos, F., Lucas, S., Wolfs, R., Salet, T., Eds.; RILEM Bookseries; Springer: Cham, Switzerland, 2020; Volume 28. [Google Scholar] [CrossRef]

- Papachristoforou, M.; Mitsopoulos, V.; Stefanidou, M. Evaluation of workability parameters in 3D printing concrete. Procedia Struct. Integr. 2018, 10, 155–162. [Google Scholar] [CrossRef]

- British Standard Institute. Method for Determination of Density of Hardened Concrete; BS 1881-114; British Standard Institute: London, UK, 1983. [Google Scholar]

- ASTM International. Standard Test Method for Compressive Strength of Hydraulic Cement Mortars (Using 2-in. or [50-mm] Cube Specimens); ASTM C109/C109M-20a; ASTM International: West Conshohocken, PA, USA, 2020. [Google Scholar]

- ASTM International. Standard Test Method for Flexural Strength of Hydraulic-Cement Mortars; ASTM C348-20; ASTM International: West Conshohocken, PA, USA, 2020. [Google Scholar]

- Aiello, M.A.; Leuzzi, F. Waste tyre rubberized concrete: Properties at fresh and hardened state. Waste Manag. 2010, 30, 1696–1704. [Google Scholar] [CrossRef] [PubMed]

- Ghizdăveț, Z.; Ștefan, B.M.; Nastac, D.; Vasile, O.; Bratu, M. Sound absorbing materials made by embedding crumb rubber waste in a concrete matrix. Constr. Build. Mater. 2016, 124, 755–763. [Google Scholar] [CrossRef]

- Valente, M.; Sambucci, M.; Sibai, A.; Musacchi, E. Multi-Physics Analysis for Rubber-Cement Applications in Building and Architectural Fields: A Preliminary Analysis. Sustainability 2020, 12, 5993. [Google Scholar] [CrossRef]

- Guo, Y.; Zhang, J.; Chen, G.; Xie, Z. Compressive behaviour of concrete structures incorporating recycled concrete aggregates, rubber crumb and reinforced with steel fibre, subjected to elevated temperatures. J. Clean. Prod. 2014, 72, 193–203. [Google Scholar] [CrossRef]

- RILEM. Functional Classification of Lightweight Concretes: Recommendation LC2, 2nd ed.; RILEM Publications Sarl: Bagneux, France, 1978. [Google Scholar]

- Ünal, O.; Uygunoğlu, T.; Yildiz, A. Investigation of properties of low-strength lightweight concrete for thermal insulation. Build. Environ. 2007, 42, 584–590. [Google Scholar] [CrossRef]

- Siddique, R.; Naik, T.R. Properties of concrete containing scrap-tire rubber—An overview. Waste Manag. 2004, 24, 563–569. [Google Scholar] [CrossRef]

- Panda, B.; Singh, G.B.; Unluer, C.; Tan, M.J. Synthesis and characterization of one-part geopolymers for extrusion based 3D concrete printing. J. Clean. Prod. 2019, 220, 610–619. [Google Scholar] [CrossRef]

- Panda, B.; Paul, S.C.; Hui, L.J.; Tay, Y.W.D.; Tan, M.J. Additive manufacturing of geopolymer for sustainable built environment. J. Clean. Prod. 2017, 167, 281–288. [Google Scholar] [CrossRef]

- Benazzouk, A.; Douzane, O.; Mezreb, K.; Quéneudec, M. Physico-mechanical properties of aerated cement composites containing shredded rubber waste. Cem. Concr. Compos. 2006, 28, 650–657. [Google Scholar] [CrossRef]

- Khaloo, A.; Dehestani, M.; Rahmatabadi, P. Mechanical properties of concrete containing a high volume of tire-rubber particles. Waste Manag. 2008, 28, 2472–2482. [Google Scholar] [CrossRef]

- Turatsinze, A.; Garros, M. On the modulus of elasticity and strain capacity of self-compacting concrete incorporating rubber aggregates. Resour. Conserv. Recycl. 2008, 52, 1209–1215. [Google Scholar] [CrossRef]

- Marini, D.; Valente, M. Basalt short fibers dispersion and fabric impregnation with magnesium alloy (AZ63): First results. Materials 2019, 12, 2960. [Google Scholar] [CrossRef] [PubMed]

- Valente, M.; Marini, D.; Genova, V.; Quitadamo, A.; Marra, F.; Pulci, G. Lightweight metallic matrix composites: Development of new composites material reinforced with carbon structures. J. Appl. Biomater. Funct. Mater. 2019, 17, 2280800019840294. [Google Scholar] [CrossRef] [PubMed]

| Research Team or Company | Project | Printed Product | Source |

|---|---|---|---|

| Eindhoven University of Technology | 3DCP | 3D printed pedestrian bridge elements | [10] |

| XTREE | 3D Pavilion | Urban furniture with functional properties | [11] |

| WASP | GAIA House | 30 m2 module with improved energy efficiency | [12] |

| Singapore Centre for 3D Printing | Saddle and Dome-shaped surfaces | 3D printed curved concrete panels | [13] |

| TU Dresden, Institute of Construction Materials | CONprint3D | On-site monolithic construction | [14] |

| GTR | Specific Gravity (kg/m3) | Particle Size Distribution (mm) |

|---|---|---|

| Rubber powder (RP) | 1209 | 0–1 |

| Rubber granules (RG) | 1195 | 2–4 |

| Mix | Cement (kg/m3) | Water (kg/m3) | Sand (kg/m3) | RP (kg/m3) | RG (kg/m3) | TA + SA + WRA + EA (kg/m3) |

|---|---|---|---|---|---|---|

| Control | 800 | 300 | 1100 | 0 | 0 | 152 |

| S50-P50 | 800 | 280 | 550 | 150 | 0 | 152 |

| P100 | 800 | 260 | 0 | 300 | 0 | 152 |

| P50-G50 | 800 | 250 | 0 | 150 | 160 | 152 |

| P25-G75 | 800 | 230 | 0 | 75 | 240 | 152 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sambucci, M.; Marini, D.; Sibai, A.; Valente, M. Preliminary Mechanical Analysis of Rubber-Cement Composites Suitable for Additive Process Construction. J. Compos. Sci. 2020, 4, 120. https://doi.org/10.3390/jcs4030120

Sambucci M, Marini D, Sibai A, Valente M. Preliminary Mechanical Analysis of Rubber-Cement Composites Suitable for Additive Process Construction. Journal of Composites Science. 2020; 4(3):120. https://doi.org/10.3390/jcs4030120

Chicago/Turabian StyleSambucci, Matteo, Danilo Marini, Abbas Sibai, and Marco Valente. 2020. "Preliminary Mechanical Analysis of Rubber-Cement Composites Suitable for Additive Process Construction" Journal of Composites Science 4, no. 3: 120. https://doi.org/10.3390/jcs4030120

APA StyleSambucci, M., Marini, D., Sibai, A., & Valente, M. (2020). Preliminary Mechanical Analysis of Rubber-Cement Composites Suitable for Additive Process Construction. Journal of Composites Science, 4(3), 120. https://doi.org/10.3390/jcs4030120