Experimental Study of the Probabilistic Fatigue Residual Strength of a Carbon Fiber-Reinforced Polymer Matrix Composite

Abstract

:1. Introduction

2. Experimental

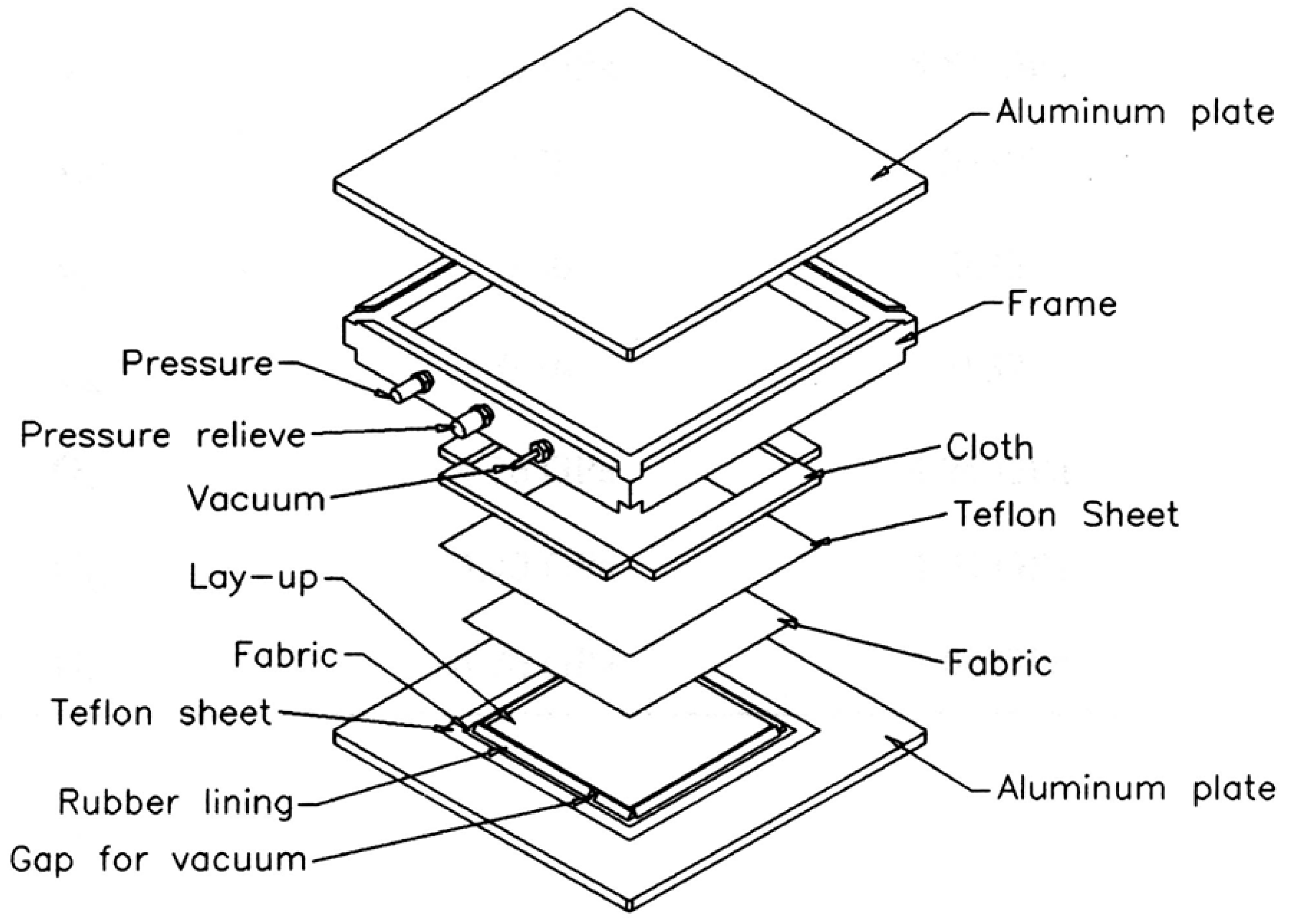

2.1. Composite Laminate Processing and Specimen Preparation for Quasistatic Tension and Fatigue Tests

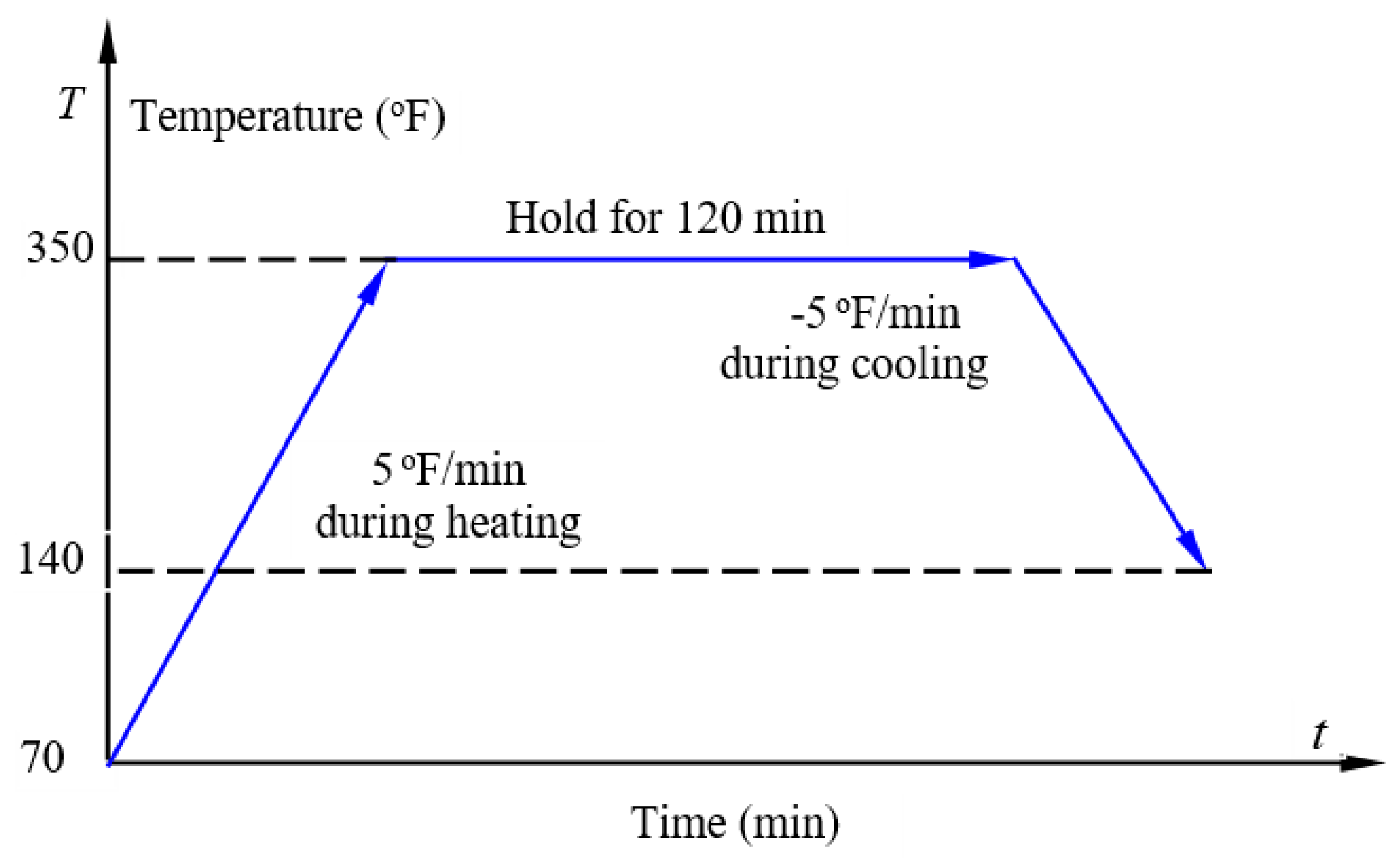

- (1)

- 5 °F/min to 350 ± 5 °F (177 ± 3 °C);

- (2)

- 120 min at 350 ± 5 °F (177 ± 3 °C);

- (3)

- −5 °F/min to 140 ± 5 °F (± 3 °C);

- (4)

- 80 ± 5 psi (0.55 ± 0.03 MPa).

2.2. Quasistatic Tension and tension–tension Fatigue Tests of the PMC Specimens

3. Data Reduction, Probabilistic Model Fitting, Free-Edge Stress Prediction, and Discussions

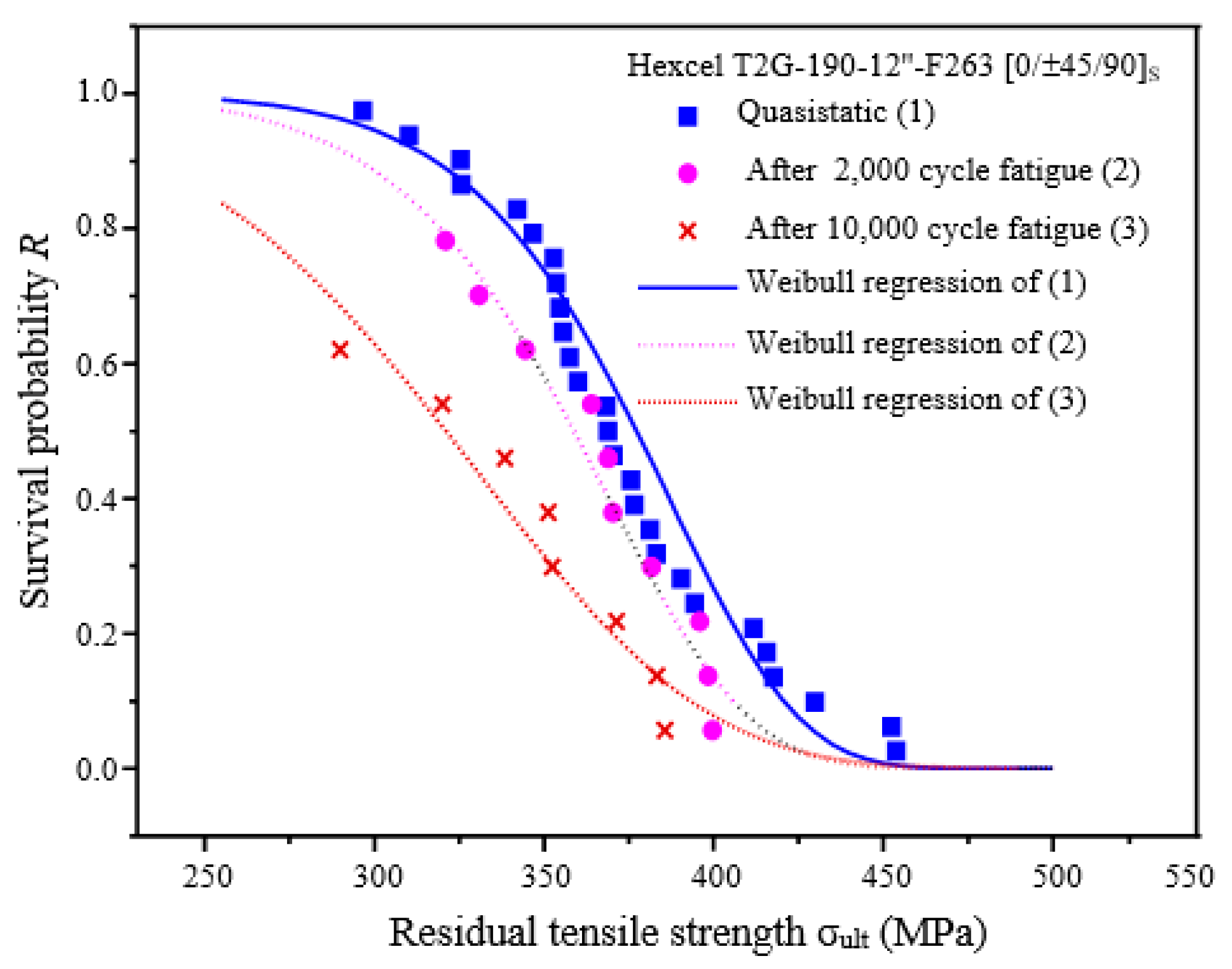

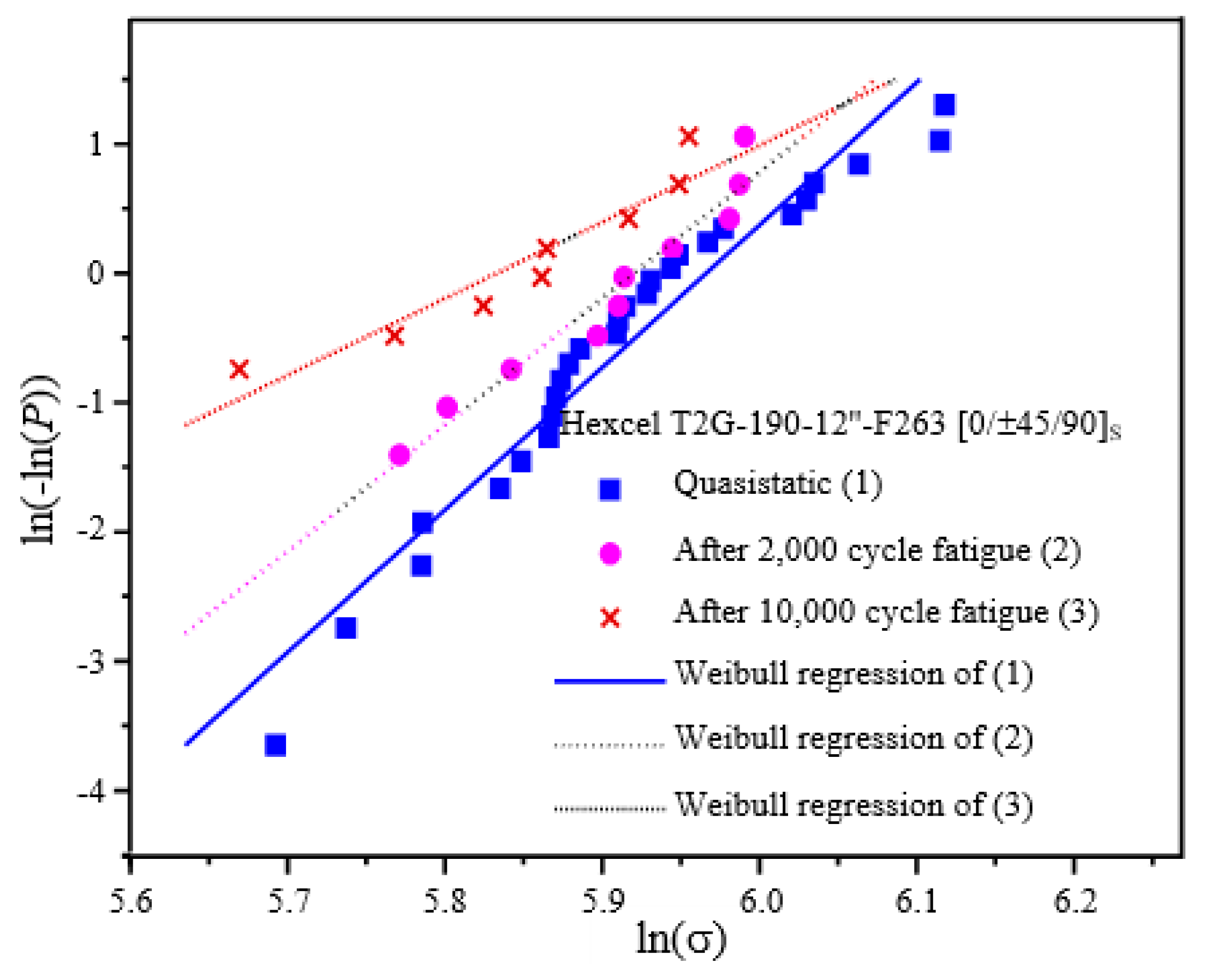

3.1. Data Reduction and Probabilistic Residual Strength Model Fitting

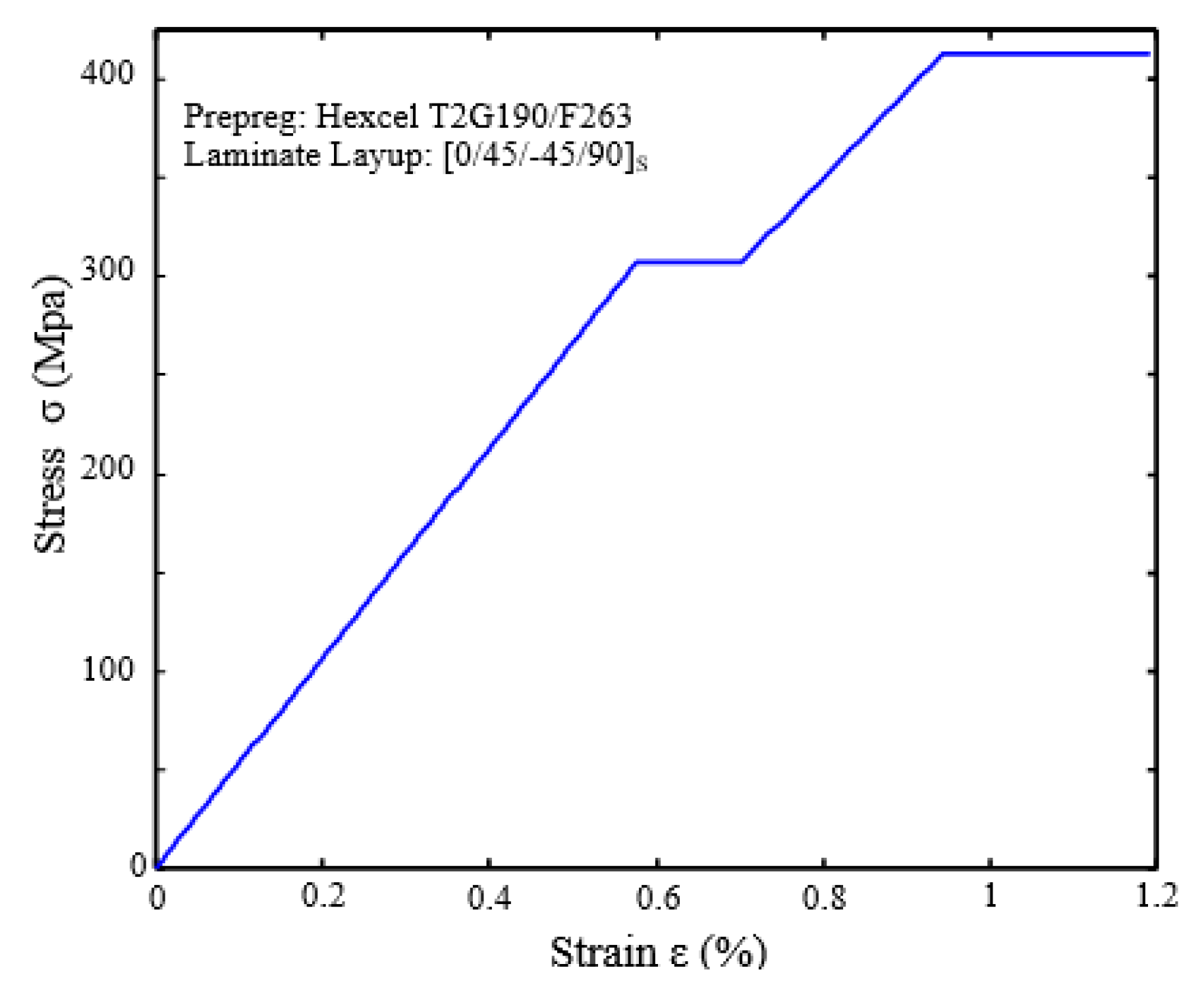

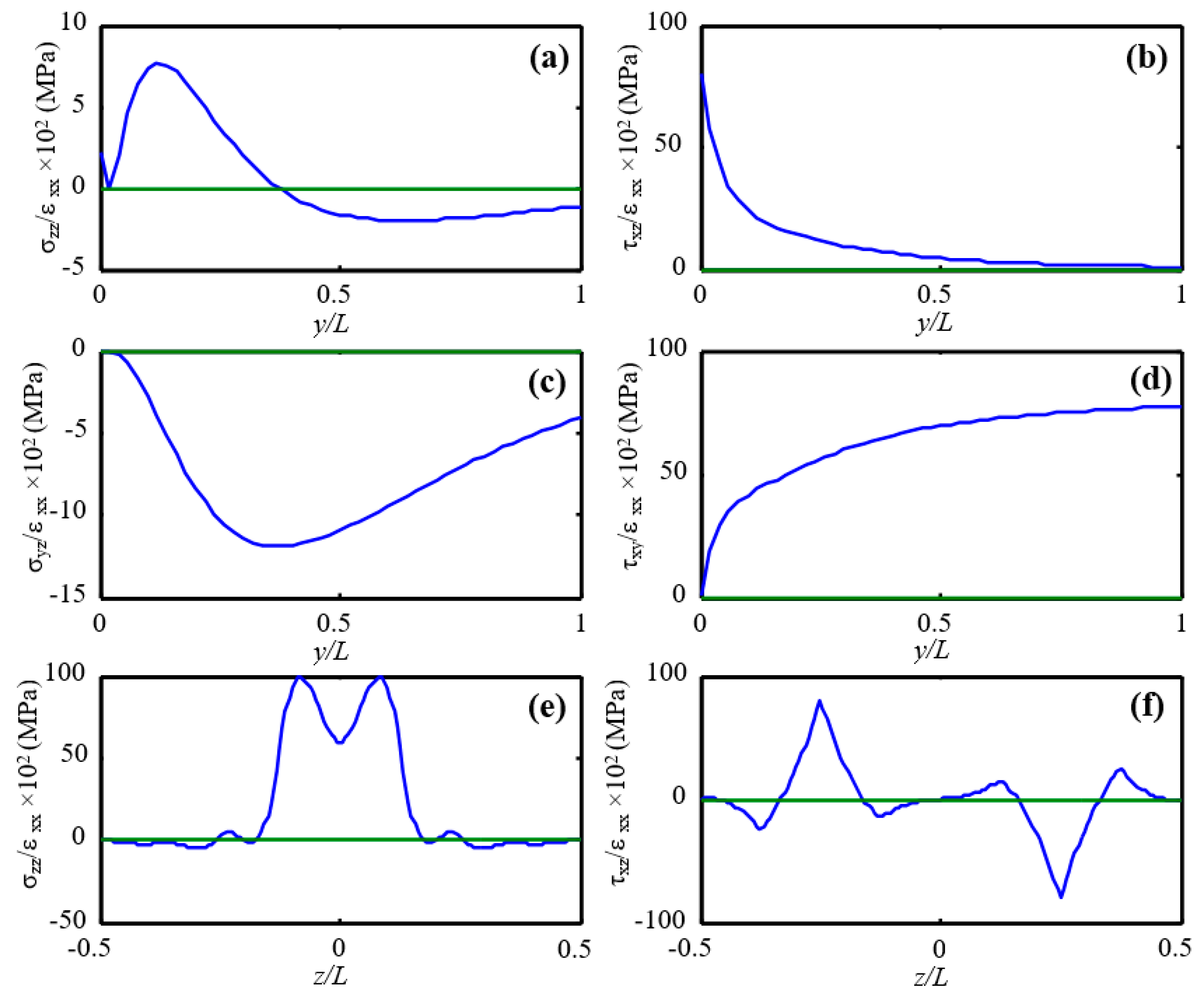

3.2. Model-Based Tensile Strength and Free-Edge Stress Predictions

4. Concluding Remarks

- (1)

- The quasistatic tensile strength and fatigue residual tensile strength of the tested Hexcel composite laminate follow two-parameter Weibull distributions very well with the shape and scale parameters decreasing with increasing fatigue cycles.

- (2)

- The peak of the laminate failure probability density and the mean residual tensile strength decreases with increasing fatigue cycles, while the probabilistic distribution of the residual tensile strength of the composite laminate becomes more and more scattered with increasing fatigue cycles.

- (3)

- The effective uniaxial modulus and tensile strength predicted by the class laminate theory (CLT) were reasonably validated by the present experimental observations.

- (4)

- The present experimental observations showed that edge delamination first occurred at the 45°/90° interfaces of the composite laminate, corresponding to interfaces of the laminate with the maximum out-of-plane shear and normal stresses as predicted by the efficient stress-function variational method.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

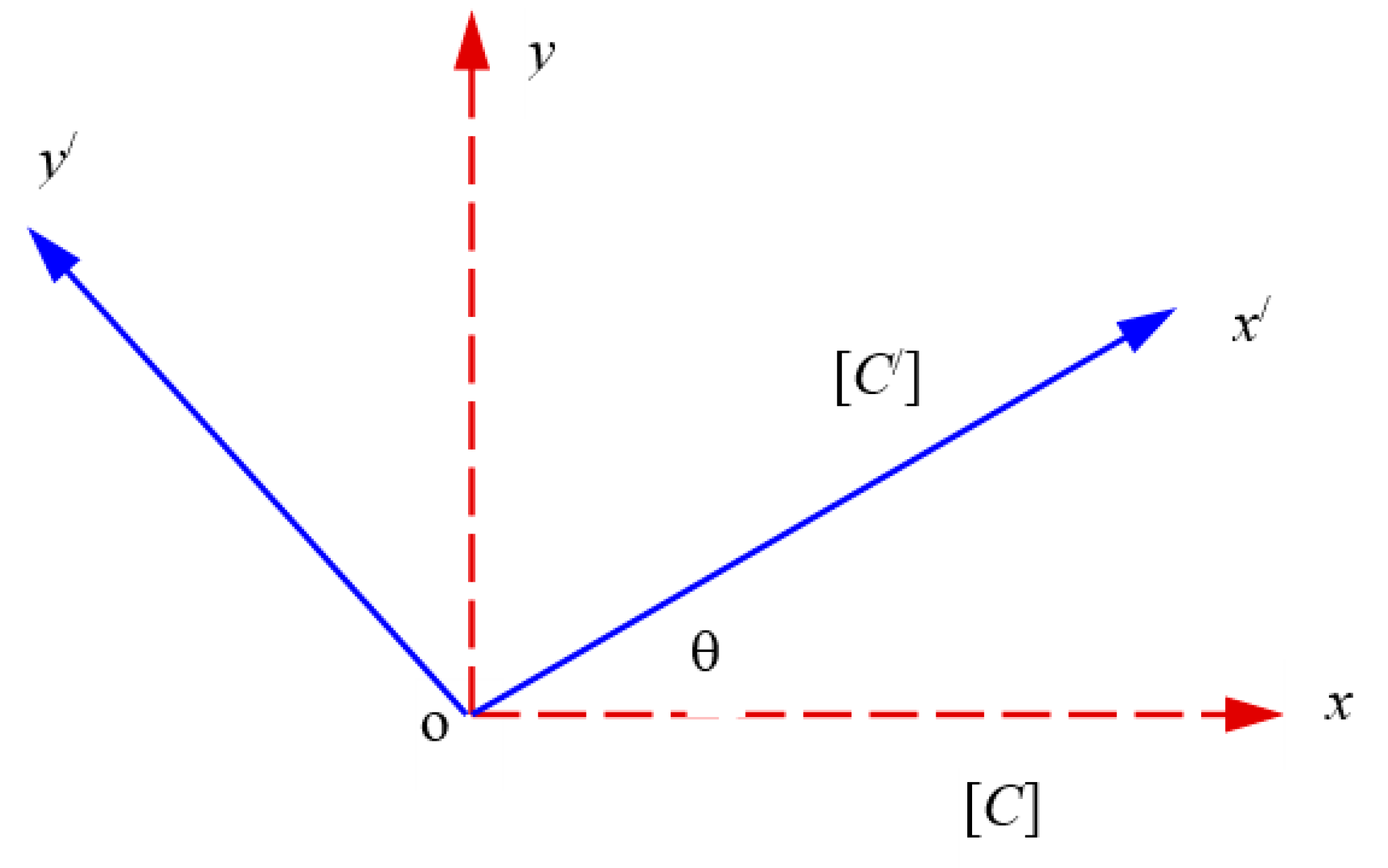

Appendix A. Stress-Function Variational Method for Free-Edge Stress Analysis of Composite Laminates

References

- Jones, R.M. Mechanics of Composite Materials, 2nd ed.; Taylor and Francis: Philadelphia, PA, USA, 1999. [Google Scholar]

- Tsai, S.W. Three decades of composites activities at US Air Force Materials Laboratory. Compos. Sci. Technol. 2005, 65, 2295–2299. [Google Scholar] [CrossRef]

- Carlson, H.C.; Goretta, K.C. Basic materials research programs at the U.S. Air Force Office of Scientific Research. Mater. Sci. Eng. B 2006, 132, 2–7. [Google Scholar] [CrossRef] [Green Version]

- Trask, R.S.; Williams, G.J.; Bond, I.P. Self-healing polymer composites: Mimicking nature to enhance performance. Bioinspir. Biomim. 2007, 2, 1–9. [Google Scholar] [CrossRef] [PubMed]

- Mallick, P.K. Fiber-Reinforced Composites: Materials, Manufacturing, and Design; CRC Press: New York, NY, USA, 2007. [Google Scholar]

- Mohanty, A.K.; Vivekanandhan, S.; Pin, J.M.; Misra, M. Composites from renewable and sustainable resources: Challenges and innovations. Science 2018, 362, 536–542. [Google Scholar] [CrossRef] [Green Version]

- Elanchezhian, C.; Ramnath, B.V.; Ramakrishnan, G.; Rajendrakumar, M.; Naveenkumar, V.; Saravanakumar, M.K. Review on mechanical properties of natural fiber composites. Mater. Today Proc. 2018, 5, 1785–1790. [Google Scholar] [CrossRef]

- Parandoush, P.; Lin, D. A review on additive manufacturing of polymer fiber composites. Compos. Struct. 2017, 182, 36–53. [Google Scholar] [CrossRef]

- Sood, M.; Dwivedi, G. Effect of fiber treatment on flexural properties of natural fiber reinforced composites: A review. Egypt. J. Pet. 2018, 27, 775–783. [Google Scholar] [CrossRef]

- Wu, X.F.; Dzenis, Y.A. Determination of dynamic delamination toughness of a graphite-fiber/epoxy composite using Hopkinson pressure bar. Polym. Compos. 2005, 26, 165–180. [Google Scholar] [CrossRef] [Green Version]

- Wu, X.F.; Ghoshal, G.; Kartashov, M.; Aslan, Z.; Turner, J.A.; Dzenis, Y.A. Experimental characterization of the impact-damage tolerance of a cross-ply graphite-fiber/epoxy laminate. Polym. Compos. 2008, 29, 534–543. [Google Scholar] [CrossRef] [Green Version]

- Gdoutos, E.E.; Pilakoutas, K.; Rodopoulos, C.A. Failure Analysis of Industrial Composite Materials; McGraw-Hill: New York, NY, USA, 2000. [Google Scholar]

- Tay, T.E. Characterization and analysis of delamination fracture in composites: An overview of developments from 1990 to 2001. Appl. Mech. Rev. 2003, 56, 1–32. [Google Scholar] [CrossRef]

- Wu, X.F. Fracture of Advanced Composites with Nanostructured Interfaces: Fabrication, Characterization and Modeling; VDM Verlag Publishing House Ltd.: Saarbrücken, Germany, 2009. [Google Scholar]

- Hahn, H.T.; Kim, R.Y. Fatigue Behavior of Composite Laminate. J. Compos. Mater. 1976, 10, 156–180. [Google Scholar] [CrossRef]

- Reifsnider, K.L.; Shulter, K.; Duke, J.C. Long-Term Behavior of Composites, ASTM STP 813; American Society for Testing and Material: Philadelphia, PA, USA, 1983; pp. 136–159. [Google Scholar]

- Reifsnider, K.L. Fatigue of Composite Materials; Elsevier: Oxford, UK, 1991. [Google Scholar]

- Diao, X.X.; Ye, L.; Mai, Y.W. Fatigue behavior of CF/PEEK composite laminate made from commingled prepreg. I: Experimental studies. Compos. Part A Appl. Sci. Manuf. 1997, 28, 739–747. [Google Scholar] [CrossRef]

- Diao, X.X.; Mai, Y.W. Fatigue life prediction of composite laminates using a stress redistribution function. J. Reinf. Plast. Compos. 1996, 15, 249–266. [Google Scholar] [CrossRef]

- Diao, X.X.; Ye, L.; Mai, Y.W. Fatigue behavior of CF/PEEK composite laminate made from commingled prepreg. II: Statistical simulations. Compos. A Appl. Sci. Manuf. 1997, 28, 734–755. [Google Scholar]

- Wu, D. Studies of Damage Evaluation in Advanced Polymer Matrix Composites Subjected to Thermomechanical Fatigue. Master’s Thesis, University of Nebraska, Lincoln, NE, USA, 2000. [Google Scholar]

- Wu, X.F.; Dzenis, Y.A. Rate effects on mode-I delamination toughness of a graphite/epoxy laminated composite. Int. J. Fract. 2001, 112, L9–L12. [Google Scholar] [CrossRef]

- Dzenis, Y.A. Cycle-based analysis of damage and failure in advanced composites under fatigue. I: Experimental observation of damage development with loading cycles. Int. J. Fatigue 2003, 25, 499–510. [Google Scholar] [CrossRef]

- Dzenis, Y.A. Cycle-based analysis of damage and failure in advanced composites under fatigue. II: Stochastic mesomechanics modeling. Int. J. Fatigue 2003, 25, 499–510. [Google Scholar] [CrossRef]

- Dzenis, Y.A.; Saunders, I. On the possibility of discrimination of mixed mode fatigue fracture mechanisms in adhesive composite joints by advanced acoustic emission analysis. Int. J. Fract. 2002, 117, L23–L28. [Google Scholar] [CrossRef]

- Rudov-Clark, S.; Mouritz, A.P. Tensile fatigue properties of a 3D orthogonal woven composite. Compos. A Appl. Sci. Manuf. 2008, 39, 1018–1024. [Google Scholar] [CrossRef]

- Cista, J.; Turon, A.; Trias, D.; Blanco, N.; Mayugo, J.A. A progressive damage model for unidirectional fibre-reinforced composites based on fibre fragmentation. Part II: Stiffness reduction in environment sensitive fibres under fatigue. Compos. Sci. Technol. 2005, 65, 2269–2275. [Google Scholar]

- Takeda, N.; Kobayashi, S.; Ogihara, S.; Kobayashi, A. Effects of toughened interlaminar layers on fatigue damage progress in quasi-isotropic CFRP laminates. Int. J. Fatigue 1999, 21, 235–242. [Google Scholar] [CrossRef]

- Atodaria, D.R.; Putatunda, S.K.; Mallick, P.K. Delamination growth behavior of a fabric reinforced laminated composite under mode I fatigue. J. Eng. Mater. Technol. 1999, 121, 381–385. [Google Scholar] [CrossRef]

- Assimina, A.P. Evolution of interlayer and intralayer cracks under compressive fatigue in composites. J. Eng. Mater. Technol. 1999, 121, 430–435. [Google Scholar]

- Asp, L.E.; Sjogren, A.; Greenhalgh, E.S. Delamination growth and thresholds in a carbon/epoxy composite under fatigue loading. J. Compos. Sci. Technol. 2001, 23, 55–68. [Google Scholar]

- McNulty, J.C.; He, M.Y.; Zok, F.W. Notch sensitivity of fatigue life in a SylramicTM/SiC composite at elevated temperature. Compos. Sci. Technol. 2001, 61, 1331–1338. [Google Scholar] [CrossRef]

- Bureau, M.N.; Perrin, F.; Denault, J.; Dickson, J.I. Interlaminar fatigue crack propagation in continuous glass fiber/polypropylene composites. Int. J. Fatigue 2002, 24, 99–108. [Google Scholar] [CrossRef]

- Sisodia, S.M.; Gamstedt, E.K.; Edgren, F.; Varna, J. Effects of voids on quasi-static and tension fatigue behavior of carbon-fibre composite laminates. J. Compos. Mater. 2015, 49, 2137–2148. [Google Scholar] [CrossRef]

- ASTM D 6115-97. Standard test method for mode I fatigue delamination growth onset of unidirectional fiber-reinforced polymer matrix composites. In Annual Book of ASTM Standards, 15.03; American Society for Testing and Materials: Philadelphia, PA, USA, 2000. [Google Scholar]

- ASTM D 6671-01. Standard test method for mixed-mode fatigue delamination growth onset of unidirectional fiber-reinforced polymer matrix composites. In Annual Book of ASTM Standards, 15.03; American Society for Testing and Materials: Philadelphia, PA, USA, 2000. [Google Scholar]

- Berthelot, J.M. Transverse cracking and delamination in cross-ply glass-fiber and carbon-fiber reinforced plastic laminates: Static and fatigue Loading. Appl. Mech. Rev. 2003, 56, 111–146. [Google Scholar] [CrossRef]

- Bak, B.L.V.; Sarrado, C.; Turon, A.; Costa, J. Delamination under fatigue loads in composite laminates: A review on the observed phenomenology and computational methods. Appl. Mech. Rev. 2014, 66, 060803. [Google Scholar] [CrossRef]

- Degrieck, J.; Paepegem, W.V. Fatigue damage modeling of fiber-reinforced composite materials: A review. Appl. Mech. Rev. 2001, 54, 279–300. [Google Scholar] [CrossRef]

- Sevenois, R.D.B.; Paepegem, W.V. Fatigue damage modeling techniques for textile composites: Review and comparison with unidirectional composite modeling techniques. Appl. Mech. Rev. 2015, 67, 020802. [Google Scholar] [CrossRef]

- Yang, J.N. Fatigue and residual strength degradation for graphite/epoxy composites under tension-compression cyclic loadings. J. Compos. Mater. 1978, 12, 19–39. [Google Scholar] [CrossRef]

- Hashin, Z. Cumulative damage theory for composites: Residual life and residual strength methods. Compos. Sci. Technol. 1985, 23, 1–19. [Google Scholar] [CrossRef]

- Rotem, A. Fatigue and residual strength of composite laminates. Eng. Fract. Mech. 1986, 25, 819–827. [Google Scholar] [CrossRef]

- Diao, X.; Ye, L.; Mai, Y.M. A statistical model of residual strength and fatigue life of composite laminate. Compos. Sci. Technol. 1995, 54, 329–336. [Google Scholar] [CrossRef]

- Whitworth, H.A. Evaluation of the residual strength degradation in composite laminates under fatigue loading. Compos. Struct. 2000, 48, 261–264. [Google Scholar] [CrossRef]

- Paepegem, W.V.; Degrieck, J. A new coupled approach of residual stiffness and strength for fatigue fibre-reinforced composites. Int. J. Fatigue 2002, 24, 747–762. [Google Scholar] [CrossRef]

- Tserpes, K.I.; Papankos, P.; Labeas, G.; Pantelakis, S.P. Fatigue damage accumulation and residual strength assessment of CFRP laminates. Compos. Struct. 2004, 63, 219–230. [Google Scholar] [CrossRef]

- Philippidis, T.P.; Passipoularidis, V.A. Residual strength after fatigue in composites: Theory vs. experiment. Int. J. Fatigue 2007, 29, 2104–2116. [Google Scholar] [CrossRef]

- Ma, Y.; Zhang, Y.; Sugahara, T.; Jin, S.; Yang, Y.; Hamada, H. Off-axis tensile fatigue assessment based on residual strength for the unidirectional 45 carbon fiber-reinforced composites at room temperature. Compos. Part A Appl. Sci. Manuf. 2016, 90, 711–723. [Google Scholar] [CrossRef]

- Llobet, J.; Maimi, P.; Mayugo, J.A.; Essa, Y.; de la Escalera, F.M. A fatigue damage and residual strength model for unidirectional carbon/epoxy composites under on-axis tension-tension loadings. Int. J. Fatigue 2017, 103, 508–515. [Google Scholar] [CrossRef]

- Mejri, M.; Toubal, L.; Cuillière, J.C.; François, V. Fatigue life and residual strength of a short-natural-fiber-reinforced plastic vs Nylon. Compos. Part B Eng. 2017, 110, 429–441. [Google Scholar] [CrossRef]

- D’Amore, A.; Grassia, L. Principal feature of fatigue and residual strength of composite material subjected to constant amplitude (CA) loading. Materials 2019, 12, 2586. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- D’Amore, A.; Grassia, L. Comparative study of phenomenological residual strength models for composite materials subjected to fatigue: Predictions at constant amplitude (CA) loading. Materials 2019, 12, 3398. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ganesan, C.; Joanna, P.S. Modeling the residual strength and fatigue life of carbon fiber composites under constant amplitude loading. Mech. Adv. Mater. Struct. 2020, 27, 1840–1848. [Google Scholar] [CrossRef]

- D’Amore, A.; Caprino, G.; Stupak, P.; Zhou, J.; Nicolais, L. Effect of stress ratio on the flexural fatigue behavior of continuous strand mat reinforced plastics. Sci. Eng. Compos. Mater. 1996, 5, 1–8. [Google Scholar] [CrossRef]

- Dzenis, Y.A.; Reneker, D.H. Delamination Resistant Composites Prepared by Small Diameter Fiber Reinforced at Ply Interface. U.S. Patent 6265333, 24 July 2001. [Google Scholar]

- Dzenis, A. Structural nanocomposites. Science 2008, 319, 419–420. [Google Scholar] [CrossRef]

- Sergiyenko, S. Experimental Analysis of Delamination in Laminated Composites with Nanoreinforced Interfaces. Master’s Thesis, University of Nebraska, Lincoln, NE, USA, 2000. [Google Scholar]

- Gokdag, E. Static and Fatigue Interlaminar Fracture of Graphite-Epoxy Composites with PAN Nanofiber Reinforcement at Interfaces. Master’s Thesis, University of Nebraska, Lincoln, NE, USA, 2001. [Google Scholar]

- Wu, X.F. Fracture of Advanced Polymer Composites with Nanofiber Reinforced Interfaces. Ph.D. Thesis, University of Nebraska, Lincoln, NE, USA, 2003. [Google Scholar]

- Sinha-Ray, S.; Pelot, D.D.; Zhou, Z.P.; Rahman, A.; Wu, X.F.; Yarin, A.L. Encapsulation of self-healing materials by coelectrospinning, emulsion electrospinning, solution blowing and intercalation. J. Mater. Chem. 2012, 22, 9138–9146. [Google Scholar] [CrossRef]

- Wu, X.F.; Rahman, A.; Zhou, Z.; Pelot, D.D.; Singa-Ray, S.; Chen, B.; Payne, S.; Yarin, A.L. Electrospinning core-shell nanofibers for interfacial toughening and self-healing of carbon-fiber/epoxy composites. J. Appl. Polym. Sci. 2013, 129, 1383–1393. [Google Scholar] [CrossRef]

- Wu, X.F.; Yarin, Y.L. Recent progress in interfacial toughening and damage self-healing of polymer composites based on electrospun and solution-blown nanofibers: An overview. J. Appl. Polym. Sci. 2013, 130, 2225–2237. [Google Scholar] [CrossRef]

- Chen, Q.; Zhang, L.F.; Rahman, A.; Zhou, Z.P.; Wu, X.F.; Fong, H. Hybrid multi-scale epoxy composite made of conventional carbon fiber fabrics with interlaminar regions containing electrospun carbon nanofiber mats. Compos. Part A Appl. Sci. Manuf. 2011, 42, 2036–2042. [Google Scholar] [CrossRef]

- Chen, Q.; Zhang, L.F.; Yoon, M.K.; Wu, X.F.; Arefin, R.H.; Fong, H. Preparation and evaluation of nano-epoxy composite resins containing electrospun glass nanofibers. J. Appl. Polym. Sci. 2012, 124, 444–451. [Google Scholar] [CrossRef]

- Chen, Q.; Zhang, L.F.; Zhao, Y.; Wu, X.F.; Fong, H. Hybrid multi-scale composites developed from glass microfiber fabrics and nano-epoxy resins containing electrospun glass nanofibers. Compos. Part B Eng. 2012, 43, 309–316. [Google Scholar] [CrossRef]

- Chen, Q.; Zhao, Y.; Zhou, Z.P.; Rahman, A.; Wu, X.F.; Wu, W.D.; Xu, T.; Fong, H. Fabrication and mechanical properties of hybrid multi-scale epoxy composites reinforced with conventional carbon fiber fabrics surface-attached with electrospun carbon nanofiber mats. Compos. Part B Eng. 2013, 44, 1–7. [Google Scholar] [CrossRef]

- Wu, X.F.; Zholobko, O.; Zhou, Z.; Rahman, A. Electrospun nanofibers for interfacial toughening and damage self-healing of polymer composites and surface coatings. In Electrospun Polymers and Composites: Ultrafine Materials, High. Performance Fibers and Wearables; Woodhead Publishing Ltd.: Cambridge, UK, 2020; pp. 315–359. [Google Scholar]

- Brugo, T.M.; Minak, G.; Zucchelli, A.; Saghafi, H.; Fotouhi, M. An investigation on the fatigue based delamination of woven carbon-epoxy composite laminates reinforced with polyamide nanofibers. Procedia Eng. 2015, 109, 65–72. [Google Scholar] [CrossRef] [Green Version]

- Daelemans, L.; van der Heijden, S.; Baere, I.D.; Rahier, H.; Paepegem, W.V. Improved fatigue delamination behavior of composite laminates with electrospun thermoplastic nanofibrous interleaves susing the central cut-ply method. Compos. Part A Appl. Sci. Manuf. 2017, 94, 10–20. [Google Scholar] [CrossRef]

- Fotouhi, M.; Fragassa, C.; Fotouhi, S.; Saghafi, H.; Minak, G. Damage characterization of nano-interleaved CFRP under static and fatigue loading. Fibers 2019, 7, 13. [Google Scholar] [CrossRef] [Green Version]

- Reneker, D.H.; Chun, I. Nanometre diameter fibres of polymer, produced by electrospinning. Nanotechnology 1996, 77, 216–223. [Google Scholar] [CrossRef] [Green Version]

- Reneker, D.H.; Yarin, A.L.; Zussman, E.; Xu, H. Electrospinning of nanofibers from polymer solutions and melts. Adv. Appl. Mech. 2007, 41, 43–195. [Google Scholar]

- Reneker, D.H.; Yarin, A.L. Electrospinning jets and polymer nanofibers. Polymer 2008, 49, 2387–2425. [Google Scholar] [CrossRef] [Green Version]

- Reneker, D.H.; Yarin, A.L.; Fong, H.; Koombhongse, S. Bending instability of electrically charged liquid jets of polymer solutions in electrospinning. J. Appl. Phys. 2000, 87, 4531–4547. [Google Scholar] [CrossRef] [Green Version]

- Yarin, A.L.; Koombhongse, S.; Reneker, D.H. Bending instability in electrospinning of nanofibers. J. Appl. Phys. 2001, 89, 3018–3026. [Google Scholar] [CrossRef] [Green Version]

- Huang, Z.M.; Zhang, Y.Z.; Kotaki, M.; Ramakrishna, S. A review on polymer nanofibers by electrospinning and their applications in nanocomposites. Compos. Sci. Technol. 2003, 63, 2223–2253. [Google Scholar] [CrossRef]

- Dzenis, Y. Spinning continuous fibers for nanotechnology. Science 2004, 304, 1917–1919. [Google Scholar] [CrossRef]

- Li, D.; Xia, Y.N. Electrospinning of nanofibers: Reinventing the wheel? Adv. Mater. 2004, 16, 1151–1170. [Google Scholar] [CrossRef]

- Theron, A.; Yarin, A.L.; Zussman, E.; Kroll, E. Multiple jets in electrospinning: Experiment and modeling. Polymer 2005, 46, 2889–2899. [Google Scholar] [CrossRef]

- Yarin, A.L.; Zussman, E. Upward needleless electrospinning of multiple nanofibers. Polymer 2004, 45, 2977–2980. [Google Scholar] [CrossRef]

- Chronakis, I.S. Novel nanocomposites and nanoceramics based on polymer nanofibers using electrospinning process-A review. J. Mater. Proc. Technol. 2005, 167, 283–293. [Google Scholar] [CrossRef]

- Ramaseshan, R.; Sundarrajan, S.; Jose, R.; Ramakrishna, S. Nanostructured ceramics by electrospinning. J. Appl. Phys. 2007, 102, 111101. [Google Scholar] [CrossRef]

- Greiner, A.; Wendorff, J.H. Electrospinning: A fascinating method for the preparation of ultrathin fibers. Angew. Chem. Int. Ed. 2007, 46, 5670–5703. [Google Scholar] [CrossRef]

- Ramakrishna, S.; Fujihara, K.; Teo, W.E.; Lim, T.C.; Ma, Z. An Introduction to Electrospinning and Nanofibers; World Scientific Press: Singapore, 2005. [Google Scholar]

- Lukas, D.; Sarkar, A.; Martinova, L.; Vodsed’alkova, K.; Lubasova, D.; Chaloupek, J.; Pokorny, P.; Mikes, P.; Chvojka, J.; Komarek, M. Physical principles of electrospinning (Electrospinning as a nano-scale technology of the twenty-first century). Text. Prog. 2009, 41, 59–140. [Google Scholar] [CrossRef]

- Nayak, R.; Padhye, R.; Kyratzis, I.L.; Truong, Y.B.; Arnold, L. Recent advances in nanofibre fabrication techniques. Text. Res. J. 2011, 82, 129–149. [Google Scholar] [CrossRef]

- Persano, L.; Camposeo, A.; Tekmen, C.; Pisignano, D. Industrial upscaling of electrospinning and applications of polymer nanofibers: A review. Macromol. Mater. Eng. 2013, 298, 504–520. [Google Scholar] [CrossRef]

- Zhou, Z.; Wu, X.F.; Ding, Y.; Zhao, Y.; Jiang, L.; Xuan, C.; Sun, C. Needless emulsion electrospinning for scalable fabrication of core-shell nanofibers. J. Appl. Polym. Sci. 2014, 131, 40896. [Google Scholar] [CrossRef]

- Mohammadzadehmoghadam, S.; Dong, Y.; Davies, I.J. Recent progress in electrospun nanofibers: Reinforcement effect and mechanical performance. J. Polym. Sci. Part B Polym. Phys. 2015, 53, 1171–1212. [Google Scholar] [CrossRef]

- Wu, X.F.; Zhou, Z.; Zholobko, O.; Jenniges, J.J.; Baatz, B.; Ahmadi, M.; Chen, J. Critical condition of electrohydrodynamic jetting from a polymer-solution droplet on a conductive wire. J. Appl. Phys. 2020, 127, 054303. [Google Scholar] [CrossRef]

- Pipes, R.B.; Pagano, N.J. Interlaminar stresses in composite laminates under uniform axial extension. J. Compos. Mater. 1970, 4, 538–548. [Google Scholar] [CrossRef]

- Pagano, N.J. On the calculation of interlaminar normal stress in composite laminate. J. Compos. Mater. 1974, 8, 65–81. [Google Scholar] [CrossRef]

- Yin, W.L. Free edge effects in anisotropic laminates under extension, bending and twisting. Part I: A stress-function-based variational approach. J. Appl. Mech. 1994, 61, 410–415. [Google Scholar] [CrossRef]

- Yin, W.L. Free edge effects in anisotropic laminates under extension, bending and twisting. Part II: Eigenfunction analysis and the results for symmetric laminates. J. Appl. Mech. 1994, 61, 416–421. [Google Scholar] [CrossRef]

- Flanagan, G. An efficient stress function approximation for the free-edge stresses in laminates. Int. J. Solids Struct. 1994, 31, 941–952. [Google Scholar] [CrossRef]

- Hsu, P.W.; Herakovich, C.T. Edge effects in angle-ply composite laminates. J. Compos. Mater. 1977, 11, 422–428. [Google Scholar] [CrossRef]

- Wang, A.S.D.; Crossman, F.W. Calculation of edge stresses in multilayer laminates by sub-structuring. J. Compos. Mater. 1978, 12, 76–83. [Google Scholar] [CrossRef]

- Spilker, R.L.; Chou, S.C. Edge effects in symmetric composite laminates: Importance of satisfying the traction-free-edge condition. J. Compos. Mater. 1980, 14, 2–20. [Google Scholar]

- Altus, A.; Rotem, A.; Shmueli, M. Free edge effect in angle ply laminates—A new three dimensional finite difference solution. J. Compos. Mater. 1980, 14, 21–30. [Google Scholar]

- Wang, S.S.; Choi, I. Boundary-layer effects in composite laminates. Part 1: Free-edge stress singularities. J. Appl. Mech. 1982, 49, 541–548. [Google Scholar] [CrossRef]

- Wang, S.S.; Choi, I. Boundary-layer effects in composite laminates. Part 2: Free-edge stress solutions and basic characteristics. J. Appl. Mech. 1982, 49, 549–560. [Google Scholar] [CrossRef]

- Kassapoglou, C.; Lagace, P.A. An efficient method for the calculation of interlaminar stresses in composite materials. J. Appl. Mech. 1986, 53, 744–750. [Google Scholar] [CrossRef]

- Ye, L. Some characteristics of distributions of free-edge interlaminar stresses in composite laminates. Int. J. Solids Struct. 1990, 26, 331–351. [Google Scholar]

- Mittelstedt, C.; Becker, W. Free-edge effects in composite laminates. Appl. Mech. Rev. 2007, 60, 217–245. [Google Scholar] [CrossRef]

- Wu, X.F.; Dzenis, Y.A. Experimental determination of probabilistic edge-delamination of a graphite-fiber/epoxy composite. Compos. Struct. 2005, 70, 100–108. [Google Scholar] [CrossRef] [Green Version]

- Wu, X.F.; Jenson, R.A. Stress-function variational method for stress analysis of bonded joints under mechanical and thermal loads. Int. J. Eng. Sci. 2011, 49, 279–294. [Google Scholar] [CrossRef]

- Wu, X.F.; Jenson, R.A. Semi-analytic stress-function variational approach for the interfacial stresses in bonded joints. J. Eng. Mech. 2014, 140, 1–11. [Google Scholar] [CrossRef] [Green Version]

- Wu, X.F.; Zhao, Y.H. Stress-function variational method for interfacial stress analysis of adhesively bonded joints. Int. J. Solids Struct. 2013, 50, 4305–4319. [Google Scholar] [CrossRef] [Green Version]

- Wang, X. Stress-Function Variational Methods for Stress Analysis of Composite Laminates and Adhesively Bonded Composite Joints. Master’s Thesis, North Dakota State University, Fargo, ND, USA, 2015. [Google Scholar]

- Wu, X.F.; Jenson, R.A.; Zhao, Y. Stress-function variational approach to the interfacial stresses and progressive cracking in surface coatings. Mech. Mater. 2014, 69, 195–203. [Google Scholar] [CrossRef]

- Minak, G.; Morelli, P.; Zucchelli, A. Fatigue residual strength of circular laminate graphite-epoxy composite plates damaged by transverse load. Compos. Sci. Technol. 2009, 69, 1358–1363. [Google Scholar] [CrossRef] [Green Version]

- ASTM D 3039/D3039M-17, Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials; ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM D 3479/D3479M-19, Standard Test Method for Tension-Tension Fatigue of Polymer Matrix Composite Materials; ASTM International: West Conshohocken, PA, USA, 2019.

- Haidyrah, A.S.; Newkirk, J.W.; Castaño, C.H. Weibull statistical analysis of Krouse type bending fatigue of nuclear material. J. Nucl. Mater. 2016, 470, 244–250. [Google Scholar] [CrossRef]

- Christensen, R.M. Mechanics of Composite Materials; Wiley: New York, NY, USA, 1979. [Google Scholar]

- Ting, T.C.T. Anisotropic Elasticity: Theory and Applications; Oxford University Press: Oxford, UK, 1996. [Google Scholar]

- Lekhnitskii, S.G. Theory of Elasticity of an Anisotropic Body; Holden-Day: San Francisco, CA, USA, 1968. [Google Scholar]

| Mechanical Properties in Material Coordinate System | Values |

|---|---|

| Young’s modulus in the fiber direction, E1 (GPa) | 132.7 |

| Young’s modulus transverse to fiber direction, E2 (GPa) | 8.83 |

| In-plane shear modulus, G12 (GPa) | 4.76 |

| Poisson’s ratio, ν12 | 0.36 |

| Poisson’s ratio, ν21 | 0.03 |

| Ultimate tensile stress in the fiber direction, X1T (MPa) | 1462 |

| Ultimate tensile stress transverse to fiber direction, X2T (MPa) | 47.7 |

| Ultimate in-plane shear stress, S6 (MPa) | 82.0 |

| Ultimate tensile strain in the fiber direction, ε1T (%) | 1.10 |

| Ultimate tensile strain transverse to fiber direction, ε2T (%) | 0.52 |

| Ultimate in-plane shear strain, γ12 ult (%) | 4.06 |

| No. of Samples | Shape Parameter m | Dimensional Parameter σ0 (MPa) | Mean Strength (MPa) | Coefficient R | |

|---|---|---|---|---|---|

| Quasistatic test | 27 | 11.015 | 390.074 | 372.560 | 0.97127 |

| 2000-cycle fatigue test | 12 (2 failed) | 9.766 | 370.508 | 352.131 | 0.97409 |

| 10,000-cycle fatigue test | 12 (4 failed) | 5.926 | 341.511 | 316.615 | 0.94804 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, X.-F.; Zholobko, O. Experimental Study of the Probabilistic Fatigue Residual Strength of a Carbon Fiber-Reinforced Polymer Matrix Composite. J. Compos. Sci. 2020, 4, 173. https://doi.org/10.3390/jcs4040173

Wu X-F, Zholobko O. Experimental Study of the Probabilistic Fatigue Residual Strength of a Carbon Fiber-Reinforced Polymer Matrix Composite. Journal of Composites Science. 2020; 4(4):173. https://doi.org/10.3390/jcs4040173

Chicago/Turabian StyleWu, Xiang-Fa, and Oksana Zholobko. 2020. "Experimental Study of the Probabilistic Fatigue Residual Strength of a Carbon Fiber-Reinforced Polymer Matrix Composite" Journal of Composites Science 4, no. 4: 173. https://doi.org/10.3390/jcs4040173

APA StyleWu, X.-F., & Zholobko, O. (2020). Experimental Study of the Probabilistic Fatigue Residual Strength of a Carbon Fiber-Reinforced Polymer Matrix Composite. Journal of Composites Science, 4(4), 173. https://doi.org/10.3390/jcs4040173