Additive Manufacturing of Carbon Fiber Reinforced Plastic Composites: The Effect of Fiber Content on Compressive Properties

Abstract

:1. Introduction

1.1. Additive Manufacturing of Carbon Fiber Composites

1.2. Compressive Properties of AM Fabricated CFRP Composites

| Short Fiber CFRP Sample | Investigations | Carbon Fiber Content (%) | Maximum Tensile Strength (Mpa) | Author |

|---|---|---|---|---|

| CF-ABS | Microstructural Evaluation through X-ray CT Technique | 15 | 67.0 | [19,20] |

| CF-ABS | Chopped CF-ABS | 20% | N/A | [21] |

| CF-PA | Chopped CF-ABS | N/A | 101 | [22] |

1.3. Research Motivations

2. Materials and Methods

2.1. AM Workpiece Fabrication Procedure

2.1.1. Material Compounding and Filamenting

2.1.2. Fabricated Workpiece

2.2. Measurement Procedure

3. Results

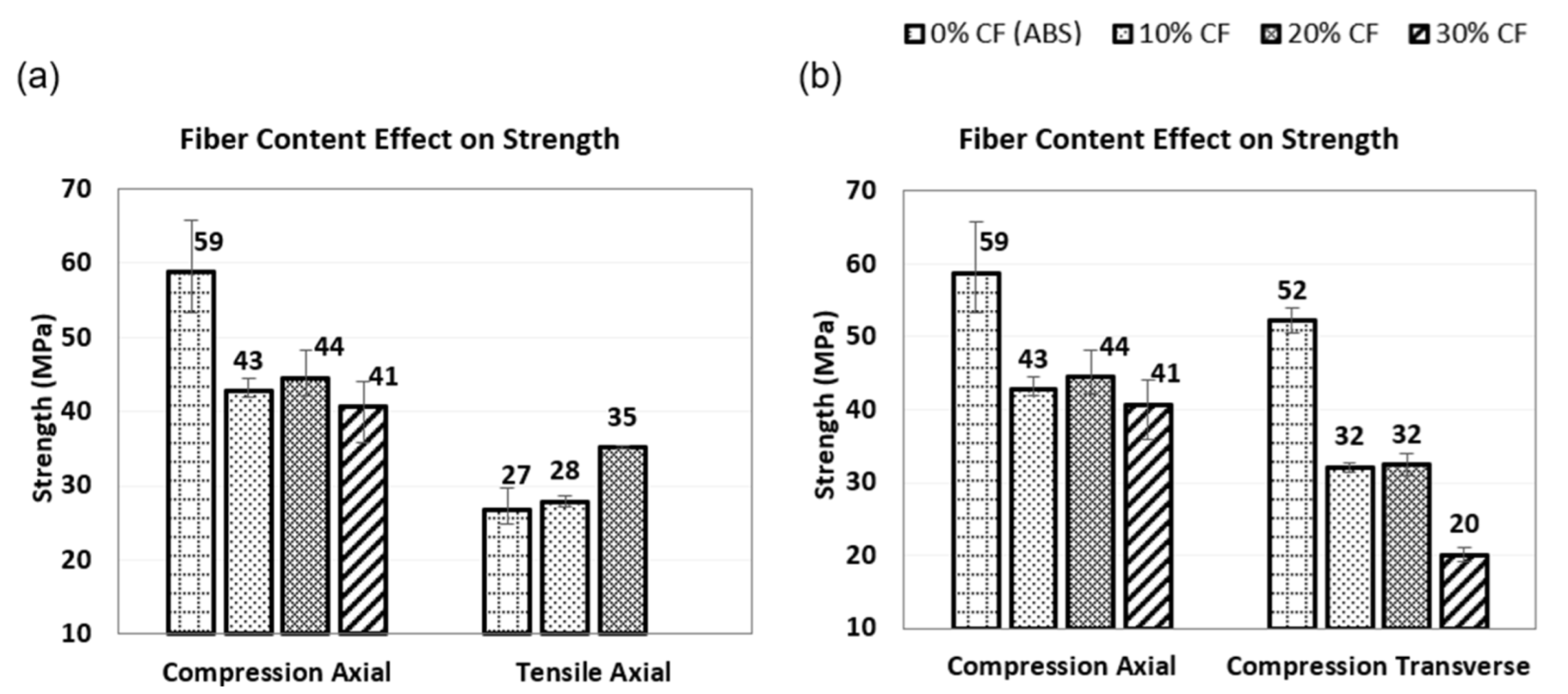

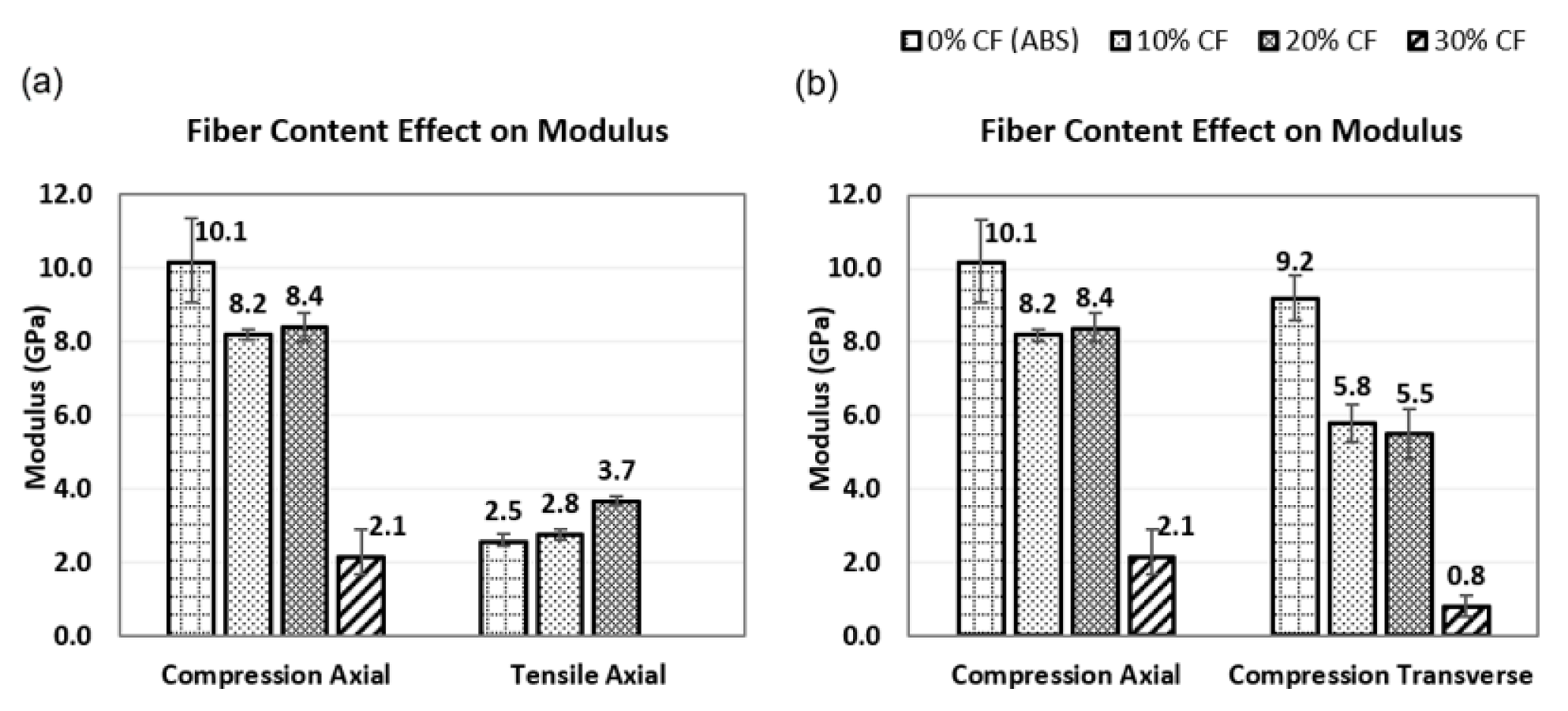

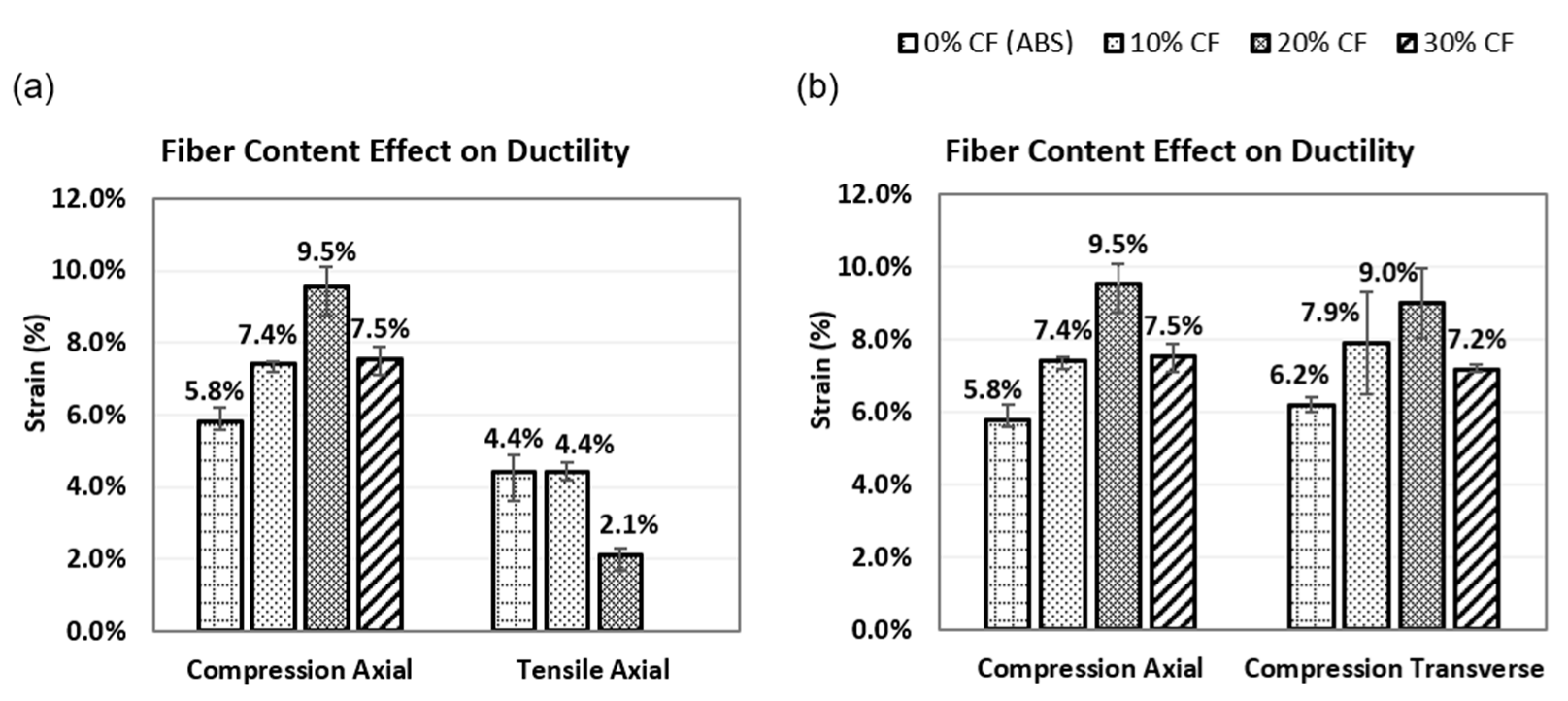

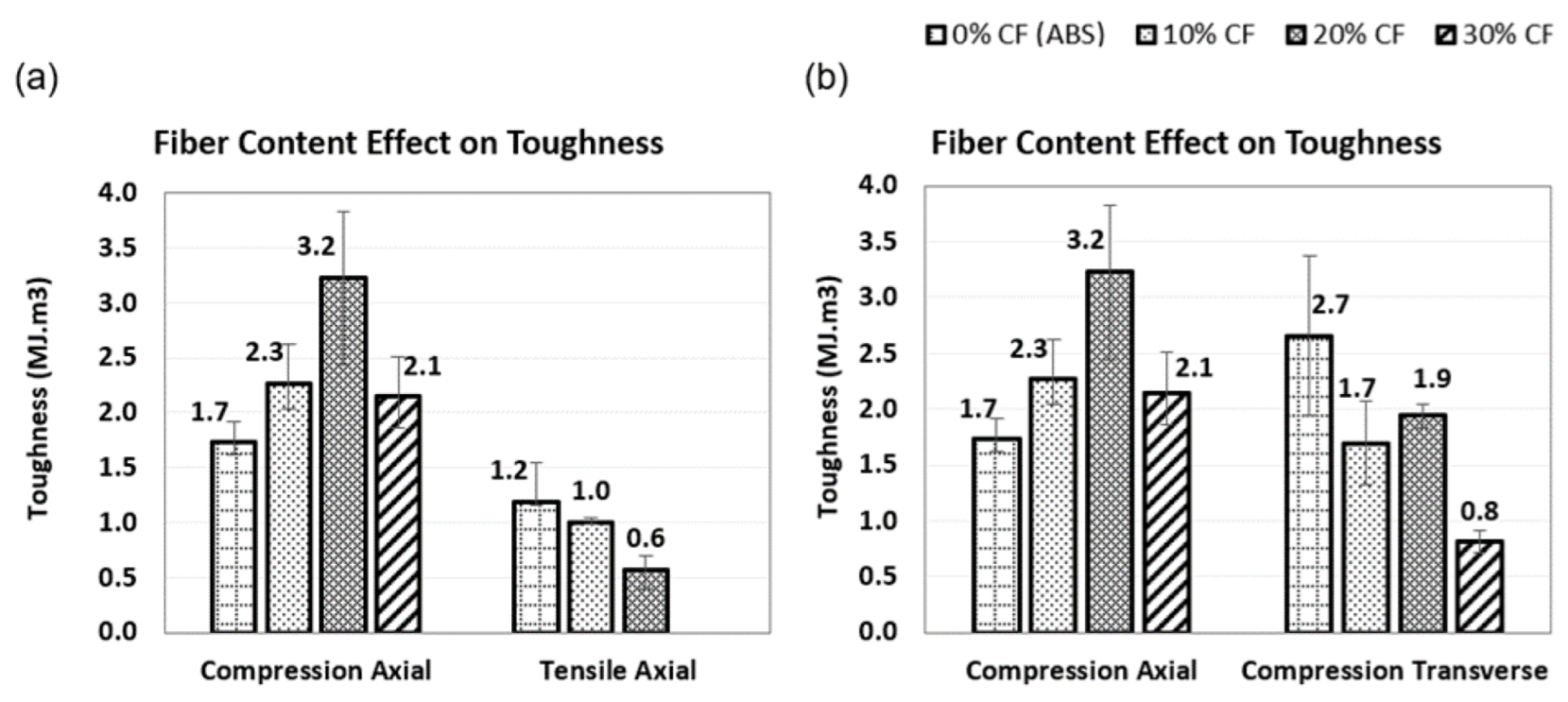

3.1. Compressive Properties

3.1.1. Compressive Strength

3.1.2. Compressive Modulus

3.1.3. Compressive Ductility

3.1.4. Compressive Toughness

3.2. Evaluation of Failure Modes

4. Conclusions

- The increasing carbon fiber content in AM fabricated short-fiber thermoplastic CFRP composites slightly reduces compressive strength and modulus. However, they increase ductility and toughness.

- The 20% carbon fiber content provided an optimized fiber volume for AM fabricated short-fiber thermoplastic CFRP composite applications subjected to compressive loading.

- AM fabricated CFRP composites generally demonstrate a higher compressive than tensile properties because the higher plastic deformation characterizes compressive loading and more easily redistributes stress at existing flaws.

- The failure mode in compression starts with the fiber-matrix debonding, followed by a unidirectional buckling of the interlayers and then barreling of the composite before an eventual shear deformation of the composite.

- The material properties trends and failure mode in compression differ from tension due to the differences in the active functions of the fiber and matrix under the different loading conditions.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Bin Hamzah, H.H.; Keattch, O.; Covill, D.; Patel, B.A. The Effects of Printing Orientation on the Electrochemical Behaviour of 3D Printed Acrylonitrile Butadiene Styrene (ABS)/Carbon Black Electrodes. Sci. Rep. 2018, 8, 9135. [Google Scholar] [CrossRef] [Green Version]

- Tymrak, B.M.; Kreiger, M.; Pearce, J.M. Mechanical Properties of Components Fabricated with Open-Source 3-D Printers under Realistic Environmental Conditions. Mater. Des. 2014, 58, 242–246. [Google Scholar] [CrossRef] [Green Version]

- Dimas, L.S.; Bratzel, G.H.; Eylon, I.; Buehler, M.J. Tough Composites Inspired by Mineralized Natural Materials: Computation, 3D Printing, and Testing. Adv. Funct. Mater. 2013, 23, 4629–4638. [Google Scholar] [CrossRef]

- Martin, J.J.; Fiore, B.E.; Erb, R.M. Designing Bioinspired Composite Reinforcement Architectures via 3D Magnetic Printing. Nat. Commun. 2015, 6, 8641. [Google Scholar] [CrossRef] [Green Version]

- Unterweger, C.; Brüggemann, O.; Fürst, C. Synthetic Fibers, and Thermoplastic Short-Fiber-Reinforced Polymers: Properties and Characterization. Polym. Compos. 2014, 35, 227–236. [Google Scholar] [CrossRef]

- Goh, G.D.; Dikshit, V.; Nagalingam, A.P.; Goh, G.L.; Agarwala, S.; Sing, S.L.; Wei, J.; Yeong, W.Y. Characterization of Mechanical Properties and Fracture Mode of Additively Manufactured Carbon Fiber and Glass Fiber Reinforced Thermoplastics. Mater. Des. 2018, 137, 79–89. [Google Scholar] [CrossRef]

- Zhang, W.; Cotton, C.; Sun, J.; Heider, D.; Gu, B.; Sun, B.; Chou, T.W. Interfacial Bonding Strength of Short Carbon Fiber/Acrylonitrile-Butadiene-Styrene Composites Fabricated by Fused Deposition Modeling. Compos. Part B Eng. 2018, 137, 51–59. [Google Scholar] [CrossRef]

- Ning, F.; Cong, W.; Hu, Z.; Huang, K. Additive Manufacturing of Thermoplastic Matrix Composites Using Fused Deposition Modeling: A Comparison of Two Reinforcements. J. Compos. Mater. 2017, 51, 3733–3742. [Google Scholar] [CrossRef]

- Mohammadizadeh, M.; Fidan, I. Thermal Analysis of 3D Printed Continuous Fiber Reinforced Thermoplastic Polymers for Automotive Applications. In Proceedings of the 30th Annual International Solid Freeform Fabrication Symposium—An Additive Manufacturing Conference, SFF 2019, Austin, TX, USA, 12–14 August 2019; pp. 899–906. [Google Scholar]

- Mohamed, O.A.; Masood, S.H.; Bhowmik, J.L. Optimization of Fused Deposition Modeling Process Parameters: A Review of Current Research and Future Prospects. Adv. Manuf. 2015, 3, 42–53. [Google Scholar] [CrossRef]

- van de Werken, N.; Tekinalp, H.; Khanbolouki, P.; Ozcan, S.; Williams, A.; Tehrani, M. Additively Manufactured Carbon Fiber-Reinforced Composites: State of the Art and Perspective. Addit. Manuf. 2020, 31, 100962. [Google Scholar] [CrossRef]

- Tekinalp, H.L.; Kunc, V.; Velez-Garcia, G.M.; Duty, C.E.; Love, L.J.; Naskar, A.K.; Blue, C.A.; Ozcan, S. Highly Oriented Carbon Fiber-Polymer Composites via Additive Manufacturing. Compos. Sci. Technol. 2014, 105, 144–150. [Google Scholar] [CrossRef] [Green Version]

- Ning, F.; Cong, W.; Qiu, J.; Wei, J.; Wang, S. Additive Manufacturing of Carbon Fiber Reinforced Thermoplastic Composites Using Fused Deposition Modeling. Compos. Part B Eng. 2015, 80, 369–378. [Google Scholar] [CrossRef]

- Duty, C.E.; Kunc, V.; Compton, B.; Post, B.; Erdman, D.; Smith, R.; Lind, R.; Lloyd, P.; Love, L. Structure and Mechanical Behavior of Big Area Additive Manufacturing (BAAM) Materials. Rapid Prototyp. J. 2017, 23, 181–189. [Google Scholar] [CrossRef]

- Post, B.K. Additive Manufacturing in Wind Turbine Components and Tooling Project ID #: T13. 2016. Available online: https://www.energy.gov/sites/prod/files/2019/05/f62/ORNL-T13-Post%204_2_19.pdf (accessed on 8 November 2021).

- Post, B.K.; Richardson, B.; Lind, R.; Love, L.J.; Lloyd, P.; Kunc, V.; Rhyne, B.J.; Roschli, A.; Hannan, J.; Nolet, S.; et al. Big Area Additive Manufacturing Application in Wind Turbine Molds. In Proceedings of the 28th Annual International Solid Freeform Fabrication Symposium—An Additive Manufacturing Conference, SFF 2017, Austin, TX, USA, 7–9 August 2017; pp. 2430–2446. [Google Scholar]

- Kunc, V.; Hassen, A.A.; Lindahl, J.; Kim, S.; Post, B. Large Scale Additively Manufactured Tooling for Composites. In Proceedings of the 15th Japan International Sampe Symposium and Exhibition, Tokyo, Japan, 27–29 November 2017; pp. 1–6. [Google Scholar]

- Brenken, B.; Barocio, E.; Favaloro, A.; Kunc, V.; Pipes, R.B. Fused Filament Fabrication of Fiber-Reinforced Polymers: A Review. Addit. Manuf. 2018, 21, 1–16. [Google Scholar] [CrossRef]

- Meraz Trejo, E.; Jimenez, X.; Billah, K.M.M.; Seppala, J.; Wicker, R.; Espalin, D. Compressive Deformation Analysis of Large Area Pellet-Fed Material Extrusion 3D Printed Parts in Relation to in Situ Thermal Imaging. Addit. Manuf. 2020, 33, 101099. [Google Scholar] [CrossRef]

- Quan, Z.; Larimore, Z.; Qin, X.; Yu, J.; Mirotznik, M.; Byun, J.H.; Oh, Y.; Chou, T.W. Microstructural Characterization of Additively Manufactured Multi-Directional Preforms and Composites via X-Ray Micro-Computed Tomography. Compos. Sci. Technol. 2016, 131, 48–60. [Google Scholar] [CrossRef]

- Quan, Z.; Larimore, Z.; Wu, A.; Yu, J.; Qin, X.; Mirotznik, M.; Suhr, J.; Byun, J.H.; Oh, Y.; Chou, T.W. Microstructural Design and Additive Manufacturing and Characterization of 3D Orthogonal Short Carbon Fiber/Acrylonitrile-Butadiene-Styrene Preform and Composite. Compos. Sci. Technol. 2016, 126, 139–148. [Google Scholar] [CrossRef]

- Wang, J.; Xiang, J.; Lin, H.; Wang, K.; Yao, S.; Peng, Y.; Rao, Y. Effects of Scanning Strategy and Printing Temperature on the Compressive Behaviors of 3D Printed Polyamide-Based Composites. Polymers 2020, 12, 1783. [Google Scholar] [CrossRef] [PubMed]

- Lee, C.S.; Kim, S.G.; Kim, H.J.; Ahn, S.H. Measurement of Anisotropic Compressive Strength of Rapid Prototyping Parts. J. Mater. Process. Technol. 2007, 187–188, 627–630. [Google Scholar] [CrossRef]

- Araya-Calvo, M.; López-Gómez, I.; Chamberlain-Simon, N.; León-Salazar, J.L.; Guillén-Girón, T.; Corrales-Cordero, J.S.; Sánchez-Brenes, O. Evaluation of Compressive and Flexural Properties of Continuous Fiber Fabrication Additive Manufacturing Technology. Addit. Manuf. 2018, 22, 157–164. [Google Scholar] [CrossRef]

- Love, L.J.; Kunc, V.; Rios, O.; Duty, C.E.; Elliott, A.M.; Post, B.K.; Smith, R.J.; Blue, C.A. The Importance of Carbon Fiber to Polymer Additive Manufacturing. J. Mater. Res. 2014, 29, 1893–1898. [Google Scholar] [CrossRef] [Green Version]

- Chacón, J.M.; Caminero, M.A.; Núñez, P.J.; García-Plaza, E.; García-Moreno, I.; Reverte, J.M. Additive Manufacturing of Continuous Fibre Reinforced Thermoplastic Composites Using Fused Deposition Modelling: Effect of Process Parameters on Mechanical Properties. Compos. Sci. Technol. 2019, 181, 107688. [Google Scholar] [CrossRef]

- Costa, A.E.; Ferreira da Silva, A.; Sousa Carneiro, O. A Study on Extruded Filament Bonding in Fused Filament Fabrication. Rapid Prototyp. J. 2019, 25, 555–565. [Google Scholar] [CrossRef]

- ASTM D695-15. In Annual Book of ASTM Standards; ASTM International: West Conshohocken, PA, USA, 2015; pp. 1–8. [CrossRef]

- ASTM D638-14. In Annual Book of ASTM Standards; ASTM International: West Conshohocken, PA, USA, 2014; pp. 1–17. [CrossRef]

- Duty, C.E. Material Development for Tooling Applications Using Big Area Additive Manufacturing (BAAM); Oak Ridge National Laboratory: Oak Ridge, TN, USA, 2015. [Google Scholar] [CrossRef] [Green Version]

- Fleck, N.; Deng, L.; Budiansky, B. Prediction of Kink Width in Compressed Fiber Composites. J. Appl. Mech. 1995, 62, 329–337. [Google Scholar] [CrossRef]

- Lo, K.H.; Chim, E.S.-M. Compressive Strength of Unidirectional Composites. J. Reinf. Plast. Compos. 1992, 11, 838–896. [Google Scholar] [CrossRef]

- Pascual-González, C.; San Martín, P.; Lizarralde, I.; Fernández, A.; León, A.; Lopes, C.S.; Fernández-Blázquez, J.P. Post-Processing Effects on Microstructure, Interlaminar and Thermal Properties of 3D Printed Continuous Carbon Fibre Composites. Compos. Part B Eng. 2021, 210, 108652. [Google Scholar] [CrossRef]

- Pukánszky, B. Interfaces and Interphases in Multicomponent Materials: Past, Present, Future. Eur. Polym. J. 2005, 41, 645–662. [Google Scholar] [CrossRef]

- Greszczuk, L.B. On Failure Modes of Unidirectional Composites Under Compressive Loading. In Fracture of Composite Materials; Springer: Singapore, 1982; pp. 231–244. ISBN 9024726999. [Google Scholar]

- Dharan, C.K.H.; Lin, C.L. Longitudinal Compressive Strength of Continuous Fiber Composites. J. Compos. Mater. 2007, 41, 1389–1405. [Google Scholar] [CrossRef]

- Junaedi, H.; Albahkali, E.; Baig, M.; Dawood, A.; Almajid, A. Ductile to Brittle Transition of Short Carbon Fiber-Reinforced Polypropylene Composites. Adv. Polym. Technol. 2020, 2020, 6714097. [Google Scholar] [CrossRef]

- Thompson, R. Compressive Strength of Continuous Fiber Unidirectional Composites. 2012. Available online: https://tigerprints.clemson.edu/all_dissertations/953 (accessed on 8 November 2021).

| Parameter | Value | Unit |

|---|---|---|

| Infill density | 100 | % |

| Nozzle Temperature | 270 | °C |

| Bed Temperature | 100 | °C |

| Printing Enclosure | 50 ± 5 | °C |

| Layer Thickness | 0.25 | mm |

| Printing Speed | 30 | mm/s |

| Raster angle | 0 and 90 | ° |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Adeniran, O.; Cong, W.; Bediako, E.; Aladesanmi, V. Additive Manufacturing of Carbon Fiber Reinforced Plastic Composites: The Effect of Fiber Content on Compressive Properties. J. Compos. Sci. 2021, 5, 325. https://doi.org/10.3390/jcs5120325

Adeniran O, Cong W, Bediako E, Aladesanmi V. Additive Manufacturing of Carbon Fiber Reinforced Plastic Composites: The Effect of Fiber Content on Compressive Properties. Journal of Composites Science. 2021; 5(12):325. https://doi.org/10.3390/jcs5120325

Chicago/Turabian StyleAdeniran, Olusanmi, Weilong Cong, Eric Bediako, and Victor Aladesanmi. 2021. "Additive Manufacturing of Carbon Fiber Reinforced Plastic Composites: The Effect of Fiber Content on Compressive Properties" Journal of Composites Science 5, no. 12: 325. https://doi.org/10.3390/jcs5120325

APA StyleAdeniran, O., Cong, W., Bediako, E., & Aladesanmi, V. (2021). Additive Manufacturing of Carbon Fiber Reinforced Plastic Composites: The Effect of Fiber Content on Compressive Properties. Journal of Composites Science, 5(12), 325. https://doi.org/10.3390/jcs5120325