Coffee Silverskin as a Multifunctional Waste Filler for High-Density Polyethylene Green Composites

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Polymer Composites

2.3. Characterization Techniques

3. Results and Discussion

3.1. Melt Flow Index of Prepared Composites

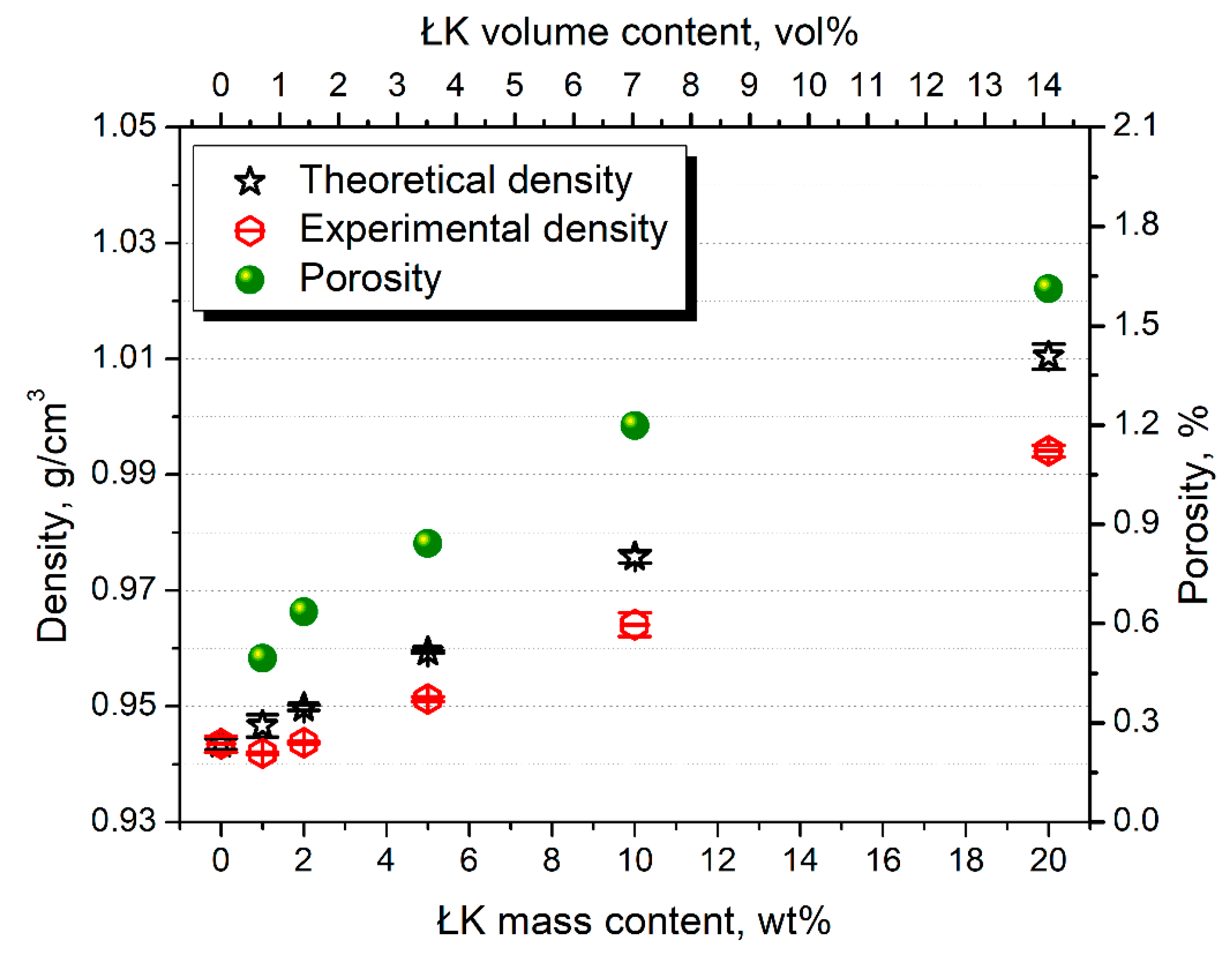

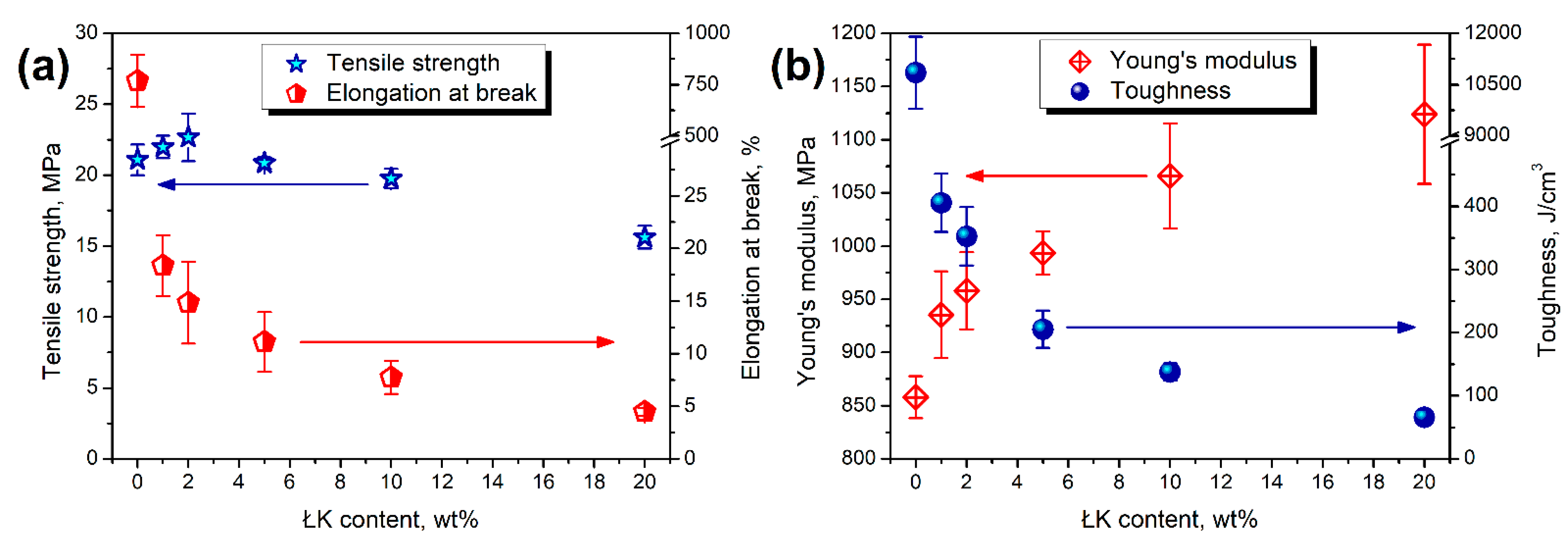

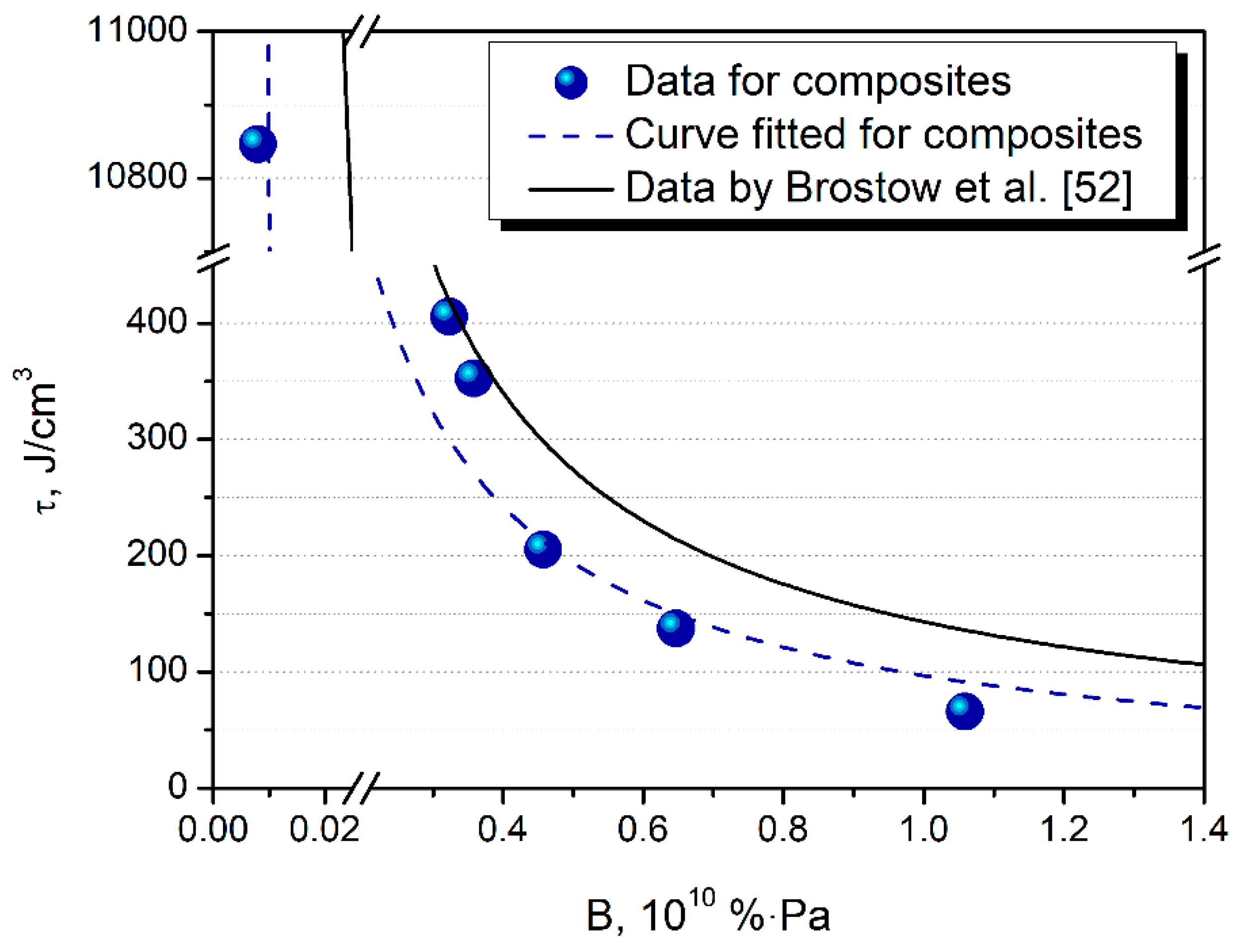

3.2. Physico-Mechanical Performance of Prepared Composites

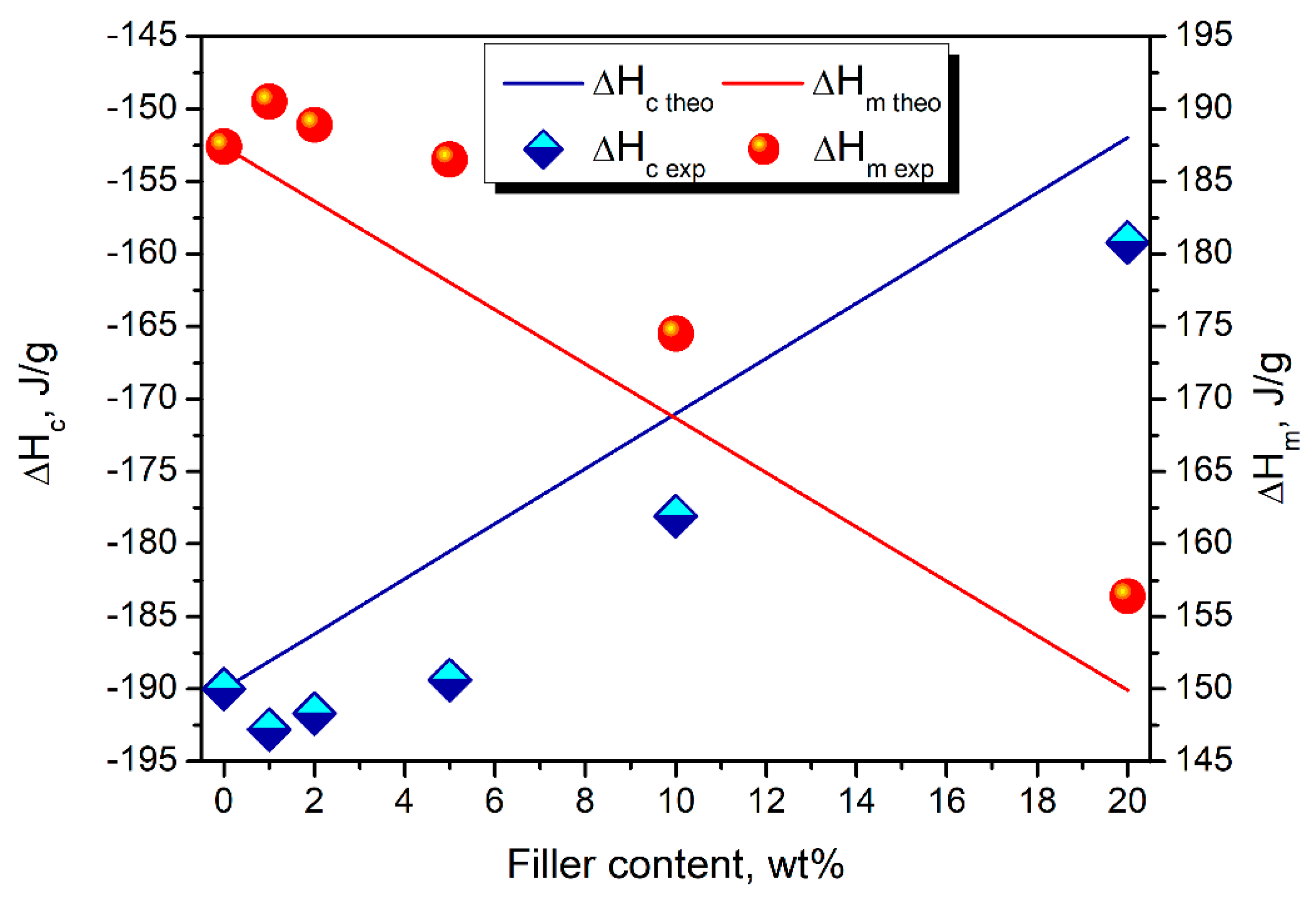

3.3. Thermal Properties of Prepared Composites

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Food Wastage: Key Facts and Figures. Available online: http://www.fao.org/news/story/en/item/196402/icode/ (accessed on 31 December 2020).

- Lynch, K.M.; Steffen, E.J.; Arendt, E.K. Brewers’ spent grain: A review with an emphasis on food and health. J. Inst. Brew. 2016, 122, 553–568. [Google Scholar] [CrossRef]

- Blinová, L.; Sirotiak, M.; Bartošová, A.; Soldán, M. Review: Utilization of Waste From Coffee Production. Res. Pap. Fac. Mater. Sci. Technol. Slovak Univ. Technol. 2017, 25, 91–101. [Google Scholar] [CrossRef] [Green Version]

- Esquivel, P.; Jiménez, V.M. Functional properties of coffee and coffee by-products. Food Res. Int. 2012, 46, 488–495. [Google Scholar] [CrossRef]

- Adams, M.R.; Dougan, J. Waste Products. In Coffee; Clarke, R.J., Macrae, R., Eds.; Springer: Dordrecht, The Netherlands, 1987; pp. 257–291. [Google Scholar] [CrossRef]

- Bharat Helkar, P.; Sahoo, A. Review: Food Industry By-Products used as a Functional Food Ingredients. Int. J. Waste Resour. 2016, 6, 1000248. [Google Scholar] [CrossRef]

- Leal, H.A.; Babetto, A.S.; Bonse, B.C. Properties of lignocellulosic composites of coffee husk filled polypropylene. AIP Conf. Proc. 2020, 2205, 020072. [Google Scholar] [CrossRef]

- Wojnowska-Baryła, I.; Kulikowska, D.; Bernat, K. Effect of Bio-Based Products on Waste Management. Sustainability 2020, 12, 2088. [Google Scholar] [CrossRef] [Green Version]

- Mazur, K.; Jakubowska, P.; Romańska, P.; Kuciel, S. Green high density polyethylene (HDPE) reinforced with basalt fiber and agricultural fillers for technical applications. Compos. Part B Eng. 2020, 202, 108399. [Google Scholar] [CrossRef]

- Bazan, P.; Mierzwiński, D.; Bogucki, R.; Kuciel, S. Bio-Based Polyethylene Composites with Natural Fiber: Mechanical, Thermal, and Ageing Properties. Materials 2020, 13, 2595. [Google Scholar] [CrossRef]

- Tsang, Y.F.; Kumar, V.; Samadar, P.; Yang, Y.; Lee, J.; Ok, Y.S.; Song, H.; Kim, K.H.; Kwon, E.E.; Jeon, Y.J. Production of bioplastic through food waste valorization. Environ. Int. 2019, 127, 625–644. [Google Scholar] [CrossRef]

- Sanchez-Vazquez, S.A.; Hailes, H.C.; Evans, J.R.G. Hydrophobic Polymers from Food Waste: Resources and Synthesis. Polym. Rev. 2013, 53, 627–694. [Google Scholar] [CrossRef]

- Jaisan, C.; Punbusayakul, N. Development of Coffee Pulp Extract-Incorporated Chitosan Film and Its Antimicrobial and Antioxidant Activities. KKU Res. J. 2016, 21, 140–149. [Google Scholar] [CrossRef]

- Mirón-Mérida, V.A.; Yáñez-Fernández, J.; Montañez-Barragán, B.; Barragán Huerta, B.E. Valorization of coffee parchment waste (Coffea arabica) as a source of caffeine and phenolic compounds in antifungal gellan gum films. LWT–Food Sci. Technol. 2019, 101, 167–174. [Google Scholar] [CrossRef]

- Garcia-Serna, E.; Martinez-Saez, N.; Mesias, M.; Morales, F.J.; del Castillo, M.D. Use of Coffee Silverskin and Stevia to Improve the Formulation of Biscuits. Pol. J. Food Nutr. Sci. 2014, 64, 243–251. [Google Scholar] [CrossRef] [Green Version]

- Narita, Y.; Inouye, K. Review on utilization and composition of coffee silverskin. Food Res. Int. 2014, 61, 16–22. [Google Scholar] [CrossRef] [Green Version]

- Ballesteros, L.F.; Teixeira, J.A.; Mussatto, S.I. Chemical, Functional, and Structural Properties of Spent Coffee Grounds and Coffee Silverskin. Food Bioprocess Technol. 2014, 7, 3493–3503. [Google Scholar] [CrossRef] [Green Version]

- Conde, T.; Mussatto, S.I. Isolation of polyphenols from spent coffee grounds and silverskin by mild hydrothermal pretreatment. Prep. Biochem. Biotechnol. 2015, 46, 406–409. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Moraczewski, K.; Stepczyńska, M.; Malinowski, R.; Karasiewicz, T.; Jagodziński, B.; Rytlewski, P. The Effect of Accelerated Aging on Polylactide Containing Plant Extracts. Polymers 2019, 11, 575. [Google Scholar] [CrossRef] [Green Version]

- Ochoa, D.; Rojas-Vargas, J.; Costa, Y. Characterization of NaOH-Treated Colombian Silverskin Coffee Fiber as a Composite Reinforcement. BioResources 2017, 12, 8803–8812. [Google Scholar]

- Dominici, F.; García García, D.; Fombuena, V.; Luzi, F.; Puglia, D.; Torre, L.; Balart, R. Bio-Polyethylene-Based Composites Reinforced with Alkali and Palmitoyl Chloride-Treated Coffee Silverskin. Molecules 2019, 24, 3113. [Google Scholar] [CrossRef] [Green Version]

- Sarasini, F.; Luzi, F.; Dominici, F.; Maffei, G.; Iannone, A.; Zuorro, A.; Lavecchia, R.; Torre, L.; Carbonell-Verdu, A.; Balart, R.; et al. Effect of Different Compatibilizers on Sustainable Composites Based on a PHBV/PBAT Matrix Filled with Coffee Silverskin. Polymers 2018, 10, 1256. [Google Scholar] [CrossRef] [Green Version]

- Totaro, G.; Sisti, L.; Fiorini, M.; Lancellotti, I.; Andreola, F.N.; Saccani, A. Formulation of Green Particulate Composites from PLA and PBS Matrix and Wastes Deriving from the Coffee Production. J. Polym. Environ. 2019, 27, 1488–1496. [Google Scholar] [CrossRef]

- Zarrinbakhsh, N.; Wang, T.; Rodriguez-Uribe, A.; Misra, M.; Mohanty, A.K. Characterization of wastes and coproducts from the coffee industry for composite material production. BioResources 2016, 11, 7637–7653. [Google Scholar] [CrossRef] [Green Version]

- Sarasini, F.; Tirillò, J.; Zuorro, A.; Maffei, G.; Lavecchia, R.; Puglia, D.; Dominici, F.; Luzi, F.; Valente, T.; Torre, L. Recycling coffee silverskin in sustainable composites based on a poly(butylene adipate-co-terephthalate)/poly(3-hydroxybutyrate-co-3-hydroxyvalerate) matrix. Ind. Crop. Prod. 2018, 118, 311–320. [Google Scholar] [CrossRef]

- Hejna, A. Potential applications of by-products from the coffee industry inpolymer technology—Current state and perspectives. Waste Manag. 2021, 121, 296–330. [Google Scholar] [CrossRef] [PubMed]

- Behrouzian, F.; Amini, A.M.; Alghooneh, A.; Razavi, S.M.A. Characterization of dietary fiber from coffee silverskin: An optimization study using response surface methodology. Bioact. Carbohydr. Diet. Fibre 2016, 8, 58–64. [Google Scholar] [CrossRef]

- Costa, A.S.G.; Alves, R.C.; Vinha, A.F.; Costa, E.; Costa, C.S.G.; Nunes, M.A.; Almeida, A.A.; Santos-Silva, A.; Oliveira, M.B.P.P. Nutritional, chemical and antioxidant/pro-oxidant profiles of silverskin, a coffee roasting by-product. Food Chem. 2018, 267, 28–35. [Google Scholar] [CrossRef]

- Toschi, T.G.; Cardenia, V.; Bonaga, G.; Mandrioli, M.; Rodriguez-Estrada, M.T. Coffee Silverskin: Characterization, Possible Uses, and Safety Aspects. J. Agric. Food Chem. 2014, 62, 10836–10844. [Google Scholar] [CrossRef]

- Napolitano, A.; Fogliano, V.; Tafuri, A.; Ritieni, A. Natural occurrence of ochratoxin A and antioxidant activities of green and roasted coffees and corresponding byproducts. J. Agric. Food Chem. 2007, 55, 10499–10504. [Google Scholar] [CrossRef]

- Ateş, G.; Elmacı, Y. Physical, chemical and sensory characteristics of fiber-enriched cakes prepared with coffee silverskin as wheat flour substitution. Food Meas. 2019, 13, 755–763. [Google Scholar] [CrossRef]

- Janissen, B.; Huynh, T. Chemical composition and value-adding applications of coffee industry by-products: A review. Resour. Conserv. Recycl. 2018, 128, 110–117. [Google Scholar] [CrossRef]

- Mysiukiewicz, O.; Barczewski, M.; Skórczewska, K.; Matykiewicz, D. Correlation between processing parameters and deg-radation of different polylactide grades during twin-screw extrusion. Polymers 2020, 12, 1333. [Google Scholar] [CrossRef] [PubMed]

- Mirabella, F.M.; Bafna, A. Determination of the crystallinity of polyethylene/?-olefin copolymers by thermal analysis: Relationship of the heat of fusion of 100% polyethylene crystal and the density. J. Polym. Sci. Pol. Phys. 2002, 40, 1637–1643. [Google Scholar] [CrossRef]

- Qiu, W.; Zhang, F.; Endo, T.; Hirotsu, T. Isocyanate as a compatibilizing agent on the properties of highly crystalline cellulose/polypropylene composites. J. Mater. Sci. 2005, 40, 3607–3614. [Google Scholar] [CrossRef]

- Kloziński, A.; Barczewski, M. Comparison of off-line, on-line and in-line measuring techniques used for determining the rheological characteristics of polyethylene composites with calcium carbonate. Polimery 2019, 64, 83–92. [Google Scholar] [CrossRef]

- Hejna, A.; Formela, K.; Saeb, M.R. Processing, mechanical and thermal behavior assessments of polycaprolactone/agricultural wastes biocomposites. Ind. Crop. Prod. 2015, 76, 725–733. [Google Scholar] [CrossRef]

- D’Antò, V.; Muraglie, S.; Castellano, B.; Candida, E.; Sfondrini, M.F.; Scribante, A.; Grippaudo, C. Influence of Dental Composite Viscosity in Attachment Reproduction: An Experimental in Vitro Study. Materials 2019, 12, 4001. [Google Scholar] [CrossRef] [Green Version]

- Aranguren, M.I.; Mora, E.; DeGroot, J.V.; Macosko, C.W. Effect of reinforcing fillers on the rheology of polymer melts. J. Rheol. 1992, 36, 1165–1182. [Google Scholar] [CrossRef]

- Mysiukiewicz, O.; Kosmela, P.; Barczewski, M.; Hejna, A. Mechanical, Thermal and Rheological Properties of Polyethylene-Based Composites Filled with Micrometric Aluminum Powder. Materials 2020, 13, 1242. [Google Scholar] [CrossRef] [Green Version]

- Gent, M.R.; Menendez, M.; Toraño, J.; Diego, I. Recycling of plastic waste by density separation: Prospects for optimization. Waste Manag. Res. 2009, 27, 175–187. [Google Scholar] [CrossRef]

- Mehdikhani, M.; Gorbatikh, L.; Verpoest, I.; Lomov, S.V. Voids in fiber-reinforced polymer composites: A review on their formation, characteristics, and effects on mechanical performance. J. Compos. Mater. 2018, 002199831877215. [Google Scholar] [CrossRef]

- Keskisaari, A.; Butylina, S.; Kärki, T. Use of construction and demolition wastes as mineral fillers in hybrid wood-polymer composites. J. Appl. Polym. Sci. 2016, 133, 43412. [Google Scholar] [CrossRef]

- Salasinska, K.; Polka, M.; Gloc, M.; Ryszkowska, J. Natural fiber composites: The effect of the kind and content of filler on the dimensional and fire stability of polyolefin-based composites. Polimery 2016, 61, 255–265. [Google Scholar] [CrossRef]

- Birt, E.A.; Smith, R.A. A review of NDE methods for porosity measurement in fibre-reinforced polymer composites. Insight Non-Destr. Test. Cond. Monit. 2004, 46, 681–686. [Google Scholar] [CrossRef]

- Michalska-Pożoga, I.; Rydzkowski, T. The effect of extrusion conditions for a screw-disk plasticizing system on the mechanical properties of wood-polymer composites (WPC). Polimery 2016, 61, 202–212. [Google Scholar] [CrossRef]

- Chan, C.; Vandi, L.J.; Pratt, S.; Halley, P.; Richardson, D.; Werker, A.; Laycock, B. Processing and characterisation of polyhydroxyalkanoate (PHA)-based wood plastic composites: Effect of non-reactive additives. Appita J. 2016, 69, 352–360. [Google Scholar]

- Perkins, W.G. Polymer toughness and impact resistance. Polym. Eng. Sci. 1999, 39, 2445–2460. [Google Scholar] [CrossRef]

- Barczewski, M.; Szostak, M.; Nowak, D.; Piasecki, A. Effect of wood flour addition and modification of its surface on the properties of rotationally molded polypropylene composites. Polimery 2018, 63, 772–784. [Google Scholar] [CrossRef]

- Brostow, W.; Hagg Lobland, H.E.; Narkis, M. Sliding wear, viscoelasticity, and brittleness of polymers. J. Mater. Res. 2006, 21, 2422–2428. [Google Scholar] [CrossRef] [Green Version]

- Galeja, M.; Hejna, A.; Kosmela, P.; Kulawik, A. Static and Dynamic Mechanical Properties of 3D Printed ABS as a Function of Raster Angle. Materials 2020, 13, 297. [Google Scholar] [CrossRef] [Green Version]

- Brostow, W.; Hagg Lobland, H.E.; Khoja, S. Brittleness and toughness of polymers and other materials. Mater. Lett. 2015, 159, 478–480. [Google Scholar] [CrossRef]

- Abdalla, M.; Dean, D.; Adibempe, D.; Nyairo, E.; Robinson, P.; Thompson, G. The effect of interfacial chemistry on molecular mobility and morphology of multiwalled carbon nanotubes epoxy nanocomposite. Polymer 2007, 48, 5662–5670. [Google Scholar] [CrossRef]

- Kubát, J.; Rigdahl, M.; Welander, M. Characterization of interfacial interactions in high density polyethylene filled with glass spheres using dynamic-mechanical analysis. J. Appl. Polym. Sci. 1990, 39, 1527–1539. [Google Scholar] [CrossRef]

- Bindu, P.; Thomas, S. Viscoelastic Behavior and Reinforcement Mechanism in Rubber Nanocomposites in the Vicinity of Spherical Nanoparticles. J. Phys. Chem. B 2013, 117, 12632–12648. [Google Scholar] [CrossRef] [PubMed]

- Zhou, W. Thermal and Dielectric Properties of the Aluminum Particle Reinforced Linear Low-Density Polyethylene Composites. Polym. Eng. Sci. 2011, 51, 917–924. [Google Scholar] [CrossRef]

- Hejna, A.; Kosmela, P. Insights into Compatibilization of Poly(ε-caprolactone)-based Biocomposites with Diisocyanates as Modifiers of Cellulose Fillers. Mindanao J. Sci. Technol. 2020, 18, 221–241. [Google Scholar]

- Hejna, A.; Barczewski, M.; Kosmela, P.; Mysiukiewicz, O. Inhibition of Polymer Photodegradation by Incorporation of Coffee Silverskin. Proceedings 2020, 4, 7219. [Google Scholar] [CrossRef]

| Parameter | Sample | |||||

|---|---|---|---|---|---|---|

| PE | PE/1ŁK | PE/2ŁK | PE/5ŁK | PE/10ŁK | PE/20ŁK | |

| E’ at 25 °C, MPa | 1637 | 1686 | 1882 | 1967 | 1998 | 2121 |

| E’ at −120 °C, MPa | 4372 | 4206 | 4565 | 4662 | 4783 | 5086 |

| C factor | 1.000 | 0.934 | 0.908 | 0.888 | 0.896 | 0.898 |

| Brittleness, 1010 %·Pa | 0.0080 | 0.3231 | 0.3580 | 0.4572 | 0.6466 | 1.0589 |

| E” at 25 °C, MPa | 103.6 | 99.8 | 108.9 | 114.2 | 115.3 | 120.6 |

| tan δ at 25 °C | 0.0633 | 0.0592 | 0.0581 | 0.0577 | 0.0579 | 0.0570 |

| A factor at 25 °C | - | −0.0586 | −0.0696 | −0.0566 | −0.0179 | 0.0507 |

| Tg, °C | −111.0 | −111.8 | −112.2 | −113.1 | −113.4 | −113.9 |

| tan δ at Tg | 0.0495 | 0.0486 | 0.0479 | 0.0465 | 0.0444 | 0.0424 |

| Cv, % | 0 | 1.50 | 2.88 | 5.32 | 8.96 | 12.74 |

| XCv | 0 | 1.50 | 1.44 | 1.06 | 0.90 | 0.64 |

| Sample | Parameter | ||||||

|---|---|---|---|---|---|---|---|

| Tc, °C | ΔHc, J/g | Tm, °C | ΔHm, J/g | Xcr, % | ΔT, °C | OIT, min | |

| PE | 112.8 | −190.0 | 134.1 | 187.4 | 63.83 | 21.3 | 20.0 |

| PE/1ŁK | 113.1 | −192.8 | 133.2 | 190.5 | 65.54 | 20.1 | 54.8 |

| PE/2ŁK | 113.0 | −191.7 | 134.1 | 188.9 | 65.65 | 21.1 | 83.9 |

| PE/5ŁK | 113.3 | −189.4 | 133.3 | 186.5 | 66.87 | 20.0 | 131.9 |

| PE/10ŁK | 113.4 | −178.1 | 133.0 | 174.5 | 66.04 | 19.6 | 139.5 |

| PE/20ŁK | 112.5 | −159.2 | 132.6 | 156.4 | 66.59 | 20.1 | 140.4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hejna, A.; Barczewski, M.; Kosmela, P.; Mysiukiewicz, O.; Kuzmin, A. Coffee Silverskin as a Multifunctional Waste Filler for High-Density Polyethylene Green Composites. J. Compos. Sci. 2021, 5, 44. https://doi.org/10.3390/jcs5020044

Hejna A, Barczewski M, Kosmela P, Mysiukiewicz O, Kuzmin A. Coffee Silverskin as a Multifunctional Waste Filler for High-Density Polyethylene Green Composites. Journal of Composites Science. 2021; 5(2):44. https://doi.org/10.3390/jcs5020044

Chicago/Turabian StyleHejna, Aleksander, Mateusz Barczewski, Paulina Kosmela, Olga Mysiukiewicz, and Anton Kuzmin. 2021. "Coffee Silverskin as a Multifunctional Waste Filler for High-Density Polyethylene Green Composites" Journal of Composites Science 5, no. 2: 44. https://doi.org/10.3390/jcs5020044

APA StyleHejna, A., Barczewski, M., Kosmela, P., Mysiukiewicz, O., & Kuzmin, A. (2021). Coffee Silverskin as a Multifunctional Waste Filler for High-Density Polyethylene Green Composites. Journal of Composites Science, 5(2), 44. https://doi.org/10.3390/jcs5020044