Improvement of Performance Profile of Acrylic Based Polyester Bio-Composites by Bast/Basalt Fibers Hybridization for Automotive Applications

Abstract

:1. Introduction

2. Materials and Methods

2.1. Acrylic Polyester Resins

2.2. Reinforcement Fibers

2.3. Composite Production

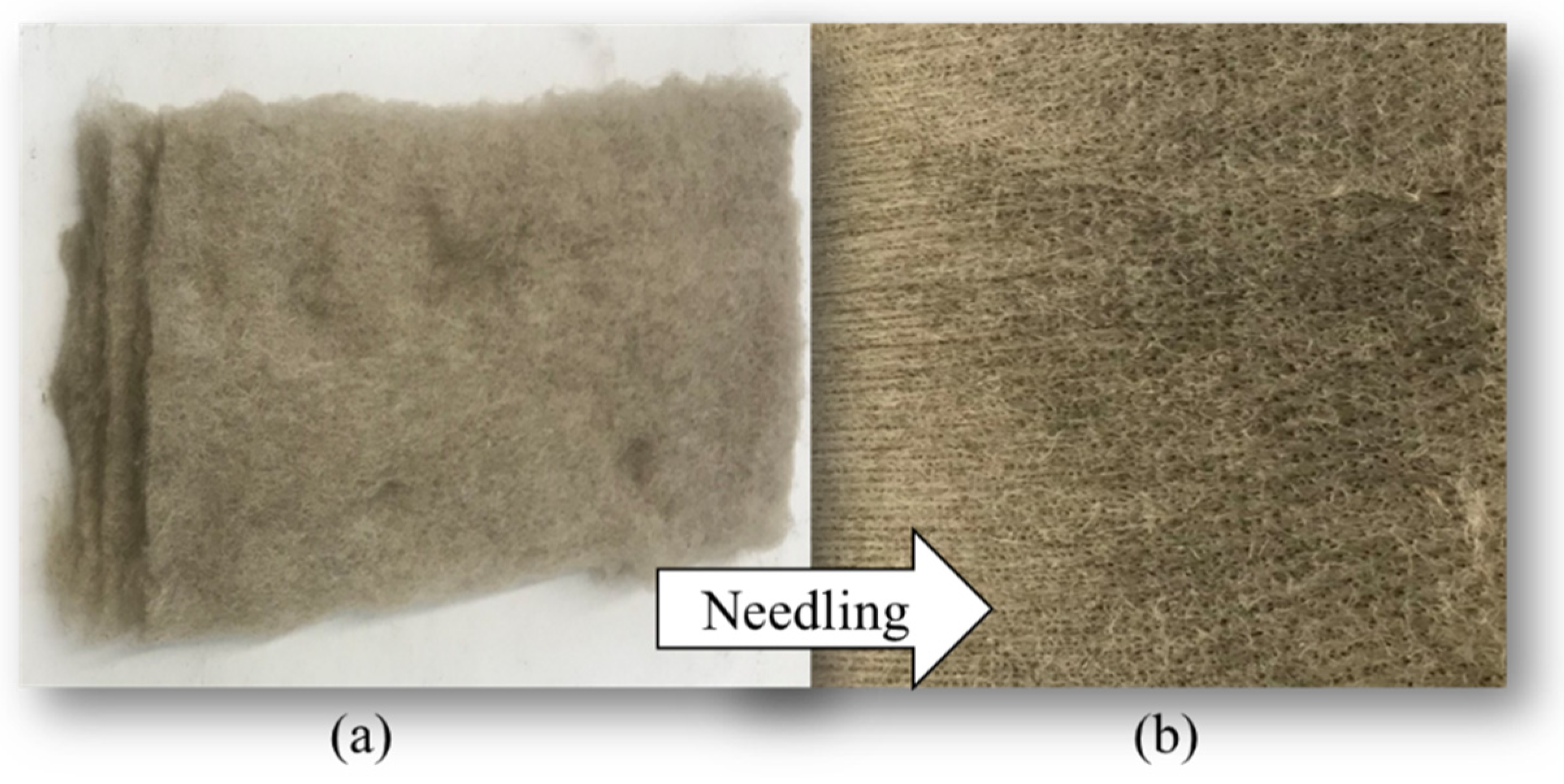

2.3.1. Fiber Mats Manufacture by Carding

2.3.2. Resin Impregnation and Compression Molding

3. Results

3.1. Thermal Analysis

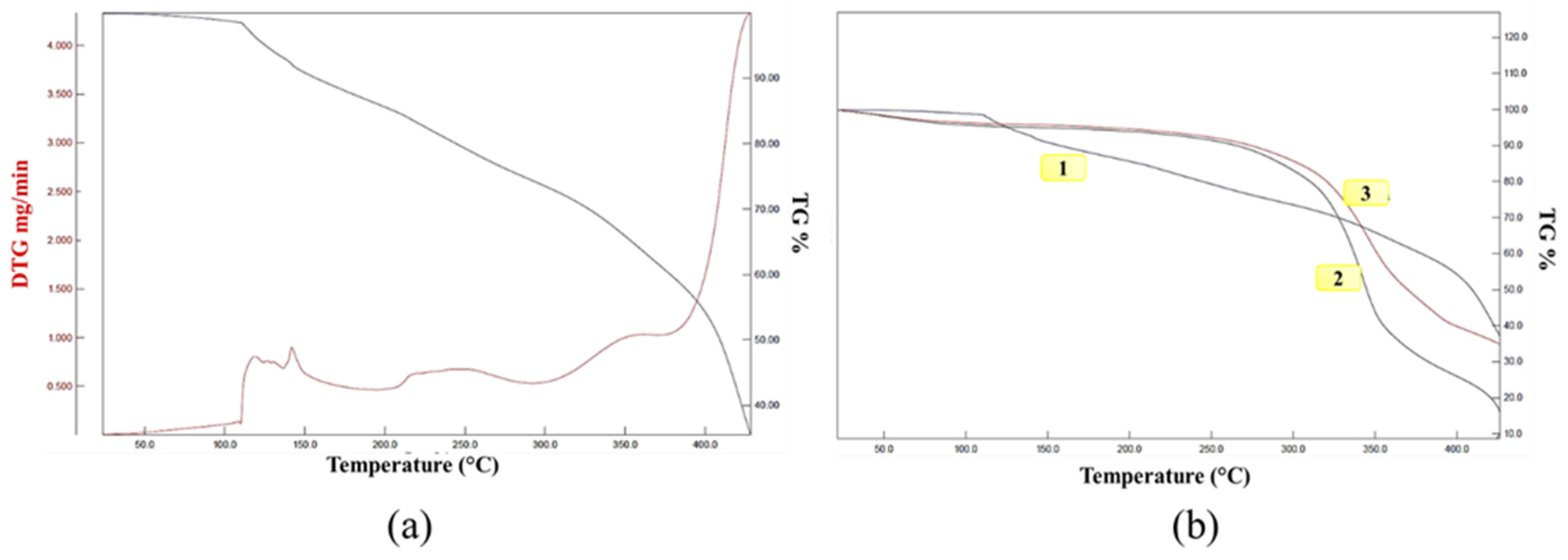

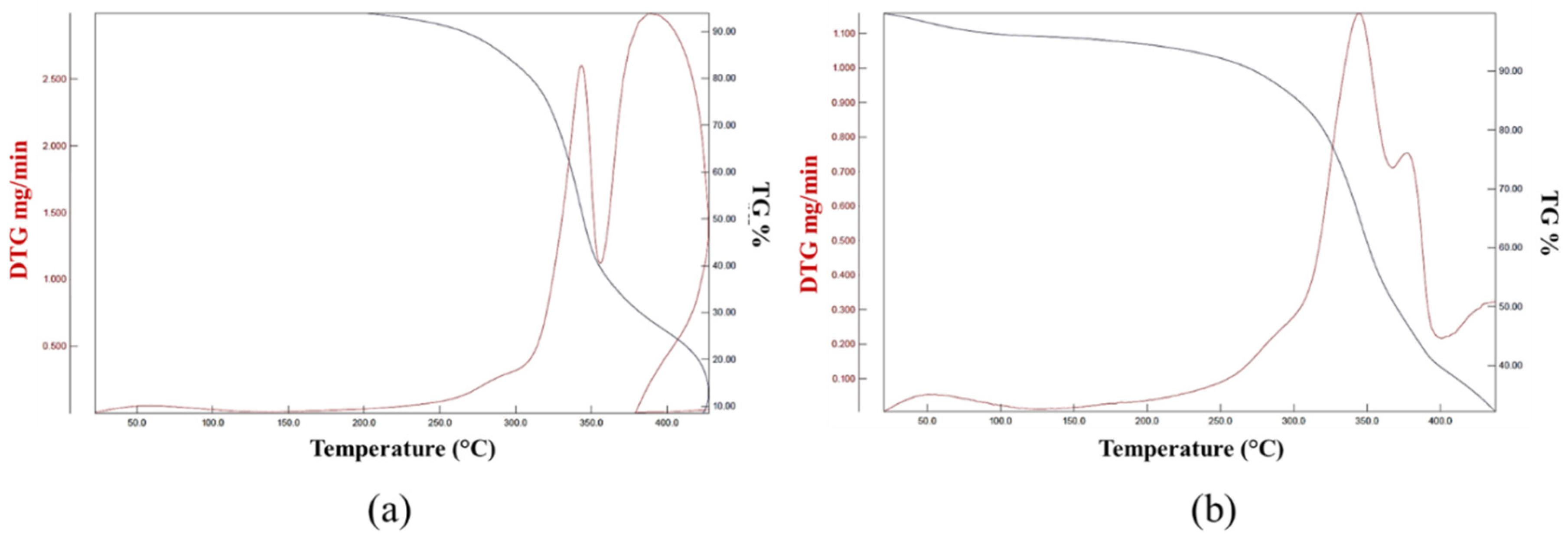

3.1.1. Thermogravimetric Analysis

3.1.2. Differential Scanning Calorimetry

3.2. Mechanical Analysis

3.2.1. Flexural Analysis

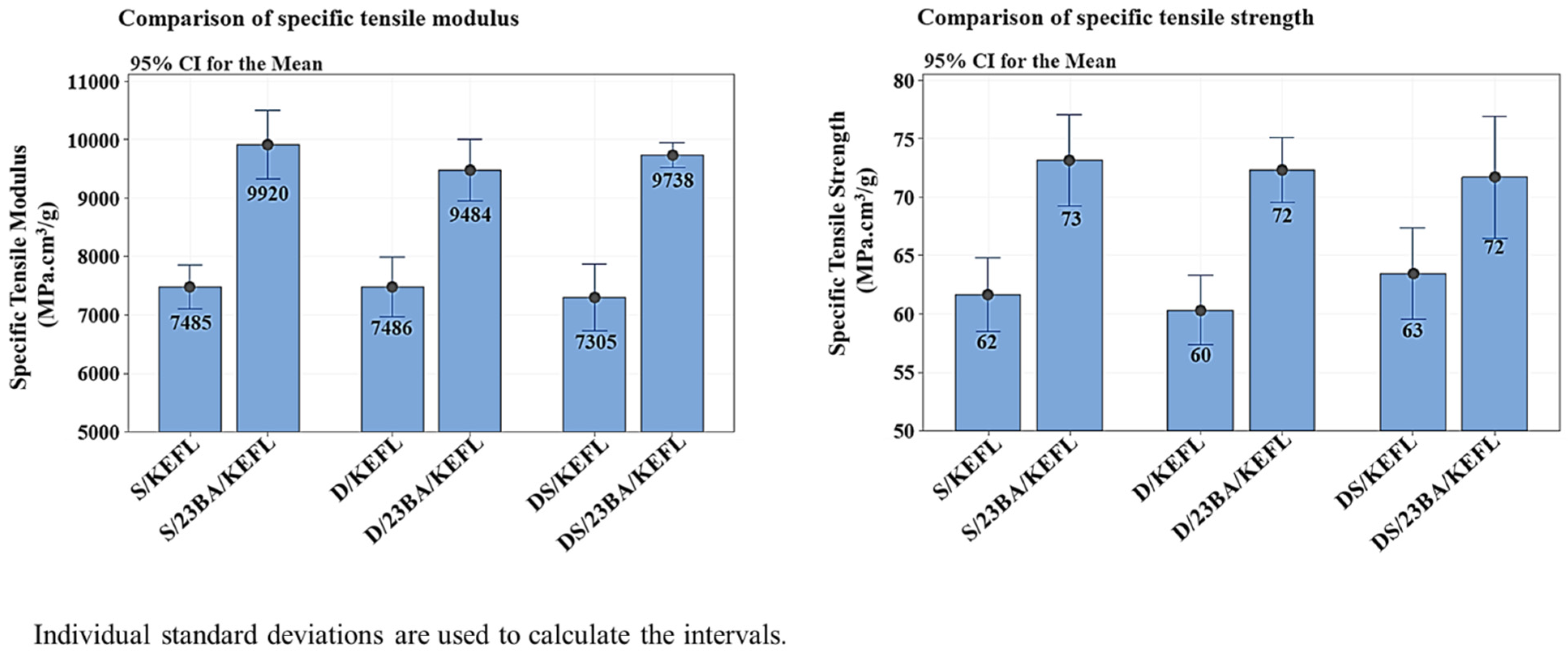

3.2.2. Tensile Analysis

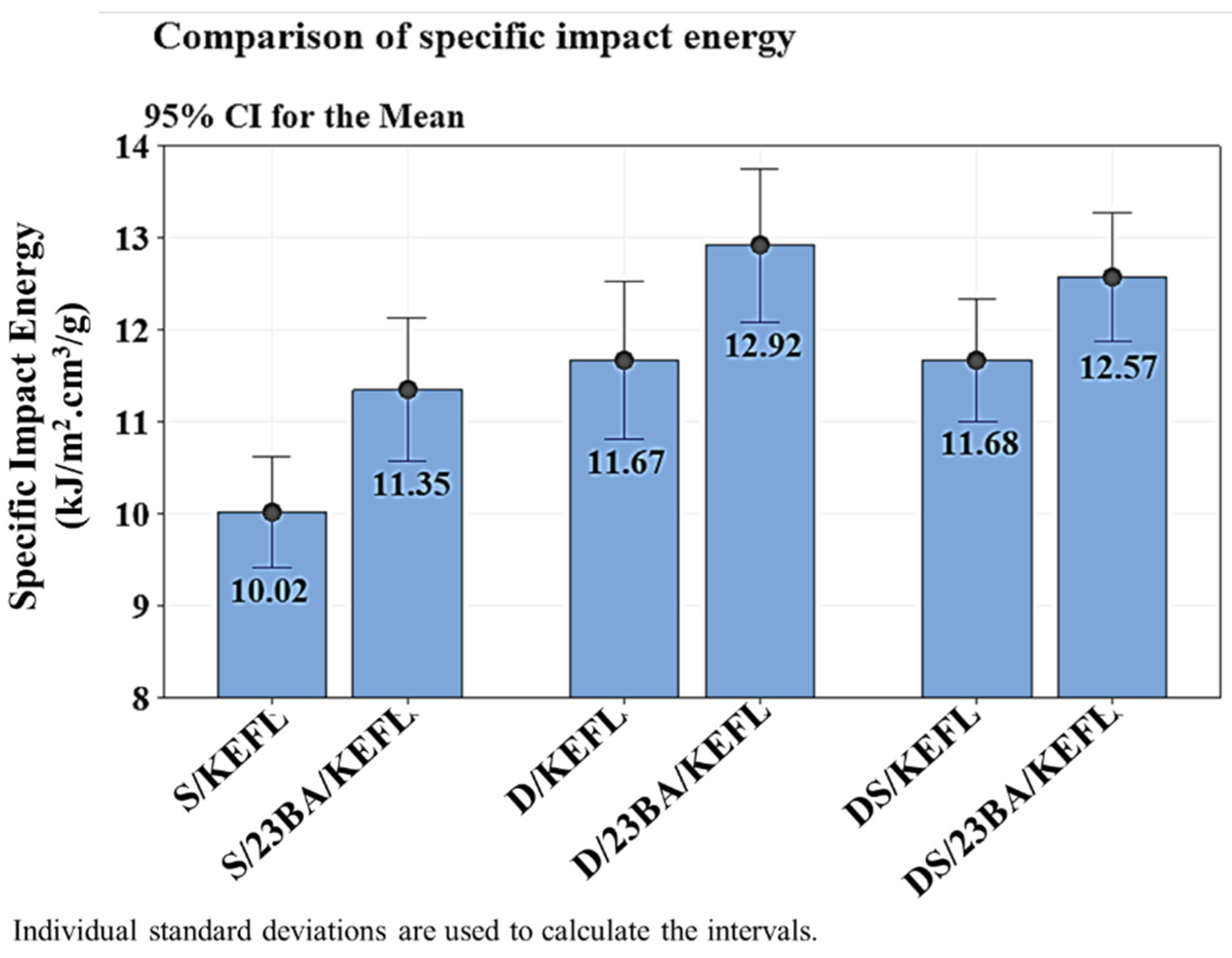

3.2.3. Charpy Impact Analysis

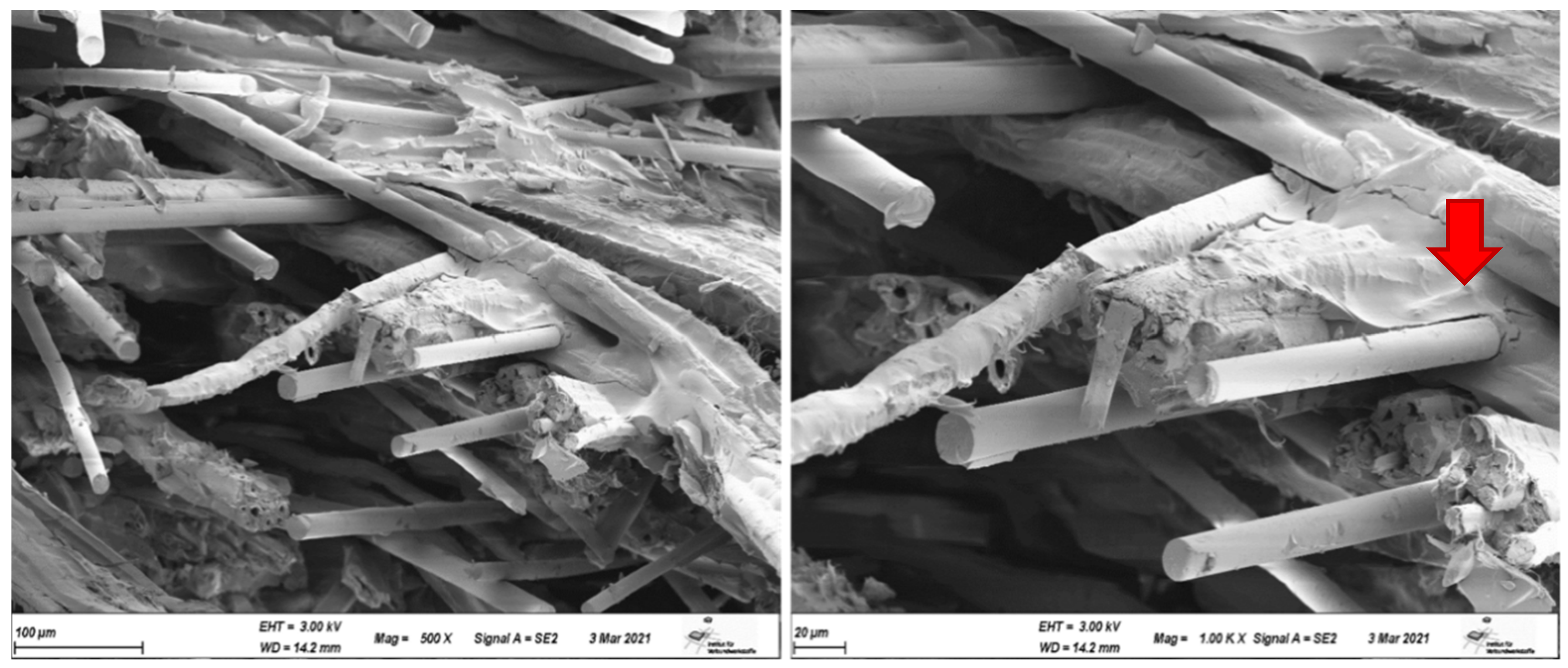

3.2.4. SEM Analysis

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Osoka, E.C.; Onukwuli, O.D.; Kamalu, C.I.O. Mechanical Properties of Selected Natural Fiber Reinforced Composites for Automobile Application. Am. J. Eng. Res. 2018, 7, 384–388. [Google Scholar]

- Beardmore, P.; Johnson, C.F. The Potential for Composites in Structural Automotive Applications. Compos. Sci. Technol. 1986, 26, 251–281. [Google Scholar] [CrossRef]

- Faruk, O.; Tjong, J.; Sain, M. (Eds.) Lightweight and Sustainable Materials for Automotive Applications; CRC Press, Taylor & Francis Group: Boca Raton, FL, USA, 2017; ISBN 978-1-4987-5687-7. [Google Scholar]

- The European Parliament and the Council of the European Union. Directive 2000/53/EC of the European Parliament and of the Council of 18 September 2000 on End of Life Vehicles. Off. J. Eur. Communities 2000, 269, 34–42. [Google Scholar]

- Marsh, G. Next Step for Automotive Materials. Mater. Today 2003, 6, 36–43. [Google Scholar] [CrossRef]

- Rajak, D.; Pagar, D.; Menezes, P.; Linul, E. Fiber-Reinforced Polymer Composites: Manufacturing, Properties, and Applications. Polymers 2019, 11, 1667. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yates, M.R.; Barlow, C.Y. Life Cycle Assessments of Biodegradable, Commercial Biopolymers—A Critical Review. Resour. Conserv. Recycl. 2013, 78, 54–66. [Google Scholar] [CrossRef]

- Behlouli, K. Natural Fiber Composites in Automotive Applications. In Handbook of Green Materials; World Scientific: Singapore, 2014; Volume 9. [Google Scholar]

- Faruk, O.; Bledzki, A.K.; Fink, H.-P.; Sain, M. Biocomposites Reinforced with Natural Fibers: 2000–2010. Prog. Polym. Sci. 2012, 37, 1552–1596. [Google Scholar] [CrossRef]

- Müssig, J.; Graupner, N. Technical applications of natural fibers: An Overview. In Industrial Application of Natural Fibres: Structure, Properties, and Technical Applications; John Wiley & Sons: Hoboken, NJ, USA, 2010; pp. 63–88. ISBN 978-0-470-69508-1. [Google Scholar]

- Mohanty, A.K.; Misra, M.; Drzal, L.T. Natural Fibers, Biopolymers, and Biocomposites: An Introduction. In Natural Fibers, Biopolymers, and Biocomposites; Taylor & Francis: Boca Raton, FL, USA, 2005; pp. 2–31. ISBN 978-0-8493-1741-5. [Google Scholar]

- Saheb, D.N.; Jog, J.P. Natural Fiber Polymer Composites: A Review. Adv. Polym. Technol. 1999, 18, 13. [Google Scholar] [CrossRef]

- Holbery, J.; Houston, D. Natural-Fiber-Reinforced Polymer Composites in Automotive Applications. JOM 2006, 58, 80–86. [Google Scholar] [CrossRef]

- Medina, L.A.; Dzalto, J. 1.11 Natural Fibers. In Comprehensive Composite Materials II; Elsevier: Amsterdam, The Netherlands, 2018; pp. 269–294. ISBN 978-0-08-100534-7. [Google Scholar]

- Carus, M.; de Beus, N.; Barth, M. Carbon Footprint and Sustainability of Different Natural Fibres for Biocomposites and Insulation Material; Nova-Institute: Hürth, Germany, 2019. [Google Scholar]

- Sarasini, F.; Tirillò, J.; Sergi, C.; Seghini, M.C.; Cozzarini, L.; Graupner, N. Effect of Basalt Fibre Hybridisation and Sizing Removal on Mechanical and Thermal Properties of Hemp Fibre Reinforced HDPE Composites. Compos. Struct. 2018, 188, 394–406. [Google Scholar] [CrossRef] [Green Version]

- Fiore, V.; Valenza, A.; Di Bella, G. Mechanical Behavior of Carbon/Flax Hybrid Composites for Structural Applications. J. Compos. Mater. 2012, 46, 2089–2096. [Google Scholar] [CrossRef] [Green Version]

- Dhakal, H.N.; Zhang, Z.Y.; Guthrie, R.; MacMullen, J.; Bennett, N. Development of Flax/Carbon Fibre Hybrid Composites for Enhanced Properties. Carbohydr. Polym. 2013, 96, 1–8. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Öztürk, S. The Effect of Fibre Content on the Mechanical Properties of Hemp and Basalt Fibre Reinforced Phenol Formaldehyde Composites. J. Mater. Sci. 2005, 40, 4585–4592. [Google Scholar] [CrossRef]

- Singha, K. A Short Review on Basalt Fiber. Int. J. Text. Sci. 2012, 1, 19–28. [Google Scholar] [CrossRef]

- Lopresto, V.; Leone, C.; de Iorio, I. Mechanical Characterization of Basalt Fibre Reinforced Plastic. Compos. Part B Eng. 2011, 42, 717–723. [Google Scholar] [CrossRef]

- Fiore, V.; Scalici, T.; Di Bella, G.; Valenza, A. A Review on Basalt Fibre and Its Composites. Compos. Part B Eng. 2015, 74, 74–94. [Google Scholar] [CrossRef]

- Manikandan, V.; Winowlin Jappes, J.T.; Suresh Kumar, S.M.; Amuthakkannan, P. Investigation of the Effect of Surface Modifications on the Mechanical Properties of Basalt Fibre Reinforced Polymer Composites. Compos. Part B Eng. 2012, 43, 812–818. [Google Scholar] [CrossRef]

- Umashankaran, M.; Gopalakrishnan, S.; Sathish, S. Preparation and Characterization of Tensile and Bending Properties of Basalt-Kenaf Reinforced Hybrid Polymer Composites. Int. J. Polym. Anal. Charact. 2020, 25, 227–237. [Google Scholar] [CrossRef]

- Ricciardi, M.R.; Papa, I.; Lopresto, V.; Langella, A.; Antonucci, V. Effect of Hybridization on the Impact Properties of Flax/Basalt Epoxy Composites: Influence of the Stacking Sequence. Compos. Struct. 2019, 214, 476–485. [Google Scholar] [CrossRef]

- Saleem, A.; Medina, L.; Skrifvars, M. Influence of Fiber Coating and Polymer Modification on Mechanical and Thermal Properties of Bast/Basalt Reinforced Polypropylene Hybrid Composites. J. Compos. Sci. 2020, 4, 119. [Google Scholar] [CrossRef]

- Czigány, T. Basalt Fiber Reinforced Hybrid Polymer Composites. Mater. Sci. Forum 2005, 473, 59–66. [Google Scholar] [CrossRef]

- Erasmus, E.; Anandjiwala, R. Studies on Enhancement of Mechanical Properties and Interfacial Adhesion of Flax Reinforced Polypropylene Composites. J. Thermoplast. Compos. Mater. 2009, 22, 485–502. [Google Scholar] [CrossRef]

- Zafeiropoulos, N.E.; Williams, D.R.; Baillie, C.A.; Matthews, F.L. Engineering and Characterisation of the Interface in Flax Fibre/Polypropylene Composite Materials. Part I. Development and Investigation of Surface Treatments. Compos. Part A Appl. Sci. Manuf. 2002, 33, 1083–1093. [Google Scholar] [CrossRef]

- Haghdan, S.; Smith, G.D. Natural Fiber Reinforced Polyester Composites: A Literature Review. J. Reinf. Plast. Compos. 2015, 34, 1179–1190. [Google Scholar] [CrossRef]

- No, B.Y.; Kim, M.G. Evaluation of Melamine-Modified Urea-Formaldehyde Resins as Particleboard Binders. J. Appl. Polym. Sci. 2007, 106, 4148–4156. [Google Scholar] [CrossRef]

- Council on Environmental Health. Chemical-Management Policy: Prioritizing Children’s Health. Pediatrics 2011, 127, 983–990. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- ACRODUR® Formaldehyde-Free Acrylic Binders. Available online: https://www.basf.com/us/en/products/General-Business-Topics/dispersions/Products/Acrodur-acrylic-resins.html (accessed on 18 October 2020).

- Islam, M.; Miao, M. Optimising Processing Conditions of Flax Fabric Reinforced Acrodur Biocomposites. J. Compos. Mater. 2014, 48, 3281–3292. [Google Scholar] [CrossRef]

- Medina, L.; Schledjewski, R.; Schlarb, A.K. Process Related Mechanical Properties of Press Molded Natural Fiber Reinforced Polymers. Compos. Sci. Technol. 2009, 69, 1404–1411. [Google Scholar] [CrossRef]

- Rasyid, M.A.; Salim, M.S.; Akil, H.M.; Ishak, Z.M. Flammability and Thermal Properties Studies of Nonwoven Flax Reinforced Acrylic Based Polyester Composites. In Proceedings of the AIP Conference Proceedings, Langkawi, Malaysia, 20–21 November 2017; p. 030010. [Google Scholar]

- Caliendo, H. Natural Fiber Composites Gaining Traction in Automotive. Available online: https://www.compositesworld.com/articles/natural-fiber-composites-gaining-traction-in-automotive (accessed on 24 August 2020).

- Saleem, A.; Medina, L.; Skrifvars, M. Mechanical Performance of Hybrid Bast and Basalt Fibers Reinforced Polymer Composites. J. Polym. Res. 2020, 27, 61. [Google Scholar] [CrossRef]

- Salim, M.S.; Rasyid, M.F.A.; Taib, R.M.; Ishak, Z.A.M. Processing Parameters Optimisation of Nonwoven Kenaf Reinforced Acrylic Based Polyester Composites. In Proceedings of the AIP Conference Proceedings, Langkawi, Malaysia, 20–21 November 2017; p. 110007. [Google Scholar]

- Peirson, B. Comparison of Specific Properties of Engineering Materials; School of Engineering Grand Valley State University: Kochi, India, 2005; p. 14. [Google Scholar]

- Rao, K.M.M.; Rao, K.M.; Prasad, A.V.R. Fabrication and Testing of Natural Fibre Composites: Vakka, Sisal, Bamboo and Banana. Mater. Des. 2010, 31, 508–513. [Google Scholar] [CrossRef]

- Prasad, A.V.R.; Rao, K.M. Mechanical Properties of Natural Fibre Reinforced Polyester Composites: Jowar, Sisal and Bamboo. Mater. Des. 2011, 32, 4658–4663. [Google Scholar] [CrossRef]

- Yousif, B.F. Effect of Oil Palm Fibres Volume Fraction on Mechanical Properties of Polyester Composites. Int. J. Mod. Phys. B 2010, 24, 4459–4470. [Google Scholar] [CrossRef] [Green Version]

- Dittenber, D.B.; GangaRao, H.V.S. Critical Review of Recent Publications on Use of Natural Composites in Infrastructure. Compos. Part A Appl. Sci. Manuf. 2012, 43, 1419–1429. [Google Scholar] [CrossRef]

- Nimanpure, S.; Hashmi, S.A.R.; Kumar, R.; Bhargaw, H.N.; Kumar, R.; Nair, P.; Naik, A. Mechanical, Electrical, and Thermal Analysis of Sisal Fibril/Kenaf Fiber Hybrid Polyester Composites. Polym. Compos. 2019, 40, 664–676. [Google Scholar] [CrossRef]

- ISO. Textiles—Determination of Linear Density—Gravimetric Method and Vibroscope Method; ISO 1973:1995; Beuth Verlag GmbH: Berlin, Germany, 1995. [Google Scholar]

- ISO. Textiles—Fibres—Determination of Breaking Force and Elongation at Break of Individual Fibres; ISO 5079:1979; Beuth Verlag GmbH: Berlin, Germany, 1979. [Google Scholar]

- Mueller, D.H.; Krobjilowski, A. New Discovery in the Properties of Composites Reinforced with Natural Fibers. J. Ind. Text. 2003, 33, 111–130. [Google Scholar] [CrossRef]

- Ismail, N.F.; Sulong, A.B.; Muhamad, N.; Tholibon, D.; MdRadzi, M.K.; Wanlbrahim, W.A.S. Review of the Compression Moulding of Natural Fiber-Reinforced Thermoset Composites: Material Processing and Characterisations. Pertanika J. Agric. Sci. 2015, 38, 533–547. [Google Scholar]

- ISO. Plastics—Determination of Flexural Properties; ISO 178:2019; Beuth Verlag GmbH: Berlin, Germany, 2019. [Google Scholar]

- ISO. Plastics—Determination of Tensile Properties—Part 4: Test Conditions for Isotropic and Anisotropic Fibre-Reinforced Plastic Composites; ISO 527-4:1997; Beuth Verlag GmbH: Berlin, Germany, 1997. [Google Scholar]

- ISO. Plastics—Determination of Charpy Impact Properties—Part 1: Non-Instrumented Impact Test; ISO 179-1:2010-06; Beuth Verlag GmbH: Berlin, Germany, 2010. [Google Scholar]

- Khalfallah, M.; Abbès, B.; Abbès, F.; Guo, Y.Q.; Marcel, V.; Duval, A.; Vanfleteren, F.; Rousseau, F. Innovative Flax Tapes Reinforced Acrodur Biocomposites: A New Alternative for Automotive Applications. Mater. Des. 2014, 64, 116–126. [Google Scholar] [CrossRef]

- Braun, E.; Levin, B.C. Polyesters: A Review of the Literature on Products of Combustion and Toxicity. Fire Mater. 1986, 10, 107–123. [Google Scholar] [CrossRef]

- Summerscales, J.; Dissanayake, N.P.J.; Virk, A.S.; Hall, W. A Review of Bast Fibres and Their Composites. Part 1—Fibres as Reinforcements. Compos. Part A Appl. Sci. Manuf. 2010, 41, 1329–1335. [Google Scholar] [CrossRef] [Green Version]

- Masseteau, B.; Michaud, F.; Irle, M.; Roy, A.; Alise, G. An Evaluation of the Effects of Moisture Content on the Modulus of Elasticity of a Unidirectional Flax Fiber Composite. Compos. Part A Appl. Sci. Manuf. 2014, 60, 32–37. [Google Scholar] [CrossRef]

- Ouajai, S.; Shanks, R.A. Composition, Structure and Thermal Degradation of Hemp Cellulose after Chemical Treatments. Polym. Degrad. Stab. 2005, 89, 327–335. [Google Scholar] [CrossRef]

- Menczel, J.D.; Prime, R.B. (Eds.) Thermal Analysis of Polymers: Fundamentals and Applications; John Wiley: Hoboken, NJ, USA, 2009; ISBN 978-0-471-76917-0. [Google Scholar]

- García-Manrique, J.A.; Marí, B.; Ribes-Greus, A.; Monreal, L.; Teruel, R.; Gascón, L.; Sans, J.A.; Marí-Guaita, J. Study of the Degree of Cure through Thermal Analysis and Raman Spectroscopy in Composite-Forming Processes. Materials 2019, 12, 3991. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mihalic, M.; Sobczak, L.; Pretschuh, C.; Unterweger, C. Increasing the Impact Toughness of Cellulose Fiber Reinforced Polypropylene Composites—Influence of Different Impact Modifiers and Production Scales. J. Compos. Sci. 2019, 3, 82. [Google Scholar] [CrossRef] [Green Version]

- Lee, S.; Lee, D.K. What Is the Proper Way to Apply the Multiple Comparison Test? Korean J. Anesthesiol. 2018, 71, 353–360. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Benkhelladi, A.; Laouici, H.; Bouchoucha, A. Tensile and Flexural Properties of Polymer Composites Reinforced by Flax, Jute and Sisal Fibres. Int. J. Adv. Manuf. Technol. 2020, 108, 895–916. [Google Scholar] [CrossRef]

- Minitab, LLC. Example of One-Way ANOVA. Minitab 18 Support; Minitab, LLC: State College, PA, USA, 2019. [Google Scholar]

- Ralph, C.; Lemoine, P.; Archer, E.; McIlhagger, A. Mechanical Properties of Short Basalt Fibre Reinforced Polypropylene and the Effect of Fibre Sizing on Adhesion. Compos. Part B Eng. 2019, 176, 107260. [Google Scholar] [CrossRef]

- Spearing, S.M.; Evans, A.G. The Role of Fiber Bridging in the Delamination Resistance of Fiber-Reinforced Composites. Acta Metall. Mater. 1992, 40, 2191–2199. [Google Scholar] [CrossRef]

| Resin. | Trade Name | Viscosity (mPas) | Solid Content (%) | pH Value |

|---|---|---|---|---|

| Solution (S) | 950 L (hard and brittle) | 900–2500 | 48–52 | 3–4 |

| Dispersion (D) | DS 3515 (hard and impact modified) | 300–1500 | 50 | 3.5 |

| Properties | Reinforcement Fibers | ||

|---|---|---|---|

| Basalt | Kenaf | Flax | |

| Elongation (Fmax) (%) | 4 ± 1.0 | 2 ± 0.5 | 2 ± 0.5 |

| Breaking force (cN) | 43 ± 11 | 437 ± 275 | 269 ± 112 |

| Tenacity (cN/dtex) | 8 ± 1 | 4 ± 2 | 4 ± 1 |

| Linear Density (dtex) | 6.1 ± 1 | 121 ± 42 | 81 ± 38 |

| Abbreviation | Composition (wt. %) |

|---|---|

| S/KEFL | 77% KEFL + 23% S (solution form resin) |

| S/23BA/KEFL | 54% KEFL + 23% BA + 23% S |

| D/KEFL | 77% KEFL + 23% D (dispersion form resin) |

| D/23BA/KEFL | 54% KEFL + 23% BA + 23% D |

| DS/KEFL | 77% KEFL + 23% DS (mixture of solution and dispersion form resin) |

| DS/23BA/KEFL | 54% KEFL + 23% BA + 23% S |

| Test | Test Standard | Specimen Dimension (mm) | Test Parameters |

|---|---|---|---|

| Flexural | DIN EN ISO 178 [50] | 80 × 25 × 2 | Span = 32 mm Speed = 2 mm/min |

| Tensile | DIN EN ISO 527-4 [51] | 250 × 25 × 2 | Speed = 2 mm/min Clamping length at start position = 150 mm |

| Impact (Charpy) | ISO 179 [52] | 80 × 15 × 2 | Hammer: Weight = 0.951 kg Velocity = 2.9 m/s Energy = 3.99 J |

| Composite. | Flexural Modulus (MPa) | Specific Flexural Modulus (MPa·cm3/g) | Flexural Strength (MPa) | Specific Flexural Strength (MPa·cm3/g) | Density (g/cm3) | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| Mean | StDev | Mean | StDev | Mean | StDev | Mean | StDev | Mean | StDev | |

| D/KEFL | 4389 | 593 | 4820 | 510 | 74 | 9 | 81 | 6 | 0.91 | 0.05 |

| D/23BA/KEFL | 6322 | 706 | 6116 | 490 | 98 | 12 | 96 | 9 | 1.03 | 0.07 |

| S/KEFL | 4568 | 734 | 4946 | 377 | 76 | 13 | 82 | 8 | 0.92 | 0.08 |

| S/23BA/KEFL | 5157 | 453 | 5606 | 318 | 91 | 9 | 95 | 1 | 0.96 | 0.11 |

| DS/KEFL | 3500 | 368 | 4131 | 299 | 63 | 7 | 74 | 3 | 0.85 | 0.08 |

| DS/23BA/KEFL | 4330 | 428 | 5067 | 124 | 80 | 4 | 90 | 5 | 0.91 | 0.04 |

| Composites | Specific Flexural Modulus (MPa·cm3/g) | Specific Flexural Strength (MPa·cm3/g) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Mean | StDev | 95% CI | GI | Mean | StDev | 95% CI | GI | |||

| Bast | 4632 | 527 | (4349; 4916) | A | p-value: 0.000 SE: 536 | 79 | 6.2 | (76; 83) | A | p-value: 0.000 SE: 6 |

| Basalt/bast | 5596 | 546 | (5313; 5880) | B | 93 | 6.3 | (90; 97) | B | ||

| Solution | 5276 | 479 | (4864; 5688) | A B | p-value: 0.013 SE: 634 | 88 | 8.8 | (82; 95) | A | p-value: 0.298 SE: 9 |

| Dispersion | 5468 | 830 | (5056; 5879) | A | 88 | 10.7 | (82; 95) | A | ||

| Mixture | 4599 | 538 | (4188; 5011) | B | 82 | 9.1 | (76; 89) | A | ||

| Composite | Tensile Modulus (MPa) | Specific Tensile Modulus (MPa·cm3/g) | Tensile Strength (MPa) | Specific Tensile Strength (MPa·cm3/g) | Density (g/cm3) | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| Mean | StDev | Mean | StDev | Mean | StDev | Mean | StDev | Mean | StDev | |

| D/KEFL | 6284 | 629 | 7486 | 406 | 48 | 5 | 60 | 2 | 0.81 | 0.02 |

| D/23BA/KEFL | 7484 | 445 | 9484 | 421 | 57 | 5 | 72 | 2 | 0.79 | 0.08 |

| S/KEFL | 6438 | 488 | 7485 | 306 | 53 | 6 | 62 | 3 | 0.86 | 0.09 |

| S/23BA/KEFL | 8780 | 506 | 9920 | 471 | 65 | 7 | 73 | 3 | 0.89 | 0.09 |

| DS/KEFL | 5985 | 544 | 7305 | 463 | 52 | 3 | 63 | 3 | 0.82 | 0.03 |

| DS/23BA/KEFL | 8156 | 581 | 9738 | 169 | 60 | 2 | 72 | 4 | 0.84 | 0.06 |

| Composite | Specific Tensile Modulus (MPa.cm3/g) | Specific Tensile Strength (MPa.cm3/g) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Mean | StDev | 95% CI | GI | Mean | StDev | 95% CI | GI | |||

| Bast | 7425 | 378 | (7220; 7629) | A | p-value: 0.000 SE: 387 | 62 | 2.8 | (60; 63) | A | p-value: 0.000 SE: 3 |

| Basalt/bast | 9714 | 396 | (9509; 9919) | B | 72 | 3.1 | (71; 74) | B | ||

| Solution | 8702 | 1337 | (7881; 9523) | A | p-value: 0.919 SE:1265 | 67 | 6.6 | (63; 71) | A | p-value: 0.892 SE: 6 |

| Dispersion | 8485 | 1123 | (7664; 9306) | A | 66 | 6.7 | (62; 70) | A | ||

| Mixture | 8522 | 1324 | (7701; 9342) | A | 67 | 5.6 | (63; 72) | A | ||

| Composite | Impact Energy (kJ/m2) | Density (g/cm3) | Specific Impact Energy (kJ/m2·cm3/g) | |||

|---|---|---|---|---|---|---|

| Mean | StDev | Mean | StDev | Mean | StDev | |

| D/KEFL | 11.02 | 0.50 | 0.95 | 0.04 | 11.67 | 0.70 |

| D/23BA/KEFL | 12.20 | 1.00 | 0.95 | 0.06 | 12.92 | 0.90 |

| S/KEFL | 8.71 | 0.61 | 0.87 | 0.08 | 10.01 | 0.85 |

| S/23BA/KEFL | 11.72 | 0.84 | 1.04 | 0.09 | 11.34 | 0.65 |

| DS/KEFL | 10.37 | 0.67 | 0.89 | 0.04 | 11.68 | 0.54 |

| DS/23BA/KEFL | 11.90 | 1.08 | 0.94 | 0.09 | 12.57 | 0.66 |

| Composites | Specific Impact Energy (kJ/m2·cm3/g) | ||||

|---|---|---|---|---|---|

| Mean | StDev | 95% CI | GI | p-value: 0.000 SE: 1.06 | |

| Bast | 10.89 | 1.08 | (10.4; 11.39) | A | |

| Basalt/bast | 12.26 | 1.05 | (11.78; 12.75) | B | |

| Solution | 10.61 | 1.04 | (10.12; 11.09) | B | p-value: SE: 0.95 |

| Dispersion | 12.40 | 1.01 | (11.84; 12.96) | A | |

| Mixture | 12.17 | 0.75 | (11.58; 12.75) | A | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Saleem, A.; Medina, L.; Skrifvars, M. Improvement of Performance Profile of Acrylic Based Polyester Bio-Composites by Bast/Basalt Fibers Hybridization for Automotive Applications. J. Compos. Sci. 2021, 5, 100. https://doi.org/10.3390/jcs5040100

Saleem A, Medina L, Skrifvars M. Improvement of Performance Profile of Acrylic Based Polyester Bio-Composites by Bast/Basalt Fibers Hybridization for Automotive Applications. Journal of Composites Science. 2021; 5(4):100. https://doi.org/10.3390/jcs5040100

Chicago/Turabian StyleSaleem, Anjum, Luisa Medina, and Mikael Skrifvars. 2021. "Improvement of Performance Profile of Acrylic Based Polyester Bio-Composites by Bast/Basalt Fibers Hybridization for Automotive Applications" Journal of Composites Science 5, no. 4: 100. https://doi.org/10.3390/jcs5040100

APA StyleSaleem, A., Medina, L., & Skrifvars, M. (2021). Improvement of Performance Profile of Acrylic Based Polyester Bio-Composites by Bast/Basalt Fibers Hybridization for Automotive Applications. Journal of Composites Science, 5(4), 100. https://doi.org/10.3390/jcs5040100