Optimization of Process Conditions for Continuous Growth of CNTs on the Surface of Carbon Fibers

Abstract

1. Introduction

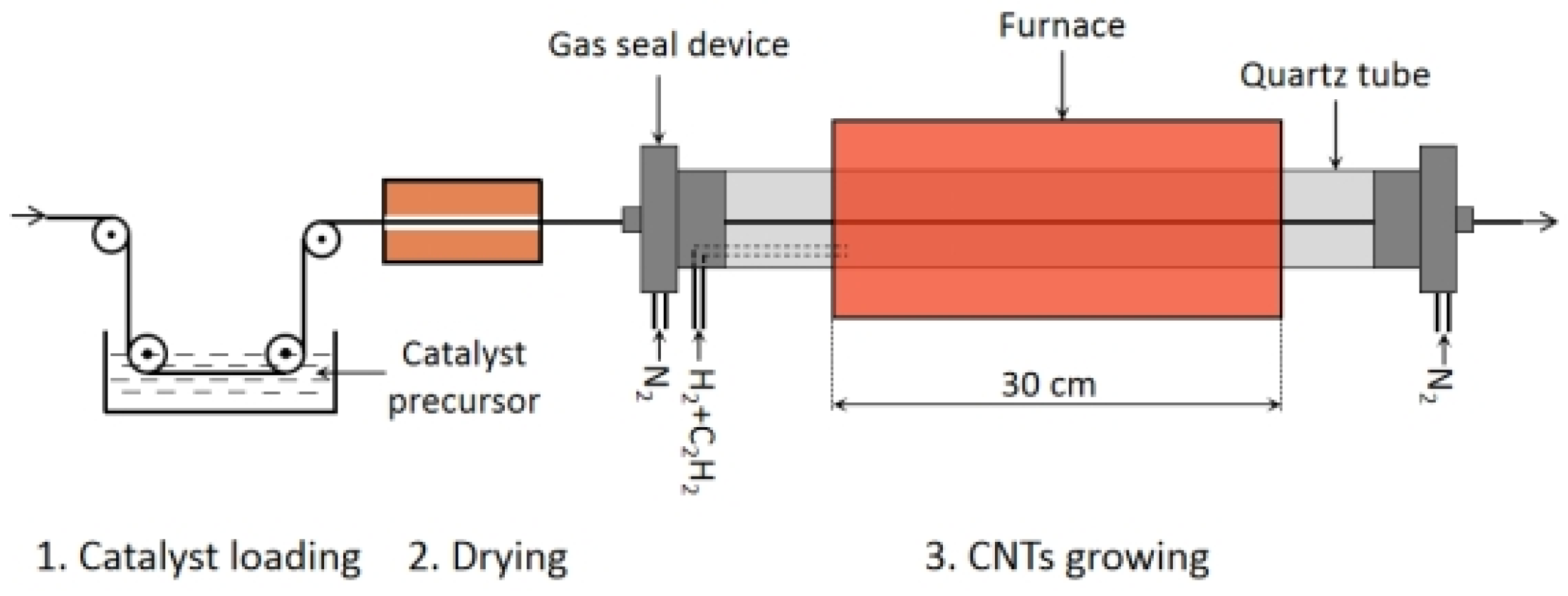

2. Materials and Methods

2.1. Experiment Method

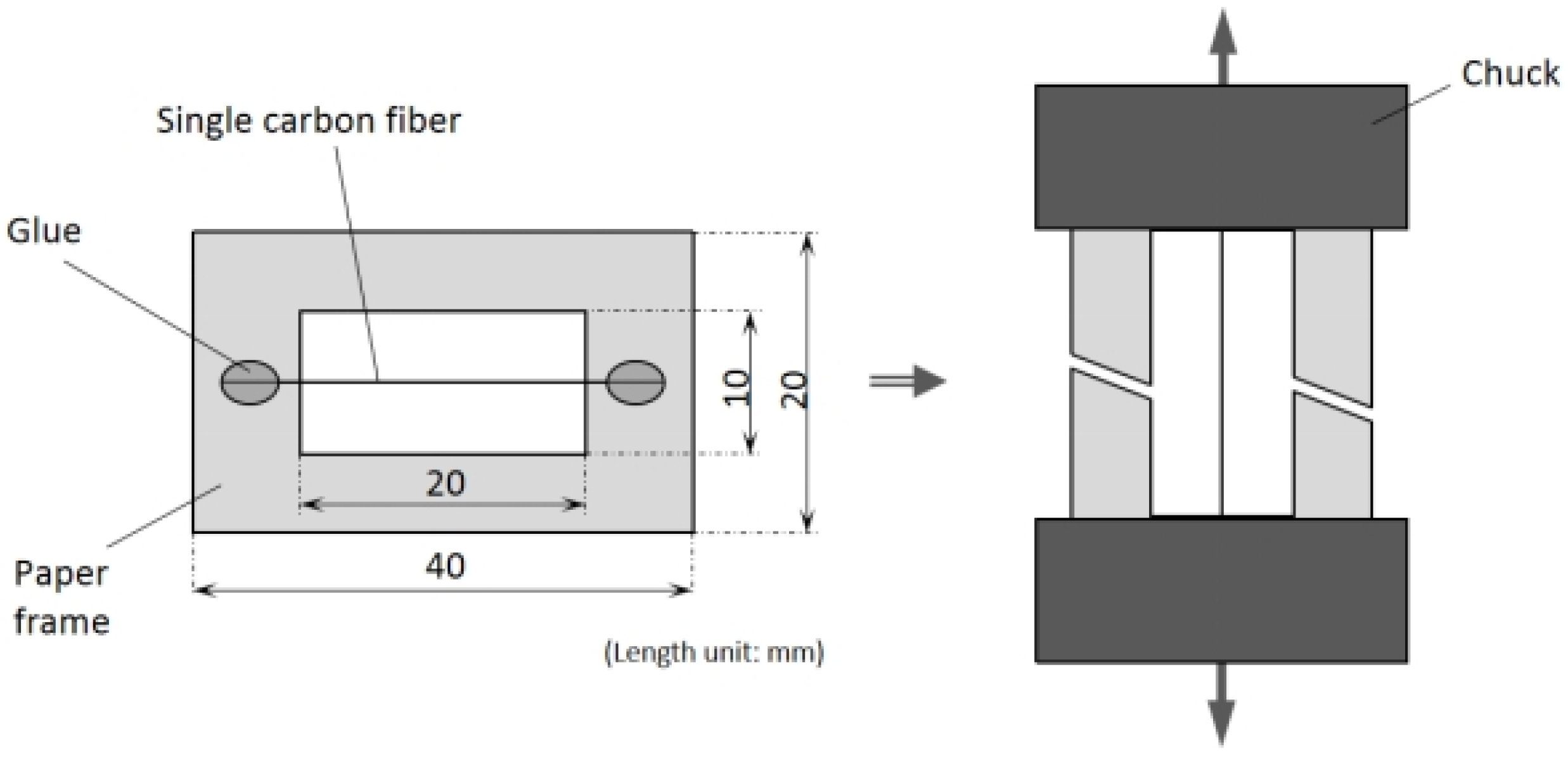

2.2. Characterization

3. Results and Discussion

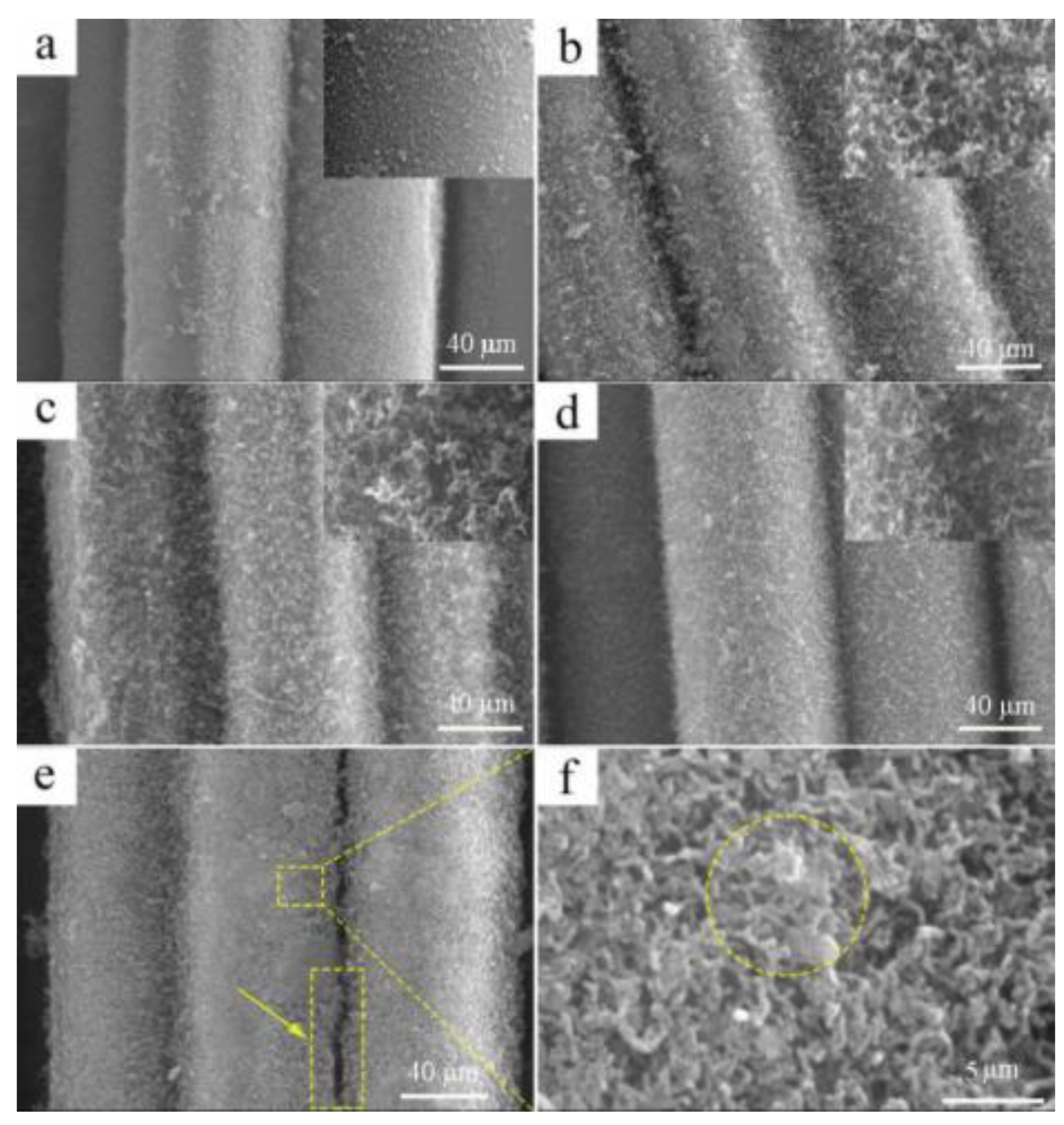

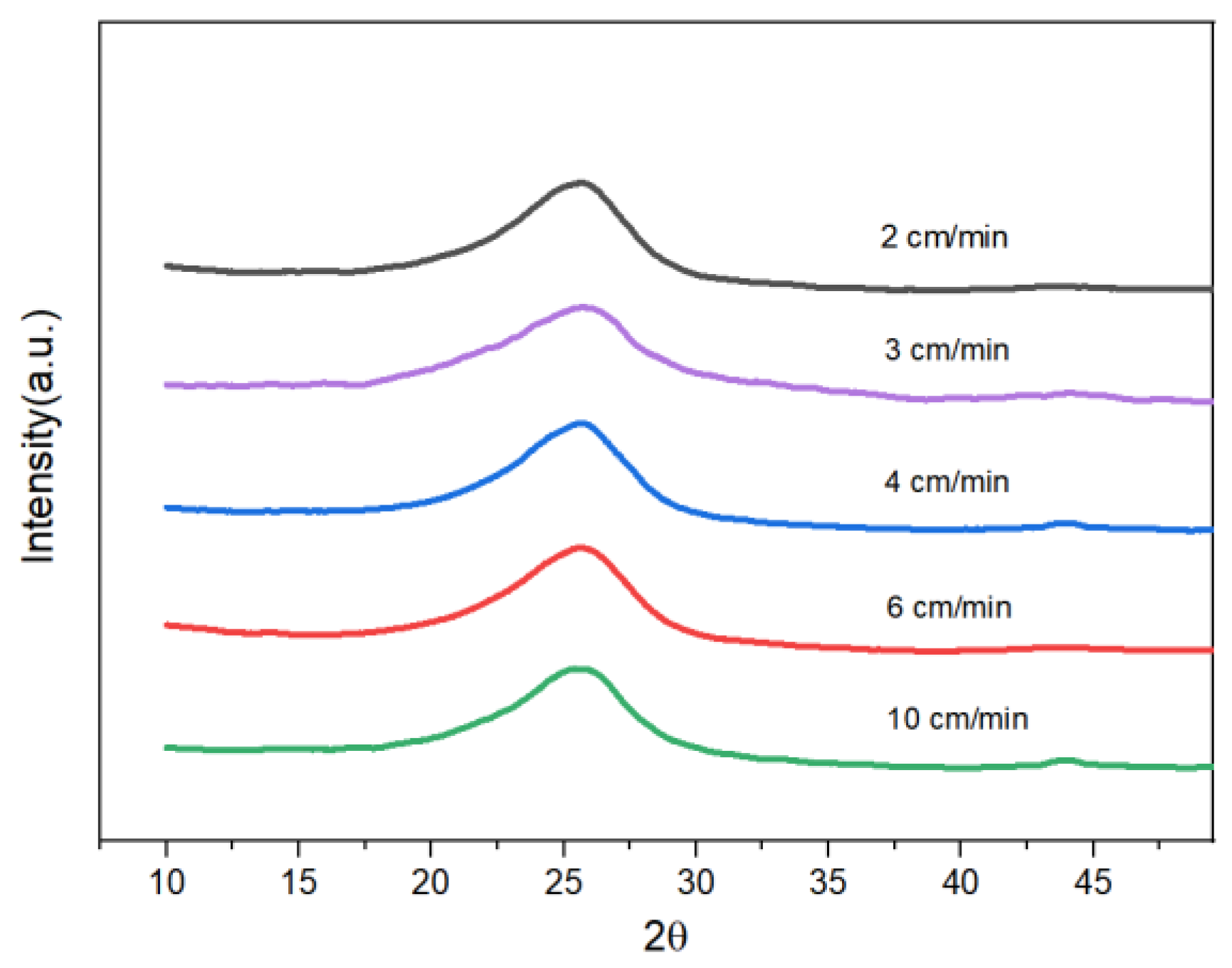

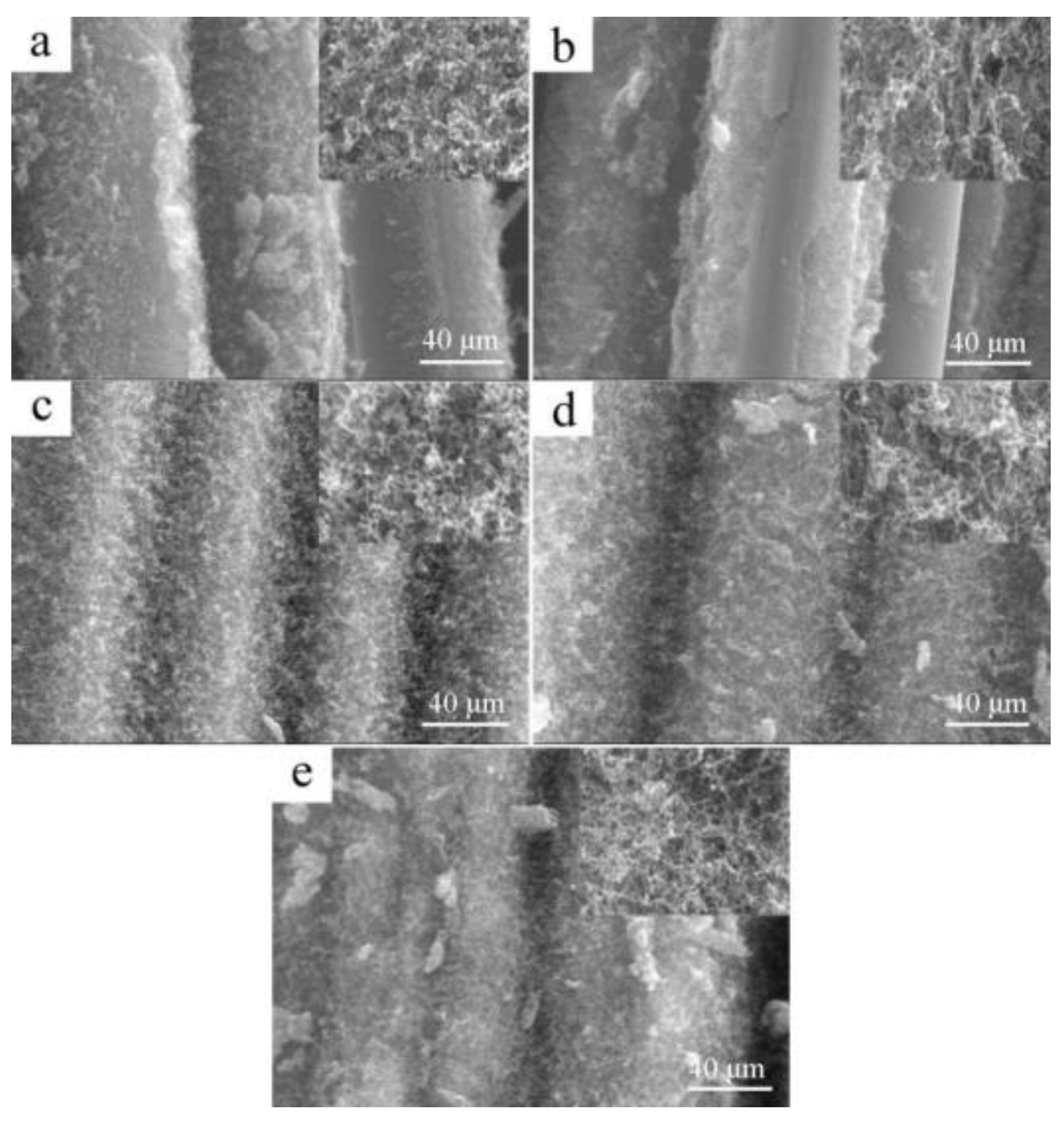

3.1. Effect of Moving Speeds on Surface Morphology of Multiscale Reinforcements

3.2. Effect of Moving Speeds on Tensile Strength of Multiscale Reinforcements

3.3. Effect of Growth Atmosphere on Morphology of Multiscale Reinforcements

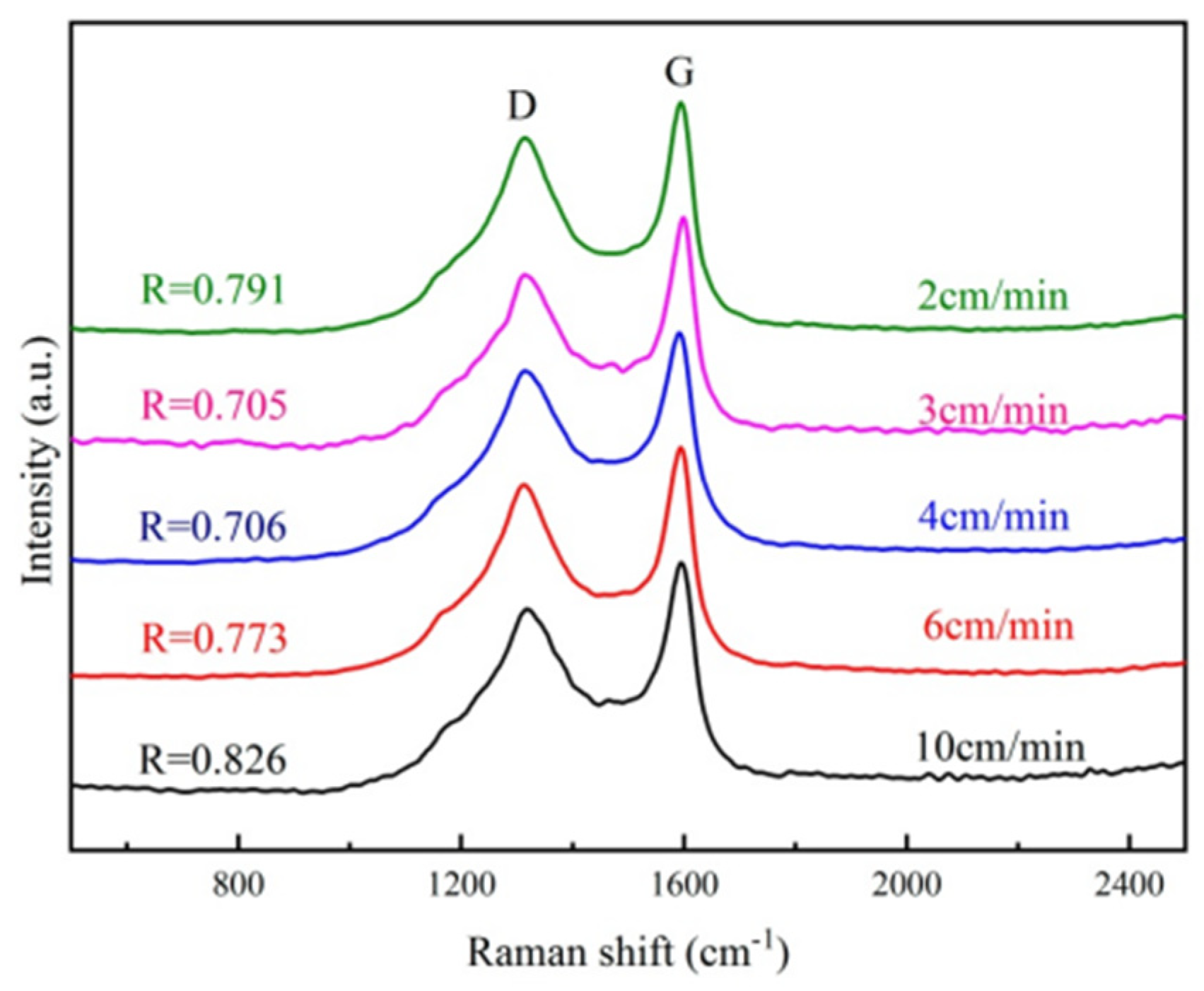

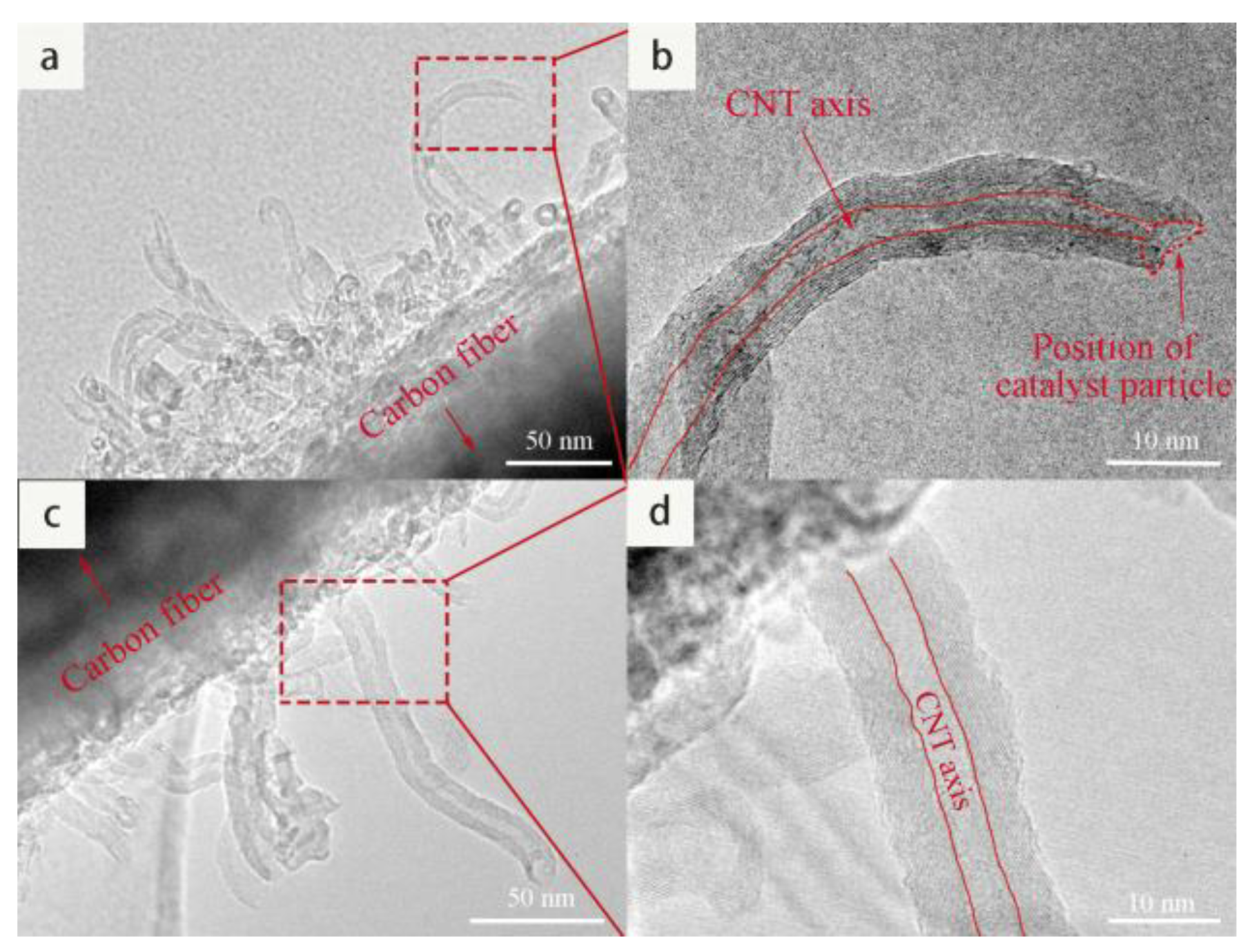

3.4. CNTs Microstructure Analysis

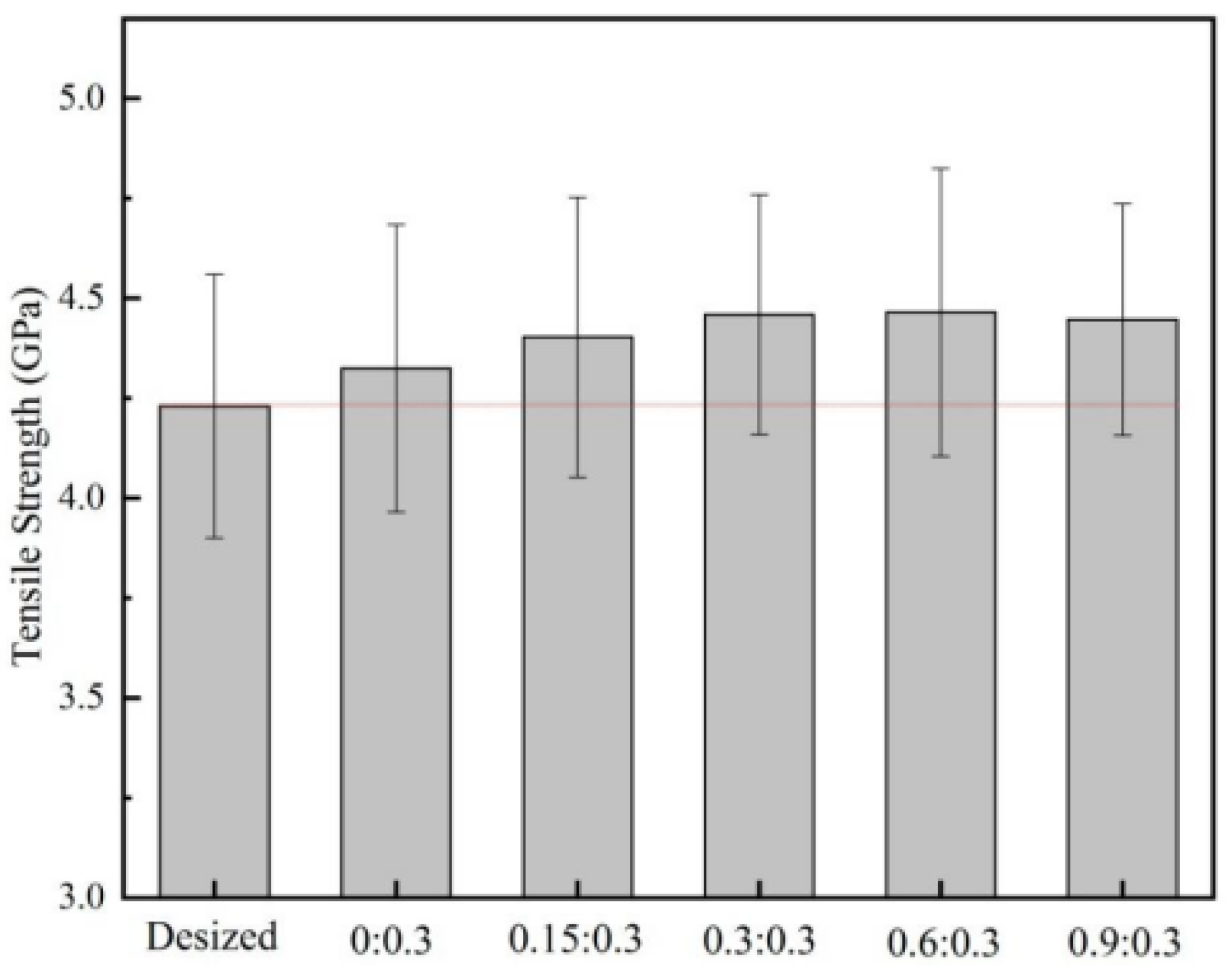

3.5. Effect of Growth Atmosphere on Tensile Strength of Multiscale Reinforcements

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Wazir, A.H.; Kakakhel, L. Preparation and characterization of pitch-based carbon fibers. N. Carbon Mater. 2009, 24, 83–88. [Google Scholar] [CrossRef]

- Ma, L.C.; Zhu, Y.Y.; Wang, M.Z.; Yang, X.B.; Song, G.J.; Huang, Y.D. Enhancing interfacial strength of epoxy resin composites via evolving hyperbranched amino-terminated POSS on carbon fiber surface. Compos. Sci. Technol. 2019, 170, 148–156. [Google Scholar] [CrossRef]

- Das, T.K.; Ghosh, P.; Das, N.C. Preparation, development, outcomes, and application versatility of carbon fiber-based polymer composites: A review. Adv. Compos. Mater. 2019, 2, 214–233. [Google Scholar] [CrossRef]

- Sun, K.; Wang, L.Y.; Wang, Z.X.; Wu, X.F.; Fan, G.H.; Wang, Z.Y.; Cheng, C.B.; Fan, R.H.; Dong, M.Y.; Guo, Z.H. Flexible silver nanowire/carbon fiber felt metacomposites with weakly negative permittivity behavior. Phys. Chem. Chem. Phys. 2020, 22, 5114–5122. [Google Scholar] [CrossRef] [PubMed]

- Zeng, J.J.; Gao, W.Y.; Duan, Z.J.; Bai, Y.L.; Guo, Y.C.; Ouyang, L.J. Axial compressive behavior of polyethylene tereph-thalate/carbon FRP-confined seawater sea-sand concrete in circular columns. Constr. Build. Mater. 2020, 234, 117383–117399. [Google Scholar] [CrossRef]

- Raphael, N.; Namratha, K.; Chandrashekar, B.N.; Sadasivuni, K.K.; Ponnamma, D.; Smitha, A.S.; Krishnaveni, S.; Cheng, C.; Byrappa, K. Surface modification and grafting of carbon fibers: A route to better interface. Prog. Cryst. Growth Charact. Mater. 2018, 64, 75–101. [Google Scholar] [CrossRef]

- Van de Werken, N.; Tekinalp, H.; Khanbolouki, P.; Ozcan, S.; Williams, A.; Tehrani, M. Additively manufactured carbon fiber-reinforced composites: State of the art and perspective. Addit. Manuf. 2020, 31, 100962. [Google Scholar] [CrossRef]

- Yuan, X.M.; Zhu, B.; Cai, X.; Qiao, K.; Zhao, S.Y.; Zhang, M. Nanoscale toughening of carbon fiber-reinforced epoxy composites through different surface treatments. Polym. Eng. Sci. 2019, 59, 625–632. [Google Scholar] [CrossRef]

- Abbas, I.; Wang, Y.X.; Elahi, H.; Siddiqui, M.A.; Ullah, M.; Qayyum, F. Effect of MoSi2-Si3N4/SiC multi-layer coating on the oxidation resistance of carbon/carbon composites above 1770 K. J. Compos. Sci. 2020, 4, 86. [Google Scholar] [CrossRef]

- De Greef, N.; Zhang, L.M.; Magrez, A.; Forró, L.; Locquet, J.-P.; Verpoest, I.; Seo, J.W. Direct growth of carbon nanotubes on carbon fibers: Effect of the CVD parameters on the degradation of mechanical properties of carbon fibers. Diam. Relat. Mater. 2015, 51, 39–48. [Google Scholar] [CrossRef]

- Qian, H.; Bismarck, A.; Greenhalgh, E.S.; Kalinka, G.; Shaffer, M.S.P. Hierarchical Composites Reinforced with Carbon Nanotube Grafted Fibers: The Potential Assessed at the Single Fiber Level. Chem. Mater. 2008, 20, 1862–1869. [Google Scholar] [CrossRef]

- Wang, Y.X.; Su, S.S.; Fan, W.X.; Qin, J.J.; Qu, C.; Wang, C.G. Metal catalyst for preparation of multiscale reinforcement of carbon nanotubes on carbon fibers. Chin. J. Mater. Res. 2018, 32, 495–501. [Google Scholar]

- Naito, K. Tensile Properties and Fracture Behavior of Different Carbon Nanotube-Grafted Polyacrylonitrile-Based Carbon Fibers. J. Mater. Eng. Perform. 2014, 23, 3916–3925. [Google Scholar] [CrossRef]

- Manawi, Y.M.; Ihsanullah; Samara, A.; Al-Ansari, T.; Atieh, M.A. A Review of Carbon Nanomaterials’ Synthesis via the Chemical Vapor Deposition (CVD) Method. Materials 2018, 11, 822. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.-L.; Kinloch, I.A.; Windle, A.H. Direct Spinning of Carbon Nanotube Fibers from Chemical Vapor Deposition Synthesis. Science 2004, 304, 276–278. [Google Scholar] [CrossRef]

- Anthony, D.B.; Sui, X.M.; Kellersztein, I.; de Luca, H.G.; White, E.R.; Wagner, H.D.; Greenhalgh, E.S.; Bismarck, A.; Shaffer, M.S. Continuous carbon nanotube synthesis on charged carbon fibers. Compos. Part. A Appl. Sci. Manuf. 2018, 112, 525–538. [Google Scholar] [CrossRef]

- Tanaka, K.; Okuda, S.; Hinoue, Y.; Katayama, T. Effects of Water Absorption on the Fiber-Matrix Interfacial Shear Strength of Carbon Nanotube-Grafted Carbon Fiber Reinforced Polyamide Resin. J. Compos. Sci. 2019, 3, 4. [Google Scholar] [CrossRef]

- Rong, H.P.; Dahmen, K.-H.; Garmestani, H.; Yu, M.H.; Jacob, K.I. Comparison of chemical vapor deposition and chemical grafting for improving the mechanical properties of carbon fiber/epoxy composites with multi-wall carbon nanotubes. J. Mater. Sci. 2013, 48, 4834–4842. [Google Scholar] [CrossRef]

- Lee, G.; Sung, M.; Youk, J.H.; Lee, J.; Yu, W.-R. Improved tensile strength of carbon nanotube-grafted carbon fiber reinforced composites. Compos. Struct. 2019, 220, 580–591. [Google Scholar] [CrossRef]

- Thostenson, E.T.; Li, W.Z.; Wang, D.Z.; Ren, Z.F.; Chou, T.W. Carbon nanotube/carbon fiber hybrid multiscale composites. J. Appl. Phys. 2002, 91, 6034–6037. [Google Scholar] [CrossRef]

- An, F.; Lu, C.X.; Guo, J.H.; He, S.Q.; Lu, H.B.; Yang, Y. Preparation of vertically aligned carbon nanotube arrays grown onto carbon fiber fabric and evaluating its wettability on effect of composite. Appl. Surf. Sci. 2011, 258, 1069–1076. [Google Scholar] [CrossRef]

- An, F.; Lu, C.X.; Li, Y.H.; Guo, J.H.; Lu, X.X.; Lu, H.B.; He, S.Q.; Yang, Y. Preparation and characterization of carbon nano-tube-hybridized carbon fiber to reinforce epoxy composite. Mater. Des. 2012, 33, 197–202. [Google Scholar] [CrossRef]

- Zhao, N.; Ma, Z.K.; Song, H.H.; Xie, Y.G.; Zhang, M. Enhancement of bioelectricity generation by synergistic modification of vertical carbon nanotubes/polypyrrole for the carbon fibers anode in microbial fuel cell. Electrochim. Acta 2019, 296, 69–74. [Google Scholar] [CrossRef]

- Luo, X.G.; Weng, W.; Liang, Y.X.; Hu, Z.X.; Zhang, Y.; Yang, J.J.; Yang, L.J.; Yang, S.Y.; Zhu, M.F.; Cheng, H.M. Multifunctional fabrics of carbon nanotube fibers. J. Mater. Chem. A 2019, 7, 8790–8797. [Google Scholar] [CrossRef]

- Su, S.S.; Wang, Y.X.; Qin, J.J.; Wang, C.G.; Yao, Z.Q.; Lu, R.J.; Wang, Q.F. Continuous method for grafting CNTs on the surface of carbon fibers based on cobalt catalyst assisted by thiourea. J. Mater. Sci. 2019, 54, 12498–12508. [Google Scholar] [CrossRef]

- Yao, Z.Q.; Wang, C.G.; Qin, J.J.; Wang, Y.X.; Wang, Q.F.; Wei, H.Z. Fex-Co1−x bimetallic catalysts for highly efficient growth of carbon nanotubes on carbon fibers. Ceram. Int. 2020, 46, 27158–27162. [Google Scholar] [CrossRef]

- Qin, J.J.; Wang, C.G.; Wang, Y.X.; Su, S.S.; Lu, R.J.; Yao, Z.Q.; Wang, Q.F.; Gao, Q. Communication—A Technique for Online Continuous Manufacture of Carbon Nanotubes-Grown Carbon Fibers. ECS J. Solid State Sci. Technol. 2019, 8, M23–M25. [Google Scholar] [CrossRef]

- Yao, Z.Q.; Wang, C.G.; Qin, J.J.; Su, S.S.; Wang, Y.X.; Wang, Q.F.; Yu, M.J.; Wei, H.Z. Interfacial improvement of carbon fi-ber/epoxy composites using one-step method for grafting carbon nanotubes on the fibers at ultra-low temperatures. Carbon 2020, 164, 133–142. [Google Scholar] [CrossRef]

- Meysami, S.S.; Koos, A.A.; Dillon, F.; Dutta, M.; Grobert, N. Aerosol-assisted chemical vapour deposition synthesis of multi-wall carbon nanotubes: III. Towards upscaling. Carbon 2015, 88, 148–156. [Google Scholar] [CrossRef]

- Jourdain, V.; Bichara, C. Current understanding of the growth of carbon nanotubes in catalytic chemical vapour deposition. Carbon 2013, 58, 2–39. [Google Scholar] [CrossRef]

- Kim, K.J.; Yu, W.-R.; Youk, J.H.; Lee, J. Degradation and Healing Mechanisms of Carbon Fibers during the Catalytic Growth of Carbon Nanotubes on Their Surfaces. ACS Appl. Mater. Interfaces 2012, 4, 2250–2258. [Google Scholar] [CrossRef] [PubMed]

- Valles, C.; Perez-Mendoza, M.; Maser, W.K.; Martínez, M.T.; Álvarez, L.; Sauvajol, J.L.; Benito, A.M. Effects of partial and total methane flows on the yield and structural characteristics of MWCNTs produced by CVD. Carbon 2009, 47, 998–1004. [Google Scholar] [CrossRef]

- Behr, M.J.; Gaulding, E.A.; Mkhoyan, K.A.; Aydil, E.S. Effect of hydrogen on catalyst nanoparticles in carbon nanotube growth. J. Appl. Phys. 2010, 108, 053303. [Google Scholar] [CrossRef]

- Wang, X.H.; Wang, C.G.; Wang, Z.Y.; Wang, Y.X.; Lu, R.J.; Qin, J.J. Colossal permittivity of carbon nanotubes grafted carbon fiber-reinforced epoxy composites. Mater. Lett. 2018, 211, 273–276. [Google Scholar] [CrossRef]

- Terrado, E.; Tacchini, I.; Benito, A.M.; Maser, W.K.; Martinez, M.T. Optimizing catalyst nanoparticle distribution to produce densely-packed carbon nanotube growth. Carbon 2009, 47, 1989–2001. [Google Scholar] [CrossRef]

- Chen, H.; Yang, J.; Shuai, Q.; Li, J.; Ouyang, Q.; Zhang, S. In-situ doping B4C nanoparticles in PAN precursors for preparing high modulus PAN-based carbon fibers with boron catalytic graphitization. Compos. Sci. Technol. 2020, 200, 108455. [Google Scholar] [CrossRef]

| Gas | Flow Rate 1 | Flow Rate 2 | Flow Rate 3 | Flow Rate 4 | Flow Rate 5 |

|---|---|---|---|---|---|

| H2 | 0 | 0.15 | 0.3 | 0.6 | 0.9 |

| C2H2 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 |

| Sample | FWHM |

|---|---|

| 2 cm/min | 0.960 |

| 3 cm/min | 0.934 |

| 4 cm/min | 0.928 |

| 6 cm/min | 0.975 |

| 10 cm/min | 1.114 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, C.; Wang, Y.; Su, S. Optimization of Process Conditions for Continuous Growth of CNTs on the Surface of Carbon Fibers. J. Compos. Sci. 2021, 5, 111. https://doi.org/10.3390/jcs5040111

Wang C, Wang Y, Su S. Optimization of Process Conditions for Continuous Growth of CNTs on the Surface of Carbon Fibers. Journal of Composites Science. 2021; 5(4):111. https://doi.org/10.3390/jcs5040111

Chicago/Turabian StyleWang, Chengjuan, Yanxiang Wang, and Shunsheng Su. 2021. "Optimization of Process Conditions for Continuous Growth of CNTs on the Surface of Carbon Fibers" Journal of Composites Science 5, no. 4: 111. https://doi.org/10.3390/jcs5040111

APA StyleWang, C., Wang, Y., & Su, S. (2021). Optimization of Process Conditions for Continuous Growth of CNTs on the Surface of Carbon Fibers. Journal of Composites Science, 5(4), 111. https://doi.org/10.3390/jcs5040111