Effect of Twist Drill Geometry and Drilling Parameters on Hole Quality in Single-Shot Drilling of CFRP/Al7075-T6 Composite Stack

Abstract

:1. Introduction

2. Materials and Methods

2.1. Worpiece Materials

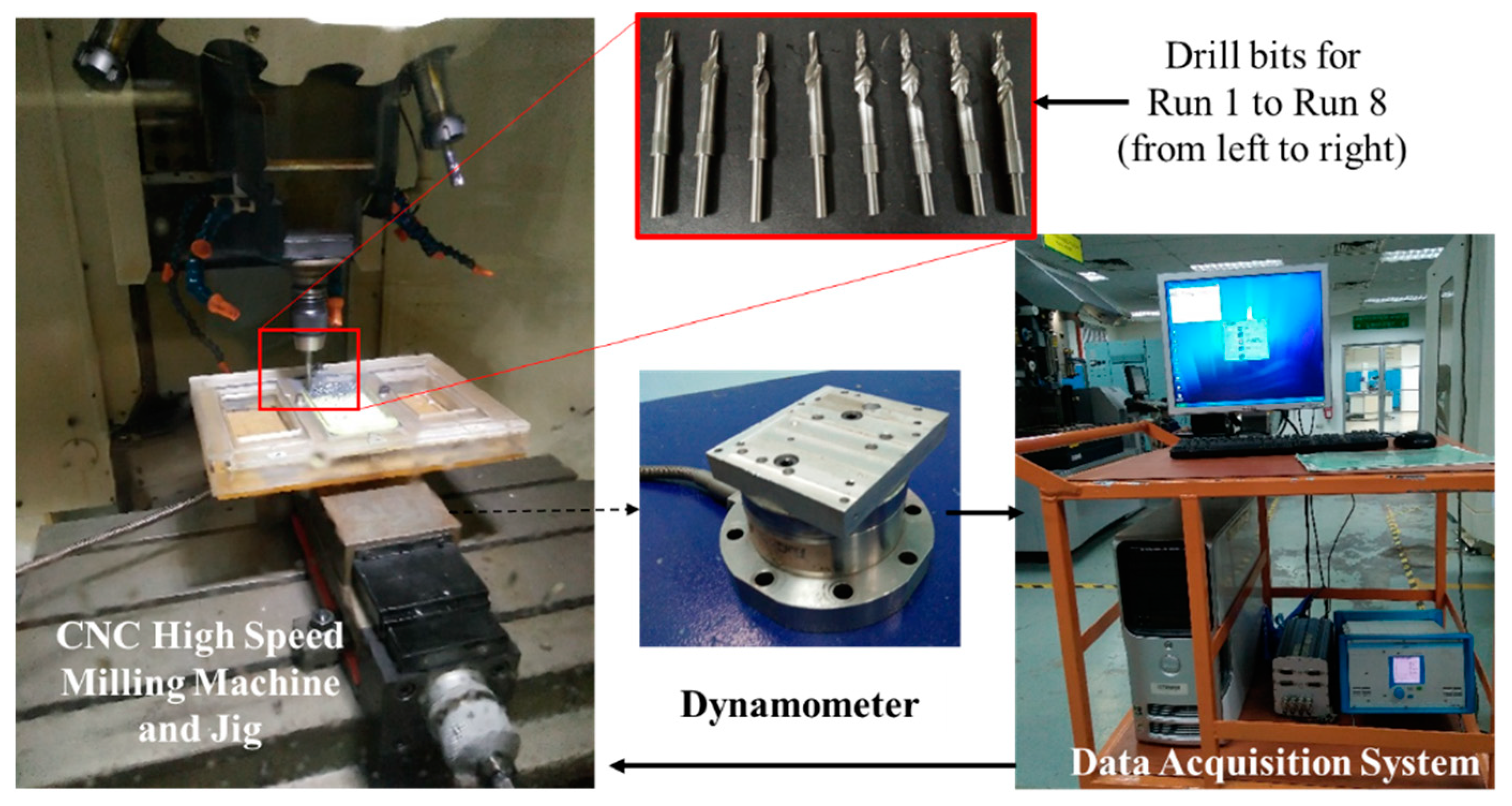

2.2. Cutting Tool and Force Measurement Setup

2.3. Drilling Process

2.4. Hole Integrity Assessment

2.5. Chip Observation

3. Results and Discussion

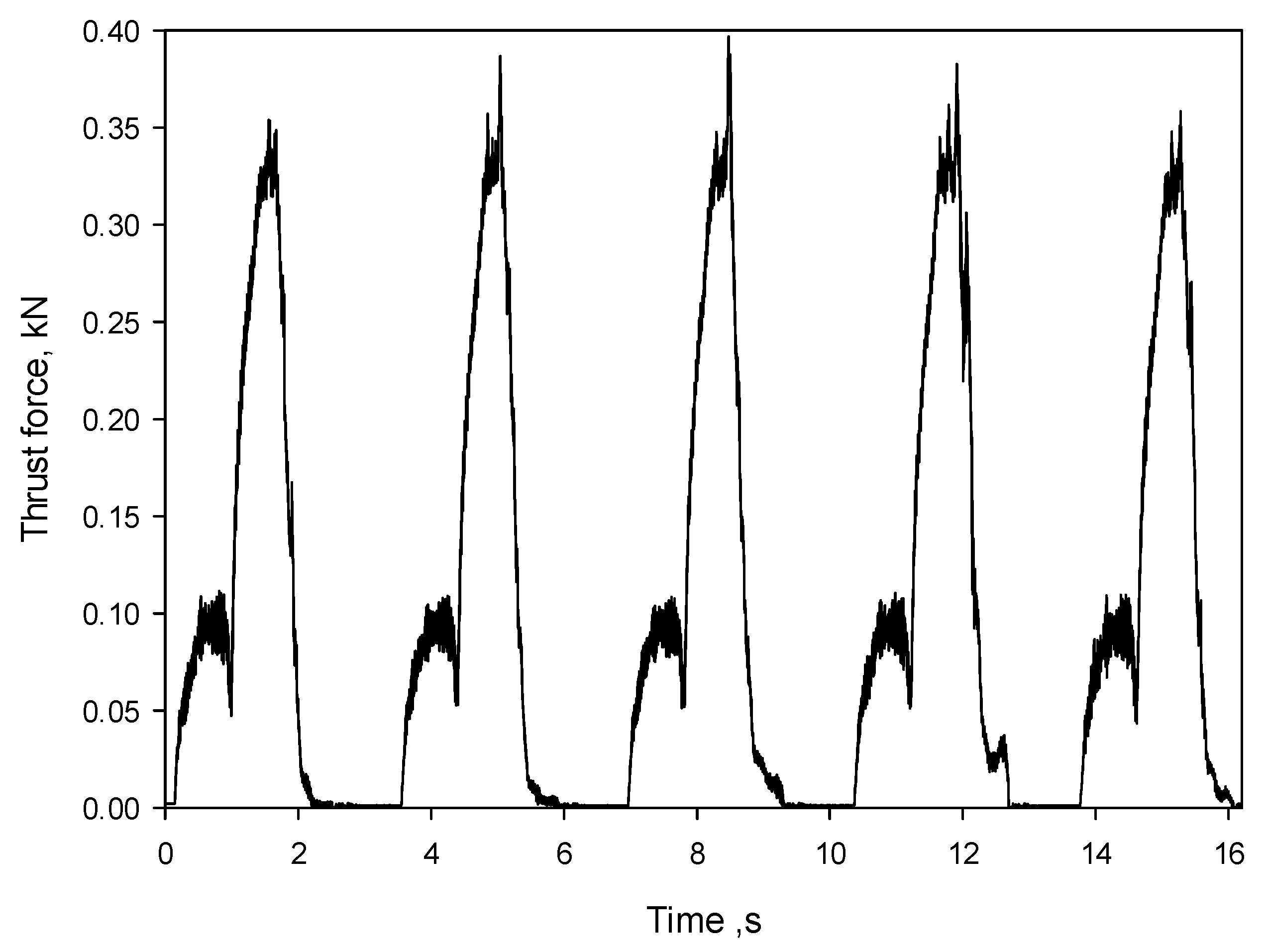

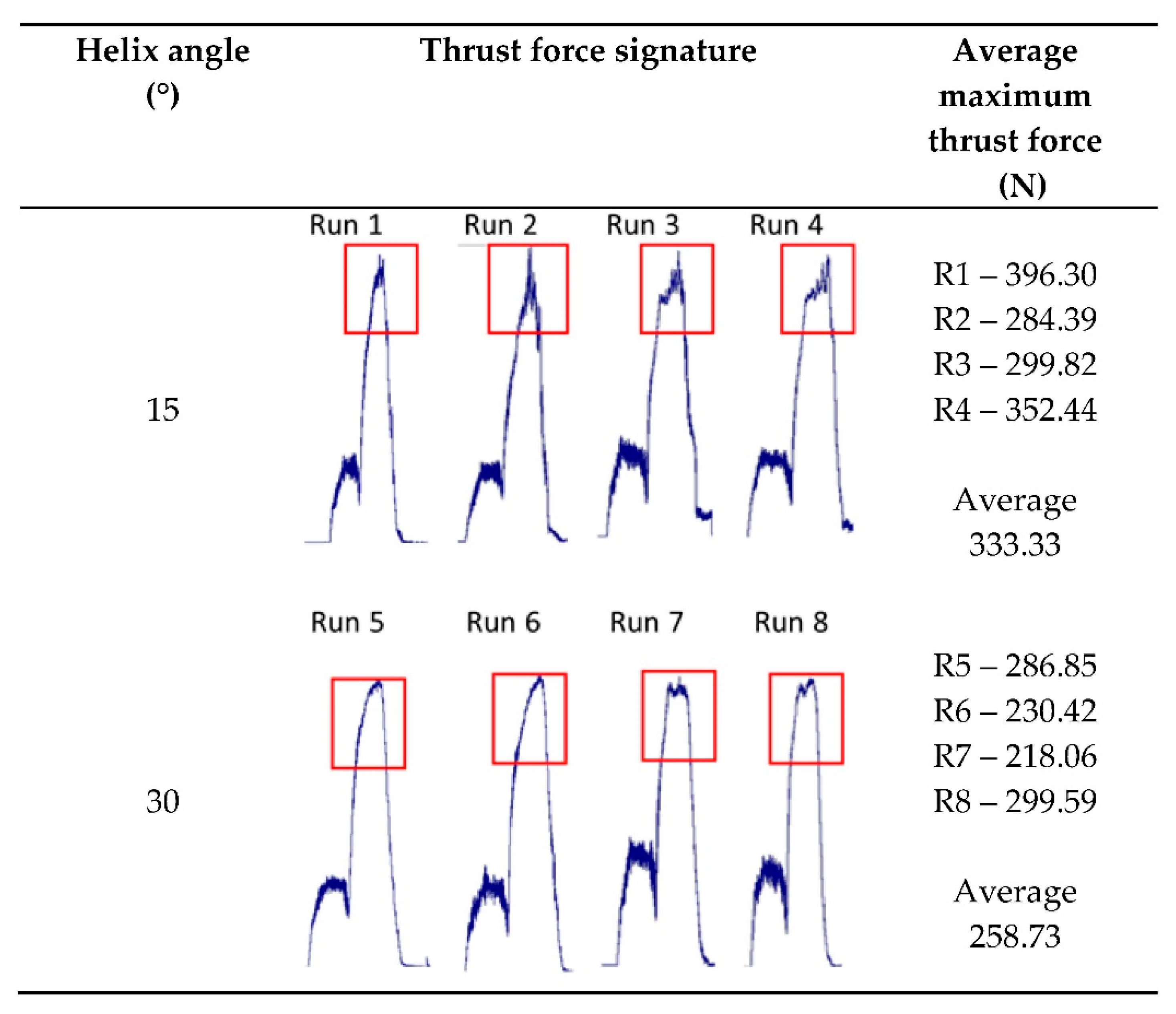

3.1. Thrust Force Analysis

3.2. Analysis of Variance

3.3. Hole Integrity Analysis

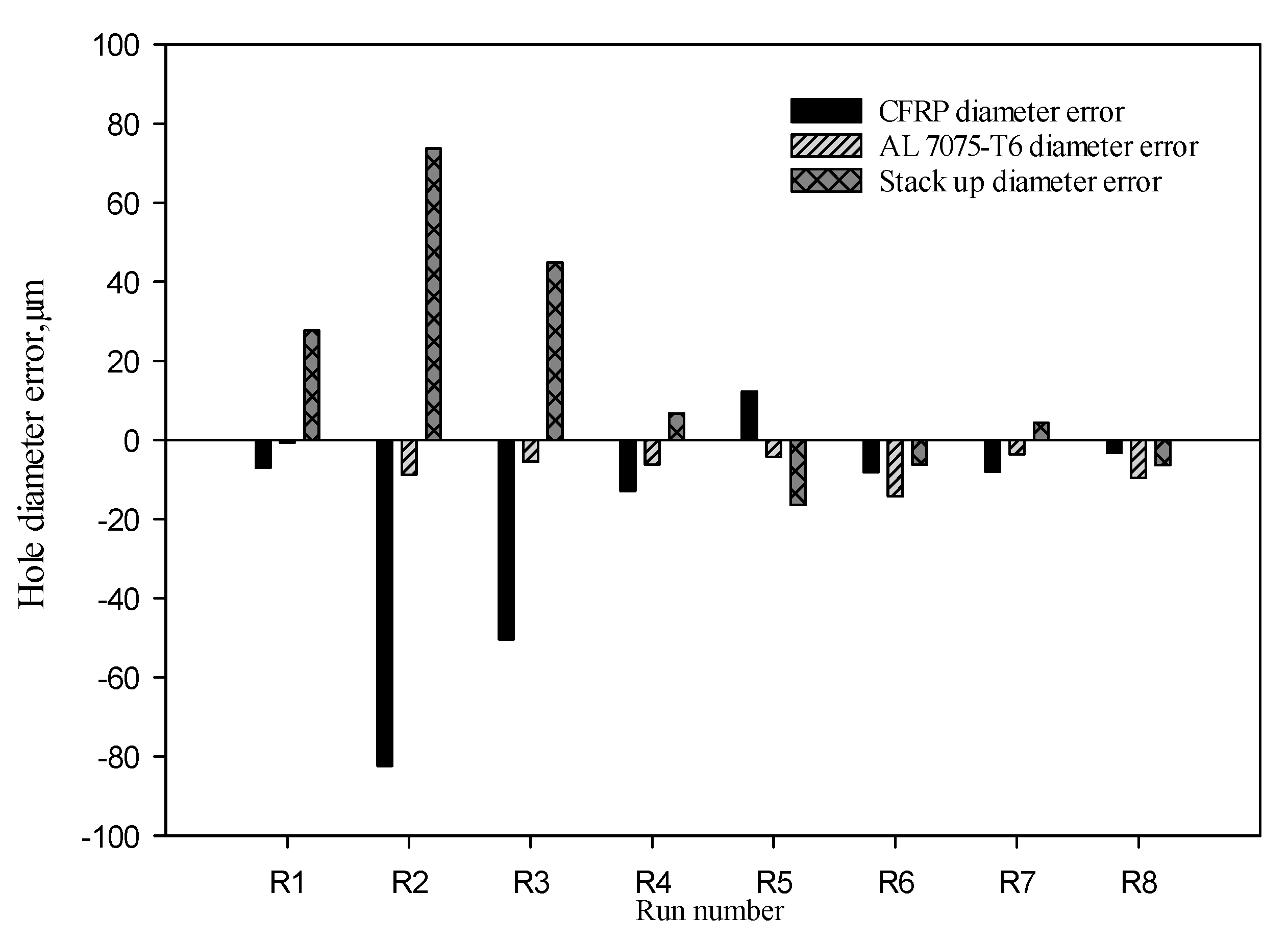

3.3.1. Hole Diameter Error

3.3.2. Hole Surface Roughness Analysis

3.4. Chip Formation Analysis

3.5. Comparison of Optimum Geometry to the Industry Standard

4. Conclusions

- From the eight runs, it is deduced that for drilling CFRP and Al7075-T6 stacked-up material, R7 has the best parameter combination, which includes a helix angle of 30°, primary clearance angle of 6°, point angle of 130°, chisel edge angle of 30°, speed of 2600 rev/min and feed rate of 0.05 mm/rev. This is supported by maximum thrust force, hole diameter error, surface roughness and chip formation analysis;

- The range of thrust force which conforms to the diameter specification is 91.54 N to 103.45 N for CFRP and 218.21 N to 347.04 N for Al7075-T6;

- For chip formation, the optimum parameters are found to be 2600 rev/min for spindle speed and 0.05 mm/rev for feed rate, whereby short broken chips and tight helical chips are formed. This aids the evacuation process during drilling, and hence provides a better surface finish;

- By comparing the customer requirements and optimum parameters obtained in this study, it is concluded that feed rate of 0.05 mm/rev is preferable for better drilling performance. These conditions also allow one to produce desirable chips during drilling.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gu, G.Y.; Kwon, D.J.; Wang, Z.J.; Kim, U.J.; Kim, I.H.; Kim, Y.S.; Park, J.M. Comparison of Optimum Drilling Conditions of Aircraft CFRP Composites using CVD and PCD Tools. In Proceedings of the 18th International Conference on Composite Materials, Jeju, Korea, 21–26 August 2011. [Google Scholar]

- Bañon, F.; Sambruno, A.; Fernandez-Vidal, S.; Fernandez-Vidal, S.R. One-shot drilling analysis of stack CFRP/UNS A92024 bonding by adhesive. Materials 2019, 12, 160. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mahdi, A.; Turki, Y.; Habak, M.; Salem, M.; Bouaziz, Z. Experimental study of thrust force and surface quality when drilling hybrid stacks. Int. J. Adv. Manuf. Technol. 2020, 107, 3981–3994. [Google Scholar] [CrossRef]

- Yarar, E.; Karabay, S. Investigation of the effects of ultrasonic assisted drilling on tool wear and optimization of drilling parameters. CIRP J. Manuf. Sci. Technol. 2020, 31, 265–280. [Google Scholar] [CrossRef]

- Pardo, A.; Majeed, M.; Heinemann, R. Process signals characterisation to enable adaptive drilling of aerospace stacks. Procedia CIRP 2020, 88, 479–484. [Google Scholar] [CrossRef]

- El Bouami, S.; Habak, M.; Franz, G.; Velasco, R.; Vantomme, P. Effect of tool geometry and cutting parameters on delamination and thrust forces in drilling CFRP/Al-Li. AIP Conf. Proc. 2016, 1769, 080012. [Google Scholar]

- Leeflang, P.S.; Verhoef, P.C.; Dahlström, P.; Freundt, T. Challenges and solutions for marketing in a digital era. Eur. Manag. J. 2014, 32, 1–12. [Google Scholar] [CrossRef]

- Chu, N.H.; Nguyen, V.D.; Ngo, Q.H. Machinability enhancements of ultrasonic-assisted deep drilling of aluminum alloys. Mach. Sci. Technol. 2020, 24, 112–135. [Google Scholar] [CrossRef]

- Hou, G.; Qiu, J.; Zhang, K.; Cao, S.; Cheng, H.; Luo, B.; Cheng, Y. Comparative tool wear and hole quality investigation in drilling of aerospace grade T800 CFRP using different external cooling lubricants. Int. J. Adv. Manuf. Technol. 2020, 106, 937–951. [Google Scholar] [CrossRef]

- Jia, Z.Y.; Zhang, C.; Wang, F.J.; Fu, R. A mechanistic prediction model for thrust force and torque during drilling of CFRP/Ti stacks. Int. J. Adv. Manuf. Technol. 2020, 106, 3105–3115. [Google Scholar] [CrossRef]

- Ma, F.J.; Zhu, X.L.; Kang, R.K.; Dong, Z.G.; Zou, S.Q. Study on the subsurface damages of glass fiber reinforced composites. Adv. Mater. Res. 2013, 797, 691–695. [Google Scholar] [CrossRef]

- Van Grootel, A.; Chang, J.; Wardle, B.L.; Olivetti, E. Manufacturing variability drives significant environmental and economic impact: The case of carbon fiber reinforced polymer composites in the aerospace industry. J. Clean. Prod. 2020, 261, 121087. [Google Scholar] [CrossRef]

- Khanna, N.; Pusavec, F.; Agrawal, C.; Krolczyk, G.M. Measurement and evaluation of hole attributes for drilling CFRP composites using an indigenously developed cryogenic machining facility. Measurement 2020, 154, 107504. [Google Scholar] [CrossRef]

- Jia, Z.Y.; Chen, C.; Wang, F.J.; Zhang, C.; Wang, Q. Analytical model for delamination of CFRP during drilling of CFRP/metal stacks. Int. J. Adv. Manuf. Technol. 2020, 106, 5099–5109. [Google Scholar] [CrossRef]

- Phadnis, V.A.; Makhdum, F.; Roy, A.; Silberschmidt, V.V. Drilling in carbon/epoxy composites: Experimental investigations and finite element implementation. Compos. Part A Appl. Sci. Manuf. 2013, 47, 41–51. [Google Scholar] [CrossRef] [Green Version]

- Fernandes, M.; Cook, C. Drilling of carbon composites using a one shot drill bit. Part I: Five stage representation of drilling and factors affecting maximum force and torque. Int. J. Mach. Tools Manuf. 2006, 46, 70–75. [Google Scholar] [CrossRef]

- Qi, Z.; Zhang, K.; Cheng, H.; Liu, S. Numerical simulation for delamination during drilling of CFRP/AL stacks. Mater. Res. INNO 2015, 19, 98–101. [Google Scholar] [CrossRef]

- Heisel, U.; Pfeifroth, T. Influence of point angle on drill hole quality and machining forces when drilling CFRP. Procedia CIRP 2012, 1, 471–476. [Google Scholar] [CrossRef] [Green Version]

- Li, S.; Zhang, D.; Liu, C.; Tang, H. Exit burr height mechanistic modeling and experimental validation for low-frequency vibration-assisted drilling of aluminum 7075-T6 alloy. J. Manuf. Process. 2020, 56, 350–361. [Google Scholar] [CrossRef]

- Aamir, M.; Tu, S.; Tolouei-Rad, M.; Giasin, K.; Vafadar, A. Optimization and modeling of process parameters in multi-hole simultaneous drilling using taguchi method and fuzzy logic approach. Materials 2020, 13, 680. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zitoune, R.; Krishnaraj, V.; Collombet, F. Study of drilling of composite material and aluminium stack. Compos. Struct. 2010, 92, 1246–1255. [Google Scholar] [CrossRef]

- Ahmed, Y.S.; Alam, M.S.; Arif, A.F.M.; Veldhuis, S.C. Use of acoustic emission and cutting force signals to monitor built-up edge formation in stainless steel turning. Int. J. Adv. Manuf. Technol. 2019, 103, 2257–2276. [Google Scholar] [CrossRef]

- Khanna, N.; Desai, K.; Sheth, A.; Larsen, J.Ø. CFRP machining on indigenously developing cryogenic machining facility: An initial study. Mater. Today Proc. 2019, 18, 4598–4604. [Google Scholar] [CrossRef]

- Montoya, M.; Calamaz, M.; Gehin, D.; Girot, F. Evaluation of the performance of coated and uncoated carbide tools in drilling thick CFRP/aluminium alloy stacks. Int. J. Adv. Manuf. Technol. 2013, 68, 2111–2120. [Google Scholar] [CrossRef] [Green Version]

- Zitoune, R.; Krishnaraj, V.; Collombet, F.; Le Roux, S. Experimental and numerical analysis on drilling of carbon fibre reinforced plastic and aluminium stacks. Compos. Struct. 2016, 146, 148–158. [Google Scholar] [CrossRef] [Green Version]

- Zitoune, R.; Cadorin, N.; Elambouacif, B.S.; Collombet, F.; Krishnaraj, V.; Bougherara, H. Influence of the double cone drill geometry on the holes quality during drilling multi-stack made of CFRP/Al. Int. J. Mater. Mech. Manuf. 2014, 2, 292–296. [Google Scholar]

- Zitoune, R.; Krishnaraj, V.; Almabouacif, B.S.; Collombet, F.; Sima, M.; Jolin, A. Influence of machining parameters and new nano-coated tool on drilling performance of CFRP/Aluminium sandwich. Compos. Part B Eng. 2012, 43, 1480–1488. [Google Scholar] [CrossRef]

- Neugebauer, R.; Ben-Hanan, U.; Ihlenfeldt, S.; Wabner, M.; Stoll, A. Acoustic emission as a tool for identifying drill position in fiber-reinforced plastic and aluminum stacks. Int. J. Mach. Tools Manuf. 2012, 57, 20–26. [Google Scholar] [CrossRef]

- Wertheim, R.; Ben-Hanan, U.; Ihlenfeldt, S.; Stoll, A.; Treppe, F.; Wabner, M. Acoustic emission for controlling drill position in fiber-reinforced plastic and metal stacks. CIRP Ann. 2012, 61, 75–78. [Google Scholar] [CrossRef]

- Wang, C.Y.; Chen, Y.H.; An, Q.L.; Cai, X.J.; Ming, W.W.; Chen, M. Drilling temperature and hole quality in drilling of CFRP/aluminum stacks using diamond coated drill. Int. J. Precis. Eng. Manuf. 2015, 16, 1689–1697. [Google Scholar] [CrossRef]

- Benezech, L.; Landon, Y.; Rubio, W. Study of manufacturing defects and tool geometry optimisation for multi-material stack drilling. In Advanced Materials Research; Trans Tech Publications Ltd.: Freienbach, Switzerland, 2012; Volume 423, pp. 1–11. [Google Scholar]

- Zhang, L.; Liu, Z.; Tian, W.; Liao, W. Experimental studies on the performance of different structure tools in drilling CFRP/Al alloy stacks. Int. J. Adv. Manuf. Technol. 2015, 81, 241–251. [Google Scholar] [CrossRef]

- El Bouami, S.; Habak, M.; Velasco, R.; Dos Santos, B.; Franz, G.; Vantomme, P. Tool geometry optimization for drilling CFRP/Ti6Al4V stacks with a lightning strike protection. AIP Conf. Proc. 2017, 1896, 090009-1–090009-6. [Google Scholar]

- Ashrafi, S.A.; Sharif, S.; Yazid, Y.M.; Davoudinejad, A. Assessment of Hole Quality and Thrust Force when Drilling CFRP/Al Stack Using Carbide Tools. In Applied Mechanics and Materials; Trans Tech Publications Ltd: Freienbach, Switzerland, 2012; Volume 234, pp. 28–33. [Google Scholar]

- Rahim, E.A.; Mohid, Z.; Hamzah, M.R.; Yusuf, A.F.; Rahman, N.A. Performance of tools design when helical milling on carbon fiber reinforced plastics (CFRP) aluminum (Al) stack. In Applied Mechanics and Materials; Trans Tech Publications Ltd.: Freienbach, Switzerland, 2014; Volume 465, pp. 1075–1079. [Google Scholar]

- Wei, Y.; An, Q.; Ming, W.; Chen, M. Effect of drilling parameters and tool geometry on drilling performance in drilling carbon fiber–reinforced plastic/titanium alloy stacks. Adv. Mech. Eng. 2016, 8, 1–16. [Google Scholar] [CrossRef] [Green Version]

- Gaitonde, V.N.; Karnik, S.R.; Achyutha, B.T.; Siddeswarappa, B. Methodology of Taguchi optimization for multi-objective drilling problem to minimize burr size. Int. J. Adv. Manuf. Technol. 2007, 34, 1–8. [Google Scholar] [CrossRef]

- SenthilKumar, M.; Prabukarthi, A.; Krishnaraj, V. Study on tool wear and chip formation during drilling carbon fiber reinforced polymer (CFRP)/titanium alloy (Ti6Al4 V) stacks. Procedia Eng. 2013, 64, 582–592. [Google Scholar] [CrossRef] [Green Version]

| Run | Helix Angle (°) | Primary Clearance (°) | Point Angle (°) | Edge Angle (°) | Speed (rev/min) | Feed Rate (mm/rev) |

|---|---|---|---|---|---|---|

| R1 | 15 | 6 | 110 | 45 | 2600 | 0.1 |

| R2 | 15 | 8 | 110 | 30 | 2600 | 0.05 |

| R3 | 15 | 6 | 130 | 45 | 1500 | 0.05 |

| R4 | 15 | 8 | 130 | 30 | 1500 | 0.1 |

| R5 | 30 | 6 | 110 | 30 | 1500 | 0.1 |

| R6 | 30 | 8 | 110 | 45 | 1500 | 0.05 |

| R7 | 30 | 6 | 130 | 30 | 2600 | 0.05 |

| R8 | 30 | 8 | 130 | 45 | 2600 | 0.1 |

| Run | Thrust Force | Ratio | |

|---|---|---|---|

| Fmax CFRP | Fmax Al7075-T6 | ||

| R1 | 109.6798 | 375.5436 | 3.4 |

| R2 | 87.6906 | 281.6864 | 3.2 |

| R3 | 105.3568 | 280.1942 | 2.7 |

| R4 | 118.6368 | 347.0388 | 2.9 |

| R5 | 99.8840 | 289.8348 | 2.9 |

| R6 | 91.5390 | 227.8538 | 2.5 |

| R7 | 103.4484 | 218.2104 | 2.1 |

| R8 | 126.1754 | 300.0978 | 2.4 |

| Source | Sum of Square | df | Mean Square | F Value | p-Value Prob > F | Percentage of Contribution |

|---|---|---|---|---|---|---|

| Model | 1142.06 | 3 | 380.69 | 66.23 | 0.0007 | - |

| Point angle | 527.27 | 1 | 525.27 | 91.38 | 0.007 | 45.09 |

| Chisel edge point | 66.65 | 1 | 66.65 | 11.60 | 0.0271 | 5.72 |

| Feed rate | 550.14 | 1 | 550.14 | 95.71 | 0.0006 | 47.22 |

| Residual | 22.99 | 4 | 5.75 | - | - | 1.97 |

| Cor Total | 1165.06 | 7 | - | - | - | 100 |

| Std Dev. | 2.40 | - | R² | - | 0.9803 | - |

| Mean | 105.30 | - | R² adjusted | - | 0.9655 | - |

| C.V% | 2.28 | - | R² predicted | - | 0.9211 | - |

| PRESS | 91.97 | - | Adequate precision | - | 22.748 | - |

| Source | Sum of Square | df | Mean Square | F Value | p-Value Prob > F | Percentage of Contribution |

|---|---|---|---|---|---|---|

| Model | 19,312.31 | 2 | 9656.15 | 89.09 | 0.0001 | - |

| Helix angle | 7716.93 | 1 | 7716.93 | 71.19 | 0.0004 | 38.87 |

| Feed rate | 11,595.38 | 1 | 11,595.38 | 106.98 | 0.0001 | 58.40 |

| Residual | 22.99 | 5 | 108.39 | - | - | 2.552 |

| Cor Total | 19,854.27 | 7 | - | - | - | 100 |

| Std Dev. | 10.41 | - | R² | - | 0.9727 | - |

| Mean | 290.06 | - | R² adjusted | - | 0.9618 | - |

| C.V% | 3.59 | - | R² predicted | - | 0.9301 | - |

| PRESS | 1387.41 | - | Adequate precision | - | 21.686 | - |

| CFRP | Al7075-T6 | ||||||

|---|---|---|---|---|---|---|---|

| Feed Rate (mm/rev) | Ave. Thrust Force (N) | Ave. Surface Roughness (µm) | Ave. Hole Diameter (mm) | Ave. Thrust Force (N) | Ave. Surface Roughness (µm) | Ave. Hole Diameter (mm) | |

| 0.05 | 103.74 | 0.244 | 4.8265 | 218.008 | 1.1986 | 4.8221 | |

| - | - | −0.008 | - | - | −0.0036 | Nom. | |

| - | - | 0.17 | - | - | 0.07 | Diff. (%) | |

| 0.1 | 127.302 | 0.8528 | 4.7975 | 274.894 | 1.6142 | 4.8368 | |

| - | - | 0.0225 | - | - | −0.0168 | Nom. | |

| - | - | 0.47 | - | - | 0.35 | Diff. (%) | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hassan, M.H.; Abdullah, J.; Franz, G.; Shen, C.Y.; Mahmoodian, R. Effect of Twist Drill Geometry and Drilling Parameters on Hole Quality in Single-Shot Drilling of CFRP/Al7075-T6 Composite Stack. J. Compos. Sci. 2021, 5, 189. https://doi.org/10.3390/jcs5070189

Hassan MH, Abdullah J, Franz G, Shen CY, Mahmoodian R. Effect of Twist Drill Geometry and Drilling Parameters on Hole Quality in Single-Shot Drilling of CFRP/Al7075-T6 Composite Stack. Journal of Composites Science. 2021; 5(7):189. https://doi.org/10.3390/jcs5070189

Chicago/Turabian StyleHassan, Muhammad Hafiz, Jamaluddin Abdullah, Gérald Franz, Chim Yi Shen, and Reza Mahmoodian. 2021. "Effect of Twist Drill Geometry and Drilling Parameters on Hole Quality in Single-Shot Drilling of CFRP/Al7075-T6 Composite Stack" Journal of Composites Science 5, no. 7: 189. https://doi.org/10.3390/jcs5070189

APA StyleHassan, M. H., Abdullah, J., Franz, G., Shen, C. Y., & Mahmoodian, R. (2021). Effect of Twist Drill Geometry and Drilling Parameters on Hole Quality in Single-Shot Drilling of CFRP/Al7075-T6 Composite Stack. Journal of Composites Science, 5(7), 189. https://doi.org/10.3390/jcs5070189