Enhanced Tensile Strength of Monolithic Epoxy with Highly Dispersed TiO2-Graphene Nanocomposites

Abstract

:1. Introduction

2. Materials and Methods

2.1. Raw Materials

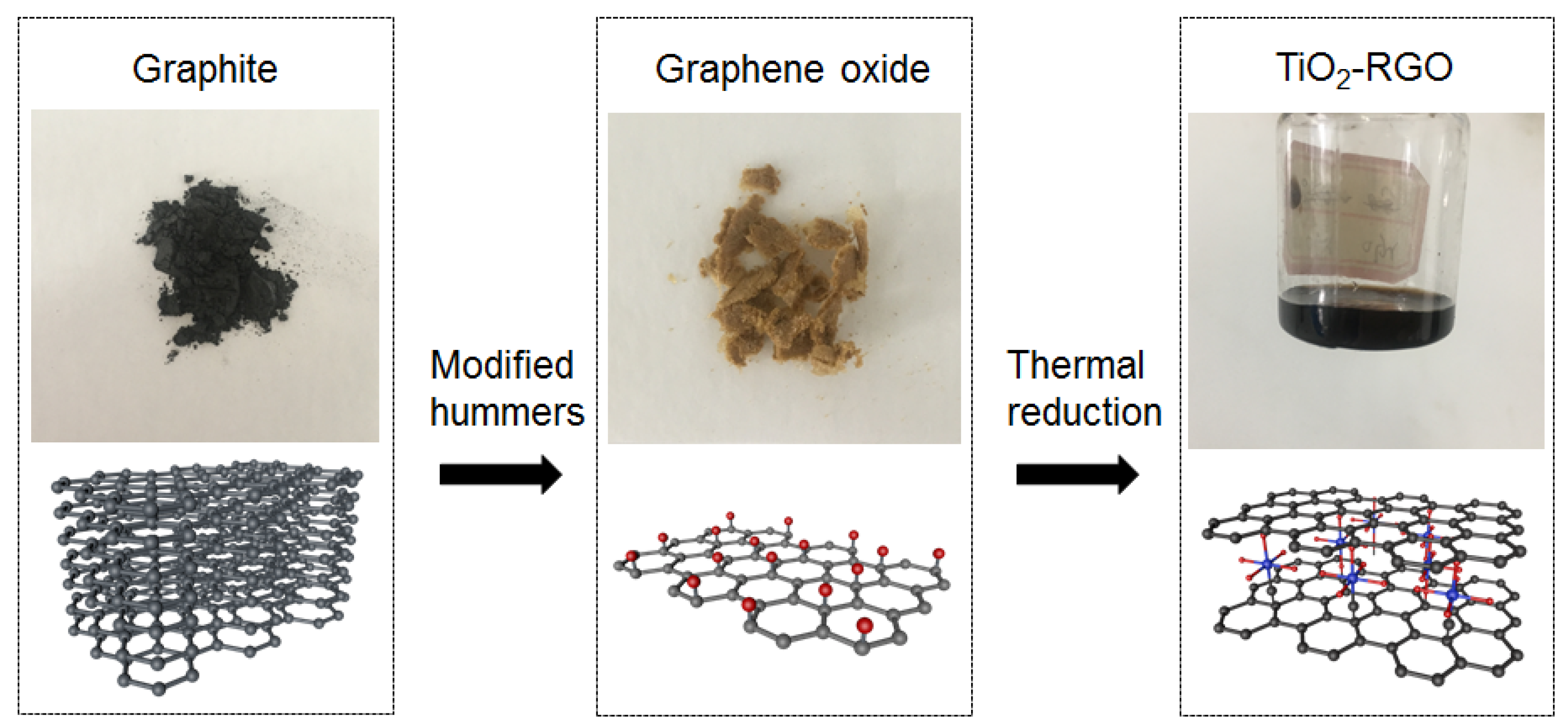

2.2. Preparation of GO, RGO and TiO2-RGO Nanocomposites

2.3. Fabrication of TiO2-RGO-EP Composites

2.4. Material Characterization & Performance Assessment

3. Results and Discussion

3.1. Morphological Features of RGO, TiO2-RGO and TiO2-RGO-EP

3.2. FT-IR and Raman Analysis of TiO2-RGO Nanoparticles

3.3. Mechanical and Morphological Properties of TiO2-RGO-EP Composites

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Bai, H.; Li, C.; Shi, G. Functional composite materials based on chemically converted graphene. Adv. Mater. 2011, 23, 1089–1115. [Google Scholar] [CrossRef]

- Geim, A.K.; Novoselov, K.S. The rise of graphene. Nat. Mater. 2007, 6, 183–191. [Google Scholar] [CrossRef]

- Geim, A.K. Graphene: Status and Prospects. Science 2009, 324, 1530–1534. [Google Scholar] [CrossRef] [Green Version]

- Cai, W.; Zhu, Y.; Li, X.; Piner, R.D.; Ruoff, R.S. Large area few-layer graphene/graphite films as transparent thin conducting electrodes. Appl. Phys. Lett. 2009, 95, 125432. [Google Scholar] [CrossRef]

- Zhu, Y.; Murali, S.; Cai, W.; Li, X.; Suk, J.W.; Potts, J.R.; Ruoff, R.S. Graphene and graphene oxide: Synthesis, properties, and applications. Adv. Mater. 2010, 22, 3906–3924. [Google Scholar] [CrossRef] [PubMed]

- Robinson, J.T.; Perkins, F.K.; Snow, E.S.; Wei, Z.; Sheehan, P. Reduced Graphene Oxide Molecular Sensors. Nano Lett. 2008, 8, 3137–3140. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wang, D.; Choi, D.; Li, J.; Yang, Z.; Nie, Z.; Kou, R.; Hu, D.; Wang, C.; Saraf, L.V.; Zhang, J.; et al. Self-Assembled TiO2–Graphene Hybrid Nanostructures for Enhanced Li-Ion Insertion. ACS Nano 2009, 3, 907–914. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zacharia, R.; Ulbricht, H.; Hertel, T. Interlayer cohesive energy of graphite from thermal desorption of polyaromatic hydrocarbons. Phys. Rev. B 2004, 69, 155406-1–155406-7. [Google Scholar] [CrossRef] [Green Version]

- Huang, G.; Chen, T.; Chen, W.; Wang, Z.; Chang, K.; Ma, L.; Huang, F.; Chen, D.; Lee, J.Y. Graphene-like MoS(2)/graphene composites: Cationic surfactant-assisted hydrothermal synthesis and electrochemical reversible storage of lithium. Small 2013, 9, 3693–3703. [Google Scholar] [CrossRef] [PubMed]

- Lotya, M.; King, P.J.; Khan, U.; De, S.; Coleman, J. High-Concentration, Surfactant-Stabilized Graphene Dispersions. ACS Nano 2010, 4, 3155. [Google Scholar] [CrossRef]

- Stankovich, S.; Piner, R.D.; Chen, X.; Wu, N.; Nguyen, S.T.; Ruoff, R.S. Stable aqueous dispersions of graphitic nanoplatelets via the reduction of exfoliated graphite oxide in the presence of poly(sodium 4-styrenesulfonate). J. Mater. Chem. 2006, 16, 155–158. [Google Scholar] [CrossRef]

- Liang, Y.; Wu, D.; Feng, X.; Müllen, K. Dispersion of Graphene Sheets in Organic Solvent Supported by Ionic Interactions. Adv. Mater. 2009, 21, 1679–1683. [Google Scholar] [CrossRef]

- Cohn, A.P.; Share, K.; Carter, R.; Oakes, L.; Pint, C.L. Ultrafast Solvent-Assisted Sodium Ion Intercalation into Highly Crystalline Few-Layered Graphene. Nano Lett. 2016, 16, 543–548. [Google Scholar] [CrossRef]

- Si, Y.; Samulski, E.T. Synthesis of water soluble graphene. Nano Lett. 2008, 8, 1679–1682. [Google Scholar] [CrossRef]

- Shahzadi, K.; Zhang, X.; Mohsin, I.; Ge, X.; Jiang, Y.; Peng, H.; Liu, H.; Li, H.; Mu, X. Reduced Graphene Oxide/Alumina, A Good Accelerant for Cellulose-Based Artificial Nacre with Excellent Mechanical, Barrier, and Conductive Properties. ACS Nano 2017, 11, 5717–5725. [Google Scholar] [CrossRef]

- Liu, W.-W.; Xia, B.-Y.; Wang, X.-X.; Wang, J.-N. Exfoliation and dispersion of graphene in ethanol-water mixtures. Front. Mater. Sci. 2012, 6, 176–182. [Google Scholar] [CrossRef]

- Hernandez, Y.; Nicolosi, V.; Lotya, M.; Blighe, F.M.; Sun, Z.; De, S.; McGovern, I.T.; Holland, B.; Byrne, M.; Gun’Ko, Y.; et al. High-yield production of graphene by liquid-phase exfoliation of graphite. Nat. Nanotechnol. 2008, 3, 563–568. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hackman, I.; Hollaway, L. Epoxy-layered silicate nanocomposites in civil engineering. Compos. Part A Appl. Sci. Manuf. 2006, 37, 1161–1170. [Google Scholar] [CrossRef]

- Monteverde, F.; Scatteia, L. Resistance to Thermal Shock and to Oxidation of Metal Diborides–SiC Ceramics for Aerospace Application. J. Am. Ceram. Soc. 2007, 90, 1130–1138. [Google Scholar] [CrossRef]

- Suh, S.W.; Kim, J.J.; Kim, S.H.; Park, B.K. Effect of PI film surface on printing of Pd(II) catalytic ink for electroless copper plating in the printed electronics. J. Ind. Eng. Chem. 2012, 18, 290–294. [Google Scholar] [CrossRef]

- Huang, J.K.; Young, W. The mechanical, hygral, and interfacial strength of continuous bamboo fiber reinforced epoxy composites. Compos. Part B Eng. 2019, 166, 272–283. [Google Scholar] [CrossRef]

- Kalali, E.N.; Hu, Y.; Wang, X.; Song, L.; Xing, W. Highly-aligned cellulose fibers reinforced epoxy composites derived from bulk natural bamboo. Ind. Crops Prod. 2019, 129, 434–439. [Google Scholar] [CrossRef]

- Mohan, T.P.; Kanny, K. Compressive characteristics of unmodified and nanoclay treated banana fiber reinforced epoxy composite cylinders. Compos. Part B Eng. 2019, 169, 118–125. [Google Scholar] [CrossRef]

- Ansari, F.; Sjöstedt, A.; Larsson, P.T.; Berglund, L.A.; Wågberg, L. Hierarchical wood cellulose fiber/epoxy biocomposites: Materials design of fiber porosity and nanostructure. Compos. Part A Appl. Sci. Manuf. 2015, 74, 60–68. [Google Scholar] [CrossRef]

- Capela, C.; Oliveira, S.E.; Ferreira, J.A.M. Fatigue behavior of short carbon fiber reinforced epoxy composites. Compos. Part B Eng. 2019, 164, 191–197. [Google Scholar] [CrossRef]

- Guo, J.; Wang, Z.; Tong, L.; Lv, H.; Liang, W. Shape memory and thermo-mechanical properties of shape memory polymer/carbon fiber composites. Compos. Part A Appl. Sci. Manuf. 2015, 76, 162–171. [Google Scholar] [CrossRef]

- Xiao, C.; Tan, Y.; Wang, X.; Gao, L.; Wang, L.; Qi, Z. Study on interfacial and mechanical improvement of carbon fiber/epoxy composites by depositing multi-walled carbon nanotubes on fibers. Chem. Phys. Lett. 2018, 703, 8–16. [Google Scholar] [CrossRef]

- Sangermano, M.; D’Anna, A.; Marro, C.; Klikovits, N.; Liska, R. UV-activated frontal polymerization of glass fibre reinforced epoxy composites. Compos. Part B Eng. 2018, 143, 168–171. [Google Scholar] [CrossRef]

- Rajaei, M.; Kim, N.; Bickerton, S.; Bhattacharyya, D. A comparative study on effects of natural and synthesised nano-clays on the fire and mechanical properties of epoxy composites. Compos. Part B Eng. 2019, 165, 65–74. [Google Scholar] [CrossRef]

- Gu, H.; Zhang, H.; Ma, C.; Xu, X.; Wang, Y.; Wang, Z.; Wei, R.; Liu, H.; Liu, C.; Shao, Q.; et al. Trace electrosprayed nanopolystyrene facilitated dispersion of multiwalled carbon nanotubes: Simultaneously strengthening and toughening epoxy. Carbon 2019, 142, 131–140. [Google Scholar] [CrossRef]

- Zhao, R.G.; Luo, W. Fracture surface analysis on nano-Si2/epoxy composite. Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process. 2008, 483, 313–315. [Google Scholar] [CrossRef]

- Ma, J.; Meng, Q.; Zaman, I.; Zhu, S.; Michelmore, A.; Kawashima, N.; Wang, C.-H.; Kuan, H. Development of polymer composites using modified, high-structural integrity graphene platelets. Compos. Sci. Technol. 2014, 91, 82–90. [Google Scholar] [CrossRef]

- Atif, R.; Shyha, I.; Inam, F. Mechanical, Thermal, and Electrical Properties of Graphene-Epoxy Nanocomposites—A Review. Polymers 2016, 8, 281. [Google Scholar] [CrossRef]

- Hummers, W.S., Jr.; Offeman, R.E. Preparation of Graphitic Oxide. J. Am. Chem. Soc. 1958, 80, 1339. [Google Scholar] [CrossRef]

- Kusiak-Nejman, E.; Wanag, A.; Kowalczyk, Ł.; Kapica-Kozar, J.; Colbeau-Justin, C.; Medrano MG, M.; Morawski, A.W. Graphene oxide-TiO2 and reduced graphene oxide-TiO2 nanocomposites: Insight in charge-carrier lifetime measurements. Catal. Today 2016, 287, 189–195. [Google Scholar] [CrossRef]

- Stankovich, S.; Dikin, D.A.; Dommett, G.H.B.; Kohlhaas, K.M.; Zimney, E.J.; Stach, E.A.; Piner, R.D.; Nguyen, S.; Ruoff, R.S. Graphene-based composite materials. Nature 2006, 442, 282–286. [Google Scholar] [CrossRef]

- Bai, X.; Zhang, X.; Hua, Z.; Ma, W.; Dai, Z.; Huang, X.; Gu, H. Uniformly distributed anatase TiO2 nanoparticles on graphene: Synthesis, characterization, and photocatalytic application. J. Alloys Compd. 2014, 599, 10–18. [Google Scholar] [CrossRef]

- Prolongo, S.; Moriche, R.; Jiménez-Suárez, A.; Sanchez, M.; Ureña, A. Advantages and disadvantages of the addition of graphene nanoplatelets to epoxy resins. Eur. Polym. J. 2014, 61, 206–214. [Google Scholar] [CrossRef]

| Raw Material | Flake Graphite | NaNO3 | H2SO4 | KMnO4 |

|---|---|---|---|---|

| dosage | 2.0 g | 1.5 g | 67.5 mL | 9.0 g |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Guo, S.; Dong, B.; Xing, F. Enhanced Tensile Strength of Monolithic Epoxy with Highly Dispersed TiO2-Graphene Nanocomposites. J. Compos. Sci. 2021, 5, 191. https://doi.org/10.3390/jcs5070191

Wang Y, Guo S, Dong B, Xing F. Enhanced Tensile Strength of Monolithic Epoxy with Highly Dispersed TiO2-Graphene Nanocomposites. Journal of Composites Science. 2021; 5(7):191. https://doi.org/10.3390/jcs5070191

Chicago/Turabian StyleWang, Yanshuai, Siyao Guo, Biqin Dong, and Feng Xing. 2021. "Enhanced Tensile Strength of Monolithic Epoxy with Highly Dispersed TiO2-Graphene Nanocomposites" Journal of Composites Science 5, no. 7: 191. https://doi.org/10.3390/jcs5070191

APA StyleWang, Y., Guo, S., Dong, B., & Xing, F. (2021). Enhanced Tensile Strength of Monolithic Epoxy with Highly Dispersed TiO2-Graphene Nanocomposites. Journal of Composites Science, 5(7), 191. https://doi.org/10.3390/jcs5070191