Fabrication of h-MoO3 Nanorods and the Properties of the MoO3/WEP Composite Coatings Research

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Synthesis of MoO3 Composite Coating

2.3. Characterization of MoO3

2.4. Electrochemistry Anticorrosion Testing of MoO3/WEP Coating

3. Results and Discussion

3.1. Optimization of MoO3 Synthesis: SEM Morphology

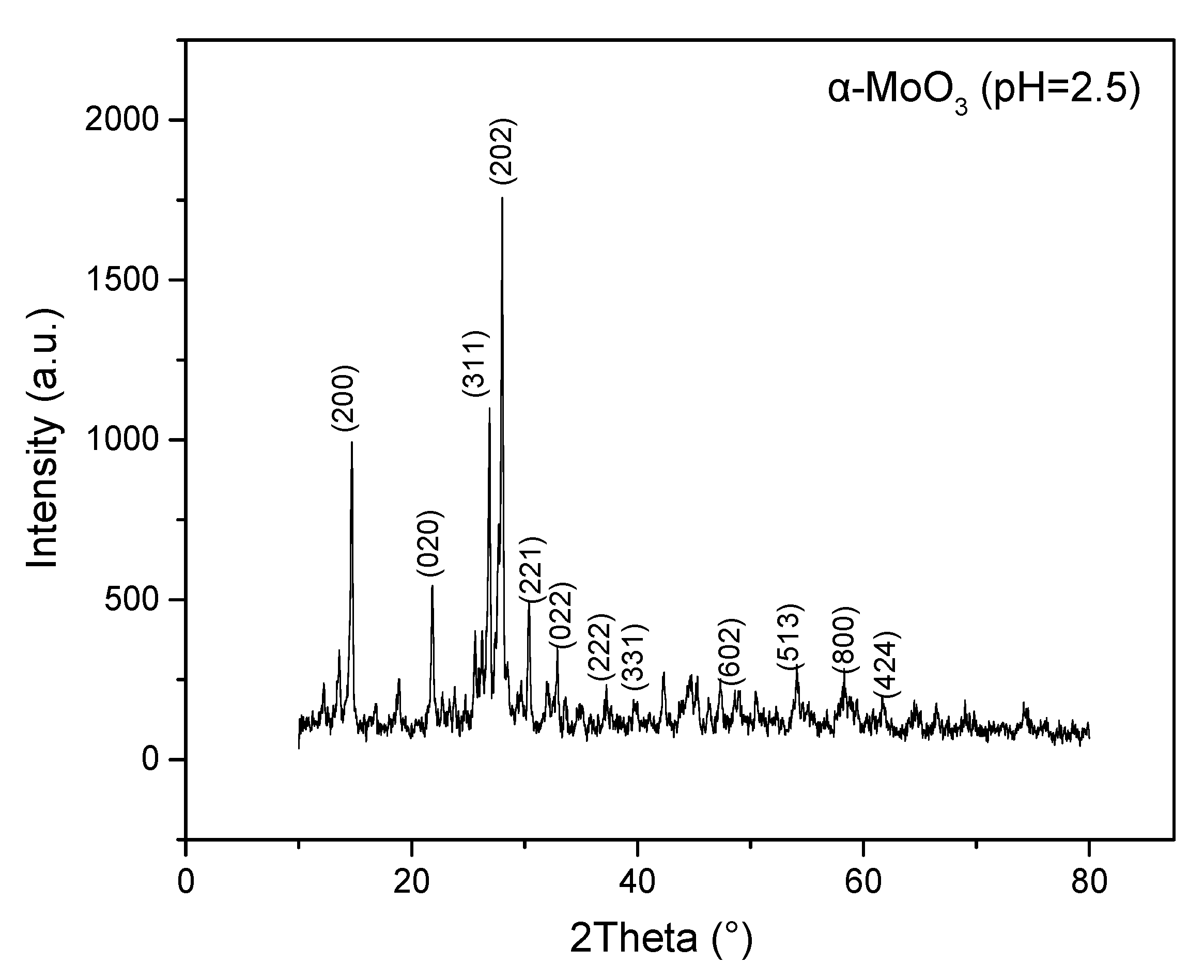

3.2. Optimization of MoO3 Synthesis: XRD Characterization

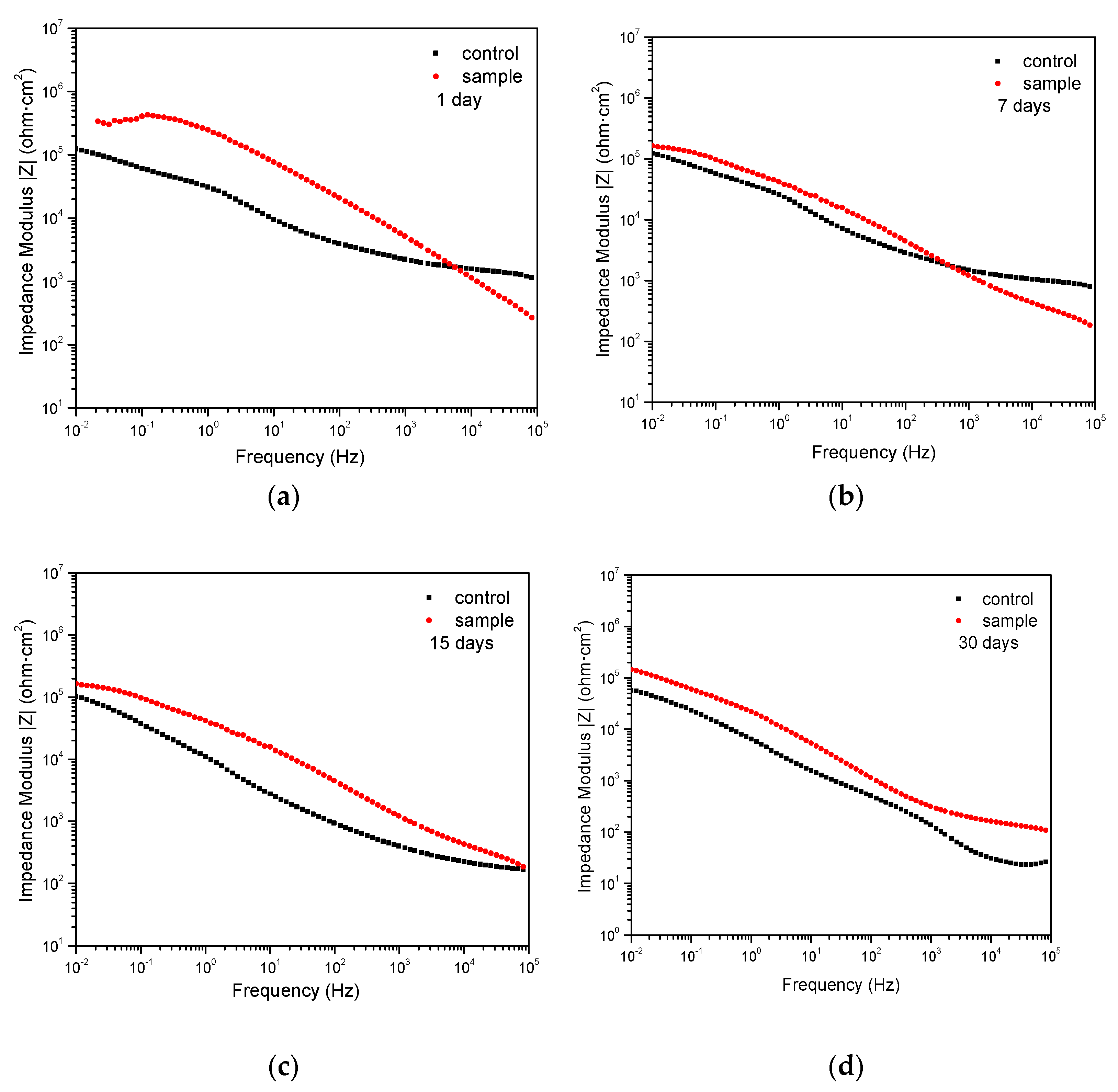

3.3. Electrochemical Impedance Spectroscopy (EIS) Testing

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Hays, G.F. World Corrosion Organization, Corrodia, Fall. 2010. Available online: http://events.nace.org/euro/corrodia/Fall_2010/wco.asp (accessed on 28 January 2016).

- Wu, X.; Zheng, S. Transparent Icephobic Coatings Using Bio-Based Epoxy Resin. Mater. Des. 2018, 140, 516–523. [Google Scholar] [CrossRef] [Green Version]

- Singh, P.K.; Modanwal, R.P. Fabrication and Mechanical Characterization of Glass Fiber/Al2O3 Hybrid-Epoxy Composite. Sādhanā 2021, 46, 1–10. [Google Scholar] [CrossRef]

- Sviridova, T.V.; Logvinovich, A.S. Electrochemical Growing of Ni-MoO3 Nanocomposite Coatings Via Redox Mechanism. Surf. Coat. Technol. 2017, 319, 6–11. [Google Scholar] [CrossRef]

- Slawinski, W.A.; Fjellvag, O.S. A Novel Polytype—the Stacking Fault Based Gamma-MoO3 Nanobelts. Acta Crystallogr B Struct. Sci. Cryst. Eng. Mater. 2016, 72, 201–208. [Google Scholar] [CrossRef] [PubMed]

- Zaman, I.; Phan, T.T.; Kuan, H.-C.; Meng, Q.; La, L.T.B.; Luong, L.; Youssf, O.; Ma, J. Epoxy/graphene platelets nanocomposites with two levels of interfacestrength. Polymer 2011, 52, 1603–1611. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Q.; Xu, Y.; Wen, Z. Influence of water-borne epoxy resin content on performance of waterborne epoxy resin compound SBR modified emulsified asphalt for tack coat. Constr. Build. Mater. 2017, 153, 774–782. [Google Scholar] [CrossRef]

- Moghaddam, A.R.; Ranjbar, Z.; Sundararaj, U.; Jannesari, A.; Kamkar, M. A novel electrically conductive water borne epoxy nanocomposite coating based on graphene: Facile method and high efficient graphene dispersion. Prog. Org. Coat. 2019, 136, 105223. [Google Scholar] [CrossRef]

- Fang, Y.; Wang, P.; Sun, L.; Wang, L. The Effect of Graphene Nanofiller on the Surface Structure and Performance of Epoxy Resin-Polyhedral Oligomeric Silsesquioxane (Ep-Poss). Nanomaterials 2021, 11, 841. [Google Scholar] [CrossRef] [PubMed]

- Shukla, M.K.; Sharma, K. Effect of Carbon Nanofillers on the Mechanical and Interfacial Properties of Epoxy Based Nanocomposites: A Review. Polym. Sci. 2019, 61, 439–460. [Google Scholar]

- Fihri, A.; Abdullatif, D. Decorated Fibrous Silica Epoxy Coating Exhibiting Anti-Corrosion Properties. Prog. Org. Coat. 2019, 127, 110–116. [Google Scholar] [CrossRef]

- Liu, H.; Wang, X. Durable Molybdenum Oxide Coated Solid-Phase Microextraction Fiber for Highly Selective and Efficient Extraction of Polycyclic Aromatic Hydrocarbons in Water. J. Sep. Sci. 2019, 42, 1878–1885. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Madhavi, S.; Lou, X.W. Ultralong α-MoO3 Nanobelts: Synthesis and Effect of Binder Choice on Their Lithium Storage Properties. J. Phys. Chem. C 2012, 116, 12508–12513. [Google Scholar] [CrossRef]

- Vipin, K.; Xu, W. Formation of hexagonal-molybdenum trioxide (h-MoO₃) nanostructures and their pseudocapacitive behavior. Nanoscale 2015, 21, 11777–11786. [Google Scholar]

- Hang, N.N.; Enrico, T.N.; Bryan, G.A.; Debora, F.R. Designing polymeric adhesives for antimicrobial materials: Poly(ethylene imine) polymer, graphene, graphene oxide and molybdenum trioxide-a biomimetic approach. J. Mater. Chem. B 2017, 28, 6616–6628. [Google Scholar]

- Rajaeiyan, A.; Bagheri-Mohagheghi, M.M. Comparison of sol-gel and co-precipitation methods on the structural properties and phase transformation of γ and α-Al2O3 nanoparticles. Adv. Manuf. 2013, 1, 176–182. [Google Scholar] [CrossRef]

- Kumar, S.; Singh, A.; Singh, R.; Singh, S.; Kumar, P.; Kumar, R. Facile h-MoO3 synthesis for NH3 gas sensing application at moderate operating temperature. Sens. Actuators B Chem. 2020, 325, 1–21. [Google Scholar] [CrossRef]

- Jittiarporn, P.; Sikong, L.; Kooptarnond, K.; Taweepreda, W.; Chooto, P.; Khangkhamano, M. Synthesis of h-MoO3 and (NH4)2Mo4O13 using precipitation method at various pH values and their photochromic properties. App. Mecha. Mater. 2016, 835, 34–41. [Google Scholar] [CrossRef]

- Hinderliter, B.R.; Croll, S.G.; Tallman, D.E.; Su, Q.; Bierwagen, G.P. Interpretation of EIS data from accelerated exposure of coated metals based on modeling of coating physical properties. Electrochim. Acta 2006, 51, 4505–4515. [Google Scholar] [CrossRef]

- Sarkar, N.; Sahoo, G.; Das, R.; Prusty, G.; Sahu, D.; Swain, S. Anticorrosion performance of three-dimensional hierarchical PANI@BN nanohybrids. Ind. Eng. Chem. Res. 2016, 55, 2921–2931. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, Y.; Song, C.; Chen, Z.; Zhou, Q. Fabrication of h-MoO3 Nanorods and the Properties of the MoO3/WEP Composite Coatings Research. J. Compos. Sci. 2021, 5, 207. https://doi.org/10.3390/jcs5080207

Zhou Y, Song C, Chen Z, Zhou Q. Fabrication of h-MoO3 Nanorods and the Properties of the MoO3/WEP Composite Coatings Research. Journal of Composites Science. 2021; 5(8):207. https://doi.org/10.3390/jcs5080207

Chicago/Turabian StyleZhou, Ying, Cuihuan Song, Zhixiang Chen, and Qixin Zhou. 2021. "Fabrication of h-MoO3 Nanorods and the Properties of the MoO3/WEP Composite Coatings Research" Journal of Composites Science 5, no. 8: 207. https://doi.org/10.3390/jcs5080207

APA StyleZhou, Y., Song, C., Chen, Z., & Zhou, Q. (2021). Fabrication of h-MoO3 Nanorods and the Properties of the MoO3/WEP Composite Coatings Research. Journal of Composites Science, 5(8), 207. https://doi.org/10.3390/jcs5080207