Mechanical and Microstructural Response of Aluminum Composites Reinforced with Ceramic Micro-Particles

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. Morphological Analysis of Powders

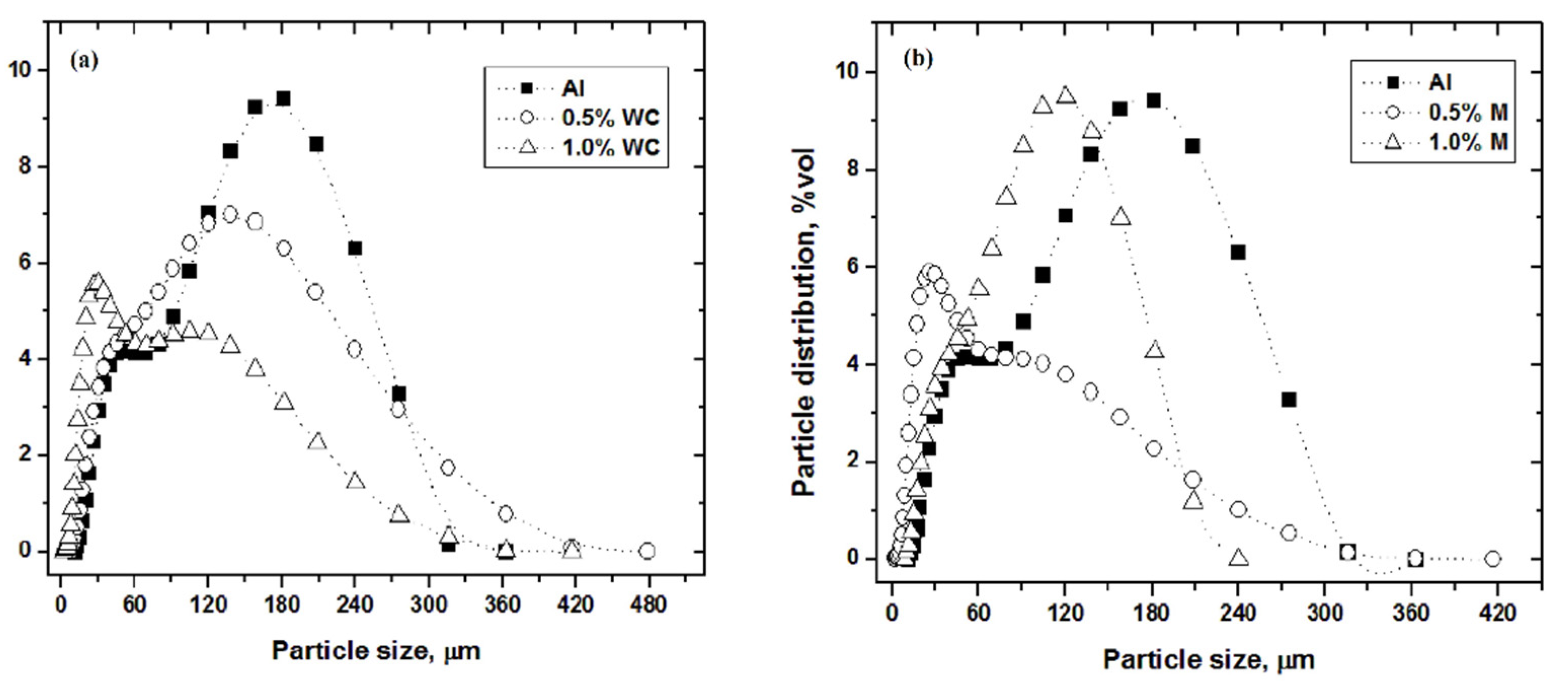

3.2. Size Distribution of Powders

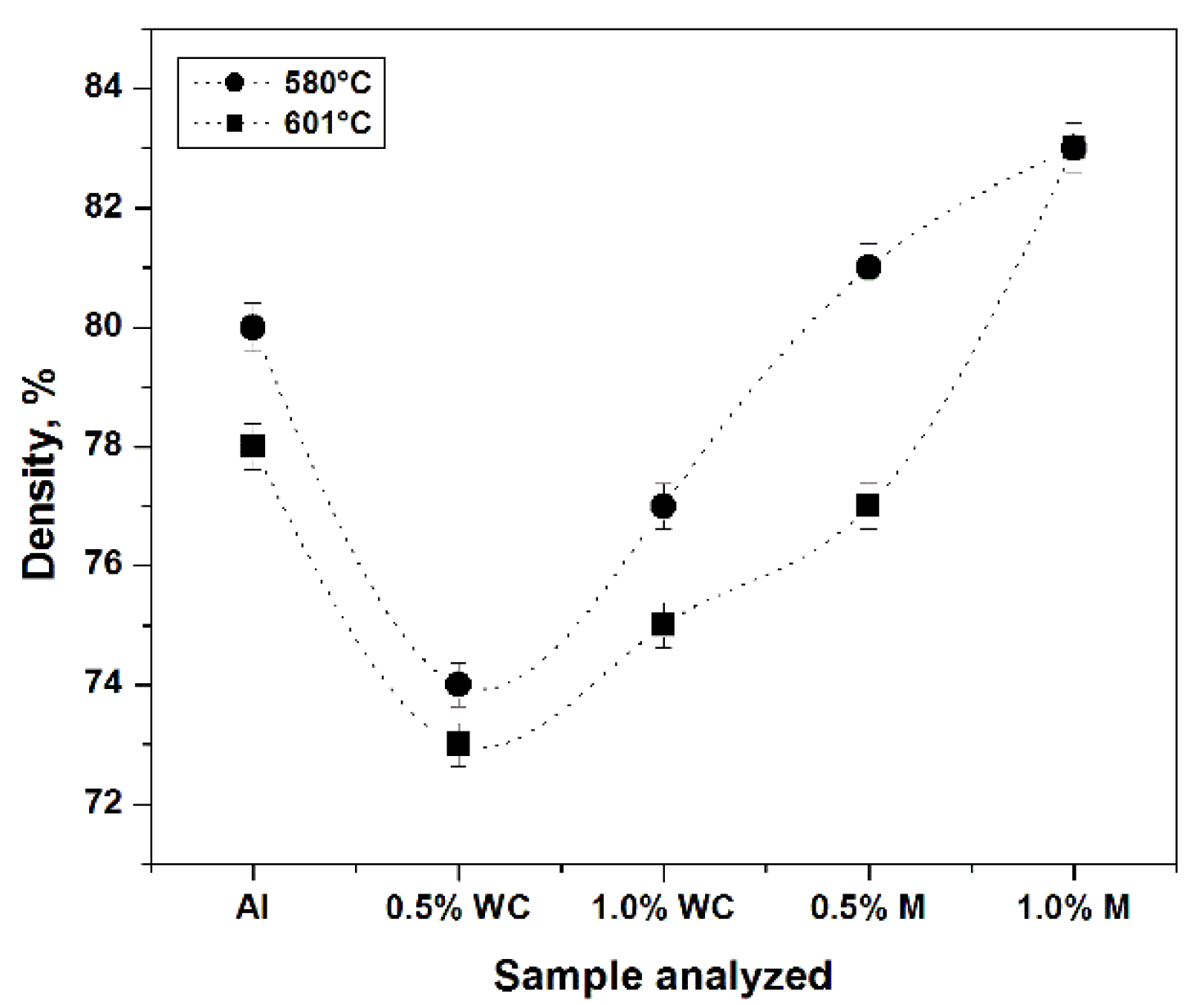

3.3. Density

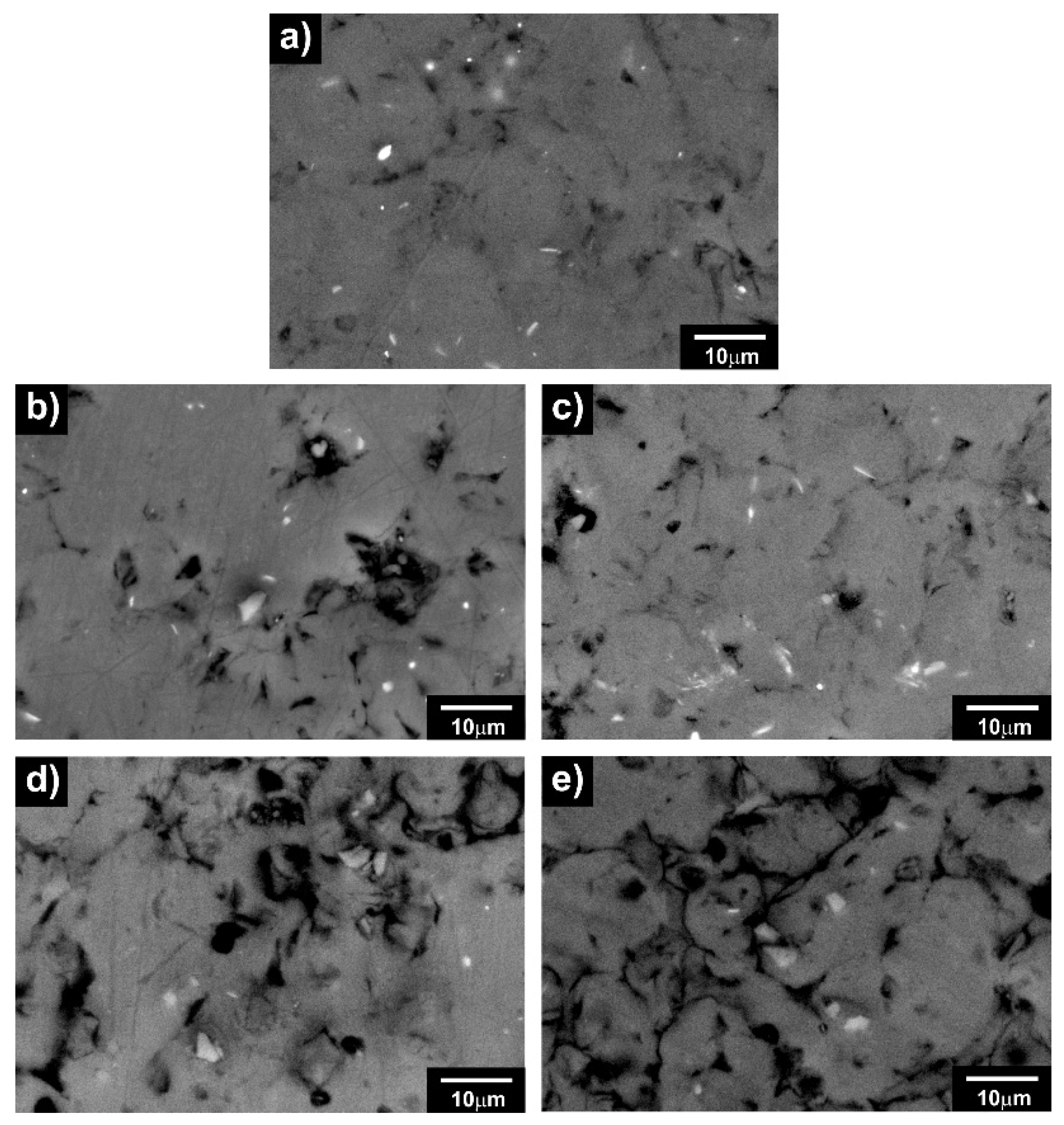

3.4. Microstructure

3.5. Mechanical Properties

3.5.1. Microhardness

3.5.2. Elastic Modulus

3.5.3. Bending Strength

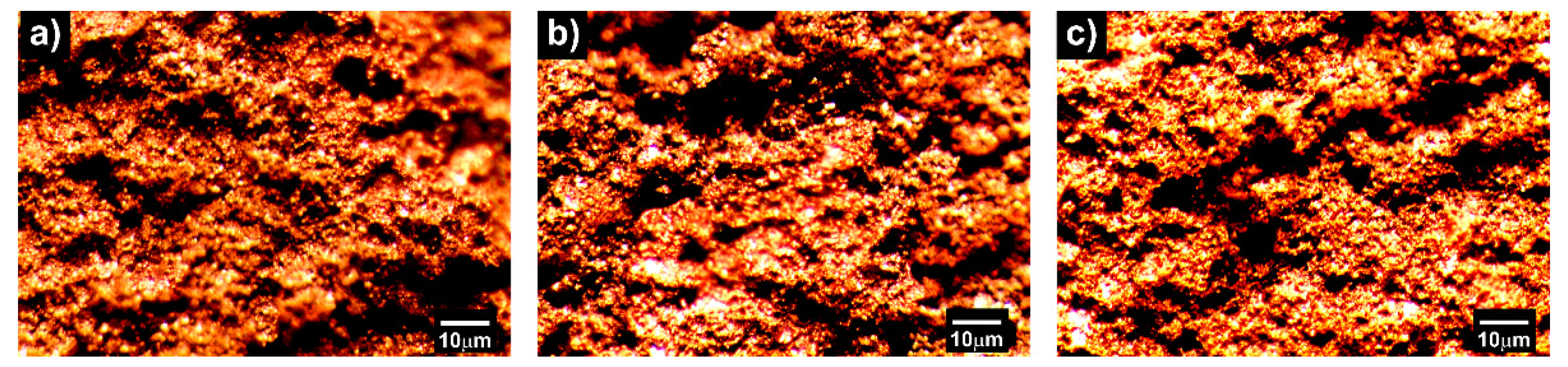

3.5.4. Fracture Surfaces

4. Conclusions

- ∘

- Aluminum-based composites can be effectively hardened by dispersing mullite particles and tungsten carbide, through powder metallurgy techniques that involve the combination of mechanical grinding, cold compaction, and pressureless sintering. The results showed that reinforced ceramics provided aluminum increments in hardness and stiffness properties.

- ∘

- The reinforcement of ductile metals by means of ceramic particles, materials that are hard and brittle in nature, coupled with powder metallurgy processing can only be reflected in increases in the hardness and elastic modulus of the metal, since the microstructures present only the distribution of the two phases in a homogeneous way, without the formation of solid solutions. Therefore, it is not feasible to achieve increases in the strength and ductility of the resulting materials through this type of process and reinforcement

- ∘

- Microstructure observations indicate that mullite particles are located at intragranular and transgranular positions of the aluminum matrix, while tungsten carbide particles were found mostly at intragranular areas of the matrix.

- ∘

- This processing methodology, with favorable results in terms of increasing the mechanical properties of aluminum, can be a simple and inexpensive processing alternative, which makes it attractive to scale the process at the industrial level.

Author Contributions

Funding

Conflicts of Interest

References

- Da Costa, E.; Velasco López, C.; Torralba Castelló, J. Materiales compuestos de matriz metálica. I parte. Tipos, propiedades, aplicaciones. Rev. Metal. 2000, 36, 179–192. [Google Scholar] [CrossRef]

- Lindroos, V.; Talvitie, M. Recent advances in metal matrix composites. J. Mater. Process. Technol. 1995, 53, 273–284. [Google Scholar] [CrossRef]

- Prasad, S.; Asthana, R. Aluminum Metal–Matrix Composites for Automotive Applications: Tribological Considerations. Tribol. Lett. 2004, 17, 445–453. [Google Scholar] [CrossRef]

- Hooker, J.; Doorbar, P. Metal matrix composites for aeroengines. In Metal and Ceramic Matrix; Cantor, B., Stone, I., Dunne, F., Eds.; Institute of Physics Publishing: Philadelphia, PA, USA, 2004; pp. 12–26. [Google Scholar]

- Torralba, J.; da Costa, C.; Velasco, F.J. P/M aluminum matrix composites: An overview. J. Mater. Process. Technol. 2003, 133, 203–206. [Google Scholar] [CrossRef]

- Kumar, G.B.V.; Rao, C.S.P.; Selvaraj, N. Mechanical and Tribological Behavior of Particulate Reinforced Aluminum Metal Matrix Composites—A review. J. Miner. Mater. Charact. Eng. 2011, 10, 59–91. [Google Scholar] [CrossRef]

- Bodukuri, A.K.; Eswaraiah, K.; Rajendar, K.; Sampath, V. Fabrication of Al–SiC–B4C metal matrix composite by powder metallurgy technique and evaluating mechanical properties. Perspect. Sci. 2016, 8, 428–431. [Google Scholar] [CrossRef]

- Verma, J.; Kumar, A.; Chandrakar, R.; Kumar, R. Processing of 5083 Aluminum Alloy Reinforced with Alumina through Microwave Sintering. J. Miner. Mater. Charact. Eng. 2012, 11, 1126–1131. [Google Scholar] [CrossRef]

- Tyagi, R. Synthesis and tribological characterization of in situ cast Al–TiC composites. Wear 2005, 259, 569–576. [Google Scholar] [CrossRef]

- Gomes, L.A.C.M.; Travessa, D.N.; González-Carrasco, J.L.; Lieblich, M.; Cardoso, K.R. Production of MA956 Alloy Reinforced Aluminum Matrix Composites by Mechanical Alloying. Mater. Res. 2015, 18, 48–54. [Google Scholar] [CrossRef][Green Version]

- Cuevas, J.C.; Barona, W.; Sanchez, H.; Castro, I. Reforzamiento de la aleación de aluminio 6061 con carburos dobles de Fe-Cr obtenidos por aleación mecánica. Sci. Tech. 2007, 1, 119–124. [Google Scholar] [CrossRef]

- Daoud, A.; Abou-Elkhair, M.T.; Rohatgi, P. Wear and friction behavior of near eutectic Al–Si+ZrO2 or WC Particle Composites. Compo. Sci. Tech. 2004, 64, 1029–1040. [Google Scholar] [CrossRef]

- Nestler, D.; Siebeck, S.; Podlesak, H.; Wagner, S.; Hockauf, M.; Bernhard, W. Powder Metallurgy of Particle-Reinforced Al-uminium Matrix Composites (AMC) by Means of High-Energy Ball Milling. Integ. Syst. Des. Tech. 2010, 93–107. [Google Scholar] [CrossRef]

- Wu, Y.; Lavemia, E.J. Advancements in synthesis and processes. In Proceedings of the Advancements in Synthesis and Processes, Toronto, ON, Canada, 20–22 October 1992. Society for Advancement of Material and Process Engineering M692. [Google Scholar]

- Tiwari, R.; Herman, H.; Sampath, S.; Gudmundsson, B. Plasma spray consolidation of high temperature composites. Mater. Sci. Eng. A 1991, 144, 127–131. [Google Scholar] [CrossRef]

- Kim, S.W.; Lee, U.J.; Han, S.W.; Kim, D.K.; Ogi, K. Heat treatment and wear characteristics of Al/SiCp composites fabricated by duplex process. Compos. Part B Eng. 2003, 34, 737–745. [Google Scholar] [CrossRef]

- Prashantha Kumar, H.G.; Anthony Xavior, M.A. Graphene Reinforced Metal Matrix Composite (GRMMC): A Review. Proc. Eng. 2014, 97, 1033–1040. [Google Scholar] [CrossRef]

- Venkatesan, S.; Xavior, M.A. Tensile behavior of aluminum alloy (AA7050) metal matrix composite reinforced with graphene fabricated by stir and squeeze cast processes. Sci. Technol. Mater. 2018, 30, 74–85. [Google Scholar] [CrossRef]

- Prashantha Kumar, H.G.; Anthony Xavior, M.A. Encapsulation and Microwave Hybrid Processing of Al 6061-Graphene-SiC Composites. Mater. Manuf. Process. 2017, 33, 19–25. [Google Scholar] [CrossRef]

- Singh, L.; Kumar, S.; Raj, S.; Badhani, P. Aluminium Metal Matrix Composites: Manufacturing and Applications. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1149, 012025. [Google Scholar] [CrossRef]

- Trunec, M.; Maca, K. Advanced Ceramic Processes. In Advanced Ceramics for Dentistry, 1st ed.; Shen, J.Z., Kosmač, T., Eds.; Elsevier Science: Amsterdam, The Netherlands, 2014; pp. 123–150. [Google Scholar]

- Clyne, T.W. Metallic Composite Materials. In Physical Metallurgy, 4th ed.; Cahn, R.W., Haasen, P., Eds.; Elsevier Science: Amsterdam, The Netherlands, 1996; pp. 2567–2625. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Castillo-Robles, J.A.; Dimas-Muñoz, A.P.; Rodríguez-García, J.A.; Calles-Arriaga, C.A.; Armendáriz-Mireles, E.N.; Pech-Rodríguez, W.J.; Rocha-Rangel, E. Mechanical and Microstructural Response of Aluminum Composites Reinforced with Ceramic Micro-Particles. J. Compos. Sci. 2021, 5, 228. https://doi.org/10.3390/jcs5090228

Castillo-Robles JA, Dimas-Muñoz AP, Rodríguez-García JA, Calles-Arriaga CA, Armendáriz-Mireles EN, Pech-Rodríguez WJ, Rocha-Rangel E. Mechanical and Microstructural Response of Aluminum Composites Reinforced with Ceramic Micro-Particles. Journal of Composites Science. 2021; 5(9):228. https://doi.org/10.3390/jcs5090228

Chicago/Turabian StyleCastillo-Robles, José A., Alicia P. Dimas-Muñoz, José A. Rodríguez-García, Carlos A. Calles-Arriaga, Eddie N. Armendáriz-Mireles, Wilian J. Pech-Rodríguez, and Enrique Rocha-Rangel. 2021. "Mechanical and Microstructural Response of Aluminum Composites Reinforced with Ceramic Micro-Particles" Journal of Composites Science 5, no. 9: 228. https://doi.org/10.3390/jcs5090228

APA StyleCastillo-Robles, J. A., Dimas-Muñoz, A. P., Rodríguez-García, J. A., Calles-Arriaga, C. A., Armendáriz-Mireles, E. N., Pech-Rodríguez, W. J., & Rocha-Rangel, E. (2021). Mechanical and Microstructural Response of Aluminum Composites Reinforced with Ceramic Micro-Particles. Journal of Composites Science, 5(9), 228. https://doi.org/10.3390/jcs5090228