Modeling Fracture Formation, Behavior and Mechanics of Polymeric Materials: A Biomedical Implant Perspective

Abstract

:1. Introduction

2. Mathematical Modeling

2.1. Loading Point Ratio

2.2. Strain Proportionality Factor

3. Methodology

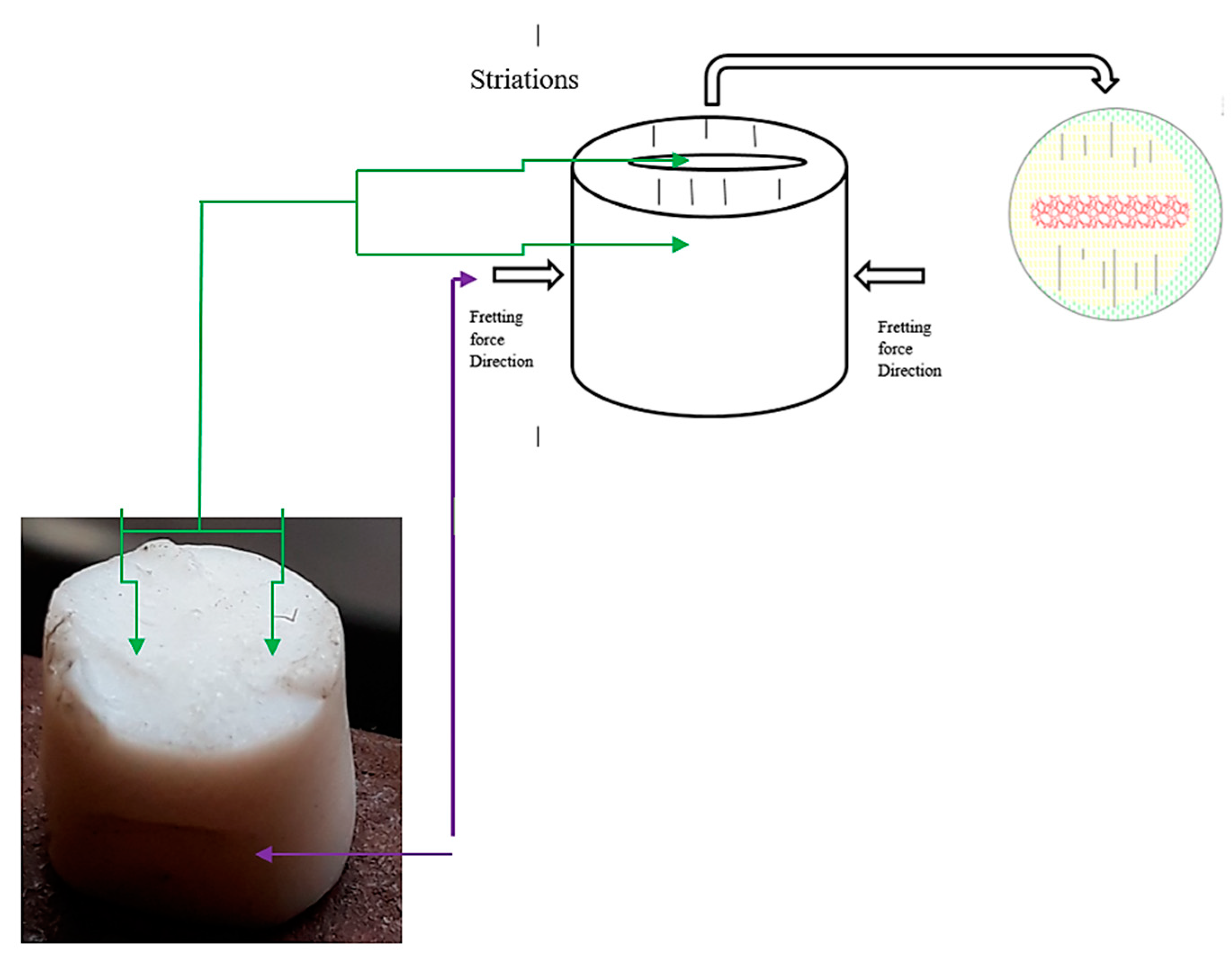

3.1. Experimental Design

3.2. Numerical Model

4. Results and Discussion

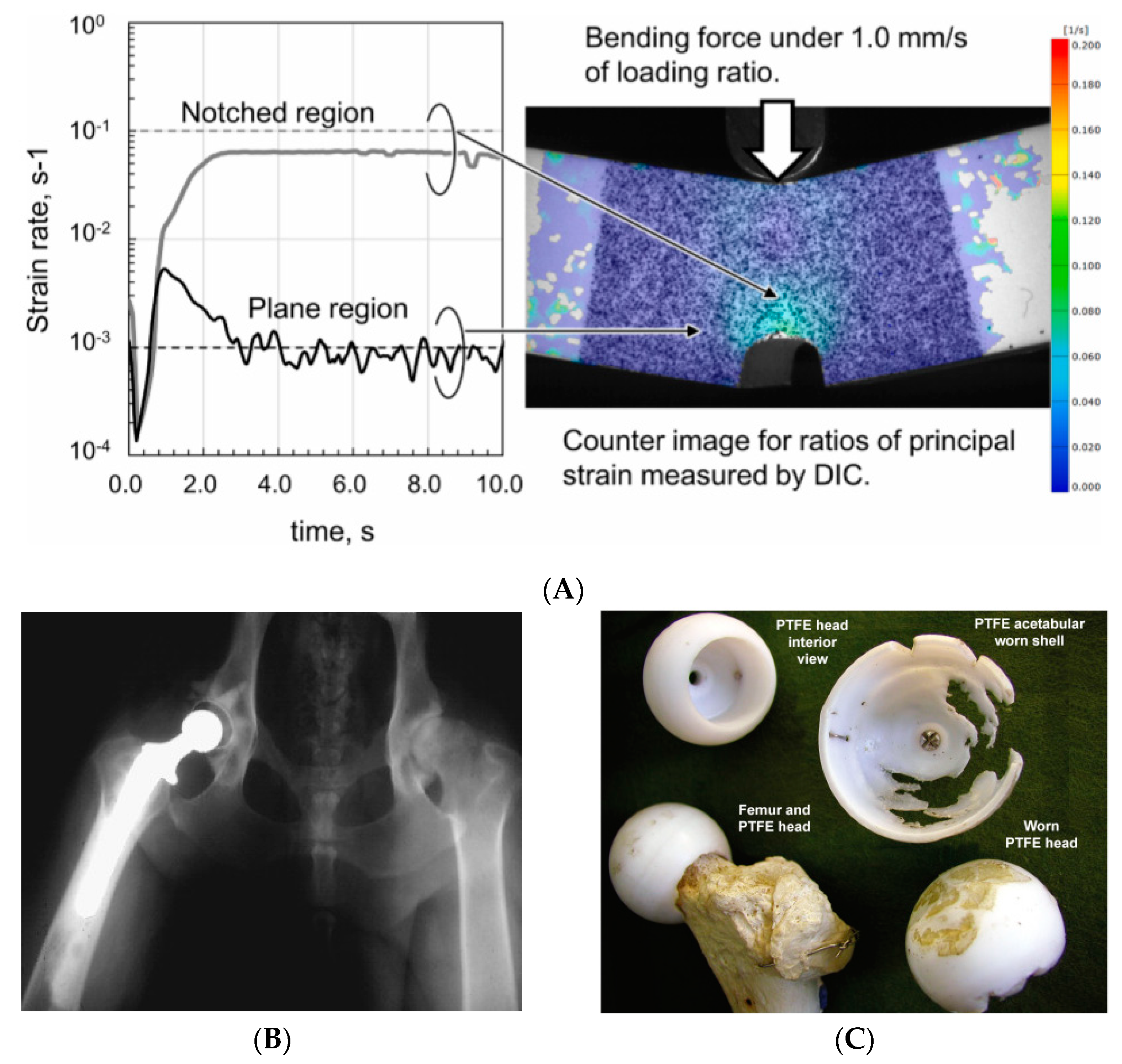

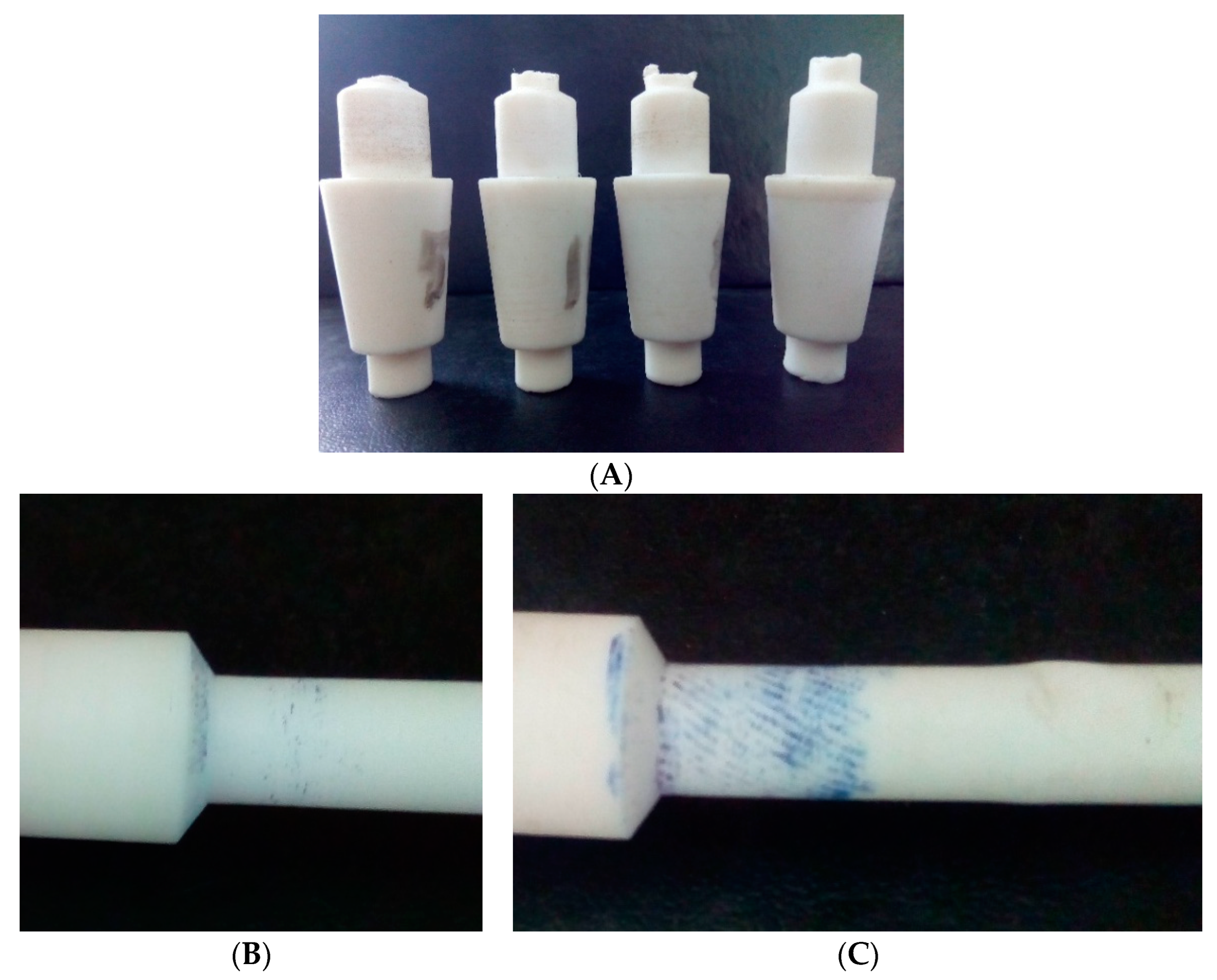

4.1. Effect of Loading Point Ratio

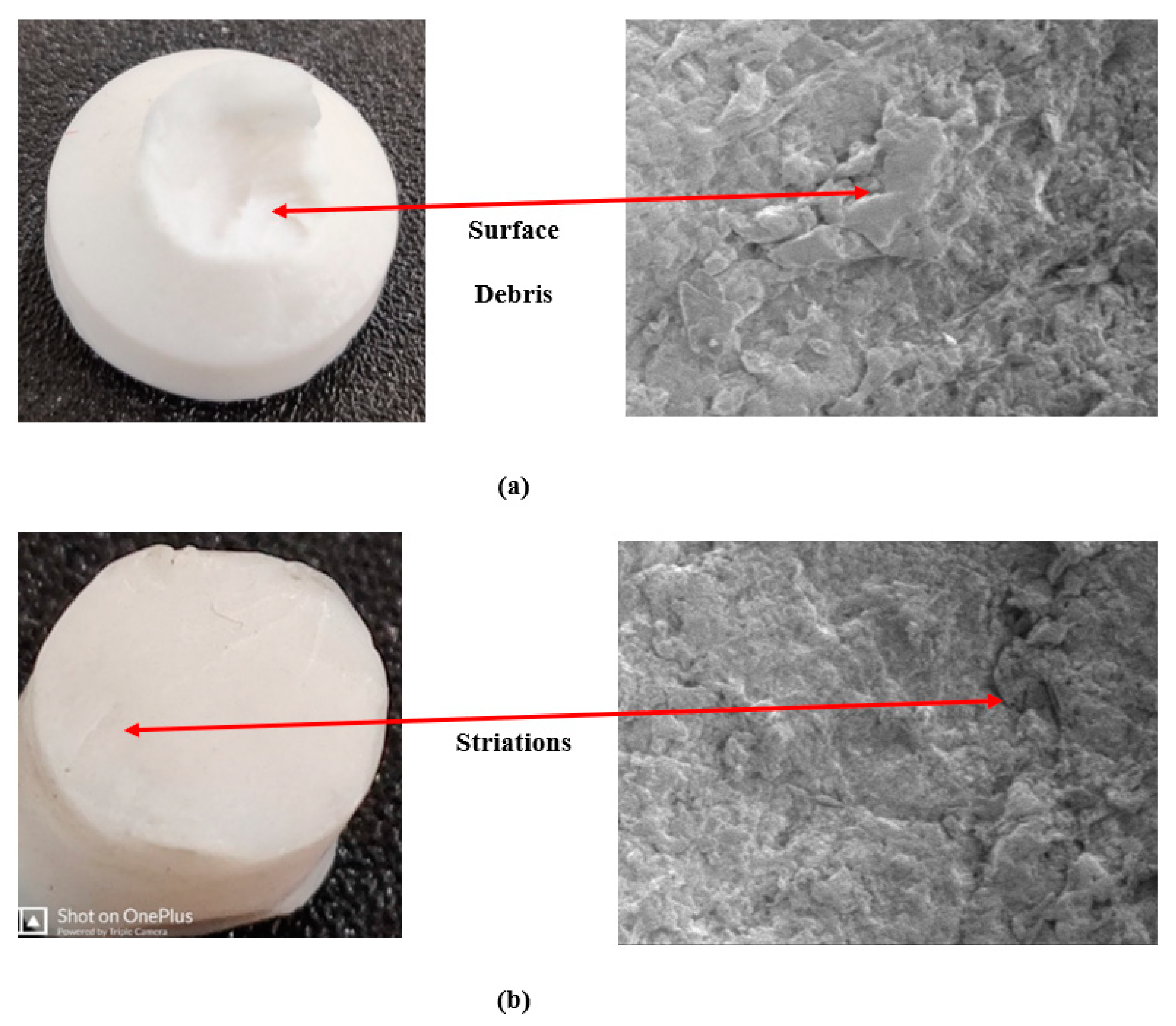

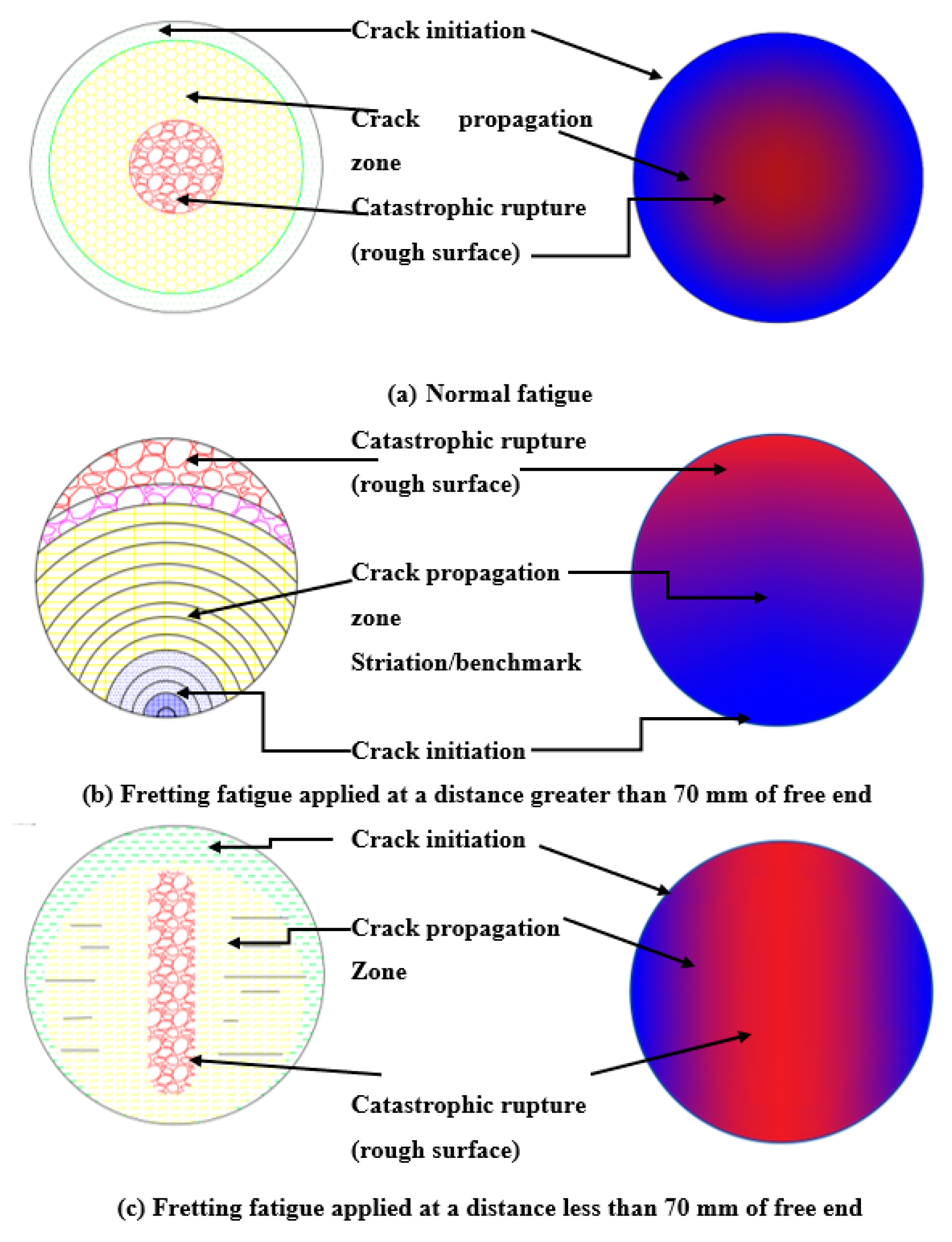

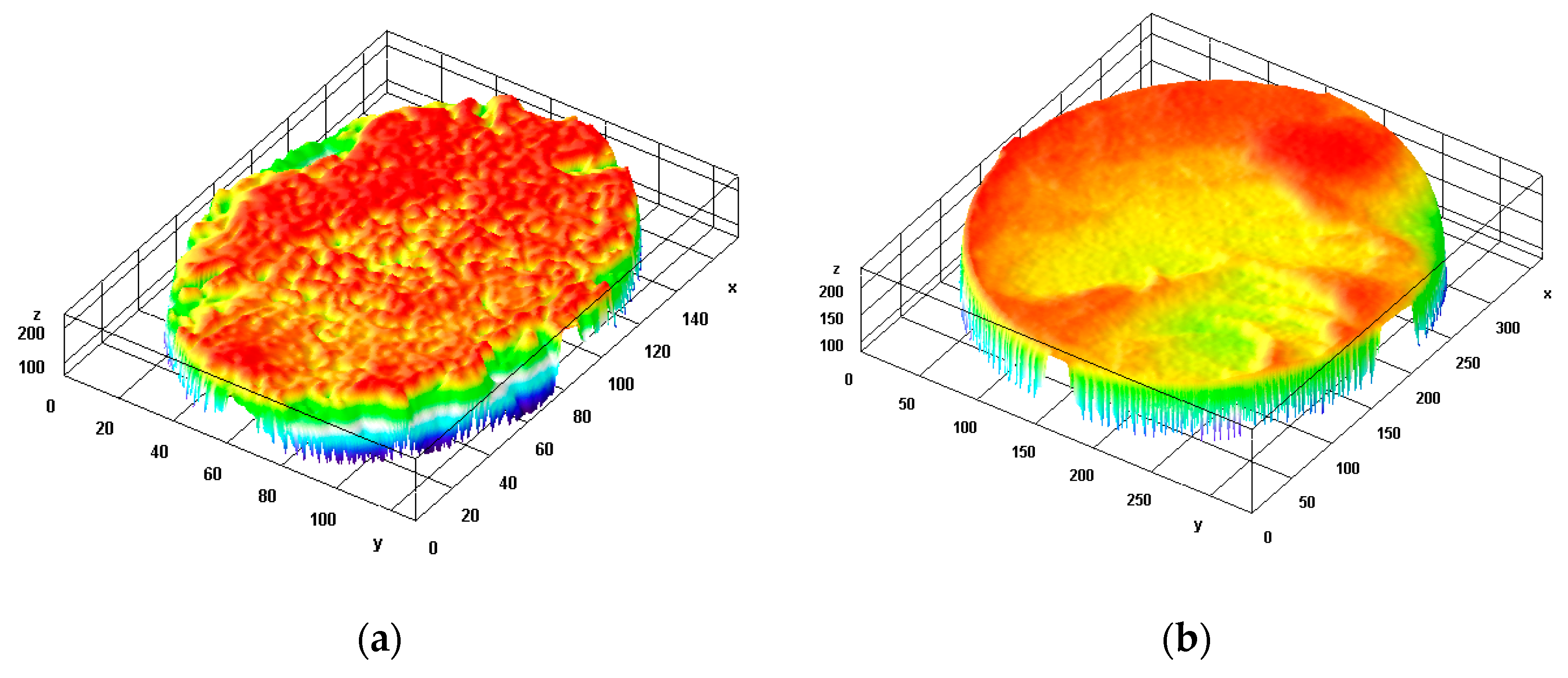

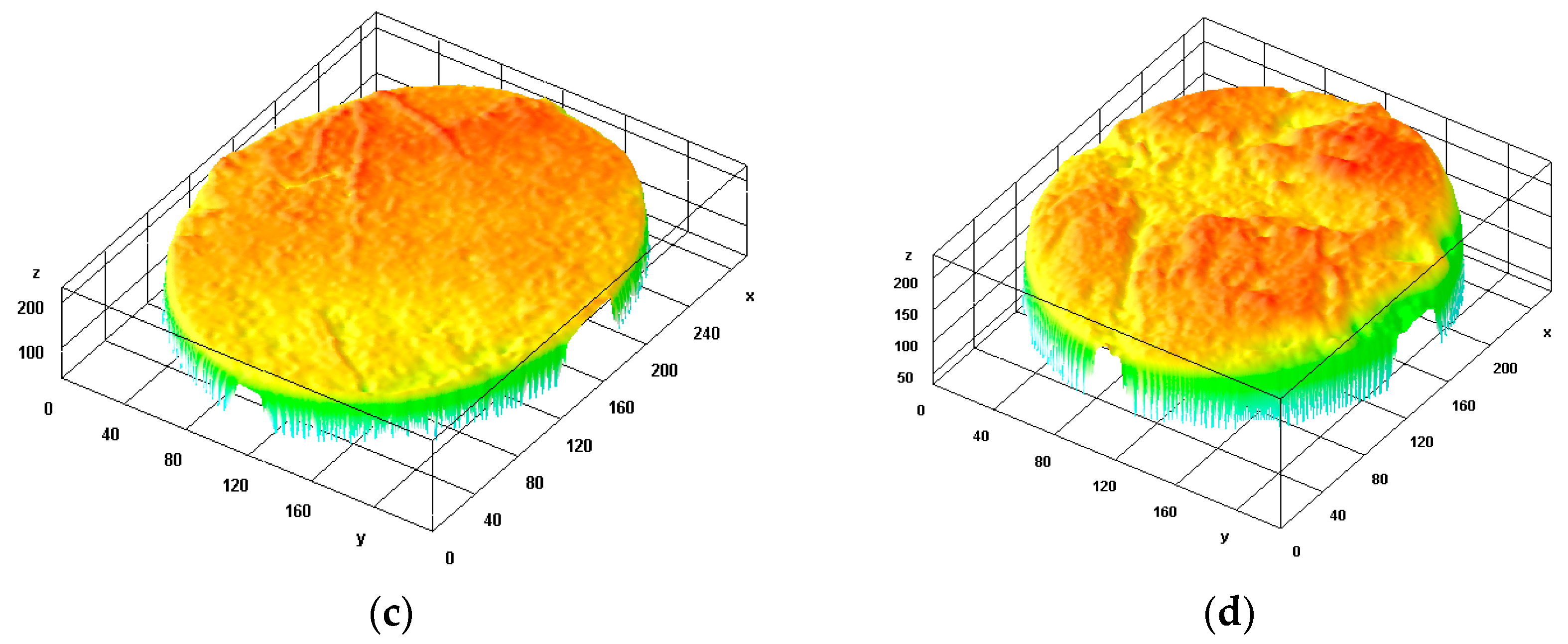

4.2. Fractography Analysis

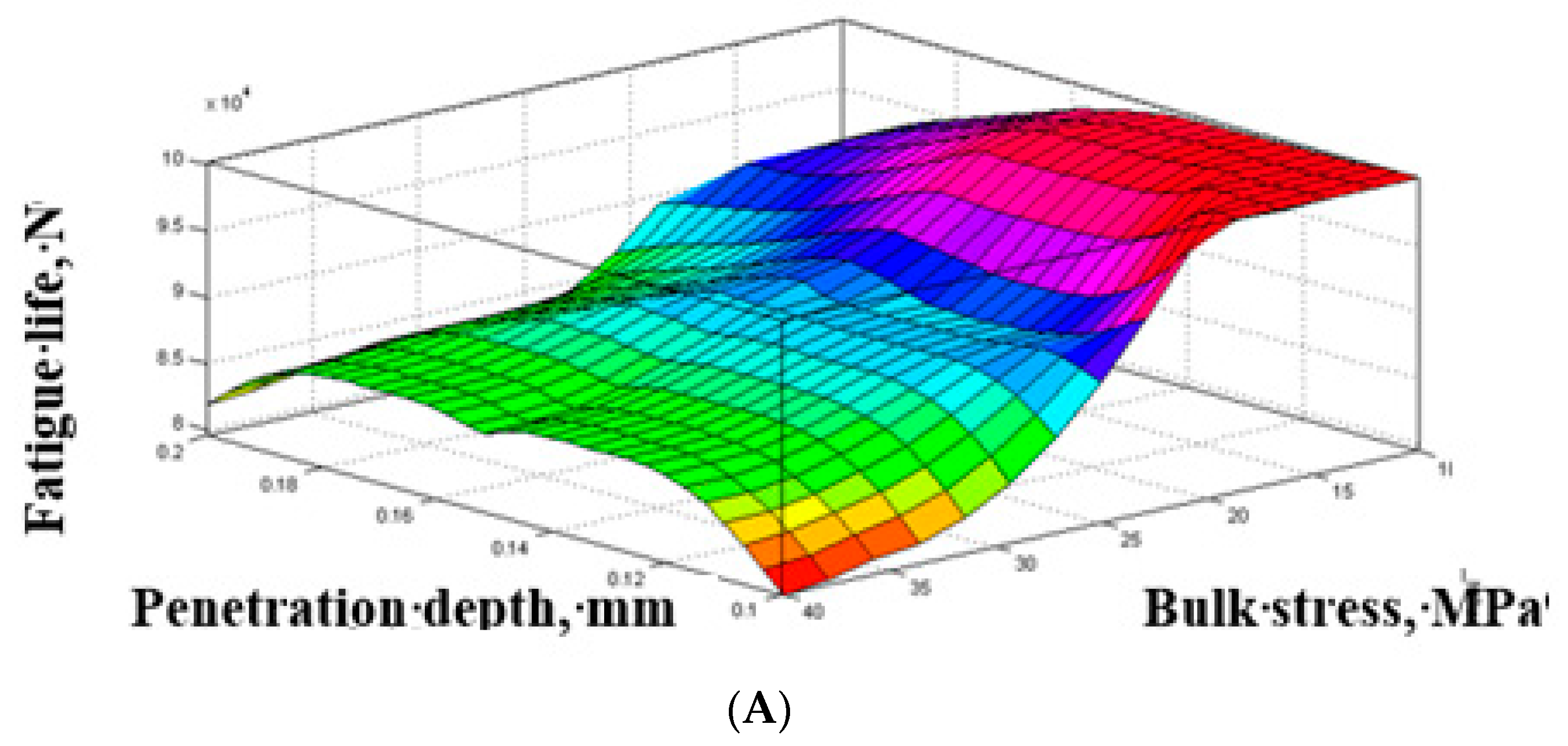

4.3. Impact of Strain Proportionality Factor

4.4. Finite Element Model (FEM) Analysis

5. Conclusions

- (1)

- Fretting action depends on the loading point ratio. Location of fretting within 70 mm from free end causes the sample fracture near the fretting zone while for loading greater than 70 mm it causes failure near the neck point or collar due to the combined effect of fretting and notch. A mathematical model is developed and an empirical equation is derived for the loading point ratio. For LPR > 3.0, the specimen fractures at the fretting zone, otherwise at the collar section. Stress distribution along the fretting contact path supports the results obtained. Thus, it suggests a point of influence for fretting action that should be avoided while designing.

- (2)

- The strain proportionality factor, k, increases up to a certain (optimal) value, and improves fatigue life due to the counterbalance of the reversed (or negative) contact pressure and opposite (positive) bending stress. From finite element stress distribution, it was found that fretting compensates the excess bulk stress at the edge corner that improves fatigue life. However, once it reaches that optimal value, fatigue life starts to yield because of the loss in strength due to imbalanced necking.

- (3)

- From geometrical aspects and schematic demonstrations, fretting acts perpendicular to the formation of cracks. Rapid rupture occurs at an angle of 90° to the direction of fretting pressure. PTFE shows both the ductile and brittle behavior in the fractured zone. For LPR < 3.0, slant lips at 45° were found for a crescent-type fracture near the collar section. Therefore, not only the fretting quantities but also fretting qualities affect fatigue life badly.

Author Contributions

Funding

Conflicts of Interest

References

- Chowdhury, M.A.; Kowser, A.; Shah, Q.M.Z.; Das, S. Characteristics and damage mechanisms of bending fretting fatigue of materials. Int. J. Damage Mech. 2017, 27, 453–487. [Google Scholar] [CrossRef]

- Shah, Q.M.Z.; Chowdhury, A.; Kowser, A. On the diversity in design for different bending fretting fatigue mechanism. SN Appl. Sci. 2019, 1, 1067. [Google Scholar] [CrossRef] [Green Version]

- Tanaka, K.; Uchiyama, Y.; Toyooka, S. The mechanism of wear of polytetrafluoroethylene. Wear 1973, 23, 153–172. [Google Scholar] [CrossRef]

- Wecker, S.M.; Davidson, T.; Cohen, J.B. Study of deformation in polytetrafluoroethylene by x-ray line broadening. J. Appl. Phys. 1974, 45, 4453–4457. [Google Scholar] [CrossRef]

- Dao, K.C.; Dicken, D.J. Fatigue failure mechanisms in polymers. Polym. Eng. Sci. 1987, 27, 271–276. [Google Scholar] [CrossRef]

- Blanchet, T.A.; Kennedy, F.E. Sliding wear mechanism of polytetrafluoroethylene (PTFE) and PTFE composites. Wear 1992, 153, 229–243. [Google Scholar] [CrossRef]

- Aglan, H.; Gan, Y.; El-Hadik, M.; Faughnan, P.; Bryan, C. Evaluation of the fatigue fracture resistance of unfilled and filled polytetrafluoroethylene materials. J. Mater. Sci. 1999, 34, 83–97. [Google Scholar] [CrossRef]

- Brownell, M.; Nair, A.K. Deformation mechanisms of polytetrafluoroethylene at the nano- and microscales. Phys. Chem. Chem. Phys. 2018, 21, 490–503. [Google Scholar] [CrossRef] [PubMed]

- Joyce, J.A. Fracture toughness evaluation of polytetrafluoroethylene. Polym. Eng. Sci. 2003, 43, 1702–1714. [Google Scholar] [CrossRef]

- Rae, P.; Dattelbaum, D. The properties of poly(tetrafluoroethylene) (PTFE) in compression. Polymer 2004, 45, 7615–7625. [Google Scholar] [CrossRef]

- Rae, P.; Brown, E. The properties of poly(tetrafluoroethylene) (PTFE) in tension. Polymer 2005, 46, 8128–8140. [Google Scholar] [CrossRef]

- Brown, E.N.; Rae, P.J.; Liu, C. Mixed-mode-I/II fracture of polytetrafluoroethylene. Mater. Sci. Eng. A 2007, 468, 253–258. [Google Scholar] [CrossRef]

- Nunes, L.; Dias, F.; Mattos, H.D.C. Mechanical behavior of polytetrafluoroethylene in tensile loading under different strain rates. Polym. Test. 2011, 30, 791–796. [Google Scholar] [CrossRef] [Green Version]

- Gao, Y.; Sun, S.; He, Y.; Wang, X.; Wu, D. Effect of poly(ethylene oxide) on tribological performance and impact fracture behavior of polyoxymethylene/polytetrafluoroethylene fiber composites. Compos. Part B Eng. 2011, 42, 1945–1955. [Google Scholar] [CrossRef]

- Zhang, J.-F.; Ju, Y.-T.; Sun, C.-X.; Wang, P.-B. The Research on Compressive Properties of Polytetrafluoroethylene at High Strain Rate. Def. Technol. 2013, 9, 181–185. [Google Scholar] [CrossRef] [Green Version]

- Sonne, M.R.; Hattel, J.H. Modeling the constitutive and frictional behavior of PTFE flexible stamps for nanoimprint lithography. Microelectron. Eng. 2013, 106, 1–8. [Google Scholar] [CrossRef]

- Chandran, K.S.R. Mechanical fatigue of polymers: A new approach to characterize the SN behavior on the basis of macroscopic crack growth mechanism. Polymer 2016, 91, 222–238. [Google Scholar] [CrossRef]

- Sawada, T. Fracture criterion considering notch brittleness of polytetrafluoroethylene under quasi-static loading. Theor. Appl. Fract. Mech. 2019, 103, 102285. [Google Scholar] [CrossRef]

- Shah, Q.Z.; Chowdhury, M.A.; Kowser, M. Failure Mechanism of Polytetrafluoroethyleneunder Friction Fatigue. J. Fail. Anal. Prev. 2019, 19, 245–249. [Google Scholar] [CrossRef]

- Hobbs, J.; Burguete, R.; Heyes, P.; Patterson, E. The effect of eccentric loading on the fatigue performance of high-tensile bolts. Int. J. Fatigue 2000, 22, 531–538. [Google Scholar] [CrossRef]

- Meyer, R.R. Buckling of 45° Eccentric-Stiffened Waffle Cylinders. J. R. Aeronaut. Soc. 1967, 71, 516–520. [Google Scholar] [CrossRef]

- Surgical Research. 2001, pp. 426–441. Available online: https://www.sciencedirect.com/topics/medicine-and-dentistry/artificial-hip-joint (accessed on 15 November 2021).

- Charnley, J. Tissue reactions to polytetrafluoroethylene. Lancet 1963, 282, 1379. [Google Scholar] [CrossRef]

- Merola, M.; Affatato, S. Materials for Hip Prostheses: A Review of Wear and Loading Considerations. Materials 2019, 12, 495. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zuo, J.; Xu, M.; Zhao, X.; Shen, X.; Gao, Z.; Xiao, J. Effects of the depth of the acetabular component during simulated acetabulum reaming in total hip arthroplasty. Sci. Rep. 2021, 11, 9836. [Google Scholar] [CrossRef]

- Seo, Y.; Wang, Z.J. Measurement and evaluation of specific absorption rate and temperature elevation caused by an artificial hip joint during MRI scanning. Sci. Rep. 2021, 11, 1134. [Google Scholar] [CrossRef] [PubMed]

- Cui, Z.; Tian, Y.-X.; Yue, W.; Yang, L.; Li, Q. Tribo-biological deposits on the articulating surfaces of metal-on-polyethylene total hip implants retrieved from patients. Sci. Rep. 2016, 6, 28376. [Google Scholar] [CrossRef] [Green Version]

- Liu, M.; Luo, Y.; Jia, D. Synthesis of mechanically durable superhydrophobic polymer materials with roughness-regeneration performance. Compos. Part A Appl. Sci. Manuf. 2020, 133, 105861. [Google Scholar] [CrossRef]

- Zhang, Z.P.; Rong, M.Z.; Zhang, M.Q. Mechanically robust, self-healable, and highly stretchable “living” crosslinked polyurethane based on a reversible CC bond. Adv. Funct. Mater. 2018, 28, 1706050. [Google Scholar] [CrossRef]

- Zhong, B.; Jia, Z.; Luo, Y.; Jia, D. A method to improve the mechanical performance of styrene-butadiene rubber via vulcanization accelerator modified silica. Compos. Sci. Technol. 2015, 117, 46–53. [Google Scholar] [CrossRef]

- Hamdia, K.M.; Silani, M.; Zhuang, X.; He, P.; Rabczuk, T. Stochastic analysis of the fracture toughness of polymeric nanoparticle composites using polynomial chaos expansions. Int. J. Fract. 2017, 206, 215–227. [Google Scholar] [CrossRef]

- Talebi, H.; Silani, M.; Bordas, S.P.A.; Kerfriden, P.; Rabczuk, T. A computational library for multiscale modeling of material failure. Comput. Mech. 2013, 53, 1047–1071. [Google Scholar] [CrossRef] [Green Version]

- Aherwar, A.; Singh, A.K.; Patnaik, A. Current and future biocompatibility aspects of biomaterials for hip prosthesis. AIMS Environ. Sci. 2015, 3, 23–43. [Google Scholar] [CrossRef]

- Shah, Q.M.Z.; Chowdhury, M.A.; Kowser, A. Fretting & friction induced fatigue failure: Damage criterion of polytetrafluoroethylene. Heliyon 2020, 6, e04066. [Google Scholar] [CrossRef]

- Zobaer, S.; Quazi, M.; Arefin, K.; Mohammad, A.C. A parametric investigation on the fretting fatigue behaviour of heat treated Al 6061-T6 under rotating bending phenomena. Aust. J. Mech. Eng. 2019, 1–13. [Google Scholar] [CrossRef]

- Perez, N. Fatigue Crack Growth. In Fracture Mechanics; Springer: Cham, Switzerland, 2017; pp. 327–372. [Google Scholar]

- Perez, N. Linear-elastic fracture mechanics. In Fracture Mechanics; Springer: Cham, Switzerland, 2017; pp. 79–130. [Google Scholar]

- Perez, N. Crack Tip Plasticity. In Fracture Mechanics; Springer: Cham, Switzerland, 2017; pp. 187–225. [Google Scholar]

| Material | Density (g/cc) | Youngs Modulus, E (GPa) | Poisson’s Ratio | Yield Tensile Strength, YTS (MPa) | Ultimate Tensile Strength, UTS (MPa) |

|---|---|---|---|---|---|

| Teflon (PTFE) | 2.3 | 0.5 | 0.46 | 30 | 43 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shah, Q.M.Z.; Kowser, M.A.; Chowdhury, M.A.; Chani, M.T.S.; Alamry, K.A.; Hossain, N.; Rahman, M.M. Modeling Fracture Formation, Behavior and Mechanics of Polymeric Materials: A Biomedical Implant Perspective. J. Compos. Sci. 2022, 6, 31. https://doi.org/10.3390/jcs6010031

Shah QMZ, Kowser MA, Chowdhury MA, Chani MTS, Alamry KA, Hossain N, Rahman MM. Modeling Fracture Formation, Behavior and Mechanics of Polymeric Materials: A Biomedical Implant Perspective. Journal of Composites Science. 2022; 6(1):31. https://doi.org/10.3390/jcs6010031

Chicago/Turabian StyleShah, Quazi Md. Zobaer, Md. Arefin Kowser, Mohammad Asaduzzaman Chowdhury, Muhammad Tariq Saeed Chani, Khalid A. Alamry, Nayem Hossain, and Mohammed M. Rahman. 2022. "Modeling Fracture Formation, Behavior and Mechanics of Polymeric Materials: A Biomedical Implant Perspective" Journal of Composites Science 6, no. 1: 31. https://doi.org/10.3390/jcs6010031

APA StyleShah, Q. M. Z., Kowser, M. A., Chowdhury, M. A., Chani, M. T. S., Alamry, K. A., Hossain, N., & Rahman, M. M. (2022). Modeling Fracture Formation, Behavior and Mechanics of Polymeric Materials: A Biomedical Implant Perspective. Journal of Composites Science, 6(1), 31. https://doi.org/10.3390/jcs6010031