The Effects of Air-Entraining Agent on Fresh and Hardened Properties of 3D Concrete

Abstract

1. Introduction

2. Materials and Methods

2.1. Concrete Mixes

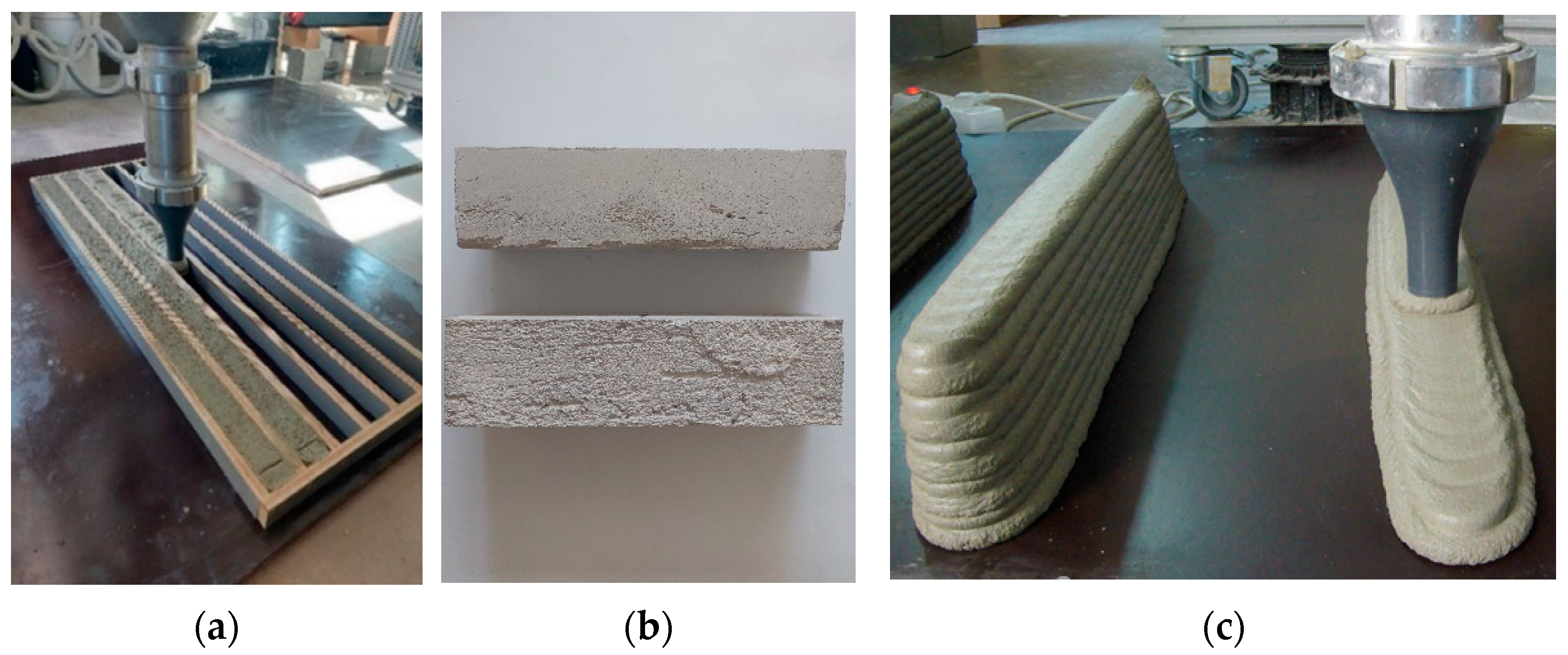

2.2. Mixing, 3D Printing and Curing

2.3. Testing

2.3.1. Fresh State Properties

2.3.2. Density, Flexural, and Compressive Strength

2.3.3. Frost Resistance

3. Results and Discussion

3.1. Fresh State Properties

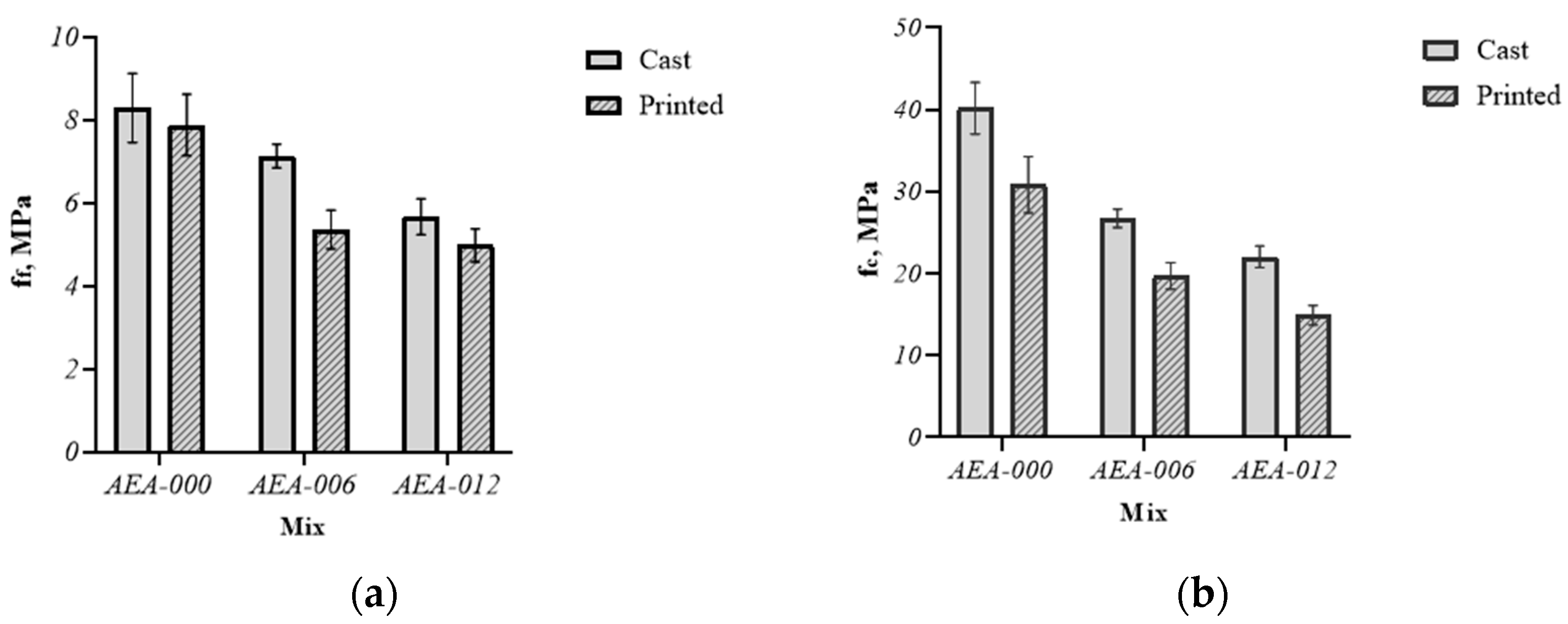

3.2. Hardened Properties

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Hossain, A.; Zhumabekova, A.; Paul, S.C.; Kim, J.R.A. Review of 3D Printing in Construction and its Impact on the Labor Market. Sustainability 2020, 12, 8492. [Google Scholar] [CrossRef]

- Mohan, M.K.; Rahul, A.V.; De Schutter, G.; Van Tittelboom, K. Extrusion-based concrete 3D printing from a material perspective: A state-of-the-art review. Cem. Concr. Compos. 2021, 115, 103855. [Google Scholar] [CrossRef]

- Wu, P.; Wang, J.; Wang, X. A critical review of the use of 3-D printing in the construction industry. Autom. Constr. 2016, 68, 21–31. [Google Scholar] [CrossRef]

- Assaad, J.J.; Hamzeh, F.; Hamad, B. Qualitative assessment of interfacial bonding in 3D printing concrete exposed to frost attack. Case Stud. Constr. Mater. 2020, 13, e00357. [Google Scholar] [CrossRef]

- Tunstall, L.E.; Ley, M.T.; Scherer, G.W. Air entraining admixtures: Mechanisms, evaluations, and interactions. Cem. Concr. Res. 2021, 150, 106557. [Google Scholar] [CrossRef]

- ACI Committee 201. 201.2R-16 Guide to Durable Concrete; ACI: Farmington Hills, MI, USA, 2016; p. 84. [Google Scholar]

- EN 206+A2:2001; Concrete—Part 1: Specification, Performance, Production and Conformity. NSAI: Northwood, Ireland, 2001.

- Souza, M.T.; Ferreira, I.M.; Guzi de Moraes, E.; Senff, L.; Novaes de Oliveira, A.P. 3D printed concrete for large-scale buildings: An overview of rheology, printing parameters, chemical admixtures, reinforcements, and economic and environmental prospects. J. Build. Eng. 2020, 32, 101833. [Google Scholar] [CrossRef]

- Zhang, P.; Li, D.; Qiao, Y.; Zhang, S.; Sun, C.; Zhao, T. Effect of air entrainment on the mechanical properties, chloride migration, and microstructure of ordinary concrete and fly ash concrete. J. Mater. Civ. Eng. 2018, 30, 04018265. [Google Scholar] [CrossRef]

- Tarhan, Y.; Şahin, R. Fresh and Rheological Performances of Air-Entrained 3D Printable Mortars. Materials 2021, 14, 2409. [Google Scholar] [CrossRef] [PubMed]

- Das, A.; Song, Y.; Mantellato, S.; Wangler, T.; Lange, D.A.; Flatt, R.J. Effect of processing on the air void system of 3D printed concrete. Cem. Concr. Res. 2022, 156, 106789. [Google Scholar] [CrossRef]

- Gyurkó, Z.; Szijártó, A.; Nemes, R. Increasing Freeze-thaw Resistance of Concrete by Additions of Powdered Cellular Concrete and Clay Bricks. Procedia Eng. 2017, 193, 11–18. [Google Scholar] [CrossRef]

- Łaźniewska-Piekarczyk, B. The frost resistance versus air voids parameters of high performance self compacting concrete modified by non-air-entrained admixtures. Constr. Build. Mater. 2013, 48, 1209–1220. [Google Scholar] [CrossRef]

- Kalhori, M.; Ramezanianpour, A.A. Innovative air entraining and air content measurement methods for roller compacted concrete in pavement applications. Constr. Build. Mater. 2021, 279, 122495. [Google Scholar] [CrossRef]

- Mayercsik, N.P.; Vandamme, M.; Kurtis, K.E. Assessing the efficiency of entrained air voids for freeze-thaw durability through modeling. Cem. Concr. Res. 2016, 88, 43–59. [Google Scholar] [CrossRef]

- Sikora, P.; Techman, M.; Federowicz, K.; El-Khayatt, A.M.; Saudi, H.A.; Elrahman, M.A.; Hoffmann, M.; Stephan, D.; Chung, S.Y. Insight into the microstructural and durability characteristics of 3D printed concrete: Cast versus printed specimens. Case Stud. Constr. Mater. 2022, 17, e01320. [Google Scholar] [CrossRef]

- Das, A.; Sanchez, A.M.A.; Wangler, T.; Flatt, R.J. Freeze-Thaw Performance of 3D Printed Concrete: Influence of Interfaces. In Proceedings of the Third RILEM International Conference on Concrete and Digital Fabrication, Leicester, UK, 25 June 2022; pp. 200–205. [Google Scholar] [CrossRef]

- CEN/TS 12390-9:2016; Testing Hardened Concrete—Part 9: Freeze-Thaw Resistance with De-Icing Salts-Scaling. BSI: Englewood, CO, USA, 2016.

- ASTM C666/C666M-15; Standard Test Method for Resistance of Concrete to Rapid Freezing and Thawing. ASTM: West Conshohocken, PA, USA, 2015.

- Nodehi, M.; Aguayo, F.; Nodehi, S.E.; Gholampour, A.; Ozbakkaloglu, T.; Gencel, O. Durability properties of 3D printed concrete (3DPC). Autom. Constr. 2022, 142, 104479. [Google Scholar] [CrossRef]

- Van Der Putten, J.; De Volder, M.; Van den Heede, P.; Deprez, M.; Cnudde, V.; De Schutter, G.; Van Tittelboom, K. Transport properties of 3D printed cementitious materials with prolonged time gap between successive layers. Cem. Concr. Res. 2022, 155, 106777. [Google Scholar] [CrossRef]

- NBN B 15-231:1987; Concrete Testing—Resistance to Freezing. SAI Global: Sydney, NSW, Australia, 1987.

- EN 12390-2:2019; Testing Hardened Concrete-Part 2: Making and Curing Specimens for Strength Tests. BSI: Englewood, CO, USA, 2019.

- EN 196-1:2016; Methods of Testing Cement-Part 1: Determination of Strength. BSI: Englewood, CO, USA, 2016.

- EN 1015-3:1999; Methods of Test for Mortar for Masonry-Part 3: Determination of Consistence of Fresh Mortar (by Flow Table). BSI: Englewood, CO, USA, 1999.

- EN 12350-7:2019; Testing Fresh Concrete-Part 7: Air Content-Pressure Methods. BSI: Englewood, CO, USA, 2019.

- Saruhan, V.; Keskinateş, M.; Felekoğlu, B. A comprehensive review on fresh state rheological properties of extrusion mortars designed for 3D printing applications. Constr. Build. Mater. 2022, 337, 127629. [Google Scholar] [CrossRef]

- Rahul, A.V.; Santhanam, M.; Meena, H.; Ghani, Z. 3D printable concrete: Mixture design and test methods. Cem. Concr. Compos. 2019, 97, 13–23. [Google Scholar] [CrossRef]

- Le, T.T.; Austin, S.A.; Lim, S.; Buswell, R.A.; Gibb, A.G.F.; Thorpe, T. Mix design and fresh properties for high-performance printing concrete. Mater. Struct. 2012, 45, 1221–1232. [Google Scholar] [CrossRef]

- Ma, G.; Li, Z.; Wang, L. Printable properties of cementitious material containing copper tailings for extrusion based 3D printing. Constr. Build. Mater. 2018, 162, 613–627. [Google Scholar] [CrossRef]

- Chen, Y.; He, S.; Zhang, Y.; Wan, Z.; Çopuroğlu, O.; Schlangen, E. 3D printing of calcined clay-limestone-based cementitious materials. Cem. Concr. 2021, 149, 106553. [Google Scholar] [CrossRef]

- EN 1015-11:2019; Methods of Test for Mortar for Masonry—Part 11: Determination of Flexural and Compressive Strength of Hardened Mortar. BSI: Englewood, CO, USA, 2019.

- Wang, S.; Zhang, G.; Wang, Z.; Huang, T.; Wang, P. Evolutions in the properties and microstructure of cement mortars containing hydroxyethyl methyl cellulose after controlling the air content. Cem. Concr. Compos. 2022, 129, 104487. [Google Scholar] [CrossRef]

- Wyrzykowski, M.; Kiesewetter, R.; Münch, B.; Baumann, R.; Lura, P. Pore structure of mortars with cellulose ether additions—Study of the air-void structure. Cem. Concr. Compos. 2015, 62, 117–124. [Google Scholar] [CrossRef]

- BS 8500-1:2015+A2:2019; Concrete. Complementary British Standard to BS EN 206—Method of Specifying and Guidance for the Specifier. BSI: Englewood, CO, USA, 2019.

- Marchon, D.; Kawashima, S.; Bessaies-Bey, H.; Mantellato, S.; Ng, S. Hydration and rheology control of concrete for digital fabrication: Potential admixtures and cement chemistry. Cem. Concr. Res. 2018, 112, 96–110. [Google Scholar] [CrossRef]

- Tay, Y.W.D.; Qian, Y.; Tan, M.J. Printability region for 3D concrete printing using slump and slump flow test. Compos. Part. B Eng. 2019, 174, 106968. [Google Scholar] [CrossRef]

- Jiang, Q.; Liu, Q.; Wu, S.; Zheng, H.; Sun, W. Modification effect of nanosilica and polypropylene fiber for extrusion-based 3D printing concrete: Printability and mechanical anisotropy. Addit. Manuf. 2022, 56, 102944. [Google Scholar] [CrossRef]

- Ouyang, X.; Guo, Y.; Qiu, X. The feasibility of synthetic surfactant as an air entraining agent for the cement matrix. Constr. Build. Mater. 2008, 22, 1774–1779. [Google Scholar] [CrossRef]

- LVS 156-1:2022; Concrete. National Annex to EN 206 Concrete. Specification, Performance, Production and Conformity. BSI: Englewood, CO, USA, 2022.

| Mix | Water | OPC | Sand 0–2 mm | Limestone Filler | SP * | VMA * | AEA * | W/OPC * |

|---|---|---|---|---|---|---|---|---|

| AEA-000 | 155 | 328 | 564 | 108 | 1.5 | 0.2 | - | 0.47 |

| AEA-006 | 155 | 328 | 564 | 108 | 1.5 | 0.2 | 0.197 | 0.47 |

| AEA-012 | 155 | 328 | 564 | 108 | 1.5 | 0.2 | 0.394 | 0.47 |

| Mix | Measured Air Content, % | Fresh State Density, kg/m3 | Slump Ø × 15, mm | Slump Ø × 25, mm | Vertical Slump, mm |

|---|---|---|---|---|---|

| AEA-000 | 8.5 | 2105 | 171 | 180 | 10 |

| AEA-006 | 14.0 | 1962 | 156 | 172 | 4 |

| AEA-012 | 15.0 | 1938 | 150 | 169 | 3 |

| Cast Mix | Printed Mix | Bulk Density, kg/m3 | Particle Density, kg/m3 | Void Ratio, % |

|---|---|---|---|---|

| AEA-000 | 2044 ± 33 | 2615 ± 82 | 21 | |

| AEA-000 | 2011 ± 62 | 23 | ||

| AEA-006 | 1769 ± 74 | 32 | ||

| AEA-006 | 1746 ± 26 | 33 | ||

| AEA-012 | 1752 ± 32 | 33 | ||

| AEA-012 | 1689 ± 20 | 35 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Spurina, E.; Sinka, M.; Ziemelis, K.; Vanags, A.; Bajare, D. The Effects of Air-Entraining Agent on Fresh and Hardened Properties of 3D Concrete. J. Compos. Sci. 2022, 6, 281. https://doi.org/10.3390/jcs6100281

Spurina E, Sinka M, Ziemelis K, Vanags A, Bajare D. The Effects of Air-Entraining Agent on Fresh and Hardened Properties of 3D Concrete. Journal of Composites Science. 2022; 6(10):281. https://doi.org/10.3390/jcs6100281

Chicago/Turabian StyleSpurina, Ella, Maris Sinka, Krists Ziemelis, Andris Vanags, and Diana Bajare. 2022. "The Effects of Air-Entraining Agent on Fresh and Hardened Properties of 3D Concrete" Journal of Composites Science 6, no. 10: 281. https://doi.org/10.3390/jcs6100281

APA StyleSpurina, E., Sinka, M., Ziemelis, K., Vanags, A., & Bajare, D. (2022). The Effects of Air-Entraining Agent on Fresh and Hardened Properties of 3D Concrete. Journal of Composites Science, 6(10), 281. https://doi.org/10.3390/jcs6100281