Thermomechanical and Pre-Ignition Properties of Multicomponent Poly(Vnylidene Fluoride)/Aluminum Oxide/Single-Walled Carbon Nanotube Hybrid Nanocomposites

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of PVDF/CNT/Al2O3 Composites

2.3. Characterization

3. Results and Discussion

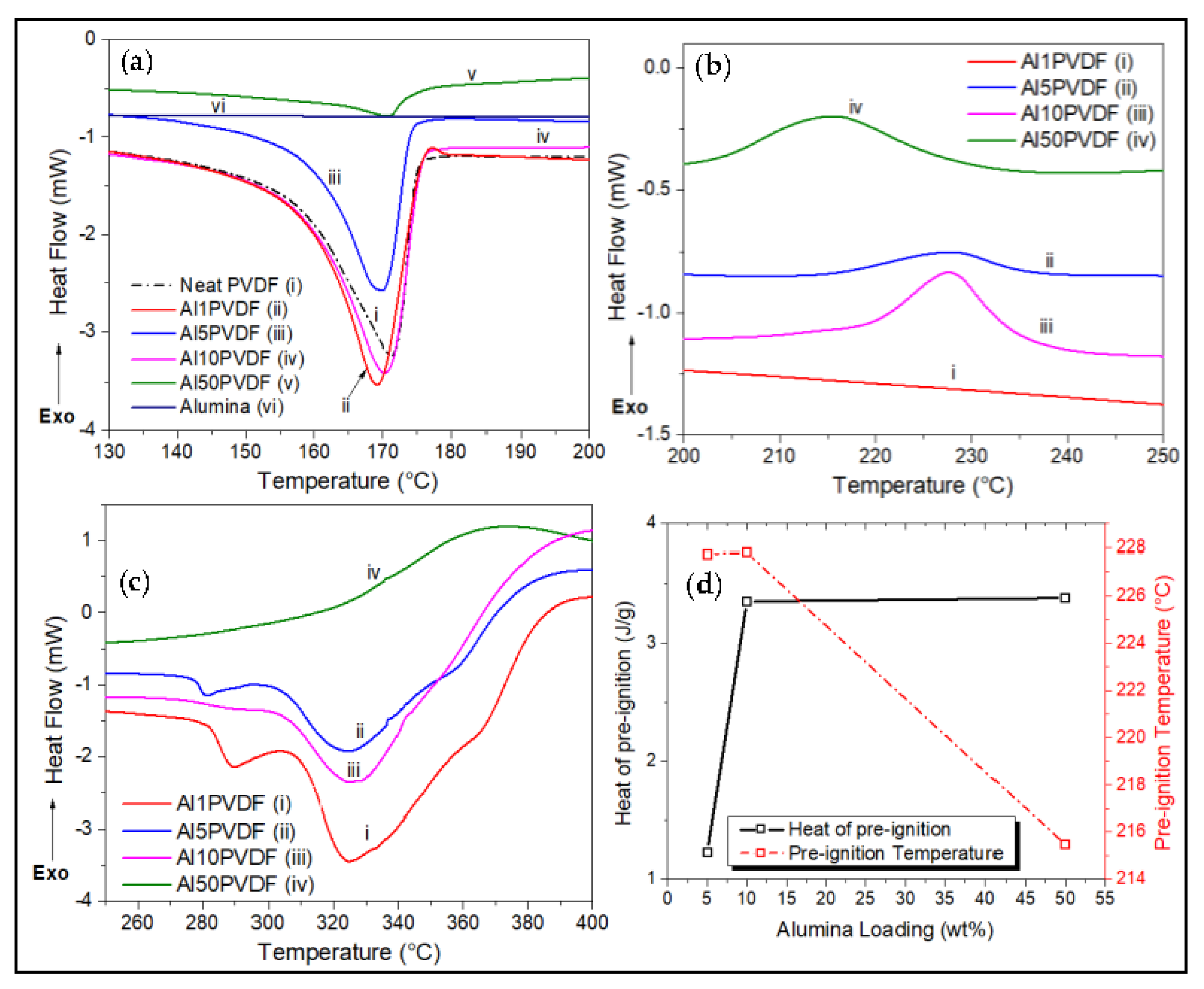

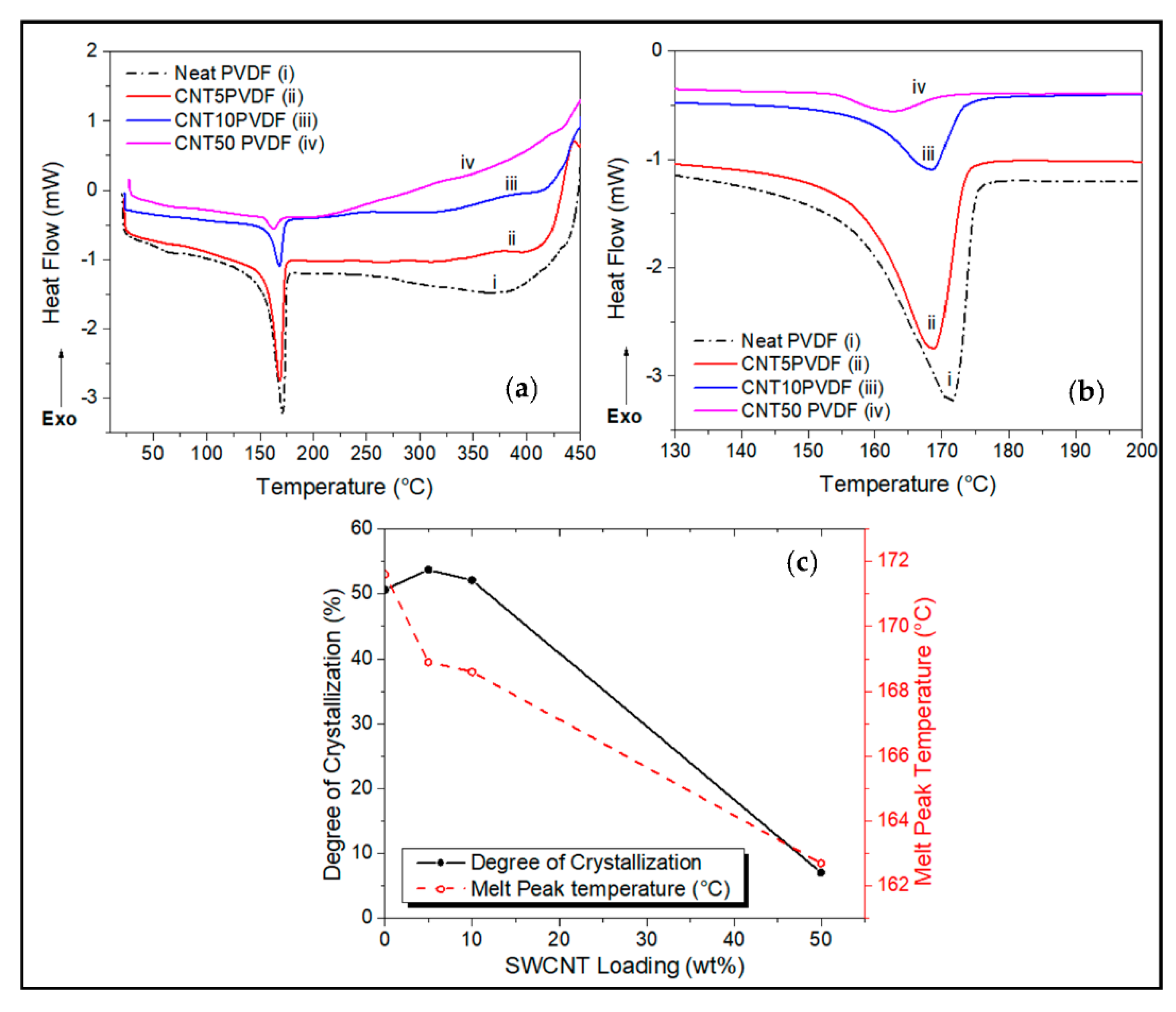

3.1. Differential Scanning Calorimetry (DSC)

3.2. Thermogravimetric Analysis (TGA)

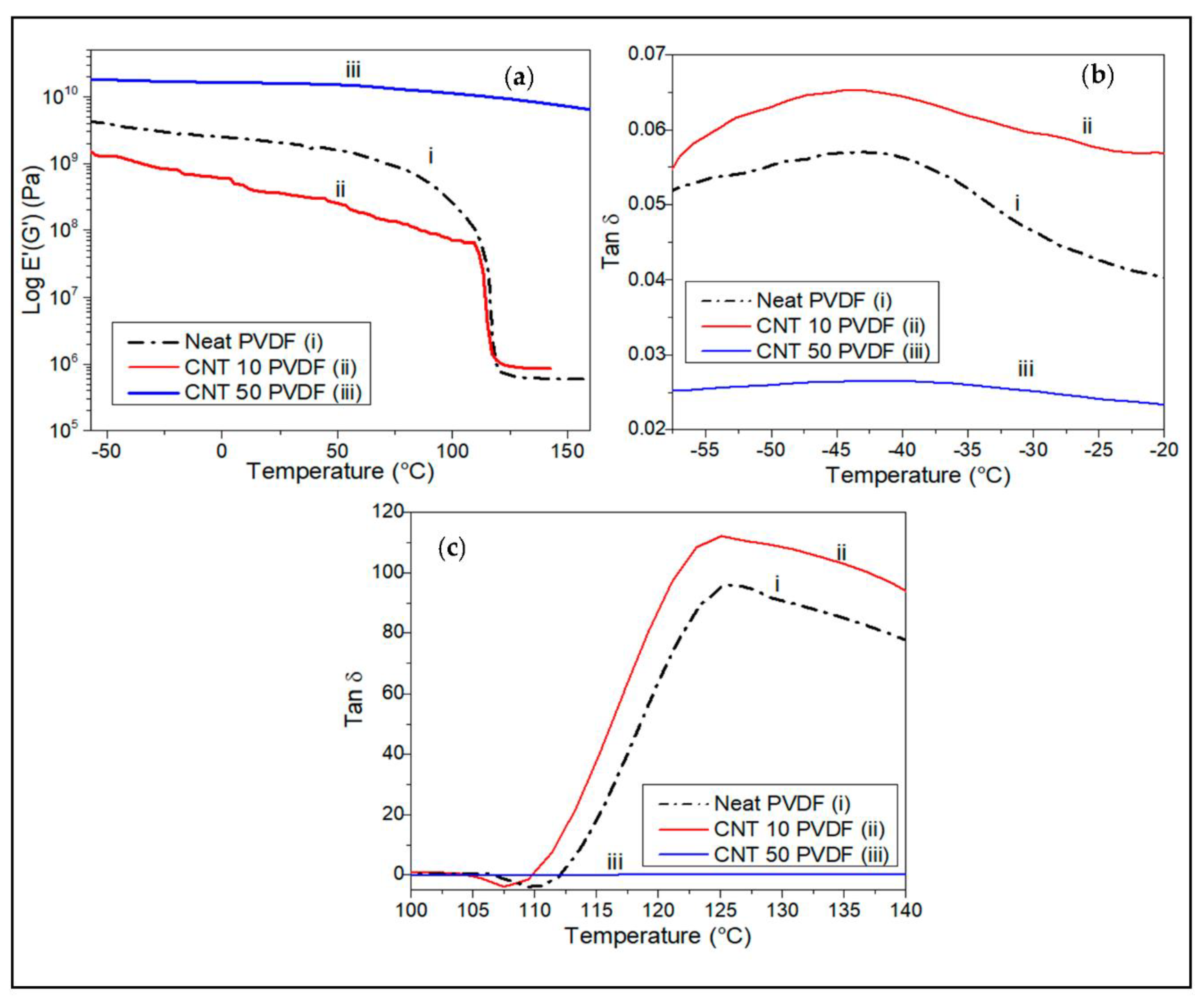

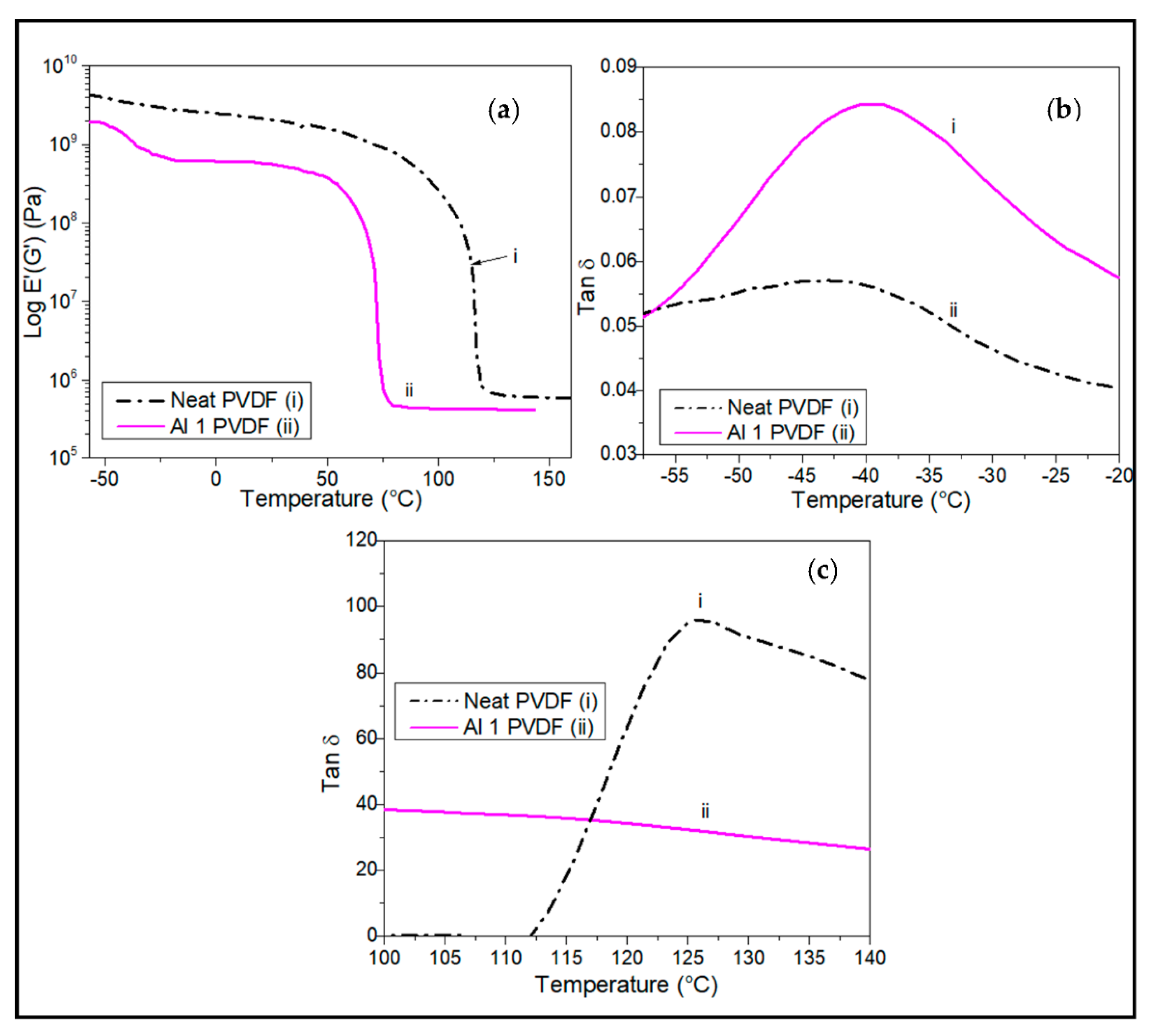

3.3. Dynamic Mechanical Analysis (DMA)

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ma, J.; Haque, R.I.; Larsen, R.M. Crystallization and mechanical properties of functionalized single-walled carbon nanotubes/polyvinylidene fluoride composites. J. Reinf. Plast. Compos. 2012, 31, 1417–1425. [Google Scholar] [CrossRef]

- Kang, G.; Cao, Y. Application and modification of poly(vinylidene fluoride) (PVDF) membranes—A review. J. Memb. Sci. 2014, 463, 145–165. [Google Scholar] [CrossRef]

- Zulfiqar, S.; Zulfiqar, M.; Rizvi, M.; Munirt, A. Study of the thermal degradation of polychlorotrifluoroethylene, poly (vinylidene fluoride) and copolymers of chiorotrifluoroethylene and vinylidene fluoride. Polym. Degrad. Stab. 1994, 43, 423–430. [Google Scholar] [CrossRef]

- Wan, C.; Bowen, C.R. Multiscale-structuring of polyvinylidene fluoride for energy harvesting: The impact of molecular-, micro- and macro-structure. J. Mater. Chem. A 2017, 5, 3091–3128. [Google Scholar] [CrossRef]

- Cao, Y.; Deng, Q.; Liu, Z.; Shen, D.; Wang, T.; Huang, Q.; Du, S.; Jiang, N.; Lin, C.-T.; Yu, J. Enhanced thermal properties of poly (vinylidene fl uoride) composites with ultrathin nanosheets of MXene. RSC Adv. 2017, 7, 20494–20501. [Google Scholar] [CrossRef]

- Kabir, E.; Khatun, M.; Nasrin, L.; Raihan, M.J.; Rahman, M. Pure β-phase formation in polyvinylidene fluoride (PVDF)—Carbon nanotube composites. J. Phys. D Appl. Phys. 2017, 50, 163002. [Google Scholar] [CrossRef]

- Feng, C.-X.; Duan, J.; Yang, J.-H.; Huang, T.; Zhang, N.; Wang, Y.; Zheng, X.-T.; Zhou, Z.-W. Carbon nanotubes accelerated poly (vinylidene fluoride) crystallization from miscible poly (vinylidene fluoride)/poly (methyl methacrylate) blend and the resultant crystalline morphologies. Eur. Polym. J. 2015, 68, 175–189. [Google Scholar] [CrossRef]

- Wang, C.; Qin, M.; Yi, Z.; Deng, H.; Wang, J.; Sun, Y.; Luo, G.; Shen, Q. Oxidation Mechanism of Core-Shell Structured Al @ PVDF Powders Synthesized by Solvent/Non-Solvent Method. Materials 2022, 15, 3036. [Google Scholar] [CrossRef]

- Qamar, Z.; Zakria, M.; Shakoor, R.I.; Raffi, M.; Mehmood, M.; Mahmood, A. Reinforcement of electroactive characteristics in polyvinylidene fluoride electrospun nanofibers by intercalation of multi-walled carbon nanotubes. J. Polym. Res. 2017, 24, 39. [Google Scholar] [CrossRef]

- Remanan, S.; Padmavathy, N.; Rabiya, R.; Ghosh, S.; Das, T.K.; Bose, S.; Sen, R.; Das, N.C. Converting polymer trash into treasure: An approach to prepare MoS2 nanosheets decorated PVDF sponge for oil/water separation and antibacterial applications. Ind. Eng. Chem. Res. 2020, 59, 20141–20154. [Google Scholar] [CrossRef]

- Mokhtari, F.; Spinks, G.M.; Sayyar, S.; Foroughi, J. Dynamic Mechanical and Creep Behaviour of Meltspun PVDF Nanocomposite Fibers. Nanomaterials 2021, 11, 2153. [Google Scholar] [CrossRef] [PubMed]

- Ouyang, Y.; Deng, Y.; Li, D.; Cai, Z.; Xu, R.; Lei, C. Electrical and Thermal Properties of Surface Nanotube/Polyvinylidene Fluoride Composites. IET Nanodielectr. 2018, 1, 122–126. [Google Scholar] [CrossRef]

- Ghosh, S.K.; Das, T.K.; Ganguly, S.; Paul, S.; Nath, K.; Katheria, A.; Ghosh, T.; Chowdhury, S.N.; Das, N.C. Carbon nanotubes and carbon nanofibers based co-continuous thermoplastic elastomeric blend composites for efficient microwave shielding and thermal management. Compos. Part A Appl. Sci. Manuf. 2022, 161, 107118. [Google Scholar] [CrossRef]

- Du, F.-P.; Qiao, X.; Wu, Y.-G.; Fu, P.; Liu, S.-P.; Zhang, Y.-F.; Wang, Q.-Y. Fabrication of porous polyvinylidene fluoride/multi-walled carbon nanotube nanocomposites and their enhanced thermoelectric performance. Polymers 2018, 10, 797. [Google Scholar] [CrossRef] [PubMed]

- Pereira, E.C.L.; Barra, G.M.O.; Soares, B.G.; Silva, A.A. Master batch approach for developing PVDF/EVA/CNT nanocomposites with co-continuous morphology and improved electrical conductivity. J. Appl. Polym. Sci. 2021, 138, 51164. [Google Scholar] [CrossRef]

- Chiu, F.; Chuang, Y.; Liao, S.; Chang, Y. Comparison of PVDF/PVAc/GNP and PVDF/PVAc/CNT ternary nanocomposites: Enhanced thermal/electrical properties and rigidity. Polym. Test. 2018, 65, 197–205. [Google Scholar] [CrossRef]

- Delisio, B.; Hu, X.; Wu, T.; Egan, G.C.; Young, G.; Zachariah, M.R. Probing the Reaction Mechanism of Aluminum/Poly(vinylidene fl uoride) Composites. J. Phys. Chem. B 2016, 120, 5534–5542. [Google Scholar] [CrossRef]

- Knott, M.C.; Craig, A.W.; Shankar, R.; Morgan, S.E.; Iacono, S.T.; Mates, J.E.; McCollum, J.M. Balancing processing ease with combustion performance in aluminum/PVDF energetic filaments. J. Mater. Res. 2020, 36, 203–210. [Google Scholar] [CrossRef]

- McCollum, J.; Morey, A.M.; Iacono, S.T. Morphological and Combustion Study of Interface Effects in Aluminum-Poly(vinylidene fluoride) Composites. Mater. Des. 2017, 134, 64–70. [Google Scholar] [CrossRef]

- Huang, B.C.; Jian, G.; Delisio, J.B.; Wang, H.; Zachariah, M.R.; Wang, H. Electrospray Deposition of Energetic Polymer Nanocomposites with High Mass Particle Loadings: A Prelude to 3D Printing of Rocket Motors. Adv. Eng. Mater. 2014, 17, 95–101. [Google Scholar] [CrossRef]

- Kim, D.W.; Kim, K.T.; Min, T.S.; Kim, K.J.; Kim, S.H. Improved Energetic-Behaviors of Spontaneously Surface-Mediated Al Particles. Sci. Rep. 2017, 7, 4659. [Google Scholar] [CrossRef]

- Pantoya, M.L.; Dean, S.W. Thermochimica Acta The influence of alumina passivation on nano-Al/Teflon reactions. Thermochim. Acta 2009, 493, 109–110. [Google Scholar] [CrossRef]

- Osborne, D.T.; Pantoya, M.L. Effect of Al particle size on the thermal degradation of Al/Teflon mixtures. Combust. Sci. Technol. 2007, 179, 1467–1480. [Google Scholar] [CrossRef]

- Xiao, Y.-J.; Wang, W.-Y.; Chen, X.-J.; Lin, T.; Zhang, Y.-T.; Yang, J.-H.; Wang, Y.; Zhou, Z.-W. Composites: Part A Hybrid network structure and thermal conductive properties in poly (vinylidene fluoride) composites based on carbon nanotubes and graphene nanoplatelets. Compos. Part A Appl. Sci. Manuf. 2016, 90, 614–625. [Google Scholar] [CrossRef]

- Li, Y.; Li, X.; Xiang, F.; Huang, T.; Wang, Y.; Wu, J. properties of PLLA/PEG blend with multiwalled carbon nanotubes. Polym. Adv. Technol. 2011, 22, 1959–1970. [Google Scholar] [CrossRef]

- Cheng, L.; Huang, C.; Yang, Y.; Li, Y.; Meng, Y.; Li, Y.; Chen, H.; Song, D.; Artiaga, R. Preparation and Combustion Performance of B/PVDF/Al Composite Microspheres. Propellants Explos. Pyrotech. 2020, 45, 657–664. [Google Scholar] [CrossRef]

- Chrissafis, K.; Bikiaris, D. Thermochimica Acta Can nanoparticles really enhance thermal stability of polymers? Part I: An overview on thermal decomposition of addition polymers. Thermochim. Acta 2011, 523, 1–24. [Google Scholar] [CrossRef]

- Yang, S.; Rafael, J.; Barrera, E.V.; Lozano, K. Thermal analysis of an acrylonitrile—Butadiene—Styrene/SWNT composite. Polym. Degrad. Stab. 2004, 83, 383–388. [Google Scholar] [CrossRef]

- Liu, Y.; Ma, J.; Liu, W.; Bian, F.; Li, X. Free radical decay and micro-structure evolution of PVDF membranes in situ irradiated by synchrotron radiation X-ray. Polym. Test. 2022, 108, 107507. [Google Scholar] [CrossRef]

| Composite | PVDF (wt.%) | SWCNT (wt.%) |

|---|---|---|

| Neat PVDF | 100 | 0 |

| CNT 5 PVDF | 95 | 5 |

| CNT10 PVDF | 90 | 10 |

| CNT 50 PVDF | 50 | 50 |

| Al2O3 1 PVDF | 99 | 0 |

| Al2O3 5 PVDF | 95 | 0 |

| Al2O3 10 PVDF | 90 | 0 |

| Al2O3 50 PVDF | 50 | 0 |

| CNT 1 Al2O3 1 PVDF | 98 | 1 |

| CNT 5 Al2O3 1 PVDF | 94 | 5 |

| CNT 1 Al2O3 5 PVDF | 94 | 1 |

| CNT 10 Al2O3 1 PVDF | 89 | 10 |

| CNT 1 Al2O3 10 PVDF | 89 | 1 |

| CNT 5 Al2O3 5 PVDF | 90 | 5 |

| CNT 10 Al2O3 10 PVDF | 80 | 10 |

| Composite | Tm (°C) | ∆Hm (J/g) | χc (%) |

|---|---|---|---|

| Neat PVDF | 171.6 | 53.2 | 50.67 |

| CNT 5 PVDF | 168.9 | 56.4 | 53.71 |

| CNT10 PVDF | 168.6 | 54.7 | 52.10 |

| CNT 50 PVDF | 162.7 | 7.4 | 7.05 |

| Al2O3 1 PVDF | 170.2 | 57.0 | 54.29 |

| Al2O3 5 PVDF | 170.0 | 38.0 | 36.19 |

| Al2O3 10 PVDF | 170.8 | 52.1 | 49.62 |

| Al2O3 50 PVDF | 171.0 | 21.5 | 20.48 |

| CNT 1 Al2O3 1 PVDF | 172.6 | 64.6 | 61.52 |

| CNT 5 Al2O3 1 PVDF | 169.7 | 47.2 | 44.95 |

| Composite | 5% Weight Loss Temp. (°C) | Char Yield at 600 °C (%) |

|---|---|---|

| Neat PVDF | 401.5 | 36.5 |

| CNT1 PVDF | 354.6 | 34.0 |

| CNT10 PVDF | 334.2 | 40.7 |

| CNT 50 PVDF | 300.7 | 63.3 |

| Al1PVDF | 318.0 | 36.9 |

| Al5PVDF | 303.2 | 39.5 |

| Al10PVDF | 297.8 | 42.7 |

| Al50PVDF | 253.7 | 46.4 |

| CNT 1 Al2O3 1 PVDF | 333.0 | 37.8 |

| CNT 10 Al2O3 1 PVDF | 190.4 | 40.6 |

| CNT 10 Al2O3 10 PVDF | 328.6 | 51.3 |

| Composite | Tg (°C) | Tm (°C) |

|---|---|---|

| Neat PVDF | −42.6 | 125.2 |

| CNT10 PVDF | −44.3 | 127.0 |

| CNT 50 PVDF | −39.4 | - |

| CNT 1 Al2O3 1 PVDF | −42.6 | 129.2 |

| CNT 10 Al2O3 1 PVDF | −37.5 | 117.7 |

| CNT 1 Al2O3 10 PVDF | −33.2 | 119.9 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gooneratne, R.; Iroh, J.O. Thermomechanical and Pre-Ignition Properties of Multicomponent Poly(Vnylidene Fluoride)/Aluminum Oxide/Single-Walled Carbon Nanotube Hybrid Nanocomposites. J. Compos. Sci. 2022, 6, 380. https://doi.org/10.3390/jcs6120380

Gooneratne R, Iroh JO. Thermomechanical and Pre-Ignition Properties of Multicomponent Poly(Vnylidene Fluoride)/Aluminum Oxide/Single-Walled Carbon Nanotube Hybrid Nanocomposites. Journal of Composites Science. 2022; 6(12):380. https://doi.org/10.3390/jcs6120380

Chicago/Turabian StyleGooneratne, Ruchinda, and Jude O. Iroh. 2022. "Thermomechanical and Pre-Ignition Properties of Multicomponent Poly(Vnylidene Fluoride)/Aluminum Oxide/Single-Walled Carbon Nanotube Hybrid Nanocomposites" Journal of Composites Science 6, no. 12: 380. https://doi.org/10.3390/jcs6120380

APA StyleGooneratne, R., & Iroh, J. O. (2022). Thermomechanical and Pre-Ignition Properties of Multicomponent Poly(Vnylidene Fluoride)/Aluminum Oxide/Single-Walled Carbon Nanotube Hybrid Nanocomposites. Journal of Composites Science, 6(12), 380. https://doi.org/10.3390/jcs6120380