Specific Application Features of Ti-TiN-(Ti,Cr,Al)N, Zr-ZrN-(Zr,Mo,Al)N, and ZrHf-(Zr,Hf)N-(Zr,Hf,Cr,Mo,Al)N Multilayered Nanocomposite Coatings in End Milling of the Inconel 718 Nickel-Chromium Alloy

Abstract

:1. Introduction

- Coating ZrHf-(Zr,Hf)N-(Zr,Hf,Cr,Mo,Al)N. This coating is based on the ZrN system, providing good resistance to cracking. The introduction into the coating composition of such elements as hafnium (Hf), molybdenum (Mo), and aluminum (Al) can enhance thermal stability and resistance to oxidation wear due to the formation of hard protective films. At the same time, Cr and Al can provide high hardness and wear resistance in combination with heat resistance. The architecture of the coating consists of three functional layers [52,53,54]:

- an adhesive layer of ZrHf, 30–50 nm thick, which provides not only good adhesion to the substrate, but also a leveling effect due to the plastic filling of micropores and irregularities on the substrate surface,

- a transition layer of (Zr,Hf)N, 0.7–1.0 µm, which provides a smoothing transition of the substrate properties to the wear-resistant layer,

- a wear-resistant layer of (Zr,Hf,Cr,Mo,Al)N, 3.0–3.5 µm which, in turn, has a nanolayer structure.

- Coating Zr-ZrN-(Zr,Mo,Al)N, which is similar in its composition to the ZrHf-(Zr,Hf)N-(Zr,Hf,Cr,Mo,Al)N coating, but contains no Hf or Cr.

- The properties of the considered coatings were compared with the properties of the coating consisting of Ti-TiN-(Ti,Cr,Al)N with similar parameters, including total thickness, thickness of the functional layers, and modulation period in the wear-resistant layer. This coating was chosen as an object of comparison due to the widespread use of coatings based on the (Ti,Al)N and (Ti,Cr,Al)N systems during the machining (in particular, the end milling) of titanium alloys [16,17,18,19,20,21,22].

2. Materials and Methods

- a transmission electron microscope (TEM) JEM 2100 (JEOL, Japan) at an accelerating voltage of 200 kV. The samples for the study (lamellas) were cut out using a Strata focused ion beam (FIB) 205 (FEI, USA),

- a scanning electron microscope (SEM) FEI Quanta 600 FEG.

3. Results

3.1. Hardness, Elastic Modulus, and Critical Fracture Load in Scratch Testing

3.2. Adhesion Component of the Coefficient of Friction (COF)

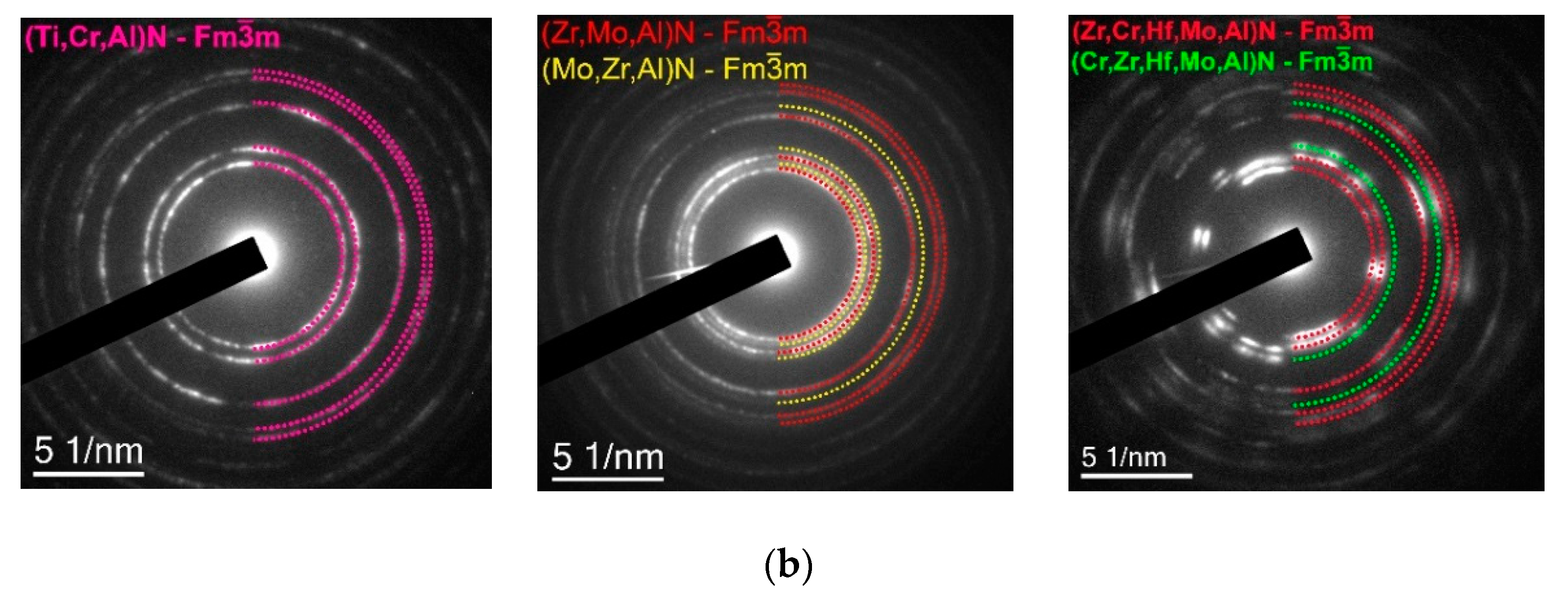

3.3. Structure and Phase Composition

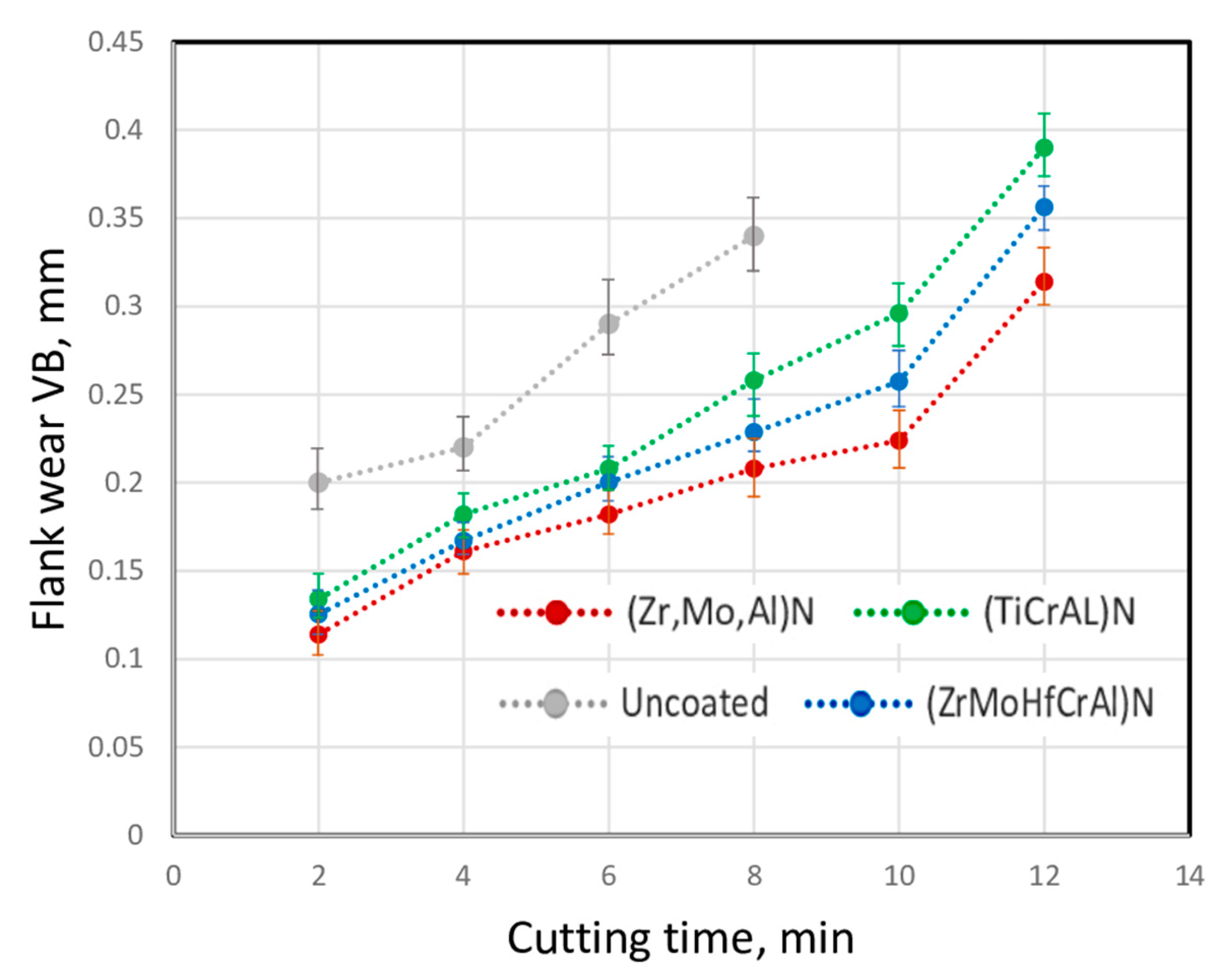

3.4. Wear Resistance in the End Milling of Inconel 718

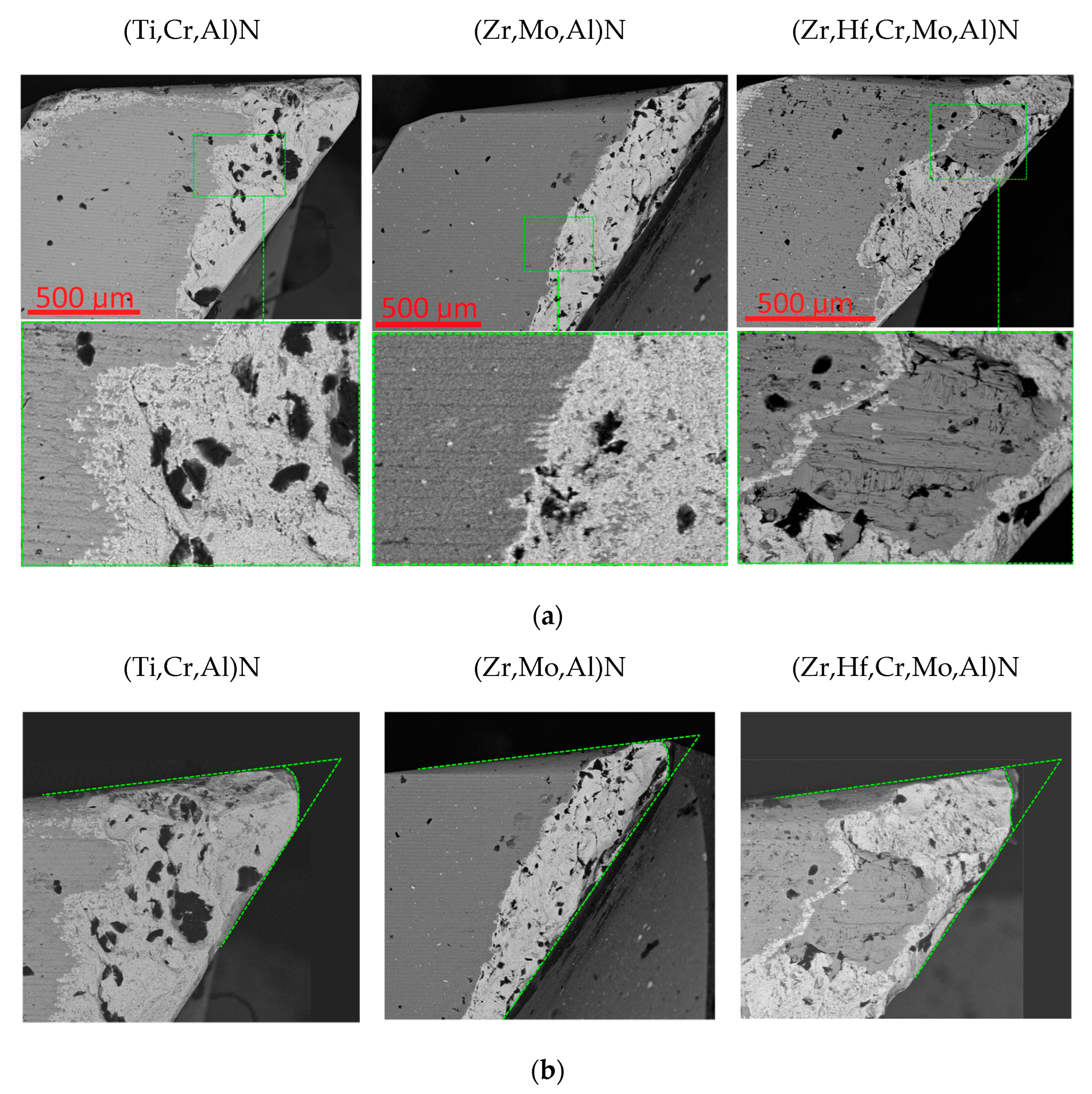

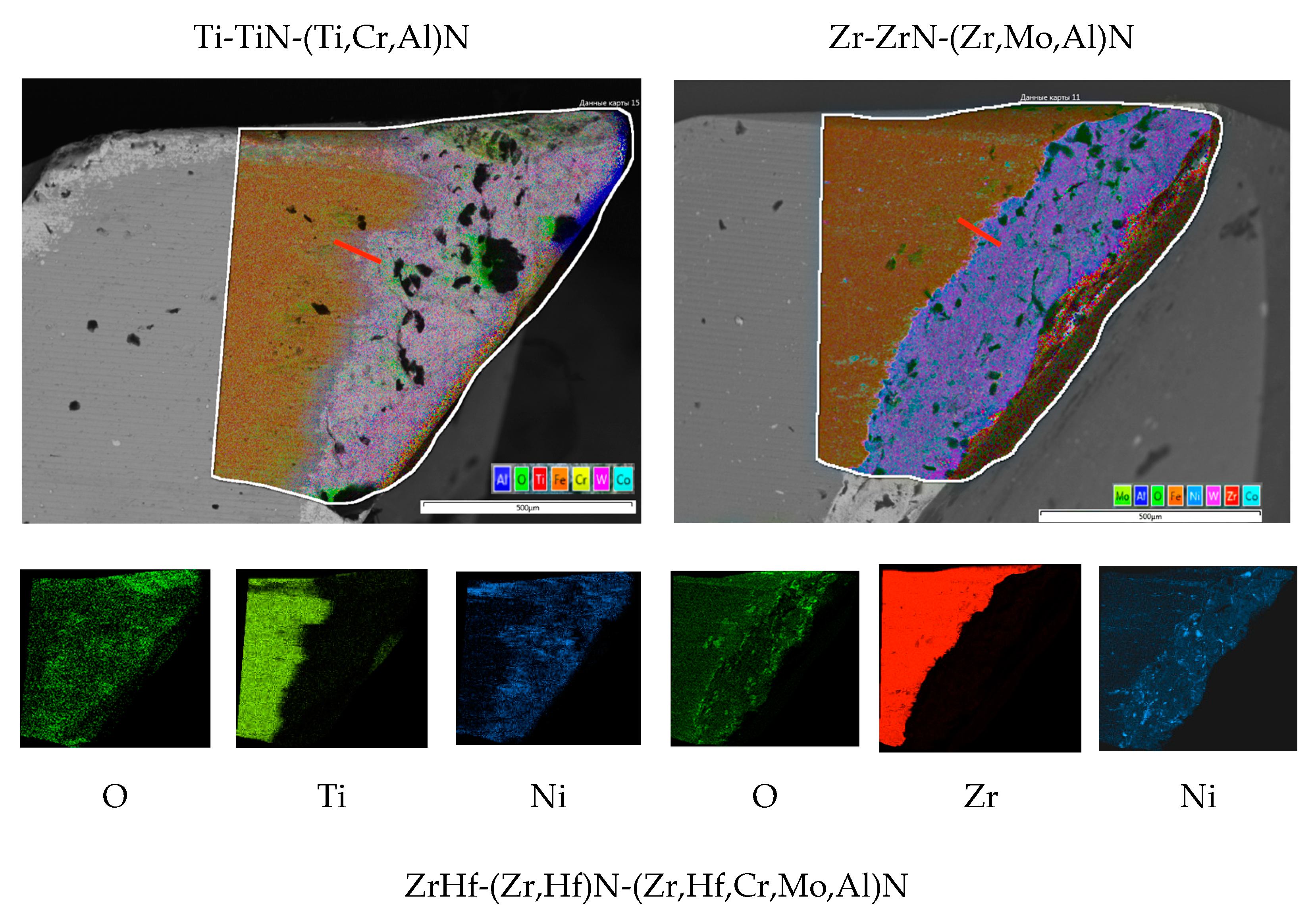

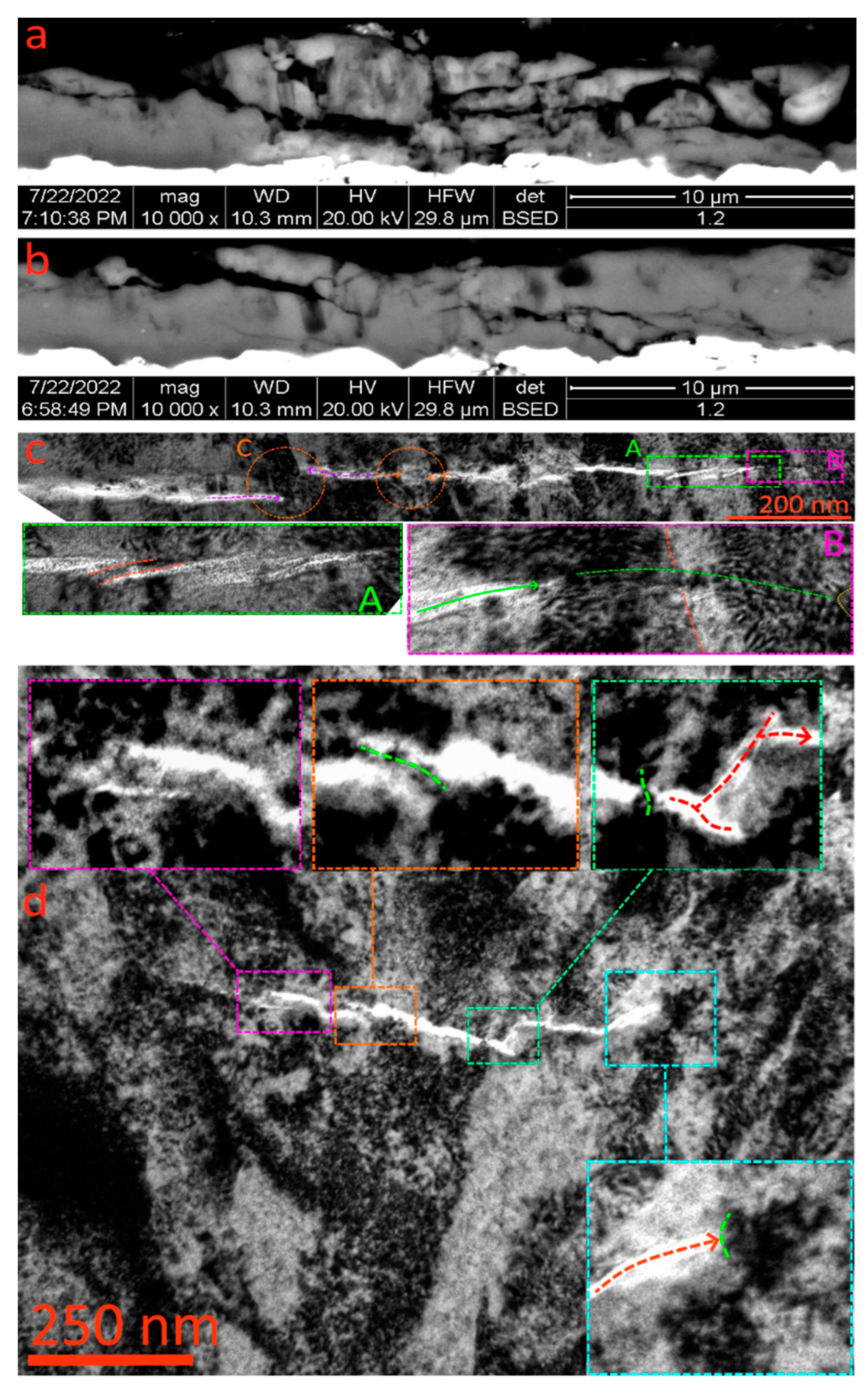

3.5. Studies of the Mechanism of Wear, Diffusion, and Oxidation Processes in the Coating Consisting of (Ti,Cr,Al)N

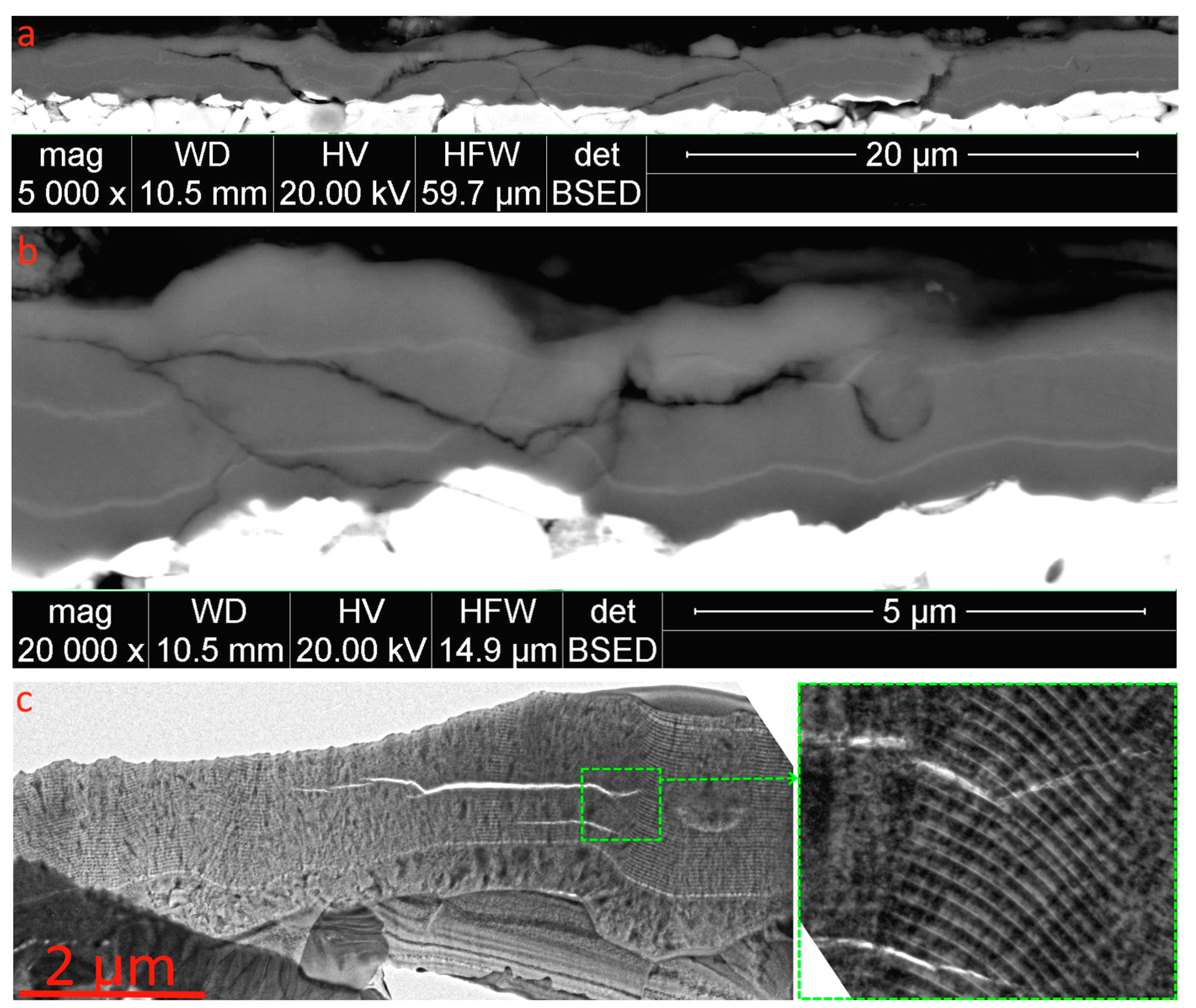

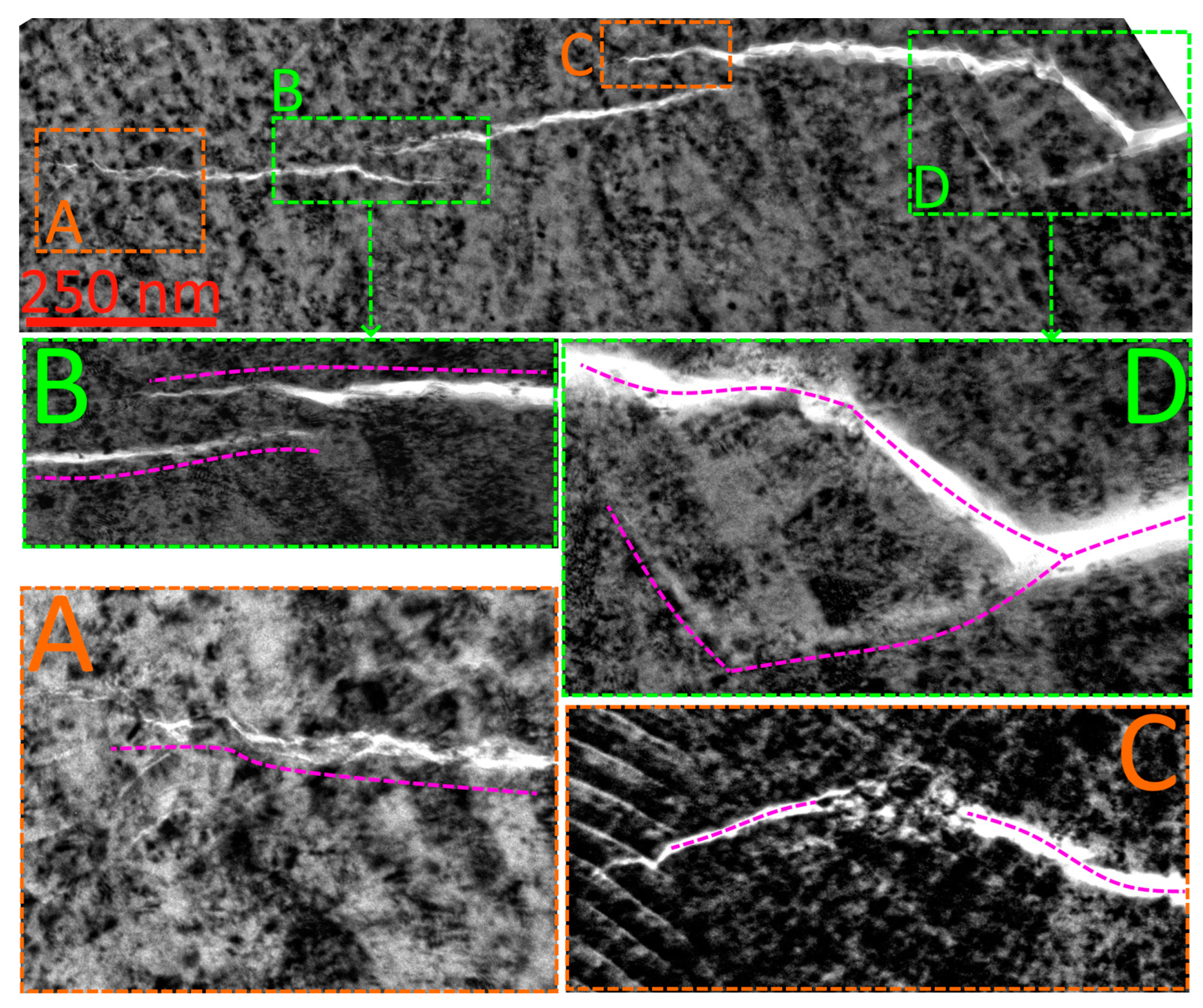

3.6. Studies of the Mechanism of Wear, Diffusion, and Oxidation Processes in the Coating Consisting of (Zr,Mo,Al)N

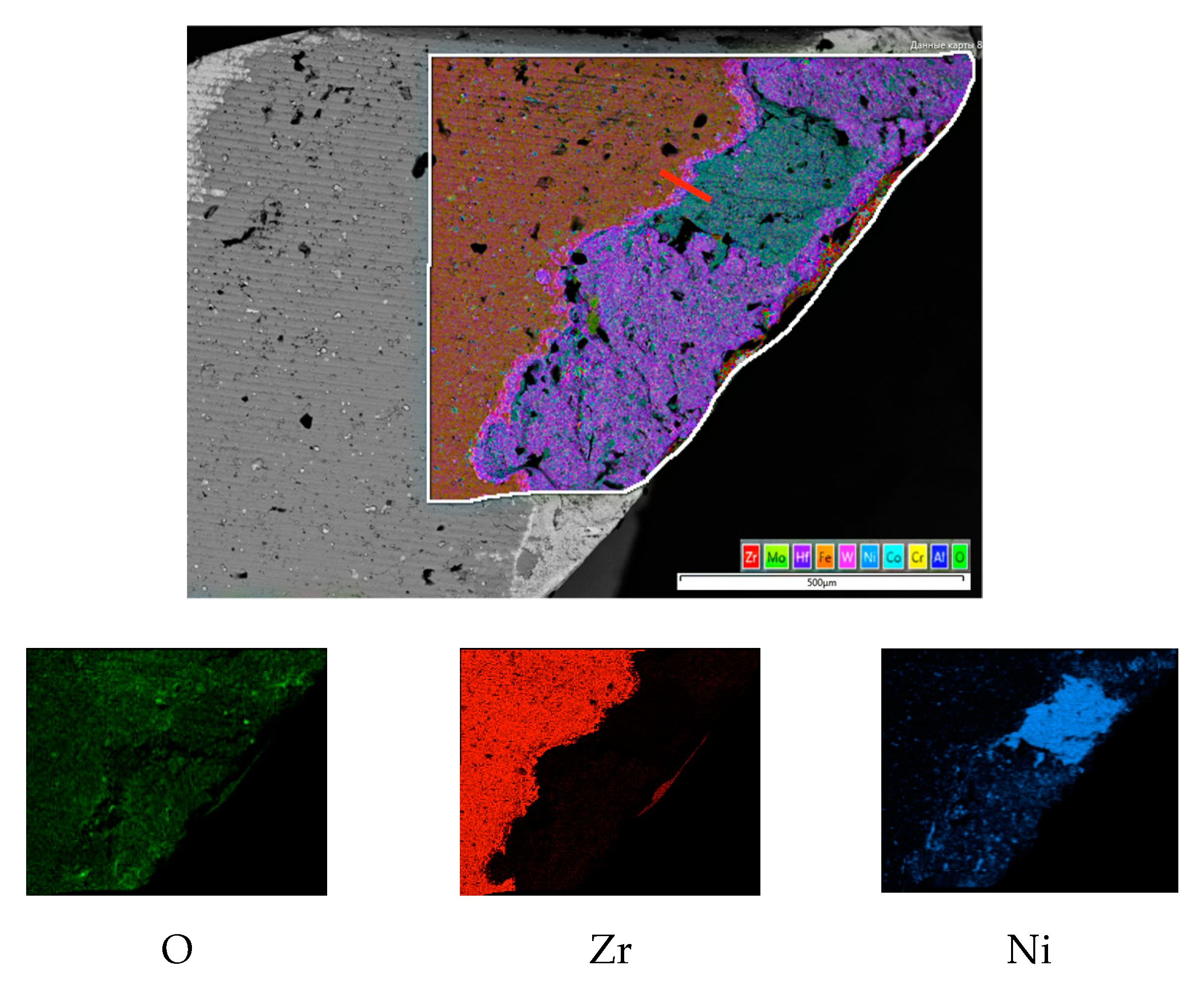

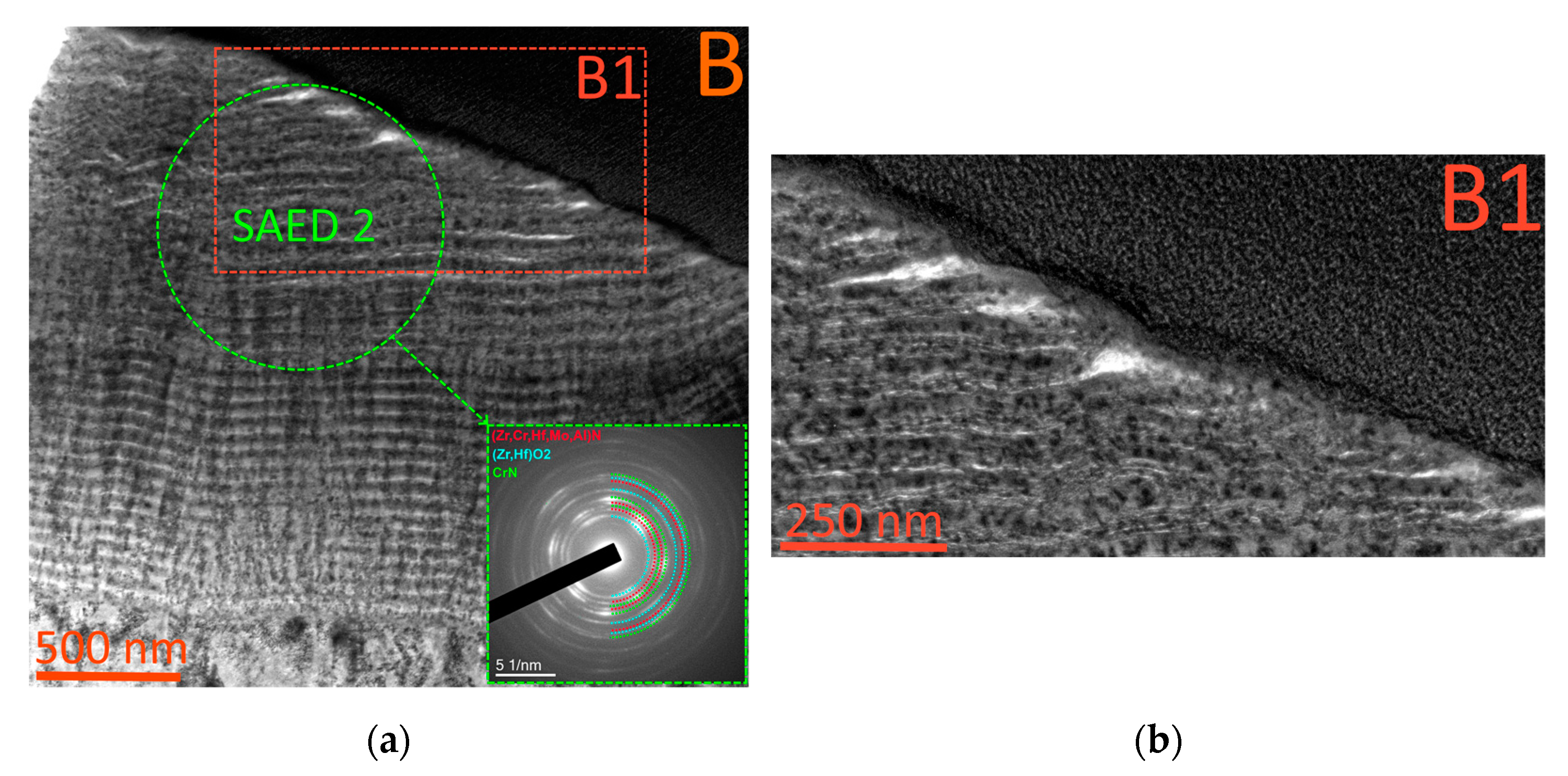

3.7. Studies of the Mechanism of Wear, Diffusion, and Oxidation Processes in the Coating Consisting of (Zr,Hf,Cr,Mo,Al)N

4. Conclusions

- The Ti-TiN-(Ti,Cr,Al)N and Zr-ZrN-(Zr,Mo,Al)N coatings have close values of hardness (31–32 GPa), while the hardness of the ZrHf-(Zr,Hf)N-(Zr,Hf,Cr,Mo,Al)N coating is slightly lower (about 27 GPa).

- The Zr-ZrN-(Zr,Mo,Al)N and ZrHf-(Zr,Hf)N-(Zr,Hf,Cr,Mo,Al)N coatings have noticeably lower values of the adhesion component fadh of the COF at elevated temperatures in comparison with the Ti-TiN-(Ti,Cr,Al)N coating.

- All three considered coatings provided an increase in the wear resistance of end milling cutters by about 2 times compared to uncoated tools. At the same time, the Zr-ZrN-(Zr,Mo,Al)N-coated tool demonstrated the highest wear resistance among all samples.

- We found significant differences in the mechanisms of wear for the tools with the examined coatings. For the coatings consisting of Ti-TiN-(Ti,Cr,Al)N and Zr-ZrN-(Zr,Mo,Al)N, active cracking was typical, while for the coating consisting of ZrHf-(Zr,Hf)N-(Zr,Hf,Cr,Mo,Al)N, the oxidation process was a key factor. The Zr-ZrN-(Zr,Mo,Al)N coating exhibitsd better resistance to cracking in comparison with the Ti-TiN-(Ti,Cr,Al)N coating.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- INCONEL® Alloy 718. UNS N07718/W.Nr. 2.4668. Publication Number SMC-045. Special Metals Corporation (2007). Available online: https://www.specialmetals.com/ (accessed on 3 September 2022).

- What Are the Applications for Inconel 718? Langley Alloys. Retrieved 3 March 2022. Available online: https://www.langleyalloys.com/knowledge-advice/what-are-the-applications-for-inconel-718 (accessed on 3 September 2022).

- NACE MR0175/ISO 15156-1:2001(E); Petroleum and Natural Gas Industries—Materials for Use in H2 S-Containing Environments in Oil and Gas Production. NACE International: Houston, TX, USA, 2001.

- American Elements, Los Angeles, California, USA. Available online: https://www.americanelements.com/inconel-718-alloy. (accessed on 3 September 2022).

- Thakur, D.G.; Ramamoorthy, B.; Vijayaraghavan, L. Effect of posttreatments on the performance of tungsten carbide (K20) tool while machining (turning) of Inconel 718. Int. J. Adv. Manuf. Technol. 2015, 76, 587–596. [Google Scholar] [CrossRef]

- Dudzinski, D.; Devillez, A.; Moufki, A.; Larrouquère, D.; Zerrouki, V.; Vigneau, J. A review of developments towards dry and machining (turning) of Inconel 718 alloy. Int. J. Mach. Tools Manuf. 2004, 44, 439–456. [Google Scholar] [CrossRef]

- Arunachalam, R.; Mannan, M.A. Machinability of nickel-based high temperature alloys. Mach. Sci. Technol. 2000, 4, 127–168. [Google Scholar]

- Nuclear Power. Available online: www.nuclear-power.com/nuclear-engineering/metals-what-are-metals/alloys-composition-properties-of-metal-alloys/superalloys/properties-of-inconel-718-nickel-based-superalloy/ (accessed on 3 September 2022).

- Zhao, J.; Liu, Z.; Wang, B.; Hu, J. PVD AlTiN coating effects on tool-chip heat partition coefficient and cutting temperature rise in orthogonal cutting Inconel 718. Int. J. Heat Mass Transf. 2020, 163, 120449. [Google Scholar] [CrossRef]

- Kuzin, V.V.; Grigoriev, S.N.; Volosova, M.A. The role of the thermal factor in the wear mechanism of ceramic tools: Part 1. Macrolevel. J. Frict. Wear 2014, 35, 505–510. [Google Scholar] [CrossRef]

- Grigoriev, S.N.; Gurin, V.D.; Volosova, M.A.; Cherkasova, N.Y. Development of residual cutting tool life prediction algorithm by processing on CNC machine tool. Materwiss. Werksttech. 2013, 44, 790–796. [Google Scholar] [CrossRef]

- Grigoriev, S.; Vereschaka, A.; Milovich, F.; Tabakov, V.; Sitnikov, N.; Andreev, N.; Sviridova, T.; Bublikov, J. Investigation of multicomponent nanolayer coatings based on nitrides of Cr, Mo, Zr, Nb, and Al. Surf. Coat. Technol. 2020, 401, 126258. [Google Scholar] [CrossRef]

- Grigoriev, S.; Vereschaka, A.; Milovich, F.; Sitnikov, N.; Andreev, N.; Bublikov, J.; Kutina, N. Investigation of the properties of the Cr,Mo-(Cr,Mo,Zr,Nb)N-(Cr,Mo,Zr,Nb,Al)N multilayer composite multicomponent coating with nanostructured wear-resistant layer. Wear 2021, 468–469, 203597. [Google Scholar] [CrossRef]

- Liao, H.; Normand, B.; Coddet, C. Influence of coating microstructure on the abrasive wear resistance of WC/Co cermet coatings. Surf. Coat. Technol. 2000, 124, 235–242. [Google Scholar] [CrossRef]

- Vereschaka, A.; Tabakov, V.; Grigoriev, S.; Sitnikov, N.; Oganyan, G.; Andreev, N.; Milovich, F. Investigation of wear dynamics for cutting tools with multilayer composite nanostructured coatings in turning constructional steel. Wear 2019, 420–421, 17–37. [Google Scholar] [CrossRef]

- Courbon, C.; Kramar, D.; Krajnik, P.; Pusavec, F.; Rech, J.; Kopac, J. Investigation of Machining Performance in High-Pressure Jet Assisted Turning of Inconel 718: An Experimental Study. Int. J. Mach. Tools Manuf. 2009, 49, 1114–1125. [Google Scholar] [CrossRef]

- Thakur, D.G.; Ramamoorthy, B.; Vijayaraghavan, L. Some Investigations on High Speed Dry Machining of Aerospace Material Inconel 718 Using Multicoated Carbide Inserts. Mater. Manuf. Process. 2012, 27, 1066–1072. [Google Scholar] [CrossRef]

- Zhao, J.; Liu, Z.; Shen, Q.; Wang, B.; Wang, Q. Investigation of Cutting Temperature during Turning Inconel 718 with (Ti,Al)N PVD Coated Cemented Carbide Tools. Materials 2018, 11, 1281. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Fan, Y.H.; Hao, Z.P.; Lin, J.Q.; Yu, Z.X. Material Response at Tool–Chip Interface and Its Effects on Tool Wear in Turning Inconel 718. Mater. Manuf. Process. 2014, 29, 1446–1452. [Google Scholar] [CrossRef]

- Ezugwu, E.O.; Bonney, J. Effect of High-Pressure Coolant Supply When Machining Nickel-Base, Inconel 718, Alloy with Coated Carbide Tools. J. Mater. Process. Technol. 2004, 153–154, 1045–1050. [Google Scholar] [CrossRef]

- Chandra Behera, B.; Sudarsan Ghosh, C.; Paruchuri, V.R. Study of Saw-Tooth Chip in Machining of Inconel 718 by Metallographic Technique. Mach. Sci. Technol. 2019, 23, 431–454. [Google Scholar] [CrossRef]

- Hua, Y.; Liu, Z. Effects of Cutting Parameters and Tool Nose Radius on Surface Roughness and Work Hardening during Dry Turning Inconel 718. Int. J. Adv. Manuf. Technol. 2018, 96, 2421–2430. [Google Scholar] [CrossRef]

- Vereschaka, A.; Tabakov, V.; Grigoriev, S.; Aksenenko, A.; Sitnikov, N.; Oganyan, G.; Seleznev, A.; Shevchenko, S. Effect of adhesion and the wear-resistant layer thickness ratio on mechanical and performance properties of ZrN—(Zr,Al,Si)N coatings. Surf. Coat. Technol. 2019, 357, 218–23424. [Google Scholar] [CrossRef]

- Sobol, O.V.; Andreev, A.A.; Grigoriev, S.N.; Volosova, M.A.; Gorban, V.F. Vacuum-arc multilayer nanostructured TiN/Ti coatings: Structure, stress state, properties. Met. Sci. Heat Treat. 2012, 54, 28–33. [Google Scholar] [CrossRef]

- Chen, L.; Du, Y.; Yin, F.; Li, J. Mechanical properties of (Ti, Al)N monolayer and TiN/(Ti, Al)N multilayer coatings. Int. J. Refract. Hard. Met. 2007, 25, 72–76. [Google Scholar] [CrossRef]

- Metel, A.S.; Grigoriev, S.N.; Melnik, Y.A.; Prudnikov, V.V. Glow discharge with electrostatic confinement of electrons in a chamber bombarded by fast electrons. Plasma Phys. Rep. 2011, 37, 628–637. [Google Scholar] [CrossRef]

- Maksakova, O.V.; Simoẽs, S.; Pogrebnjak, A.D.; Bondar, O.V.; Kravchenko, Y.O.; Koltunowicz, T.N.; Shaimardanov, Z.K. Multilayered ZrN/CrN coatings with enhanced thermal and mechanical properties. J. Alloys Compd. 2019, 776, 679–690. [Google Scholar] [CrossRef]

- Maksakova, O.V.; Webster, R.F.; Tilley, R.D.; Ivashchenko, V.I.; Postolnyi, B.O.; Bondar, O.V.; Takeda, Y.; Rogoz, V.M.; Sakenova, R.E.; Zukowski, P.V.; et al. Nanoscale architecture of (CrN/ZrN)/(Cr/Zr) nanocomposite coatings: Microstructure, composition, mechanical properties and first-principles calculations. J. Alloys Compd. 2020, 831, 154808. [Google Scholar] [CrossRef]

- Tiwari, A.; Talwekar, R.H.; Verma, M.L. First-Principles Study on the Structural, Electronic, Optical, Mechanical, and Adsorption Properties of Cubical Transition Metal Nitrides MN (M = Ti, Zr and Hf). J. Electron. Mater. 2021, 50, 3312–3325. [Google Scholar] [CrossRef]

- Wu, Z.T.; Qi, Z.B.; Zhang, D.F.; Wang, Z.C. Microstructure, mechanical properties and oxidation resistance of (Zr, Hf)Nx coatings by magnetron co-sputtering. Surf. Coat. Technol. 2015, 276, 219–227. [Google Scholar] [CrossRef]

- Atar, E.; Kayali, E.S.; Cimenoglu, H. The effect of oxidation on the structure and hardness of (Zr,Hf)N coatings. Defect Diffus. Forum 2010, 297–301, 1395–1399. [Google Scholar] [CrossRef]

- Atar, E.; Kayali, E.S.; Cimenoglu, H. Sliding wear behaviour of ZrN and (Zr, 12 wt% Hf)N coatings. Tribol. Int. 2006, 39, 297–302. [Google Scholar] [CrossRef]

- Tsai, D.-C.; Chang, Z.-C.; Kuo, L.-Y.; Lin, T.-J.; Lin, T.-N.; Shieu, F.-S. Solid solution coating of (TiVCrZrHf)N with unusual structural evolution. Surf. Coat. Technol. 2013, 217, 84–87. [Google Scholar] [CrossRef]

- Hsu, S.-Y.; Lai, Y.-T.; Chang, S.-Y.; Tsai, S.-Y.; Duh, J.-G. Combinatorial synthesis of reactively co-sputtered high entropy nitride (HfNbTiVZr)N coatings: Microstructure and mechanical properties. Surf. Coat. Technol. 2022, 442, 128564. [Google Scholar] [CrossRef]

- Pogrebnjak, A.D.; Yakushchenko, I.V.; Bagdasaryan, A.A.; Bondar, O.V.; Krause-Rehberg, R.; Abadiasc, G.; Chartierc, P.; Oyoshid, K.; Takeda, Y.; Beresnev, V.M.; et al. Microstructure, physical and chemical properties of nanostructured (Ti–Hf–Zr–V–Nb)N coatings under different deposition conditions. Mater. Chem. Phys. 2014, 147, 1079–1091. [Google Scholar] [CrossRef]

- Cui, P.; Li, W.; Liu, P.; Zhang, K.; Ma, F.; Chen, X.; Feng, R.; Liaw, P.K. Effects of nitrogen content on microstructures and mechanical properties of (AlCrTiZrHf)N high-entropy alloy nitride films. J. Alloys Compd. 2020, 834, 155063. [Google Scholar] [CrossRef]

- Nemchenko, U.S.; Beresnev, V.M.; Klimenko, S.A.; Podchernyaeva, I.A.; Turbin, P.V.; Andreev, A.A. Wear resistance of the multicomponent coatings of the (Ti-Zr-Hf-V-Nb-Ta)N system at elevated temperature. J. Superhard Mater. 2015, 37, 322–326. [Google Scholar] [CrossRef]

- Tsai, D.-C.; Liang, S.-C.; Chang, Z.-C.; Lin, T.-N.; Shiao, M.-H.; Shieu, F.-S. Effects of substrate bias on structure and mechanical properties of (TiVCrZrHf)N coatings. Surf. Coat. Technol. 2012, 207, 293–299. [Google Scholar] [CrossRef]

- Wang, Y.; Tang, Y.; Wan, W.; Zhang, X. High-Temperature Oxidation Resistance of CrMoN Films. J. Mater. Eng. Perform. 2020, 29, 6412–6416. [Google Scholar] [CrossRef]

- Jaf, Z.N.; Jiang, Z.-T.; Miran, H.A.; Altarawneh, M.; Veder, J.-P.; Minakshi, M.; Zhou, Z.; Lim, H.N.; Huang, N.M.; Dlugogorski, B.Z. Physico-chemical properties of CrMoN coatings—Combined experimental and computational studies. Thin Solid Films 2020, 693, 137671. [Google Scholar] [CrossRef]

- Zhao, Y.; Chen, S.; Chen, Y.; Wu, S.; Xie, W.; Yan, W.; Wang, S.; Liao, B.; Zhang, S. Super-hard and anti-corrosion (AlCrMoSiTi)Nx high entropy nitride coatings by multi-arc cathodic vacuum magnetic filtration deposition. Vacuum 2022, 195, 110685. [Google Scholar] [CrossRef]

- Feng, X.; Zhang, K.; Zheng, Y.; Zhou, H.; Wan, Z. Chemical state, structure and mechanical properties of multi-element (CrTaNbMoV)Nx films by reactive magnetron sputtering. Mater. Chem. Phys. 2020, 239, 121991. [Google Scholar] [CrossRef]

- Bagdasaryan, A.A.; Pshyk, A.V.; Coy, L.E.; Konarski, P.; Misnik, M.; Ivashchenko, V.I.; Kempiński, M.; Mediukh, N.R.; Pogrebnjak, A.D.; Beresnev, V.M.; et al. A new type of (TiZrNbTaHf)N/MoN nanocomposite coating: Microstructure and properties depending on energy of incident ions. Compos. Part B Eng. 2018, 146, 132–144. [Google Scholar] [CrossRef]

- Kong, J.-Z.; Hou, T.-J.; Wang, Q.-Z.; Yin, L.; Zhou, F.; Zhou, Z.-F.; Li, L.K.-Y. Influence of titanium or aluminum doping on the electrochemical properties of CrN coatings in artificial seawater. Surf. Coat. Technol. 2016, 307, 118–124. [Google Scholar] [CrossRef]

- Wang, Q.Z.; Zhou, F.; Yan, J.W. Evaluating mechanical properties and crack resistance of CrN, CrTiN, CrAlN and CrTiAlN coatings by nanoindentation and scratch tests. Surf. Coat. Technol. 2016, 285, 203–213. [Google Scholar] [CrossRef]

- Beliardouh, N.E.; Bouzid, K.; Nouveau, C.; Tlili, B.; Walock, M.J. Tribological and electrochemical performances of Cr/CrN and Cr/CrN/CrAlN multilayer coatings deposited by RF magnetron sputtering. Tribol. Int. 2015, 82, 443–452. [Google Scholar] [CrossRef]

- Fox-Rabinovich, G.S.; Yamomoto, K.; Veldhuis, S.C.; Kovalev, A.I.; Dosbaeva, G.K. Tribological adaptability of TiAlCrN PVD coatings under high performance dry machining conditions. Surf. Coat. Technol. 2005, 200, 1804–1813. [Google Scholar] [CrossRef]

- Bobzin, K. High-performance coatings for cutting tools. CIRP J. Manuf. Sci. Technol. 2017, 18, 1–9. [Google Scholar] [CrossRef]

- Vereschaka, A.; Tabakov, V.; Grigoriev, S.; Sitnikov, N.; Milovich, F.; Andreev, N.; Sotova, C.; Kutina, N. Investigation of the influence of the thickness of nanolayers in wear-resistant layers of Ti-TiN-(Ti,Cr,Al)N coating on destruction in the cutting and wear of carbide cutting tools. Surf. Coat. Technol. 2020, 385, 125402. [Google Scholar] [CrossRef]

- Inspektor, A.; Salvador, P.A. Architecture of PVD coatings for metalcutting applications: A review. Surf. Coat. Technol. 2014, 257, 138–153. [Google Scholar] [CrossRef]

- Holleck, H.; Schier, V. Multilayer PVD coatings for wear protection. Surf. Coat. Technol. 1995, 76–77, 328–336. [Google Scholar] [CrossRef]

- PalDey, S.; Deevi, S.C. Single layer and multilayer wear resistant coatings of (Ti,Al)N: A review. Mater. Sci. Eng. A 2003, 342, 58–79. [Google Scholar] [CrossRef]

- Liao, Y.S.; Shiue, R.H. Carbide tool wear mechanism in turning of Inconel 718 superalloy. Wear 1996, 193, 16–24. [Google Scholar] [CrossRef]

- Prengel, H.G.; Jindal, P.C.; Wendt, K.H.; Santhanam, A.T.; Hedge, P.L.; Penich, R.M.A. New class of high performance PVD coatings for carbide cutting tools. Surf. Coat. Technol. 2001, 139, 25–34. [Google Scholar] [CrossRef]

- Ducros, C.; Benevent, V.; Sanchette, F. Deposition, characterization and machining performance of multilayer PVD coatings on cemented carbide cutting tools. Surf. Coat. Technol. 2003, 163–164, 681–688. [Google Scholar] [CrossRef]

- Grigoriev, S.N.; Vereschaka, A.A.; Fyodorov, S.V.; Sitnikov, N.N.; Batako, A.D. Comparative analysis of cutting properties and nature of wear of carbide cutting tools with multi-layered nano-structured and gradient coatings produced by using of various deposition methods. Int. J. Adv. Manuf. Technol. 2017, 90, 3421–3435. [Google Scholar] [CrossRef]

- Grigoriev, S.; Vereschaka, A.; Uglov, V.; Milovich, F.; Cherenda, N.; Andreev, N.; Migranov, M.; Seleznev, A. Influence of tribological properties of Zr-ZrN-(Zr,Cr,Al)N and Zr-ZrN-(Zr,Mo,Al)N multilayer nanostructured coatings on the cutting properties of coated tools during dry turning of Inconel 718 alloy. Wear 2023, 512-513, 204521. [Google Scholar] [CrossRef]

- Volosova, M.; Grigoriev, S.; Metel, A.; Shein, A. The Role of Thin-Film Vacuum-Plasma Coatings and Their Influence on the Efficiency of Ceramic Cutting Inserts. Coatings 2018, 8, 287. [Google Scholar] [CrossRef] [Green Version]

- Grigoriev, S.N.; Metel, A.S.; Fedorov, S.V. Modification of the structure and properties of high-speed steel by combined vacuum-plasma treatment. Met. Sci. Heat Treat. 2012, 54, 8–12. [Google Scholar] [CrossRef]

- Metel, A.S.; Grigoriev, S.N.; Melnik, Y.A.; Panin, V.V. Filling the vacuum chamber of a technological system with homogeneous plasma using a stationary glow discharge. Plasma Phys. Rep. 2009, 35, 1058–1067. [Google Scholar] [CrossRef]

- Alexey, V. Improvement of working efficiency of cutting tools by modifying its surface properties by application of wear-resistant complexes. Adv. Mater. Res. 2013, 712–715, 347–351. [Google Scholar]

- Fominski, V.Y.; Grigoriev, S.N.; Gnedovets, A.G.; Romanov, R.I. Pulsed laser deposition of composite Mo–Se–Ni–C coatings using standard and shadow mask configuration. Surf. Coat. Technol. 2012, 206, 5046–5054. [Google Scholar] [CrossRef]

- Vereshchaka, A.A.; Vereshchaka, A.S.; Mgaloblishvili, O.; Morgan, M.N.; Batako, A.D. Nano-scale multilayered-composite coatings for the cutting tools. Int. J. Adv. Manuf. Technol. 2014, 72, 303–317. [Google Scholar] [CrossRef]

- Grigoriev, S.; Vereschaka, A.; Zelenkov, V.; Sitnikov, N.; Bublikov, J.; Milovich, F.; Andreev, N.; Mustafaev, E. Specific features of the structure and properties of arc-PVD coatings depending on the spatial arrangement of the sample in the chamber. Vacuum 2022, 200, 111047. [Google Scholar] [CrossRef]

- Grigoriev, S.; Vereschaka, A.; Zelenkov, V.; Sitnikov, N.; Bublikov, J.; Milovich, F.; Andreev, N.; Sotova, C. Investigation of the influence of the features of the deposition process on the structural features of microparticles in PVD coatings. Vacuum 2022, 202, 111144. [Google Scholar] [CrossRef]

- Kuzin, V.V.; Grigoriev, S.N. Method of Investigation of the Stress-Strain State of Surface Layer of Machine Elements from a Sintered Nonuniform Material. Appl. Mech. Mater. 2013, 486, 32–35. [Google Scholar] [CrossRef]

- Grigoriev, S.N.; Kozochkin, M.P.; Sabirov, F.S.; Kutin, A.A. Diagnostic Systems as Basis for Technological Improvement. Proc. CIRP 2012, 1, 599–604. [Google Scholar] [CrossRef]

- Shuster, L.S.; Migranov, M.S. Device for Investigating Adhesion Interaction. RU 34249, 26 March 2003. [Google Scholar]

- Vereschaka, A.; Grigoriev, S.; Milovich, F.; Sitnikov, N.; Migranov, M.; Andreev, N.; Bublikov, J.; Sotova, C. Investigation of tribological and functional properties of Cr,Mo-(Cr,Mo)N-(Cr,Mo,Al)N multilayer composite coating. Tribol. Int. 2021, 155, 106804. [Google Scholar] [CrossRef]

- Vereschaka, A.; Milovich, F.; Migranov, M.; Andreev, N.; Alexandrov, I.; Muranov, A.; Mikhailov, M.; Tatarkanov, A. Investigation of the tribological and operational properties of (Mex,Moy,Al1-(x+y))N (Me –Ti, Zr or Cr) coatings. Tribol. Int. 2022, 165, 107305. [Google Scholar] [CrossRef]

- Grigoriev, S.; Vereschaka, A.; Milovich, F.; Migranov, M.; Andreev, N.; Bublikov, J.; Sitnikov, N.; Oganyan, G. Investigation of the tribological properties of Ti-TiN-(Ti,Al,Nb,Zr)N composite coating and its efficiency in increasing wear resistance of metal cutting tools. Tribol. Int. 2021, 164, 107236. [Google Scholar] [CrossRef]

- Grigoriev, S.; Vereschaka, A.; Milovich, F.; Andreev, N.; Bublikov, J.; Seleznev, A.; Kutina, N. Influence of Mo content on the properties of multilayer nanostructured coatings based on the (Mo,Cr,Al)N system. Tribol. Int. 2022, 174, 107741. [Google Scholar] [CrossRef]

- Vereschaka, A.A.; Grigoriev, S.N. Study of cracking mechanisms in multi-layered composite nano-structured coatings. Wear 2017, 378–379, 43–57. [Google Scholar] [CrossRef]

| Ni | Fe | Cr | Cu | Mo | Nb | C | Mn | Si | Ti | Al | Co |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 50.00–55.00 | Remainder | 17.00–21.00 | 0.30 max | 2.80–3.30 | 4.75–5.50 | 0.08 max | 0.35 max | 0.35 max | 0.65–1.15 | 0.20–0.80 | 1.00 max |

| Coating | Hardness, GPa | Elastic Modulus, GPa | Critical Fracture Load LC2, N |

|---|---|---|---|

| (Ti,Cr,Al)N | 31.9 ± 1.4 | 580.50 ± 22.4 | 38 |

| (Zr,Mo,Al)N | 32.3 ± 1.2 | 432.15 ± 21.4 | >40 |

| (Zr,Hf,Cr,Mo,Al)N | 27.3 ± 1.3 | 532.23 ± 26.1 | >40 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vereschaka, A.; Milovich, F.; Andreev, N.; Migranov, M.; Alexandrov, I.; Muranov, A.; Mikhailov, M.; Tatarkanov, A. Specific Application Features of Ti-TiN-(Ti,Cr,Al)N, Zr-ZrN-(Zr,Mo,Al)N, and ZrHf-(Zr,Hf)N-(Zr,Hf,Cr,Mo,Al)N Multilayered Nanocomposite Coatings in End Milling of the Inconel 718 Nickel-Chromium Alloy. J. Compos. Sci. 2022, 6, 382. https://doi.org/10.3390/jcs6120382

Vereschaka A, Milovich F, Andreev N, Migranov M, Alexandrov I, Muranov A, Mikhailov M, Tatarkanov A. Specific Application Features of Ti-TiN-(Ti,Cr,Al)N, Zr-ZrN-(Zr,Mo,Al)N, and ZrHf-(Zr,Hf)N-(Zr,Hf,Cr,Mo,Al)N Multilayered Nanocomposite Coatings in End Milling of the Inconel 718 Nickel-Chromium Alloy. Journal of Composites Science. 2022; 6(12):382. https://doi.org/10.3390/jcs6120382

Chicago/Turabian StyleVereschaka, Alexey, Filipp Milovich, Nikolay Andreev, Mars Migranov, Islam Alexandrov, Alexander Muranov, Maxim Mikhailov, and Aslan Tatarkanov. 2022. "Specific Application Features of Ti-TiN-(Ti,Cr,Al)N, Zr-ZrN-(Zr,Mo,Al)N, and ZrHf-(Zr,Hf)N-(Zr,Hf,Cr,Mo,Al)N Multilayered Nanocomposite Coatings in End Milling of the Inconel 718 Nickel-Chromium Alloy" Journal of Composites Science 6, no. 12: 382. https://doi.org/10.3390/jcs6120382

APA StyleVereschaka, A., Milovich, F., Andreev, N., Migranov, M., Alexandrov, I., Muranov, A., Mikhailov, M., & Tatarkanov, A. (2022). Specific Application Features of Ti-TiN-(Ti,Cr,Al)N, Zr-ZrN-(Zr,Mo,Al)N, and ZrHf-(Zr,Hf)N-(Zr,Hf,Cr,Mo,Al)N Multilayered Nanocomposite Coatings in End Milling of the Inconel 718 Nickel-Chromium Alloy. Journal of Composites Science, 6(12), 382. https://doi.org/10.3390/jcs6120382