Mechanical Properties of Polylactide Filled with Micronized Chalcedonite

Abstract

:1. Introduction

2. Materials and Methods

2.1. Polylactide (PLA)

2.2. Micronized Chalcedonite

2.3. Research Methodology

3. Results and Discussion

4. Conclusions

Funding

Data Availability Statement

Conflicts of Interest

References

- Heimowska, A. Threat to the marine environment by drifting polymer materials. Res. Pap. Marit. Univ. Gdyn. 2019, 93, 141–145. [Google Scholar]

- Vilaplana, F.; Karlsson, S. Quality Concepts for the Improved Useof Recycled Polymeric Materials: A Review. Macromol. Mater. Eng. 2008, 293, 274–297. [Google Scholar] [CrossRef]

- Vasile, C.; Kulshereshtha, A.K.; Bumbu, G.G. Terminology. In Handbook of Polymer Blends and Composites, Tom 3A; Rapra Technology Limited: Shawbury, UK, 2003. [Google Scholar]

- Meneses, R.A.M.; Cabrera-Papamija, G.; Machuca-Martínez, F.; Rodríguez, L.A.; Diosa, J.E.; Mosquera-Vargas, E. Plastic recycling, and their use as raw material for the synthesis of carbonaceous materials. Heliyon 2022, 8, e09028. [Google Scholar] [CrossRef] [PubMed]

- Wilczyński, K.; Garbarski, J.; Nastaj, A.; Lewandowski, A.; Fabijański, M.; Wilczyński, K.J.; Buziak, K.; Narowski, P.; Zawistowski, H. Processing of Polymer Materials; Publishing House of the Warsaw University of Technology: Warsaw, Poland, 2018. [Google Scholar]

- Rajeshkumar, L. Biodegradable polymer blends and composites from renewable resources. In Woodhead Publishing Series in Composites Science and Engineering, Biodegradable Polymers, Blends and Composites; Woodhead Publishing: Cambridge, UK, 2022; pp. 527–549. [Google Scholar] [CrossRef]

- Krajenta, J.; Pawlak, A.; Galeski, A. All-polymer composites–a new approach with the use of disentangled semi-crystalline polymers. Part II. Preparation of composites from partially disentangled polylactide. Polimery 2020, 65, 261–267. [Google Scholar] [CrossRef]

- Tejada-Oliveros, R.; Fiori, S.; Gomez-Caturla, J.; Lascano, D.; Montanes, N.; Quiles-Carrillo, L.; Garcia-Sanoguera, D. Development and Characterization of Polylactide Blends with Improved Toughness by Reactive Extrusion with Lactic Acid Oligomers. Polymers 2022, 14, 1874. [Google Scholar] [CrossRef]

- Agarwal, S. Biodegradable Polymers: Present Opportunities and Challenges in Providing a Microplastic-Free Environment. Macromol. Chem. Phys. 2020, 221, 2000017. [Google Scholar] [CrossRef] [Green Version]

- Wang, X.; Peng, S.; Chen, H.; Yu, X.; Zhao, X. Mechanical properties, rheological behaviors, and phase morphologies of high-toughness PLA/PBAT blends by in-situ reactive compatibilization. Compos. B Eng. 2019, 173, 107028. [Google Scholar] [CrossRef]

- Muthuraj, R.; Misra, M.; Mohanty, A.K. Biodegradable compatibilized polymer blends for packaging applications: A literature review. J. Appl. Polim. Nauka. 2018, 135, 45726. [Google Scholar] [CrossRef] [Green Version]

- Fabijański, M. Effect of calcium carbonate addition on mechanical properties of polylactidepolilaktydu. Przem. Chem. 2017, 96, 894–896. [Google Scholar] [CrossRef]

- Müllera, K.; Bugnicourt, E.; Latorre, M.; Jorda, M.; Echegoyen Sanz, Y.; Lagaron, J.; Miesbauera, O.; Bianchin, A.; Hankin, S.; Bölz, U. Review on the Processing and Properties of Polymer Nanocomposites and Nanocoatings and Their Applications in the Packaging, Automotive and Solar Energy Fields. Nanomateriały 2017, 7, 74. [Google Scholar] [CrossRef]

- Osman, A.F.; Siah, L.; Alrashdi, A.A.; Ul-Hamid, A.; Ibrahim, I. Improving the Tensile and Tear Properties of Thermoplastic Starch/Dolomite Biocomposite Film through Sonication Process. Polymers 2021, 13, 274. [Google Scholar] [CrossRef] [PubMed]

- Tryznowski, M.; Żołek-Tryznowska, Z. Surface Properties of Poly (Hydroxyurethane)s Based on Five-Membered Bis-Cyclic Carbonate of Diglycidyl Ether of Bisphenol A. Materials 2020, 13, 5184. [Google Scholar] [CrossRef] [PubMed]

- Avolio, R.; Castaldo, R.; Goj, G.; Ambrogi, V.; Fiori, S.; Avella, M.; Cocca, M.; Errico, M.E. Plasticization of poly (lactic acid) through blending with oligomers of lactic acid: Effect of the physical aging on properties. Eur. Polim. J. 2015, 66, 533–542. [Google Scholar] [CrossRef]

- Kołodziejczak, P.; Bober, M.; Chmielewski, T. Wear Resistance Comparison Research of High-Alloy Protective Coatings for Power Industry Prepared by Means of CMT Cladding. Appl. Sci. 2022, 12, 4568. [Google Scholar] [CrossRef]

- Tábi, T.; Ageyeva, T.; Kovács, J.G. Improving the ductility and heat deflection temperature of injection molded Poly (lactic acid) products: Comprehensive review. Polym. Test. 2021, 101, 107282. [Google Scholar] [CrossRef]

- Żochowski, P.; Bajkowski, M.; Grygoruk, R.; Magier, M.; Burian, W.; Pyka, D.; Bocian, M.; Jamroziak, K. Finite element modeling of ballistic inserts containing aramid fabrics under projectile impact conditions–comparison of methods. Compos. Struct. 2022, 294, 115752. [Google Scholar] [CrossRef]

- Foltynowicz, Z.; Jakubiak, P. Polylactid acid—biodegradable polymer obtained from vegetable resources. Polimery 2022, 47, 769–774. [Google Scholar] [CrossRef]

- Fabijański, M. Study on mechanical properties of phosphogypsum-filled polylactide. Przem. Chemi. 2016, 95, 2227–2229. [Google Scholar] [CrossRef]

- Fabijański, M. Effect of multiple processing on the strength properties of polylactide/polystyrene mixture. Przem. Chem. 2022, 101, 65–68. [Google Scholar] [CrossRef]

- Haneef, I.N.H.M.; Buys, Y.F.; Shaffiar, N.M.; Shaharuddin, S.I.S.; Hamid, A.M.A.; Sabri, M.F.M.; Afifi, A.M. Effect of HNT on mechanical and thermal properties of poly (lactic acid)/polypropylene carbonate blends. Polimery 2021, 66, 459–465. [Google Scholar] [CrossRef]

- Gałęski, A.; Piórkowska, E.; Pluta, M.; Kuliński, Z.; Masirek, R. Modification of physical properties of polylactide. Polimery 2022, 50, 562–569. [Google Scholar] [CrossRef]

- He, Y.; Wu, S.; Yuen, A.C.Y.; Huang, F.; Boyer, C.; Wang, C.H.; Zhang, J. Scalable Manufacturing Process and Multifunctional Performance of Cotton Fibre-Reinforced Poly (Lactic Acid) (PLA) Bio-Composites Coated by Graphene Oxide. Polymers 2022, 14, 3946. [Google Scholar] [CrossRef] [PubMed]

- Naziemiec, Z.; Saramak, D. Effective methods of chalcedonite processing. Min. Sci. 2021, 28, 7–18. [Google Scholar] [CrossRef]

- Gawenda, T.; Surowiak, A.; Stempkowska, A.; Krawczykowska, A.; Saramak, D. Effective Removing of Light Impurities from an Aggregate in SEL Separator. Inż. Miner. 2021, 1, 53–60. [Google Scholar] [CrossRef]

- Surowiak, A.; Gawenda, T.; Stempkowska, A.; Niedoba, T.; Nad, A. The Influence of Selected Properties of Particles in the Jigging Process of Aggregates on an Example of Chalcedonite. Minerals 2020, 10, 600. [Google Scholar] [CrossRef]

- Naziemiec, Z.; Pichniarczyk, P.; Saramak, D. Current issues of processing and industrial utilization of chalcedonite. Inż. Miner. 2017, 1, 89–96. [Google Scholar]

- Naziemiec, Z.; Pichniarczyk, P.; Saramak, D. Methods of improvement chalcedonite processing effectiveness with the use of density separation. Miner. Resourc. Manag. 2017, 33, 163–178. [Google Scholar] [CrossRef]

- Data Sheet: IngeoBiopolymer 3100HP. Available online: https://www.natureworksllc.com/~/media/Files/NatureWorks/Technical-Documents/Technical-Data-Sheets/TechnicalDataSheet_3100HP_injection-molding_pdf.pdf (accessed on 7 November 2022).

- Data Sheet: CRUSiL M 20. Available online: https://crusil.pl/wp-content/uploads/2017/11/Karta-katalogowa-Chalcedonit_mikronizowany_20_PL_v1.pdf (accessed on 7 November 2022).

- PN-EN ISO 527-2:2012; Plastics—Determination of Tensile Properties—Part 2: Test Conditions for Moulding and Extrusion Plastics. ISO: Geneva, Switzerland, 2012.

- PN-EN ISO 179-1:2010; Plastics—Determination of Charpy Impact Properties—Part 1: Non-Instrumented Impact Test. ISO: Geneva, Switzerland, 2010.

- PN-EN ISO 868:2005; Plastics and Ebonite—Determination of Indentation Hardness by Means of a Durometer (Shore Hardness). ISO: Geneva, Switzerland, 2005.

- PN-EN ISO 62:2008; Plastics—Determination of Water Absorption. ISO: Geneva, Switzerland, 2008.

| Composition, % wt. | |

|---|---|

| SiO2 | >98.5 |

| Al2O3 | <0.02 |

| Fe2O3 | <0.09 |

| CaO | <0.05 |

| MgO | <0.05 |

| K2O | <0.08 |

| Na2O | <0.05 |

| TiO2 | <0.02 |

| Parameters | Value |

|---|---|

| Specific density | 2.60 g/cm3 |

| Bulk density | 0.59 g/cm3 |

| Bulk density | 1.17 g/cm3 |

| Loss on ignition LOI 1 h 950 °C | 0.90% |

| Standard refractoriness PN-EN 993-12sP | 173 (1730 °C) |

| Granulation D97 | 20 µm |

| Granulation D50 | 6.45 µm |

| Optical properties L/a/b | 95.8/0.32/1.2 |

| Lp. | PLA, % wt. | Crusil M20, % wt. |

|---|---|---|

| 0 | 100 | 0 |

| 1 | 95 | 5 |

| 2 | 90 | 10 |

| 3 | 85 | 15 |

| 4 | 80 | 20 |

| 5 | 70 | 30 |

| Injection Parameters | Values | |

|---|---|---|

| injection: | ||

| speed | 30% | |

| pressure | 120 bar | |

| processing temperature | zone 1 | 200 °C |

| zone 2 | 190 °C | |

| zone 3 | 180 °C | |

| zone 4 | 160 °C | |

| zone 5 | 80 °C | |

| pressure: | ||

| time | 8 s | |

| holding pressure | 50 bar | |

| closing force: | ||

| average | 844 N | |

| closing the mold: | ||

| pressure | 170 bar | |

| speed | 40% | |

| time to secure the form | 5 s | |

| cycle time | 120 s | |

| against pressure | 5 bar | |

| mold opening: | ||

| against pressure | 10 bar | |

| cooling time | 30 s | |

| temperature | 80 °C | |

| Filler Content, %wt. | 0 | 5 | 10 | 15 | 20 | 25 | 30 |

|---|---|---|---|---|---|---|---|

| The average weight of the paddles, g | 24.48 | 25.07 | 25.61 | 26.20 | 26.83 | 27.87 | 27.80 |

| Average weight of the bars, g | 14.78 | 15.04 | 15.59 | 15.65 | 15.90 | 16.24 | 16.58 |

| Contents, % wt. | 0 | 5 | 10 | 15 | 20 | 25 | 30 |

|---|---|---|---|---|---|---|---|

| Tensile strength, σ, MPa | 68.10 | 61.60 | 59.00 | 57.30 | 54.60 | 52.30 | 49.80 |

| Standard deviation | 2.91 | 1.50 | 0.82 | 1.76 | 1.76 | 0.79 | 1.07 |

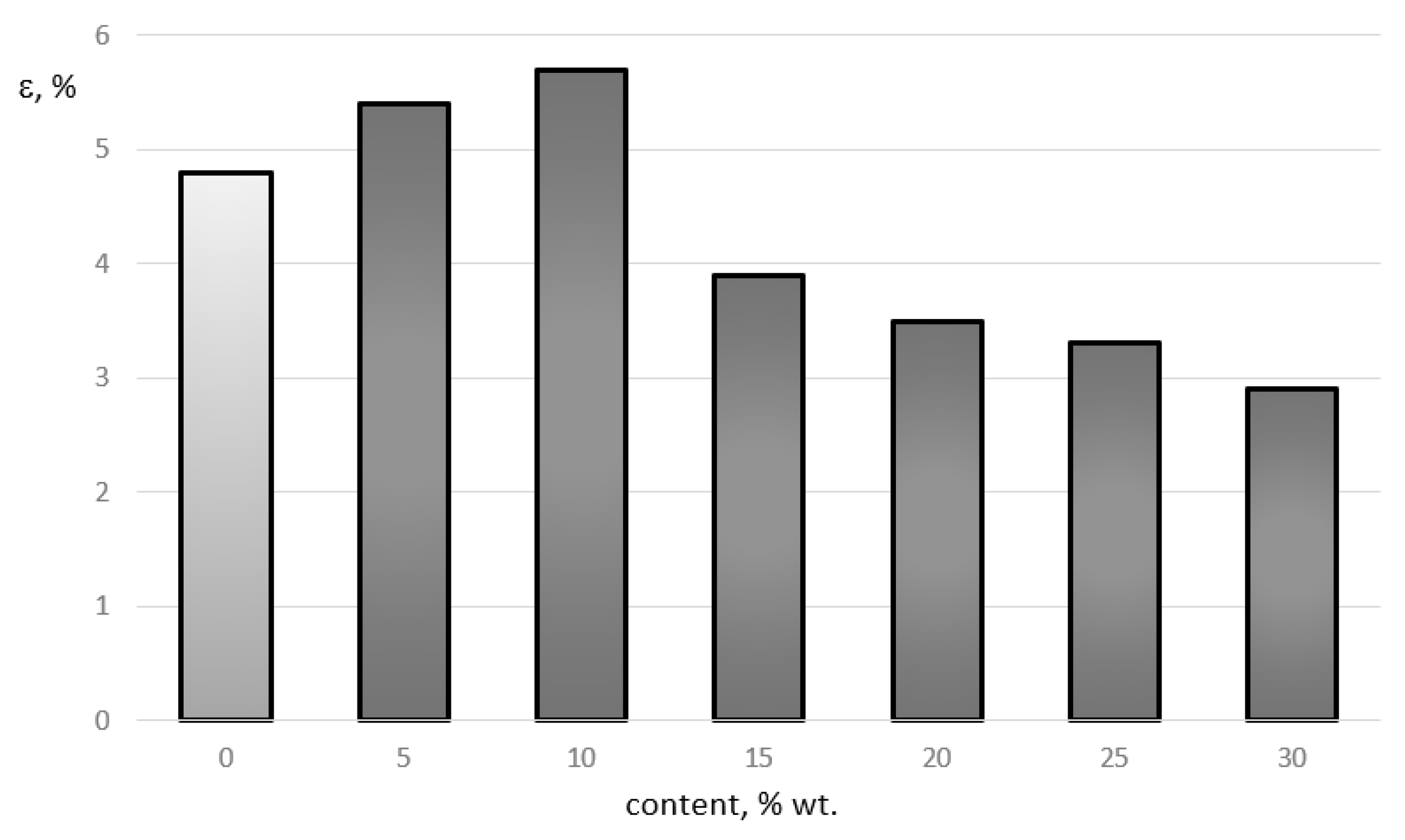

| Elongation, ε, % | 4.8 | 5.4 | 5.7 | 3.9 | 3.5 | 3.3 | 2.9 |

| Standard deviation | 0.09 | 0.15 | 0.09 | 0.12 | 0.13 | 0.12 | 0.11 |

| Contents, % wt. | 0 | 5 | 10 | 15 | 20 | 25 | 30 |

|---|---|---|---|---|---|---|---|

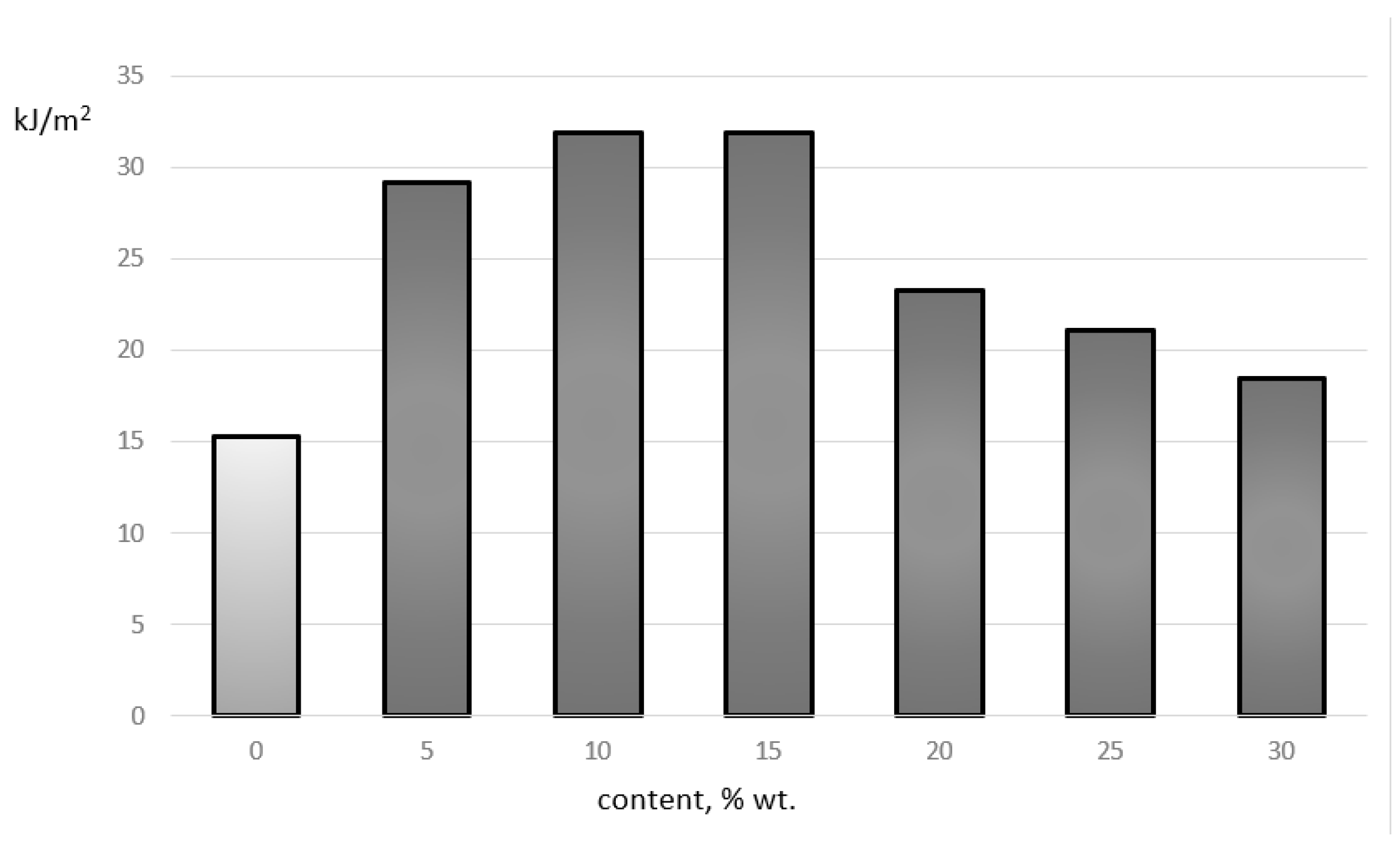

| Impact strength, kJ/m2 | 15.25 | 29.12 | 31.87 | 31.87 | 23.25 | 21.12 | 18.50 |

| Standard deviation | 0.54 | 1.14 | 1.28 | 1.54 | 1.24 | 1.56 | 1.52 |

| Contents, % wt. | 0 | 5 | 10 | 15 | 20 | 25 | 30 |

|---|---|---|---|---|---|---|---|

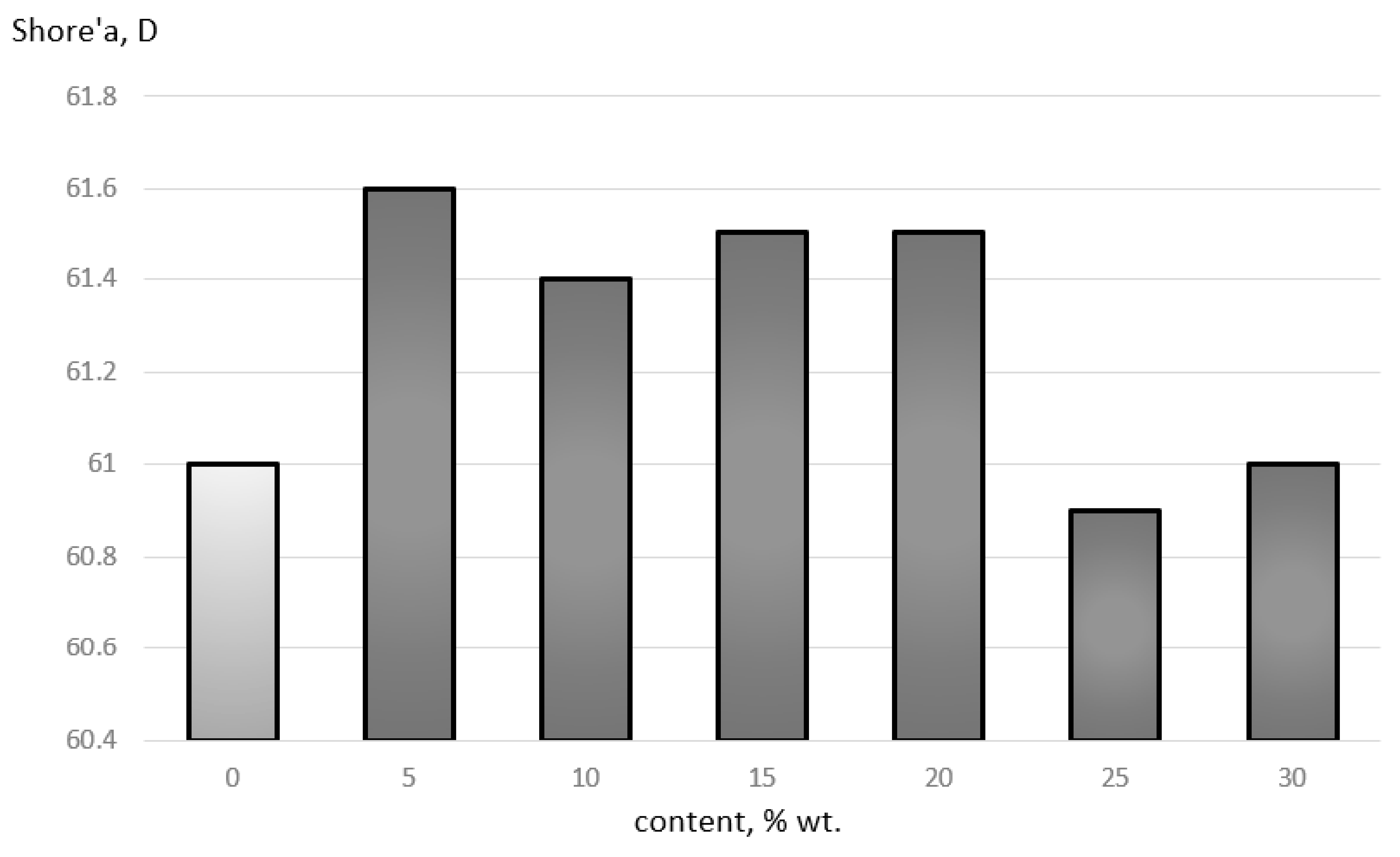

| Shore hardness, scale D | 61.0 | 61.6 | 61.4 | 61.5 | 61.5 | 60.9 | 61.0 |

| Standard deviation | 1.38 | 0.67 | 1.71 | 0.75 | 0.83 | 0.84 | 0.85 |

| Contents, % wt. | 0 | 5 | 10 | 15 | 20 | 25 | 30 |

|---|---|---|---|---|---|---|---|

| Average weight of samples before soaking, g | 10.534 | 10.850 | 11.102 | 11.380 | 11.594 | 12.041 | 12.060 |

| Average weight of samples after soaking for 24 h, g | 10.523 | 10.866 | 11.083 | 11.364 | 11.596 | 12.054 | 12.053 |

| Average weight of samples after soaking for 168 h, g | 10.577 | 10.892 | 11.143 | 11.420 | 11.632 | 12.075 | 12.097 |

| Weight difference after 7 h | 0.021 | 0.017 | 0.018 | 0.015 | 0.016 | 0.015 | 0.016 |

| The difference in weight after 168 h | 0.042 | 0.042 | 0.041 | 0.040 | 0.037 | 0.034 | 0.037 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fabijanski, M. Mechanical Properties of Polylactide Filled with Micronized Chalcedonite. J. Compos. Sci. 2022, 6, 387. https://doi.org/10.3390/jcs6120387

Fabijanski M. Mechanical Properties of Polylactide Filled with Micronized Chalcedonite. Journal of Composites Science. 2022; 6(12):387. https://doi.org/10.3390/jcs6120387

Chicago/Turabian StyleFabijanski, Mariusz. 2022. "Mechanical Properties of Polylactide Filled with Micronized Chalcedonite" Journal of Composites Science 6, no. 12: 387. https://doi.org/10.3390/jcs6120387

APA StyleFabijanski, M. (2022). Mechanical Properties of Polylactide Filled with Micronized Chalcedonite. Journal of Composites Science, 6(12), 387. https://doi.org/10.3390/jcs6120387