Microstructural Evaluation and Fracture Behavior of AZ31/Nb2O5 Metal Matrix Composite

Abstract

:1. Introduction

2. Materials and Methods

- (i)

- Crystallite diameter (D) = /

- (ii)

- Dislocation Density (δ) = 1/D2

- (iii)

- Microstrain (ε) = β/(4 tanθ)

- where β—values corresponding to FWHM value (Full width at half maximum) of XRD profile, k—Shape factor (0.89), λ—Wavelength of XRD radiation, θ—peak position.

3. Results & Discussion

3.1. Microstructural Evaluation

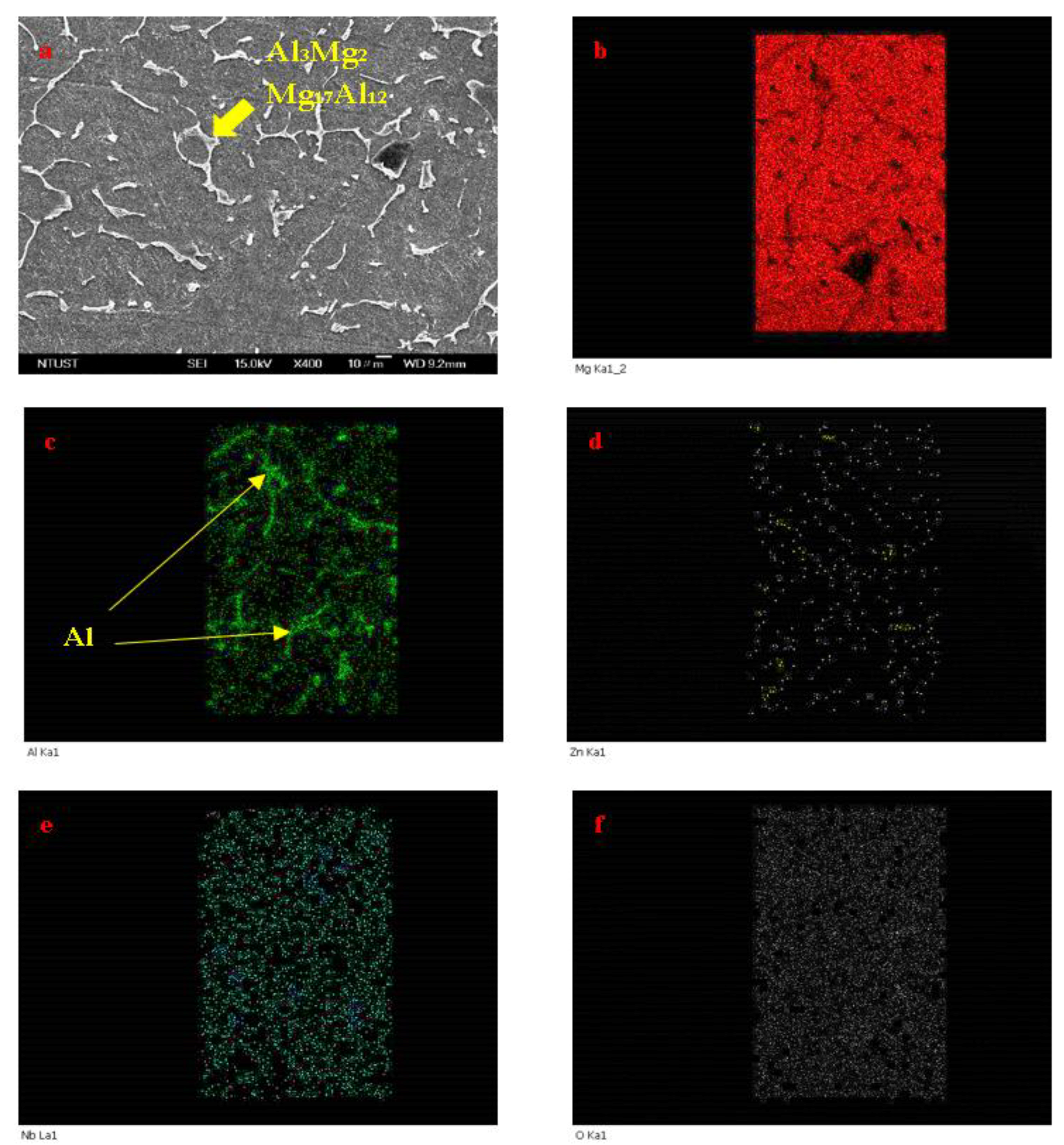

3.1.1. SEM Image Analysis

3.1.2. XRD-Analysis and Phase Quantification

3.2. Compression and Microhardness

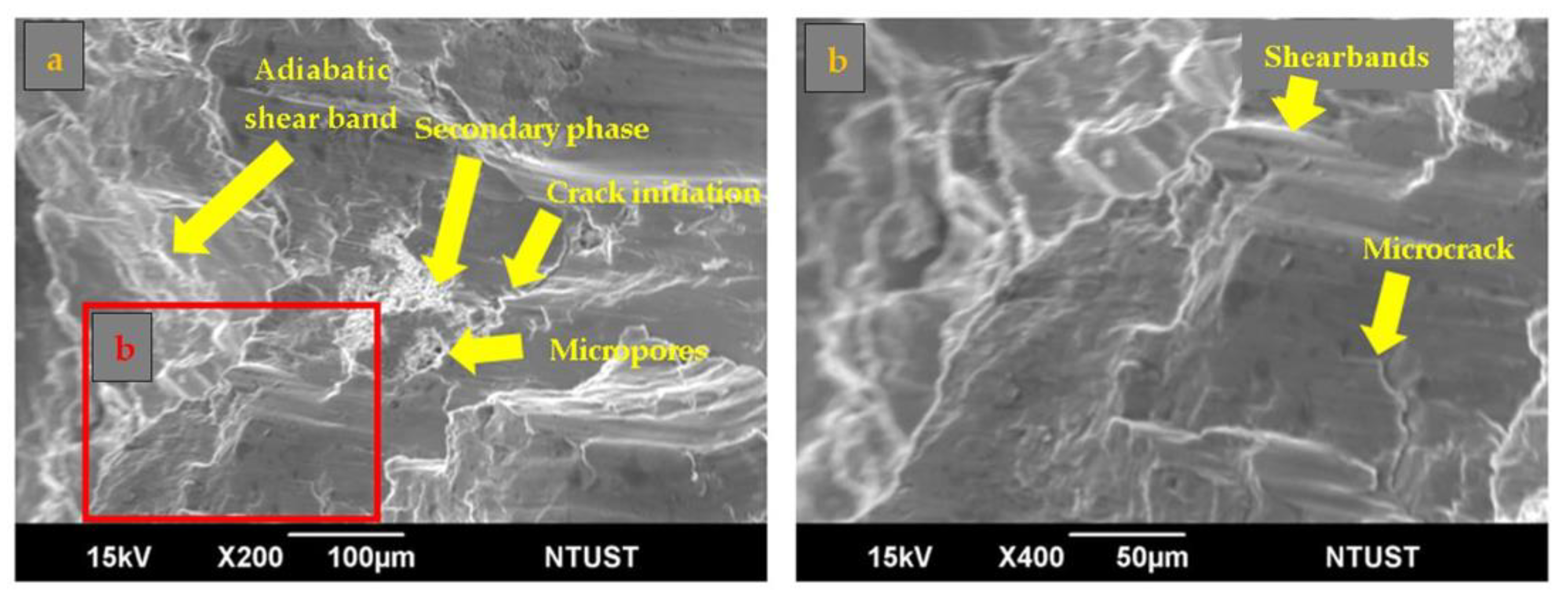

3.3. Fractography

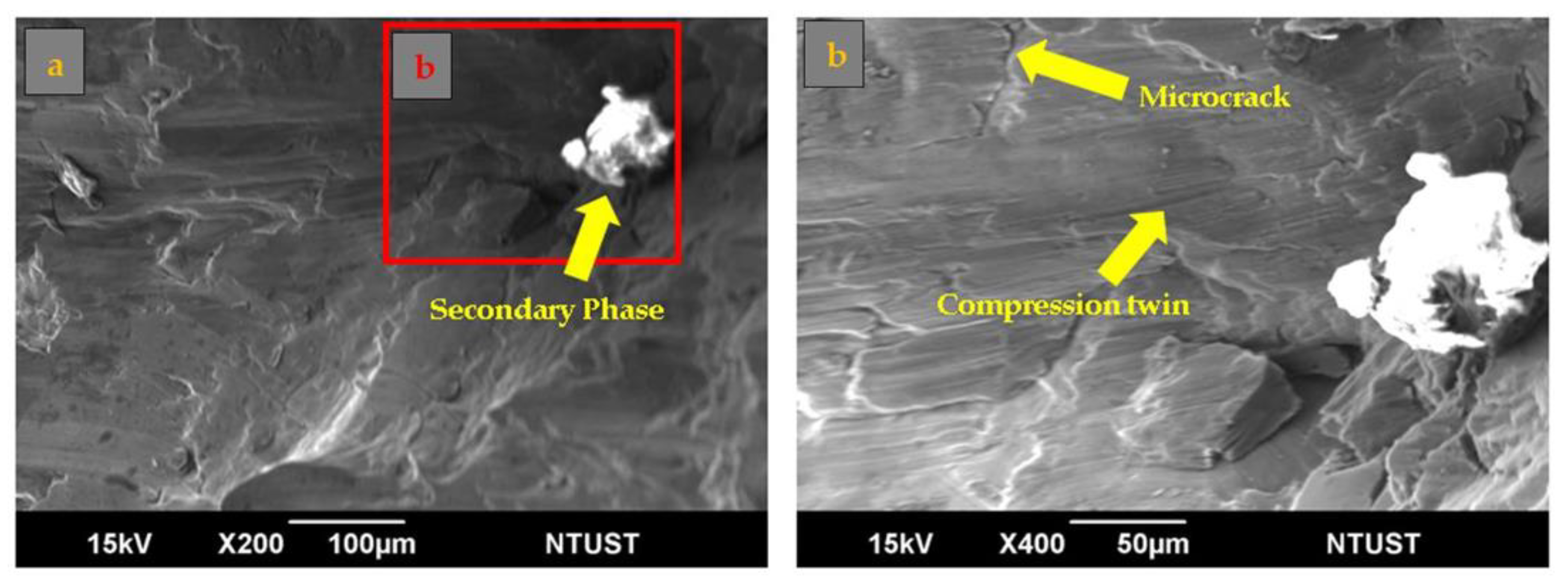

3.3.1. Fracture Study of AZ31

3.3.2. Fracture Study of 3% Nb2O5 + AZ31

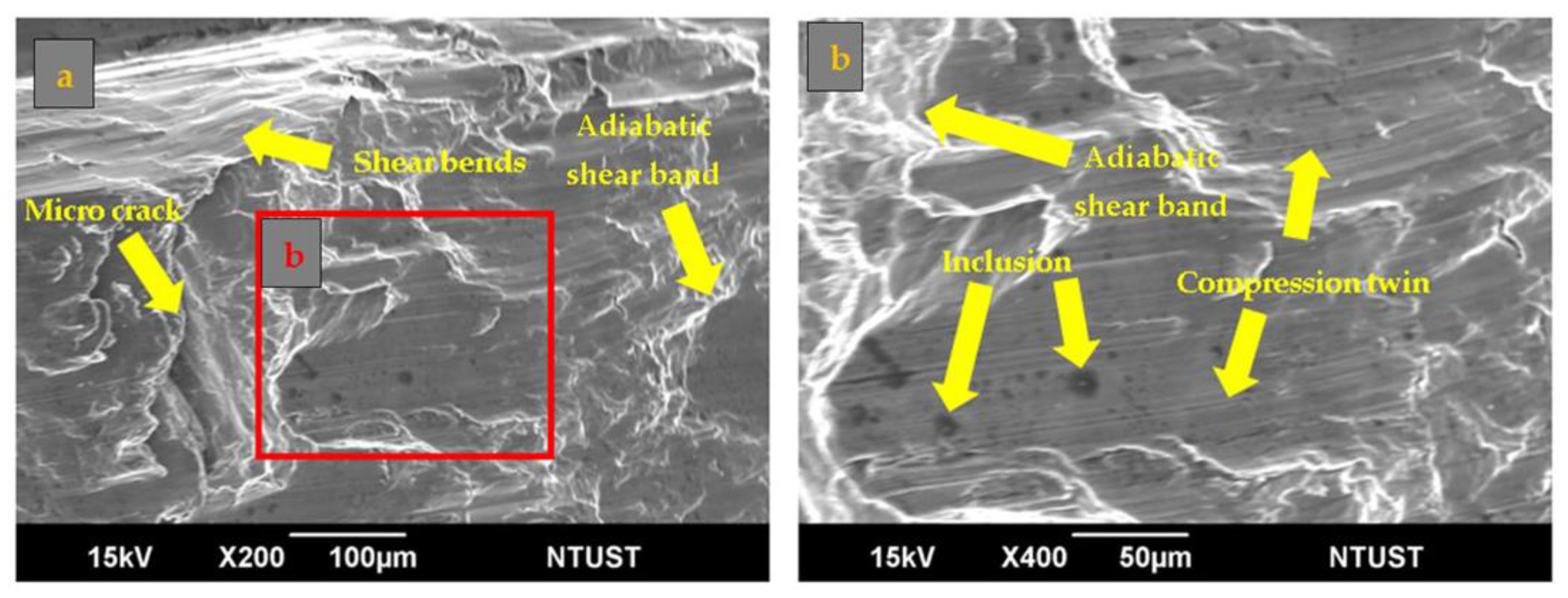

3.3.3. Fracture Study of 6% Nb2O5 + AZ31

4. Conclusions

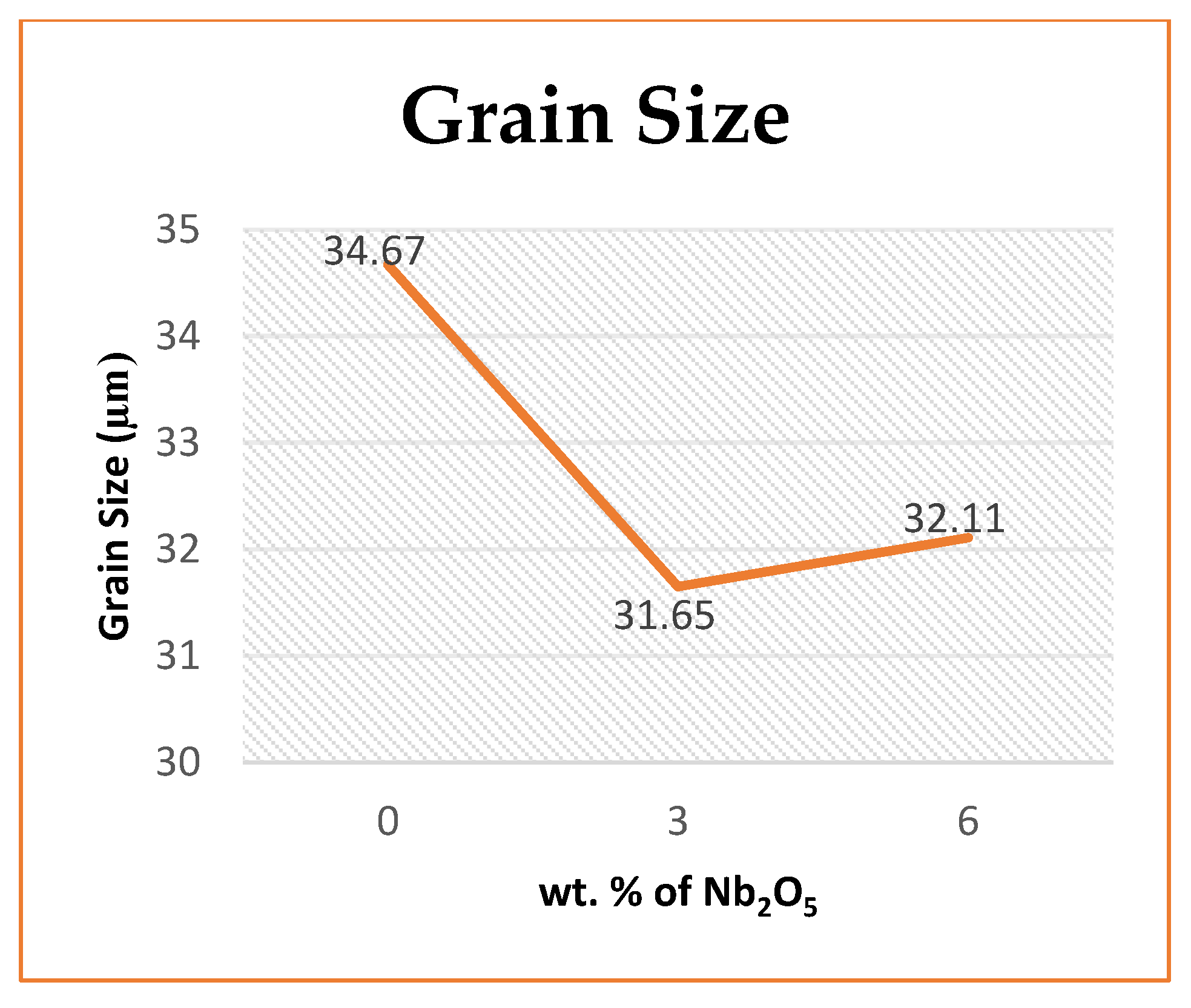

- Although there is no shift in plane obtained, the addition of reinforcement distributes the secondary phase evenly throughout the matrix, which reduces the local inhomogeneity in the case of 3% Nb2O5. Furthermore, an improvement in grain size reduction was observed.

- The compression stress–strain curve reviled that the stress endurance increased by 18.68% for 3% Nb2O5 reinforcement with peak stress of 323.25 MPa. However, in the case of microhardness, the increment was 6.5% (3% Nb2O5) and 8.3% (6% Nb2O5) compared to the AZ31 composite.

- The fracture analyses show maximum basal slip in AZ31 and 6% Nb2O5 + AZ31, but 3% Nb2O5 shows much more ASB, which indicates the resistance towards the applied stress.

Author Contributions

Funding

Conflicts of Interest

References

- Song, J.; Chen, J.; Xiong, X.; Peng, X.; Chen, D.; Pan, F. Research Advances of Magnesium and Magnesium Alloys Worldwide in 2021. J. Magnes. Alloys 2022, 10, 863–898. [Google Scholar] [CrossRef]

- Aghion, E.; Bronn, B.; Eliezer, D. The Role of the Magnesium Industry in Protecting the Environment. J. Mater. Process. Technol. 2001, 117, 381–385. [Google Scholar] [CrossRef]

- Huang, S.J.; Mose, M.P.; Kannaiyan, S. Artificial Intelligence Application in Solid State Mg-Based Hydrogen Energy Storage. J. Compos. Sci. 2021, 5, 145. [Google Scholar] [CrossRef]

- Huang, S.J.; Ali, A.N. Effects of Heat Treatment on the Microstructure and Microplastic Deformation Behavior of SiC Particles Reinforced AZ61 Magnesium Metal Matrix Composite. Mater. Sci. Eng. A 2018, 711, 670–682. [Google Scholar] [CrossRef]

- Huang, S.J.; Subramani, M.; Borodianskiy, K. Strength and Ductility Enhancement of AZ61/Al2O3/SiC Hybrid Composite by ECAP Processing. Mater. Today Commun. 2022, 31, 103261. [Google Scholar] [CrossRef]

- Subramani, M.; Huang, S.J.; Borodianskiy, K. Effect of SiC Nanoparticles on AZ31 Magnesium Alloy. Materials 2022, 15, 1004. [Google Scholar] [CrossRef]

- Huang, S.-J.; Subramani, M.; Chiang, C.-C. Effect of Hybrid Reinforcement on Microstructure and Mechanical Properties of AZ61 Magnesium Alloy Processed by Stir Casting Method. Compos. Commun. 2021, 25, 100772. [Google Scholar] [CrossRef]

- Subramani, M.; Huang, S.J.; Borodianskiy, K. Effect of WS2 Nanotubes on the Mechanical and Wear Behaviors of AZ31 Stir Casted Magnesium Metal Matrix Composites. J. Compos. Sci. 2022, 6, 182. [Google Scholar] [CrossRef]

- Abbas, A.; Huang, S.J. Investigating the Hall-Petch Constants for as-Cast and Aged Az61/Cnts Metal Matrix Composites and Their Role on Superposition Law Exponent. J. Compos. Sci. 2021, 5, 103. [Google Scholar] [CrossRef]

- Abbas, A.; Huang, S.J. Investigation of Severe Plastic Deformation Effects on Microstructure and Mechanical Properties of WS2/AZ91 Magnesium Metal Matrix Composites. Mater. Sci. Eng. A 2020, 780, 139211. [Google Scholar] [CrossRef]

- Song-Jeng, S.K.; Huang, M.S. Effect of Nano-Nb2O5 on the Microstructure and Mechanical Properties of AZ31 Alloy Matrix Nanocomposites. Adv. Nano Res. 2022, 13, 407–416. [Google Scholar] [CrossRef]

- Zhu, J.; Yang, W.; Yang, H.; Wang, F. Effect of Nb2O5 on the Microstructure and Mechanical Properties of TiAl Based Composites Produced by Hot Pressing. Mater. Sci. Eng. A 2011, 528, 6642–6646. [Google Scholar] [CrossRef]

- Safavi, M.S.; Walsh, F.C.; Visai, L.; Khalil-Allafi, J. Progress in Niobium Oxide-Containing Coatings for Biomedical Applications: A Critical Review. ACS Omega 2022, 7, 9088–9107. [Google Scholar] [CrossRef]

- Sunil, B.R.; Ganesh, K.V.; Pavan, P.; Vadapalli, G.; Swarnalatha, C.; Swapna, P.; Bindukumar, P.; Pradeep Kumar Reddy, G. Effect of Aluminum Content on Machining Characteristics of AZ31 and AZ91 Magnesium Alloys during Drilling. J. Magnes. Alloys 2016, 4, 15–21. [Google Scholar] [CrossRef] [Green Version]

- Nie, J.F. Precipitation and Hardening in Magnesium Alloys. Metall. Mater. Trans. A 2012, 43, 3891–3939. [Google Scholar] [CrossRef] [Green Version]

- Zhou, Y.; Zhu, Y.; Zhu, Y.; Li, L. Phase Transformation, Kinetics and Thermodynamics during the Combustion Synthesis of Mg2Al3 Alloy. J. Alloys Compd. 2015, 628, 257–262. [Google Scholar] [CrossRef]

- Sarkar, K.; Kumar, V.; Das, S.B.; Kumar, M.; Manash, A.; Biswas, C.; Mukherjee, S. Studies of Structural, Electrical and Optical Properties of MgNb2O6-Mg4Nb2O9nanocomposite for Possible Opto-Electronic Applications. In Proceedings of the Materials Today: Proceedings; Elsevier Ltd.: Amsterdam, The Netherlands, 2021; Volume 44, pp. 2459–2465. [Google Scholar]

- Lei, R.S.; Wang, M.P.; Li, Z.; Wei, H.G.; Yang, W.C.; Jia, Y.L.; Gong, S. Structure Evolution and Solid Solubility Extension of Copper-Niobium Powders during Mechanical Alloying. Mater. Sci. Eng. A 2011, 528, 4475–4481. [Google Scholar] [CrossRef]

- Singh, A.; Rosalie, J.M.; Somekawa, H.; Mukai, T. Crystallographic Relationship of Orthorhombic φ-Al5Mg 11Zn4 Phase to Icosahedral Quasicrystalline Phase. J. Alloys Compd. 2011, 509, 4676–4681. [Google Scholar] [CrossRef]

- Manuja, M.; Thomas, T.; John, S.; Jose, J.; Jose, G. Electrochemical Characterization of Orthorhombic Tungsten Trioxide Hydrate for Battery Applications. J. Alloys Compd. 2021, 869, 159234. [Google Scholar] [CrossRef]

- Zhang, H.; Bai, X.; Hou, M.; Wang, L.; Zhang, Q.; Fan, J.; Wu, Y.; Dong, H.; Xu, B. Enhancing Compressive Mechanical Properties of Rolled AZ31 Mg Alloy Plates by Pre-Compression. Mater. Sci. Eng. A 2020, 772, 138686. [Google Scholar] [CrossRef]

- Paramsothy, M.; Hassan, S.F.; Srikanth, N.; Gupta, M. Enhancement of Compressive Strength and Failure Strain in AZ31 Magnesium Alloy. J. Alloys Compd. 2009, 482, 73–80. [Google Scholar] [CrossRef]

- Malik, A.; Wang, Y.; Cheng, H.; Khan, M.A.; Nazeer, F.; An, R.; Bao, J.; Wang, M. Fracture Behavior of Twin Induced Ultra-Fine Grained ZK61 Magnesium Alloy under High Strain Rate Compression. J. Mater. Res. Technol. 2019, 8, 3475–3486. [Google Scholar] [CrossRef]

| Types of Cast Ingots | Nb2O5 wt.% | Nb2O5 Size (nm) |

|---|---|---|

| Pure AZ31 | 0 | - |

| Nb2O5/AZ31 | 3 | 100 |

| Nb2O5/AZ31 | 6 | 100 |

| Phase Quantification | |||

|---|---|---|---|

| Composition (wt.%) | Major Phase | Crystal Structure | Percentage |

| AZ31 | Mg | Hexagonal | 25.6 |

| Al12Mg17 | Cubic | 0.8 | |

| Al3Mg2 | Cubic | 6.2 | |

| Al5Mg11Zn4 | Orthorhombic | 67.4 | |

| Mg4Nb2O9 | Hexagonal | 0 | |

| 3% Nb2O5/AZ31 | Mg | Hexagonal | 20 |

| Al12Mg17 | Cubic | 0.6 | |

| Al3Mg2 | Cubic | 4.3 | |

| Al5Mg11Zn4 | Orthorhombic | 52.9 | |

| Mg4Nb2O9 | Hexagonal | 22.1 | |

| 6% Nb2O5/AZ31 | Mg | Hexagonal | 19.4 |

| Al12Mg17 | Cubic | 0.5 | |

| Al3Mg2 | Cubic | 5.6 | |

| Al5Mg11Zn4 | Orthorhombic | 51.8 | |

| Mg4Nb2O9 | Hexagonal | 23 | |

| Composite | Ultimate Compressive Strength (MPa) | Strain (%) | Microhardness (HV) |

|---|---|---|---|

| Pure AZ31 | 272.36 | 22.69 | 55.06 ± 7.56 |

| 3 wt.% Nb2O5/AZ31 | 323.25 | 24.09 | 58.68 ± 2.85 |

| 6 wt.% Nb2O5/AZ31 | 297.23 | 25.25 | 59.68 ± 5.13 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, S.-J.; Sarkar, M.; Kannaiyan, S. Microstructural Evaluation and Fracture Behavior of AZ31/Nb2O5 Metal Matrix Composite. J. Compos. Sci. 2022, 6, 390. https://doi.org/10.3390/jcs6120390

Huang S-J, Sarkar M, Kannaiyan S. Microstructural Evaluation and Fracture Behavior of AZ31/Nb2O5 Metal Matrix Composite. Journal of Composites Science. 2022; 6(12):390. https://doi.org/10.3390/jcs6120390

Chicago/Turabian StyleHuang, Song-Jeng, Manas Sarkar, and Sathiyalingam Kannaiyan. 2022. "Microstructural Evaluation and Fracture Behavior of AZ31/Nb2O5 Metal Matrix Composite" Journal of Composites Science 6, no. 12: 390. https://doi.org/10.3390/jcs6120390

APA StyleHuang, S.-J., Sarkar, M., & Kannaiyan, S. (2022). Microstructural Evaluation and Fracture Behavior of AZ31/Nb2O5 Metal Matrix Composite. Journal of Composites Science, 6(12), 390. https://doi.org/10.3390/jcs6120390