Modeling Flexural Failure in Carbon-Fiber-Reinforced Polymer Composites

Abstract

:1. Introduction

2. Materials and Methods

2.1. ASTM D7264

2.2. CFRP Systems

2.3. Failure Criteria

2.4. Prediction of Flexural Strength

2.5. Finite-Element Model

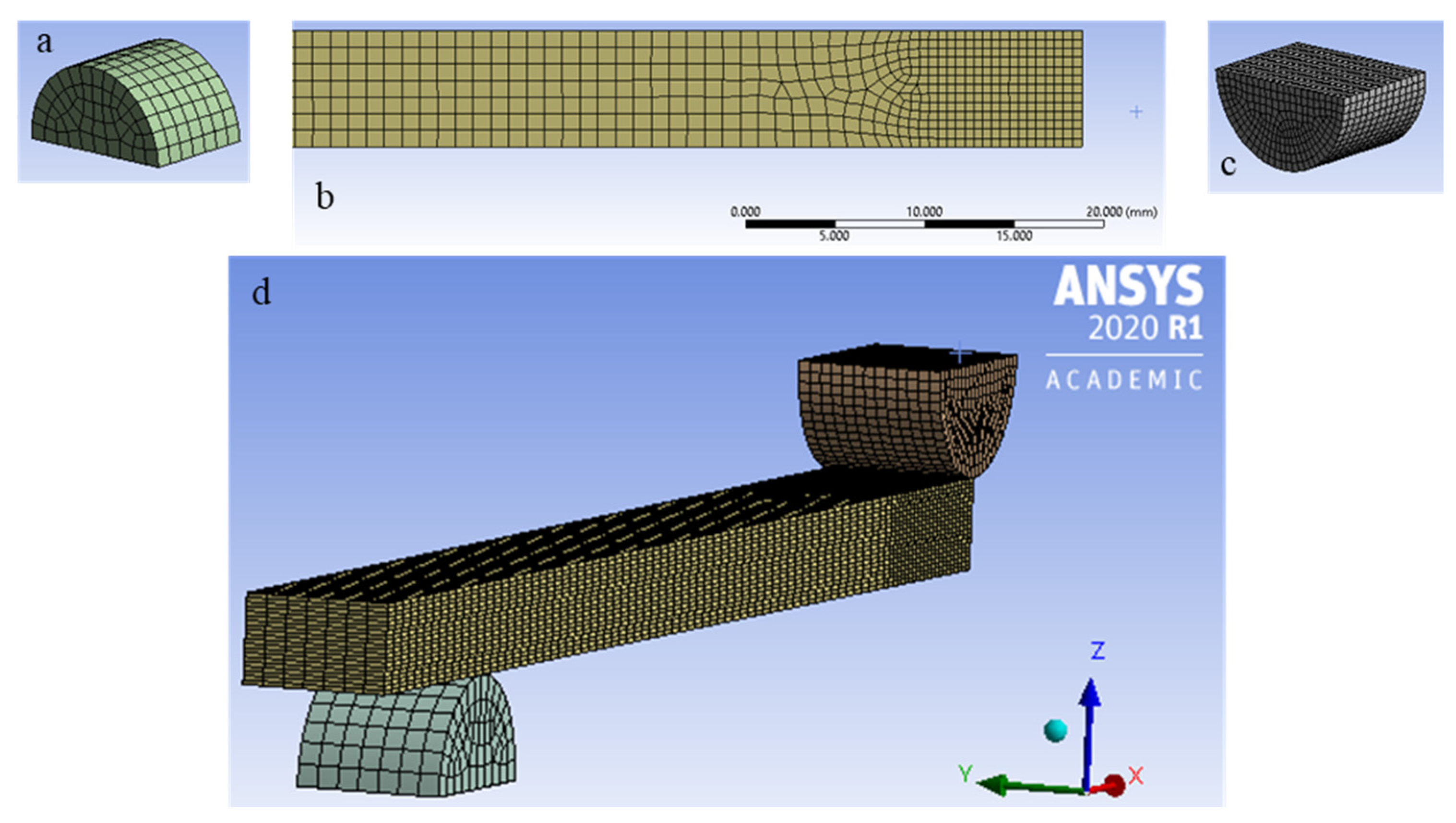

2.5.1. Geometry

2.5.2. Domain Discretization (Meshing)

2.5.3. Boundary Conditions and Contact Settings

2.5.4. Solver and Postprocessing

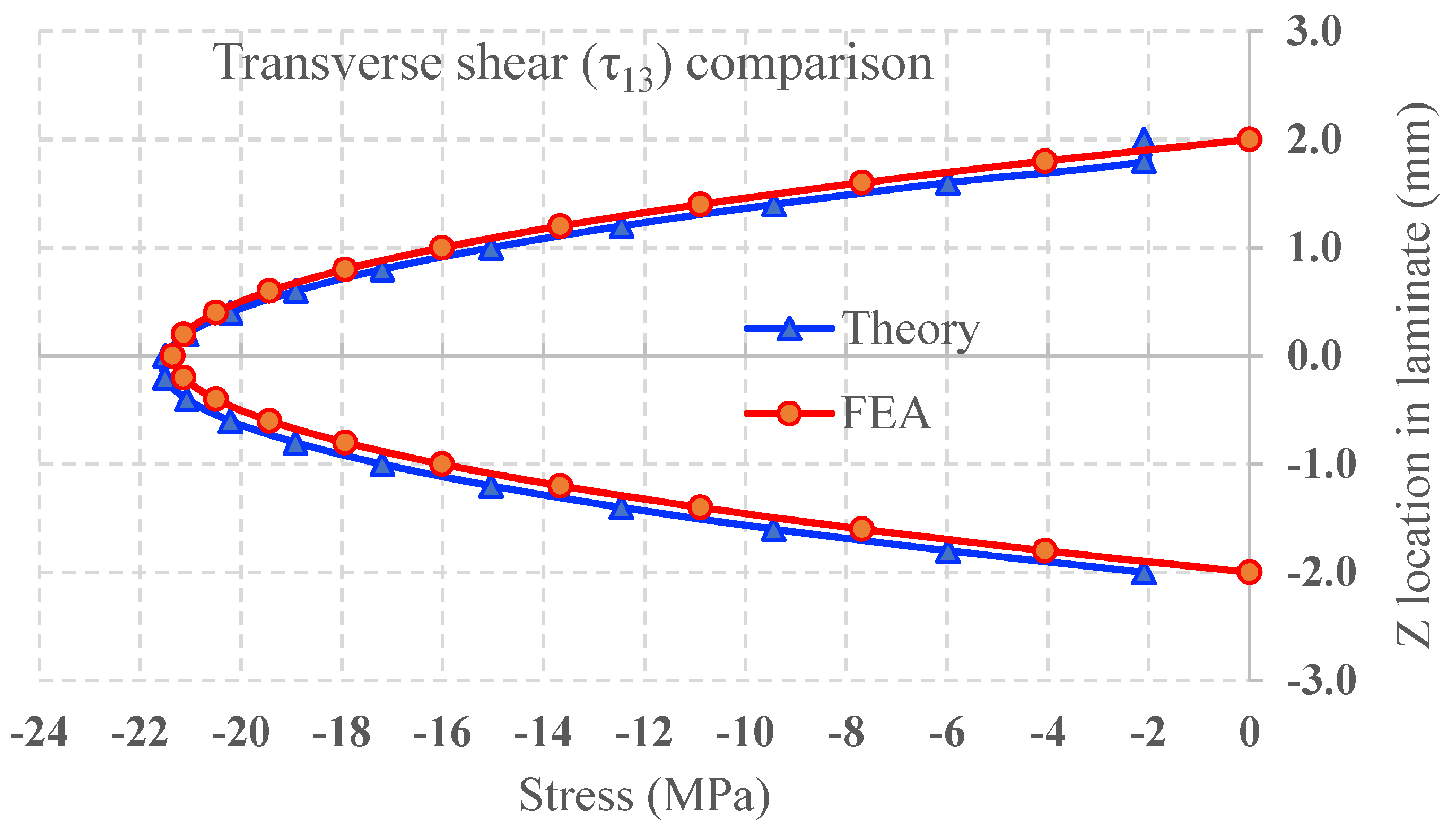

2.6. Model Verification with Shear Stresses in Beam Bending

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Daniel, I.M.; Ishai, O. Engineering Mechanics of Composite Materials, 2nd ed; Oxford University Press: New York, NY, USA, 2006. [Google Scholar]

- ASTM D7264/D7264M-07; Standard Test Method for Flexural Properties of Polymer Matrix Composite Materials. ASTM: West Conshohocken, PA, USA, 2015.

- Lian, E.; Lovingfoss, R.; Tanoto, V. Medium Toughness PAEK thermoplastics Toray TC1225 (LM PAEK) T700GC 12K T1E Unidirectional Tape Qualification Material Property Data Report. Natl. Inst. Aviat. Res. 2021. Available online: https://www.wichita.edu/industry_and_defense/NIAR/Documents/TorayTC1225UnitapeCAM-RP-2019-036RevA5.10.2021MPDRFinal.pdf (accessed on 15 September 2021).

- N.A. Solvay. APC-2 PEEK Datasheet. 2017. Available online: https://www.solvay.com/en/product/apc-2peeks2 (accessed on 10 February 2021).

- Marlett, K.; Ng, Y.; Tomblin, J.; By, A.; Hooper, E. Hexcel 8552 AS4 Unidirectional Material Property Data Report. Natl. Inst. Aviat. Res. 2011. Available online: https://www.wichita.edu/industry_and_defense/NIAR/Research/hexcel-8552/AS4-Unitape-2.pdf (accessed on 10 February 2021).

- Favaloro, M. Thermoplastic Composites in Aerospace—The Future Looks Bright | CompositesWorld. Available online: https://www.compositesworld.com/articles/thermoplastic-composites-in-aerospace-past-present-and-future (accessed on 29 April 2021).

- Offringa, A.R. Thermoplastic composites—Rapid processing applications. Compos. Part A Appl. Sci. Manuf. 1996, 27 Pt A, 329–336. [Google Scholar] [CrossRef]

- National Institute for Aviation Research. Available online: https://www.wichita.edu/research/NIAR/ (accessed on 1 May 2021).

- Gardiner, G. Integrating Antennas into Composite Aerostructures. 2021. Available online: https://www.compositesworld.com/articles/integrating-antennas-into-composite-aerostructures (accessed on 1 May 2021).

- Francis, S. Thermoplastic Composites: Poised to Step Forward. 2019. Available online: https://www.compositesworld.com/articles/thermoplastic-composites-poised-to-step-forward (accessed on 1 May 2021).

- Schellekens, J.C.J.; de Borst, R. The use of the Hoffman yield criterion in finite element analysis of anisotropic composites. Comput. Struct. 1990, 37, 1087–1096. [Google Scholar] [CrossRef]

- N.A. ANSYS Inc. Failure Criteria for Reinforced Materials—ACP Documentation. 2021. Available online: https://ansyshelp.ansys.com/account/secured?returnurl=/Views/Secured/corp/v221/en/acp_ug/acp_failure_analysis.html (accessed on 15 September 2021).

- Sung, M.; Jang, J.; Tran, V.L.; Hong, S.T.; Yu, W.R. Increased breaking strain of carbon fiber-reinforced plastic and steel hybrid laminate composites. Compos. Struct. 2020, 235, 111768. [Google Scholar] [CrossRef]

- Fam, A.; Sharaf, T. Flexural performance of sandwich panels comprising polyurethane core and GFRP skins and ribs of various configurations. Compos. Struct. 2010, 92, 2927–2935. [Google Scholar] [CrossRef]

- Budynas, R.G.; Nisbett, J.K. Shigley’s Mechanical Engineering Design, 11th ed.; McGraw-Hill Education: New York, NY, USA, 2020; p. 119. [Google Scholar]

- Sancaktar, E. Mechanics of solids and structures. ASME Int. Mech. Eng. Congr. Expo. Proc. 2019, 10 Pt A, 53–90. [Google Scholar]

- Pai, P.F. Geometrically exact beam theory without Euler angles. Int. J. Solids Struct. 2011, 48, 3075–3090. [Google Scholar] [CrossRef] [Green Version]

| Parameter | Span Length L (mm) | Thickness t (mm) | Width—Into the Page (mm) | Additional Overhang (%) | Loading Nose Radius (mm) |

|---|---|---|---|---|---|

| Value | 128 | 4 | 13 | 20 | 5 |

| Composite System (Fiber/Resin) | Tensile Strength (MPa) | Compressive Strength (MPa) | Flexural Strength (MPa) | Ultimate Tensile Strain (%) | Ultimate Compressive Strain (%) |

|---|---|---|---|---|---|

| T700/Toray LM PAEK | 2322 | 1226 | 1455 | 1.86 | 0.98 |

| APC2/PEEK (Solvay) | 2070 | 1360 | 2000 | 1.45 | 1.10 |

| AS4/Hexcel 8552 | 2205 | 1530 | 1889 | 1.56 | 1.09 |

| Theory | Category | Failure Criterion |

|---|---|---|

| Maximal stress | Noninteractive | |

| Maximal strain | Noninteractive | |

| Hashin–Rotem | Partially interactive | |

| Tsai–Wu | Fully interactive | |

| Hoffman | Fully interactive | Same as Tsai—Wu, coefficient definitions differ. |

| Tsai–Hill | Fully interactive |

| Composite System (Fiber/Resin) | Tensile Strength (MPa) | Compressive Strength (MPa) | Flexural Strength (MPa) | FEA-Flexural Strength (MPa) | % Error between FEA and Experiment |

|---|---|---|---|---|---|

| T700/Toray LM PAEK | 2322 | 1226 | 1455 | 1367 | −6.1 |

| AS4/Hexcel 8552 Epoxy | 2205 | 1530 | 1889 | 1717 | −9.1 |

| APC2/Solvay PEEK | 2070 | 1360 | 2000 | 1725 | −13.8 |

| Compressive Strength (MPa) | FEA Maximum Compressive Stress (MPa) | Relative Difference (%) | |

|---|---|---|---|

| Toray T700/LM PAEK | 1226 | 1338 | 9.2 |

| Solvay APC-2/PEEK | 1360 | 1700 | 25 |

| Hexcel AS4/8552 epoxy | 1530 | 1690 | 10.5 |

| Toray T700/PAEK | Hexcel AS4/8552 | Solvay APC2/PEEK | |

|---|---|---|---|

| σ1 (MPa) | −1338 | 1706 | −1700 |

| σ2 (MPa) | −41 | 35 | −50 |

| τ12 (MPa) | 0.6 | −0.9 | 0.9 |

| F1σ1 | 0.603 | −0.325 | 0.440 |

| F2σ2 | −0.225 | 0.452 | −0.285 |

| F11σ12 | 0.687 | 0.947 | 1.061 |

| F22σ22 | 0.135 | 0.156 | 0.145 |

| F66τ122 | 0.000 | 0.000 | 0.000 |

| σ1σ2 | −0.197 | −0.225 | −0.347 |

| Total | 1.003 | 1.005 | 1.014 |

| Failure Criteria | FEA-Predicted Strength (MPa) | Error (%) |

|---|---|---|

| Tsai–Wu | 1366.6 | −6.06 |

| Max strain | 1257.3 | −13.58 |

| Max stress | 1243.6 | −14.52 |

| Tsai–Hill | 1243.6 | −14.52 |

| Hoffman | 1352.9 | −7.00 |

| Hashin | 1243.6 | −14.52 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Burgani, T.d.S.; Alaie, S.; Tehrani, M. Modeling Flexural Failure in Carbon-Fiber-Reinforced Polymer Composites. J. Compos. Sci. 2022, 6, 33. https://doi.org/10.3390/jcs6020033

Burgani TdS, Alaie S, Tehrani M. Modeling Flexural Failure in Carbon-Fiber-Reinforced Polymer Composites. Journal of Composites Science. 2022; 6(2):33. https://doi.org/10.3390/jcs6020033

Chicago/Turabian StyleBurgani, Thiago de Sousa, Seyedhamidreza Alaie, and Mehran Tehrani. 2022. "Modeling Flexural Failure in Carbon-Fiber-Reinforced Polymer Composites" Journal of Composites Science 6, no. 2: 33. https://doi.org/10.3390/jcs6020033

APA StyleBurgani, T. d. S., Alaie, S., & Tehrani, M. (2022). Modeling Flexural Failure in Carbon-Fiber-Reinforced Polymer Composites. Journal of Composites Science, 6(2), 33. https://doi.org/10.3390/jcs6020033