Investigation of the Mechanical Properties of Vinylester-Based Sheet Moulding Compound (SMC) Subject to Particle Recycling

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

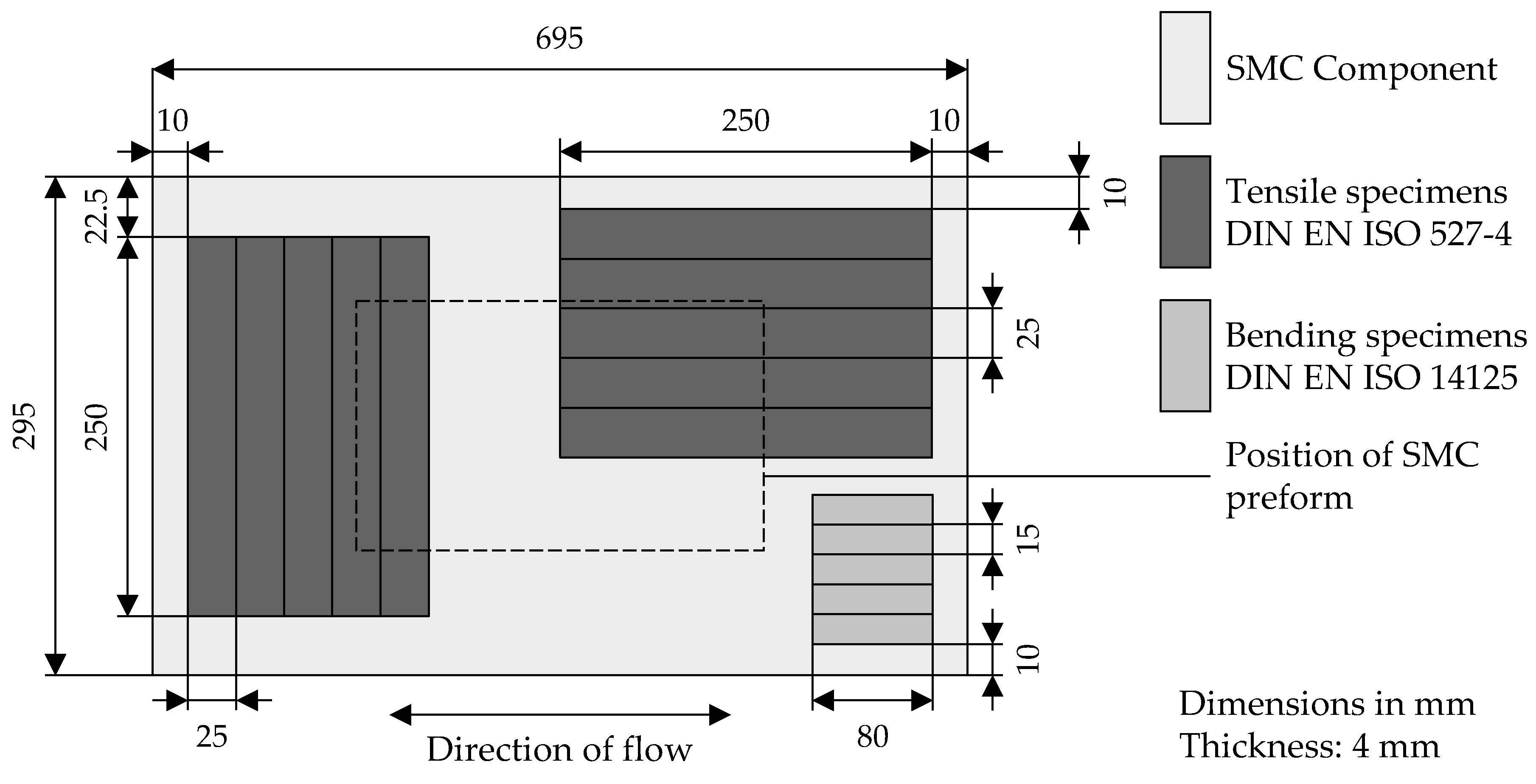

2.2. Manufacturing of SMC Components on a Laboratory Scale

2.3. Experimental Methods

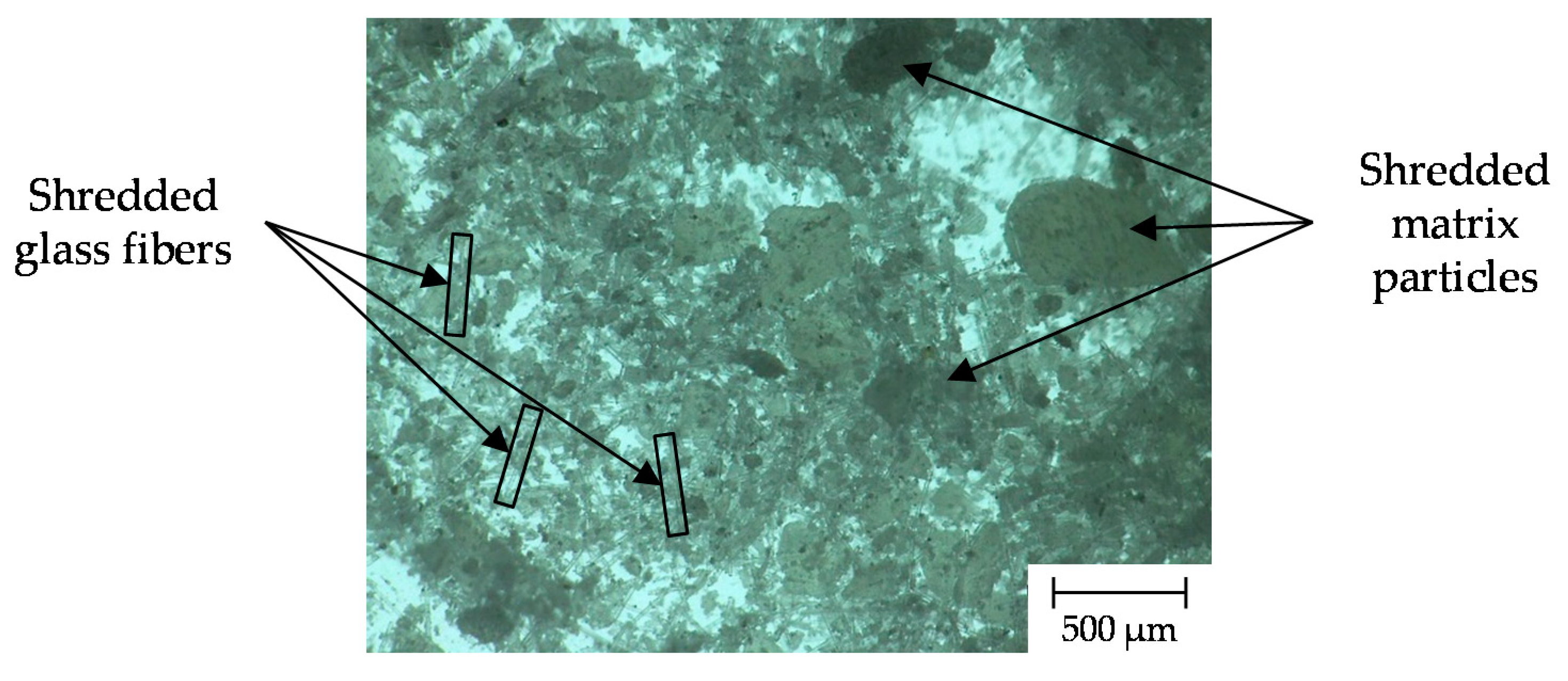

2.3.1. Microscopic Investigations

2.3.2. Mechanical Testing

Tensile Tests

Four-Point Bending Tests

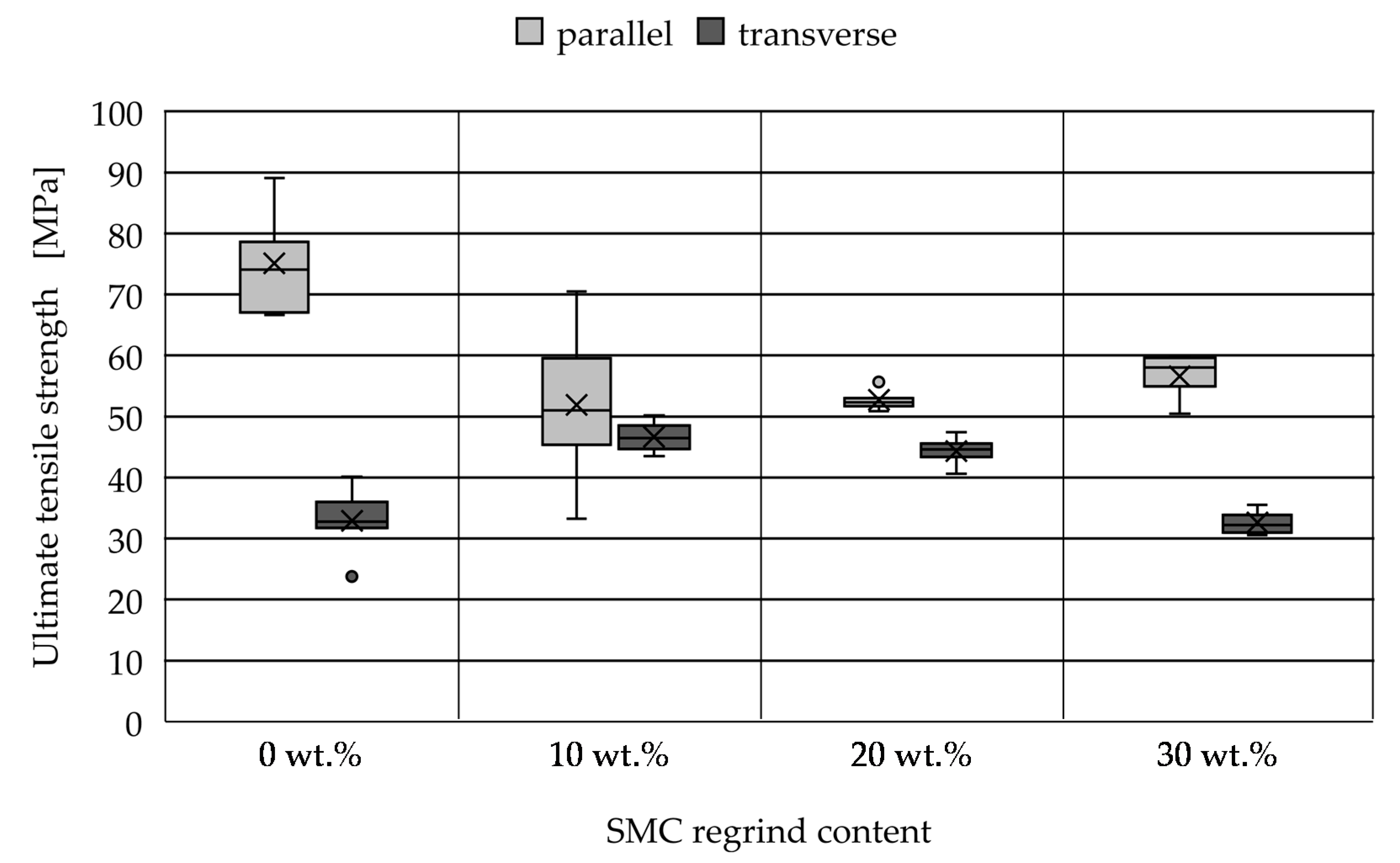

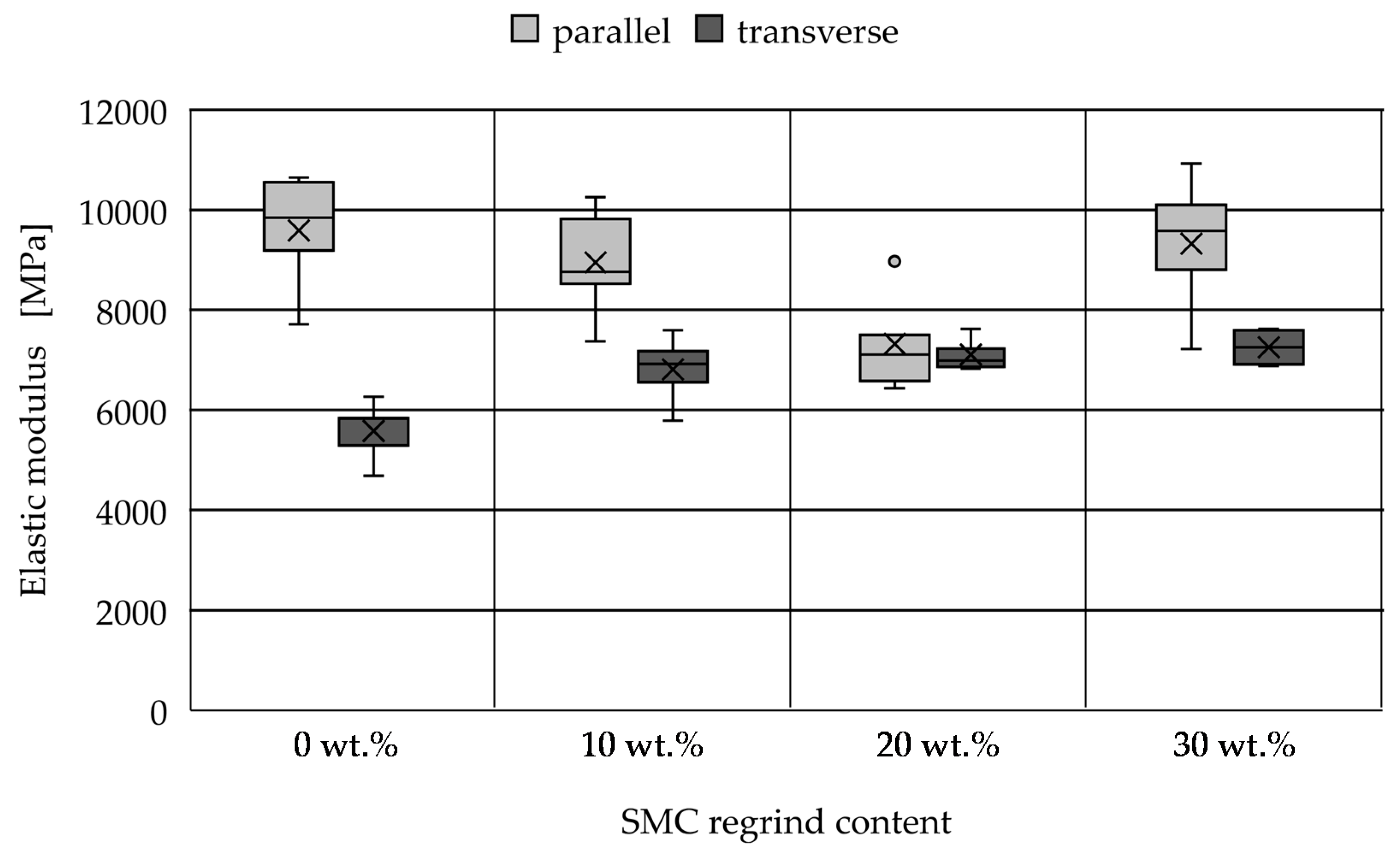

3. Results and Discussion

3.1. Validation of SMC Manufacturing on a Laboratory Scale

3.2. Microscopic Characteristics of the SMC Regrind

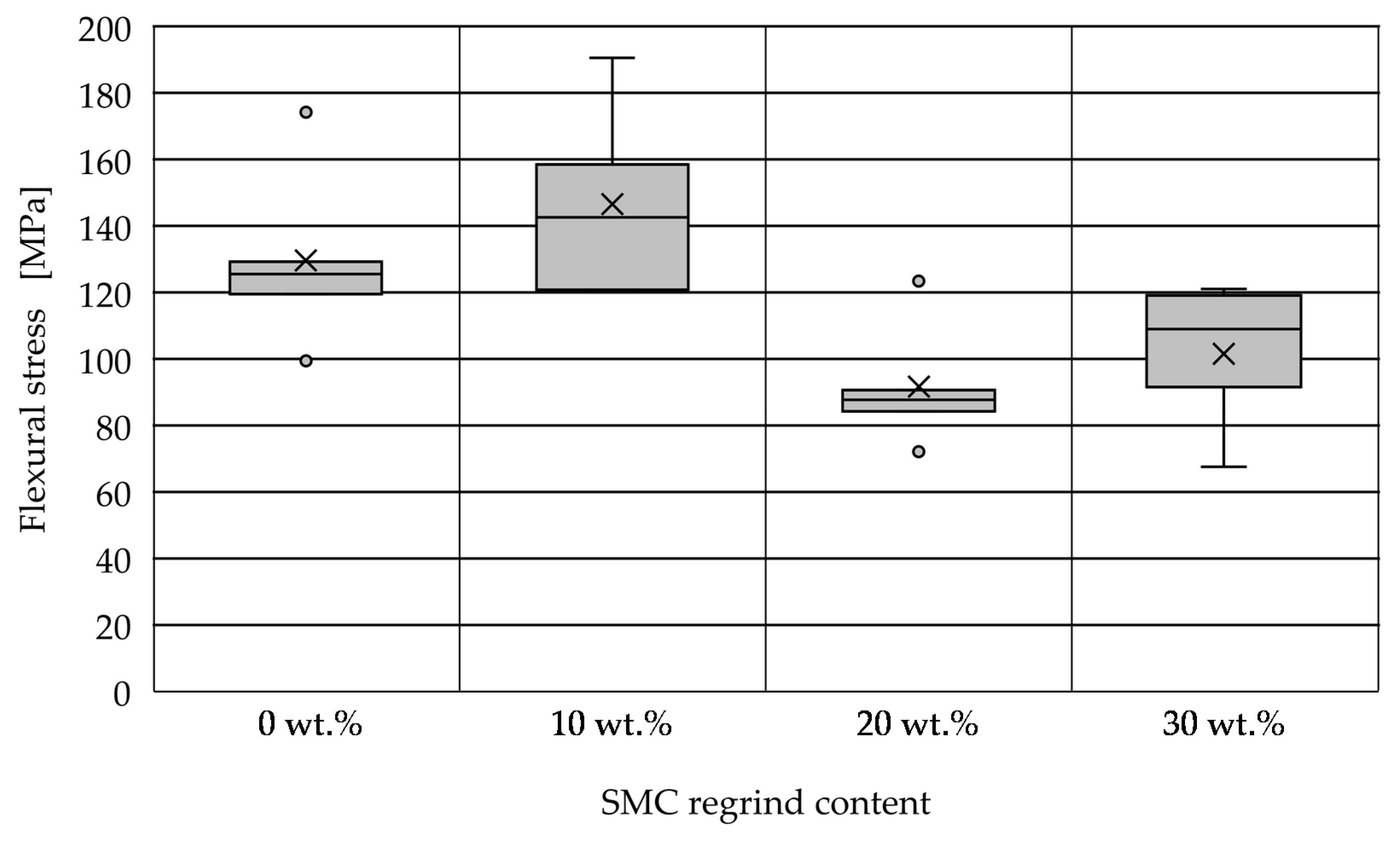

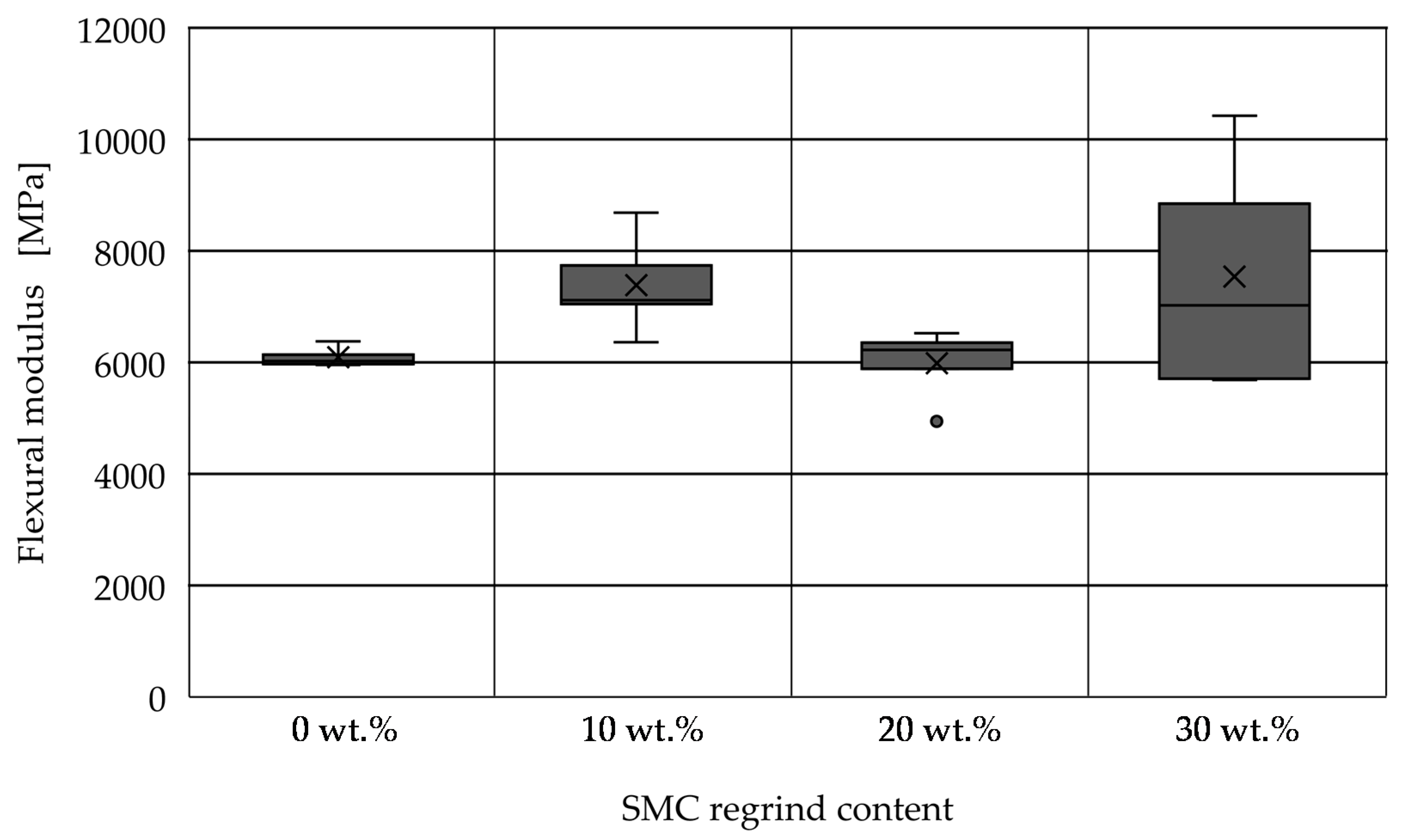

3.3. Mechanical Properties of the SMC Components

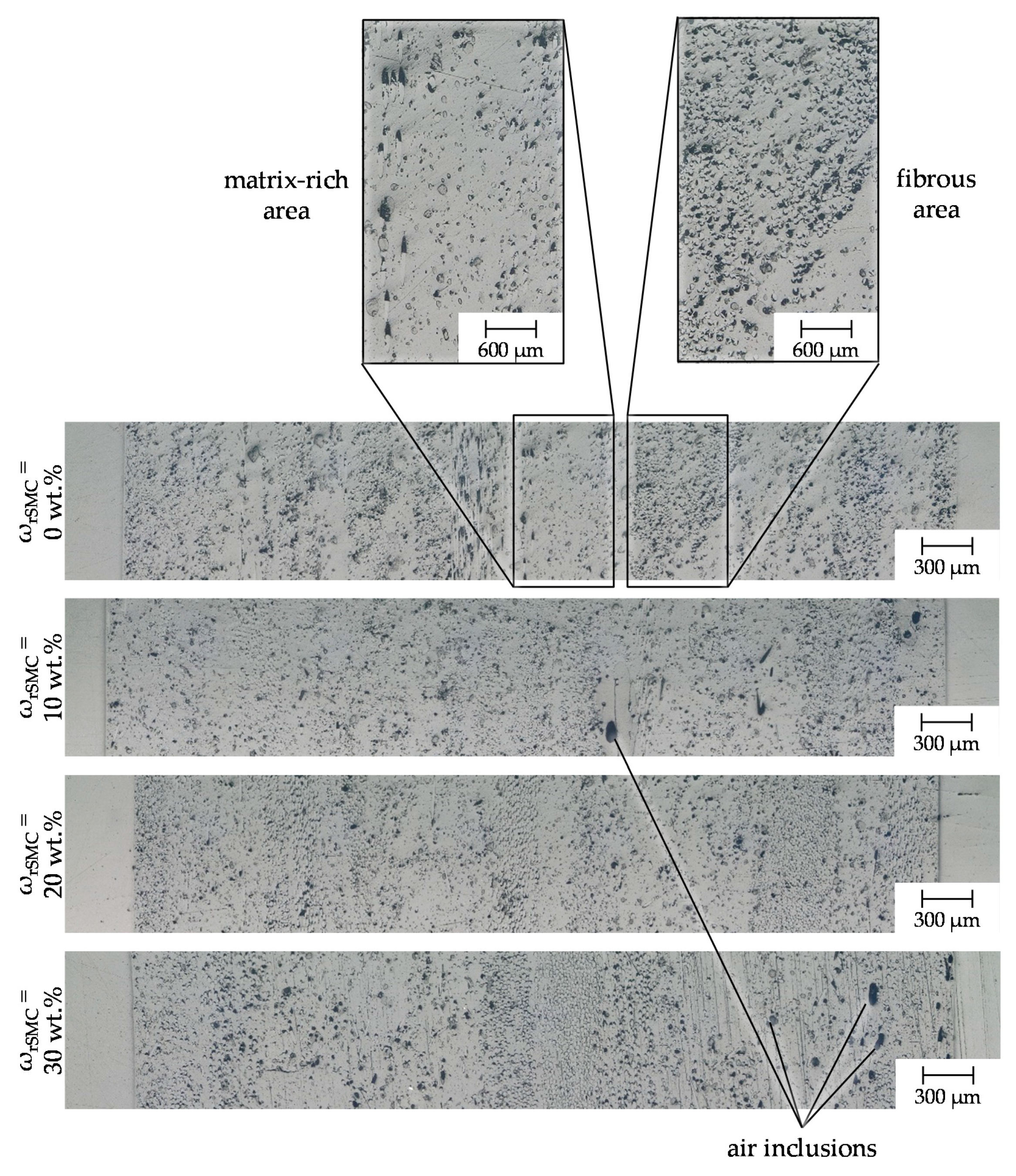

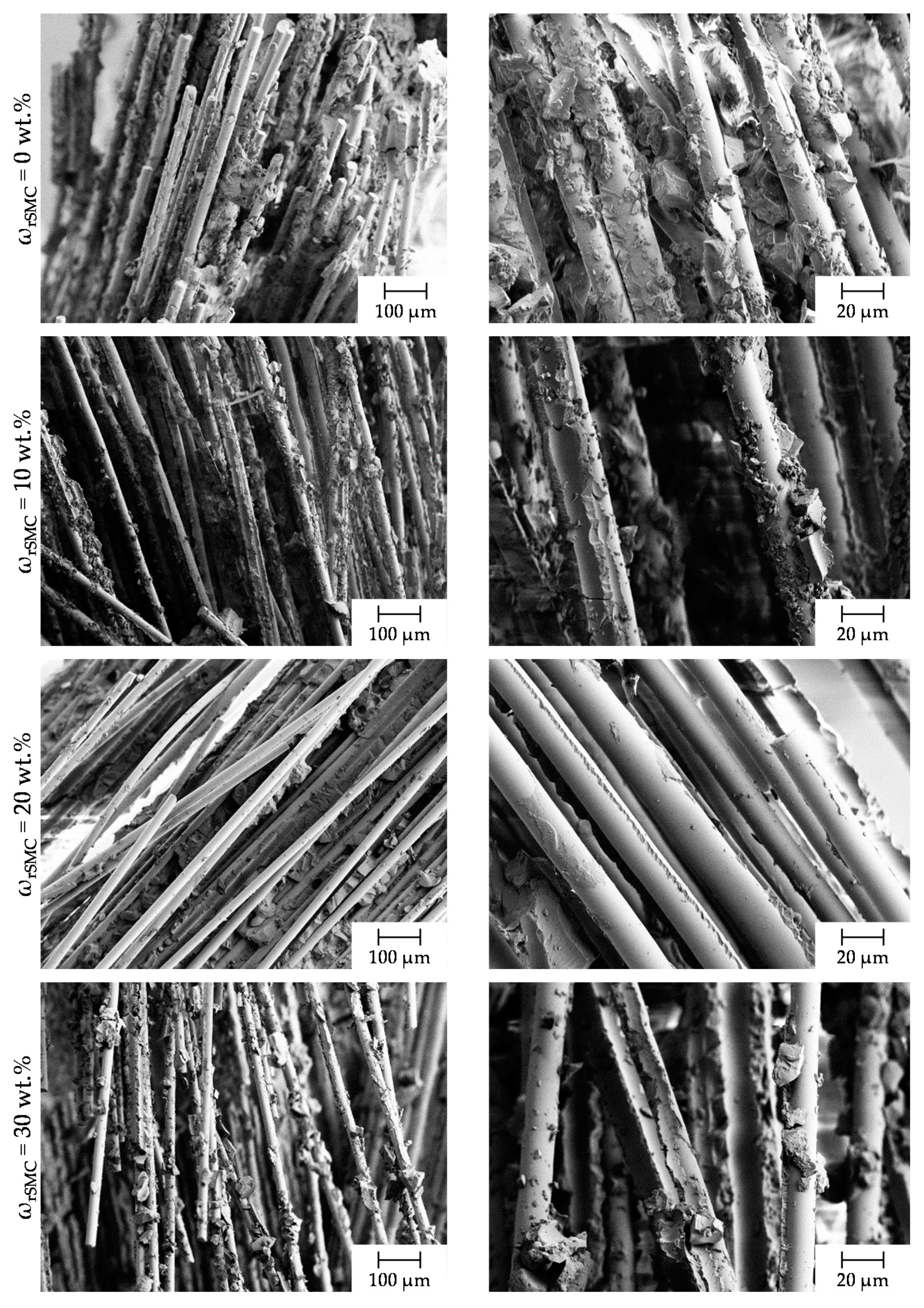

3.4. Microscopic Characteristics of the SMC Components

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Witten, E.; Schuster, A. Der Markt für Glasfaserverstärkte Kunststoffe (GFK) 2019: Marktentwicklungen, Herausforderungen und Chancen; Industrievereinigung Verstärkte Kunststoffe: Frankfurt, Germany, 2019. [Google Scholar]

- Witten, E. Aktuelle Entwicklungen und Trends im Composites-Markt. Available online: https://www.weiterbildung.ifam.fraunhofer.de/de/blog/composites-markt.html (accessed on 20 January 2022).

- Lässig, R.; Eisenhut, M.; Mathias, A.; Schulte, R.T.; Peters, F.; Kühmann, T.; Waldmann, T.; Begemann, W. Serienproduktion von Hochfesten Faserverbundbauteilen: Persprektiven Für Den Deutschen Maschinen- und Anlagenbau; Roland Berger: Munich, Germany, 2012. [Google Scholar]

- Stauber, R.C. Kunststoffe und Kunststofftechnologien für das Automobil der Zukunft. ATZextra 2010, 15, 12–17. [Google Scholar] [CrossRef]

- Pickering, S.J. Recycling technologies for thermoset composite materials—current status. Compos. Part A Appl. Sci. Manuf. 2006, 37, 1206–1215. [Google Scholar] [CrossRef]

- Prinçaud, M.; Aymonier, C.; Loppinet-Serani, A.; Perry, N.; Sonnemann, G. Environmental Feasibility of the Recycling of Carbon Fibers from CFRPs by Solvolysis Using Supercritical Water. ACS Sustain. Chem. Eng. 2014, 2, 1498–1502. [Google Scholar] [CrossRef] [Green Version]

- Vo Dong, P.A.; Azzaro-Pantel, C.; Cadene, A.-L. Economic and environmental assessment of recovery and disposal pathways for CFRP waste management. Resour. Conserv. Recycl. 2018, 133, 63–75. [Google Scholar] [CrossRef] [Green Version]

- Job, S.; Leek, G.; Mativenga, P.T.; Oliveux, G.; Pickering, S.; Shuaib, N.A. Composites Recycling: Where Are We Now? Composites UK: Berkhamsted, UK, 2016; Available online: https://compositesuk.co.uk/system/files/documents/Recycling%20Report%202016.pdf (accessed on 20 January 2022).

- Meng, F.; Pickering, S.J.; McKechnie, J. An Environmental Comparison of Carbon Fibre Composite Waste End-of-life Options. In Proceedings of the SAMPE Europe Conference 2018, Southampton, UK, 11–13 September 2018. [Google Scholar]

- Baur, E.; Harsch, G.; Moneke, M. (Eds.) Werkstoff-Führer Kunststoffe: Eigenschaften, Prüfungen, Kennwerte, 11th ed.; Carl Hanser Verlag: Munich, Germany, 2019. [Google Scholar]

- Karuppannan Gopalraj, S.; Kärki, T. A review on the recycling of waste carbon fibre/glass fibre-reinforced composites: Fibre recovery, properties and life-cycle analysis. SN Appl. Sci. 2020, 2, 1–21. [Google Scholar] [CrossRef] [Green Version]

- Oliveux, G.; Dandy, L.O.; Leeke, G.A. Current status of recycling of fibre reinforced polymers: Review of technologies, reuse and resulting properties. Prog. Mater. Sci. 2015, 72, 61–99. [Google Scholar] [CrossRef] [Green Version]

- Ferdous, W.; Manalo, A.; Yu, P.; Salih, C.; Abousnina, R.; Heyer, T.; Schubel, P. Tensile Fatigue Behavior of Polyester and Vinyl Ester Based GFRP Laminates-A Comparative Evaluation. Polymers 2021, 13, 386. [Google Scholar] [CrossRef]

- Ferdous, W.; Ngo, T.D.; Nguyen, K.T.Q.; Ghazlan, A.; Mendis, P.; Manalo, A. Effect of fire-retardant ceram powder on the properties of phenolic-based GFRP composites. Compos. Part B Eng. 2018, 155, 414–424. [Google Scholar] [CrossRef]

- Reygrobellet, J.N.; Lopez Cuesta, J.M.; Crespy, A. Incorporation of unsaturated polyester based matrix composites into a PP-PE copolymer for recycling. In International Committee on Composite Materials, Proceedings of the 1999 International Conference on Composite Materials, Paris, France, 5–9 July 1999; ICCM/12TCA: Tours, France, 2000. [Google Scholar]

- Winter, H.; Mostert, H.A.M.; Smeets, P.J.H.M.; Paas, G. Recycling of sheet-molding compounds by chemical routes. J. Appl. Polym. Sci. 1995, 57, 1409–1417. [Google Scholar] [CrossRef]

- Tesoro, G.; Wu, Y. Chemical Products from Cured Unsaturated Polyester. Adv. Polym. Technol. 1993, 12, 185–196. [Google Scholar] [CrossRef]

- Henshaw, J.M.; Han, W.; Owens, A.D. An Overview of Recycling Issues for Composite Materials. J. Thermoplast. Compos. Mater. 1996, 9, 4–20. [Google Scholar] [CrossRef]

- Derosa, R.; Telfeyan, E.; Mayes, J.S. Current State of Recycling Sheet Molding Compounds and Related Materials. J. Thermoplast. Compos. Mater. 2005, 18, 219–240. [Google Scholar] [CrossRef]

- Petterson, J.; Nilsson, P. Recycling of SMC and BMC in Standard Process Equipment. J. Thermoplast. Compos. Mater. 1994, 7, 56–63. [Google Scholar] [CrossRef]

- Inoh, T.; Yokoi, T.; Sekiyama, K.-I.; Kawamura, N.; Mishima, Y. SMC Recycling Technology. J. Thermoplast. Compos. Mater. 1994, 7, 42–55. [Google Scholar] [CrossRef]

- Seiler, E.; Teipel, U. Recycling von Kompositbauteilen aus Kunststoffen als Matrixmaterial—ReKomp Abschlussbericht Projektverbund ForCycle—Ressourcenstrategie für Bayern unter Besonderer Berücksichtigung von Sekundärrohstoffen, Nürnberg. 2017. Available online: https://docplayer.org/56978897-Abschlussbericht-recycling-von-kompositbauteilen-aus-kunststoffen-als-matrixmaterial-rekomp-laufzeit.html (accessed on 20 January 2022).

- Fette, M.; Hentschel, M.; Santafe, J.G.; Wille, T.; Büttemeyer, H.; Schiebel, P. New Methods for Computing and Developing Hybrid Sheet Molding Compound Structures for Aviation Industry. Procedia CIRP 2017, 66, 45–50. [Google Scholar] [CrossRef]

- Oldenbo, M.; Fernberg, S.P.; Berglund, L.A. Mechanical behaviour of SMC composites with toughening and low density additives. Compos. Part A Appl. Sci. Manuf. 2003, 34, 875–885. [Google Scholar] [CrossRef]

- Oldenbo, M. Anisotropy and Non-Linear Effects in SMC Composites: From Material Data to FE-Simulation of Structures. Ph.D. Thesis, Luleå University of Technology, Luleå, Sweden, 2004. [Google Scholar]

- Palmer, J.; Ghita, O.R.; Savage, L.; Evans, K.E. Recyclate fibres-matrix interface analysis for reuse in sheet moulding compounds (SMC). In Proceedings of the 13th European Conference on Composite Materials, Stockholm, Sweden, 2–5 June 2008. [Google Scholar]

- Gortner, F. Bio-Basierte und Nachwachsende Füllstoffe für Dichtereduzierte Sheet Molding Compounds. Ph.D. Thesis, Technische Universität Kaiserslautern, Kaiserslautern, Germany, 2019. [Google Scholar]

- Kia, H.G. (Ed.) Sheet Moulding Compounds: Science and Technology; Hanser Gardner Publications: Cincinnati, OH, USA; Munich, Germany, 1993. [Google Scholar]

- Orgéas, L.; Dumont, P.J.J. Sheet Moulding Compounds. In Wiley Encyclopedia of Composites; Nicolais, L., Borzacchiello, A., Lee, S.M., Eds.; Wiley Interscience: Hoboken, NY, USA, 2011. [Google Scholar]

- Kim, D.-H.; Kim, H.-G.; Kim, H.-S. Design optimization and manufacture of hybrid glass/carbon fiber reinforced composite bumper beam for automobile vehicle. Compos. Struct. 2015, 131, 742–752. [Google Scholar] [CrossRef]

- Sambale, H. Fiber Spraying Process for Efficient Preform Production. Available online: https://en.kunststoffe.de/a/article/article-276444 (accessed on 20 January 2022).

- Schmidt & Heinzmann GmbH & Co. KG. Fiber Spraying. Available online: https://schmidt-heinzmann.de/fiber-processing/fiber-spraying/ (accessed on 20 January 2022).

- Keckl, C. Einfluss der Eindickung von Dichtereduziertem Sheet Moulding Compound auf Die Formteilwelligkeit. Ph.D. Thesis, Karlsruher Institut für Technologie, Karlsruhe, Germany, 2016. [Google Scholar]

- Macherauch, E.; Zoch, H.-W. Praktikum in Werkstoffkunde: 95 Ausführliche Versuche aus Wichtigen Gebieten der Werkstofftechnik, 12th ed.; Springer Vieweg: Wiesbaden, Germany, 2014. [Google Scholar]

- Erdmann, J. Biobasierte Kunststoffe mit Cellulosefaserverstärkung: Zusammenhänge Zwischen Struktur, Haftung und Mechanischen Eigenschaften. Ph.D. Thesis, Martin-Luther-Universität Halle-Wittenberg, Halle, Germany, 2017. [Google Scholar]

- Lamanna, G.; Ceparano, A. Mechanical Characterization of Sheet Moulding Composites for the Automotive Industry. Open Mater. Sci. 2014, 8, 108–113. [Google Scholar] [CrossRef] [Green Version]

- Piry, M. Mechanische Auslegung von SMC-Bauteilen und Charakterisierung der Relevanten Werkstoffeigenschaften: Mechanical Dimensioning of SMC-Components and Characterization of the Relevant Material Properties. Ph.D. Thesis, Rheinisch-Westfälische Technische Hochschule Aachen, Aachen, Germany, 2004. [Google Scholar]

- Schiebisch, J. Zum Recycling von Faserverbundkunststoffen mit Duroplastmatrix. Ph.D. Thesis, Universität Erlangen-Nürnberg, Erlangen, Germany, 1995. [Google Scholar]

- Hour, K.-Y.; Sehitoglu, H. Damage Development in a Short Fiber Reinforced Composite. J. Compos. Mater. 1993, 27, 782–805. [Google Scholar] [CrossRef]

- Wang, S.S.; Chim, E.-M. Fatigue Damage and Degradation in Random Short-Fiber SMC Composite. J. Compos. Mater. 1983, 17, 114–134. [Google Scholar] [CrossRef]

- Fitoussi, J.; Guo, G.; Baptiste, D. A statistical micromechanical model of anisotropic damage for S.M.C. composites. Compos. Sci. Technol. 1998, 58, 759–763. [Google Scholar] [CrossRef]

| Material | Definition |

|---|---|

| SMC regrind | ground VE-SMC material (recyclate) |

| SMC resin | mixture of resin, additives and (varied mass percentages of) SMC regrind |

| SMC preform | glass fibers impregnated with SMC resin |

| SMC components | compression moulded SMC |

| Component | Trade Name | Parts Per Hundred Resin |

|---|---|---|

| Vinylester (VE) resin | Reichhold Dion 31056 | 92.5 |

| Low profile additive (Solution of a saturated polyester in styrene for shrinkage compensation) | Reichhold Norpol 9892 | 7.5 |

| Processing additive | BYK BYK-P 9085 | 5 |

| Wetting agent | BYK BYK-9076 | 3 |

| Curing agent (tert.-Butylperoxy-2-ethylhexylcarbonat) | Nouryon Trigonox 117 | 1.5 |

| Dispersing/anti-shrinkage agent (Polyethylen (PE) powder) | Axalta Coathylene HA 1681 | 2.5 |

| Thickener (magnesium oxide (MgO) paste) | Luvatol EK 100 KM | 8 |

| Material Properties | Unit | Value |

|---|---|---|

| Density of SMC preform | g/cm3 | 1.9 |

| Weight per unit area | g/m2 | 3000 |

| Fiber weight proportion | % by weight | 35 |

| Fiber length | mm | 50 |

| SMC regrind share per formulation | % by weight | 0; 10; 20; 30 |

| Process Parameters | Unit | Value |

|---|---|---|

| Press force | kN | 2100 |

| Initial mold coverage | % | 50 |

| Position of SMC preform | - | centered |

| Pre-heating time | s | 45 |

| Curing time | s | 300 |

| Compression speed | mm/s | 5 |

| Mold temperature (top/bottom) | °C | 150/135 |

| Settings | Unit | Value |

|---|---|---|

| Load Cell | kN | 150 |

| Preload | N | 5 |

| Loading Rate | mm/min | 2 |

| Settings | Unit | Value |

|---|---|---|

| Load Cell | kN | 100 |

| Preload | N | 2 |

| Loading Rate | mm/min | 2 |

| Support span | mm | 66 |

| Loading span | mm | 22 |

| Radius of the compression fins | mm | 5 |

| Properties | Unit | Conventional SMC Fiber Weight Proportion 50 wt.% | Manually Manufactured SMC Fiber Weight Proportion 35 wt.% |

|---|---|---|---|

| Tensile strength | [MPa] | 134.5 | 75.1 |

| Elastic modulus | [GPa] | 10.1 | 9.6 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Austermann, V.; Neuhaus, J.; Schneider, D.; Dahlmann, R.; Hopmann, C. Investigation of the Mechanical Properties of Vinylester-Based Sheet Moulding Compound (SMC) Subject to Particle Recycling. J. Compos. Sci. 2022, 6, 84. https://doi.org/10.3390/jcs6030084

Austermann V, Neuhaus J, Schneider D, Dahlmann R, Hopmann C. Investigation of the Mechanical Properties of Vinylester-Based Sheet Moulding Compound (SMC) Subject to Particle Recycling. Journal of Composites Science. 2022; 6(3):84. https://doi.org/10.3390/jcs6030084

Chicago/Turabian StyleAustermann, Vera, Jonas Neuhaus, Daniel Schneider, Rainer Dahlmann, and Christian Hopmann. 2022. "Investigation of the Mechanical Properties of Vinylester-Based Sheet Moulding Compound (SMC) Subject to Particle Recycling" Journal of Composites Science 6, no. 3: 84. https://doi.org/10.3390/jcs6030084

APA StyleAustermann, V., Neuhaus, J., Schneider, D., Dahlmann, R., & Hopmann, C. (2022). Investigation of the Mechanical Properties of Vinylester-Based Sheet Moulding Compound (SMC) Subject to Particle Recycling. Journal of Composites Science, 6(3), 84. https://doi.org/10.3390/jcs6030084