Mechanical Characterization and Finite Element Analysis of Hierarchical Sandwich Structures with PLA 3D-Printed Core and Composite Maize Starch Biodegradable Skins

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

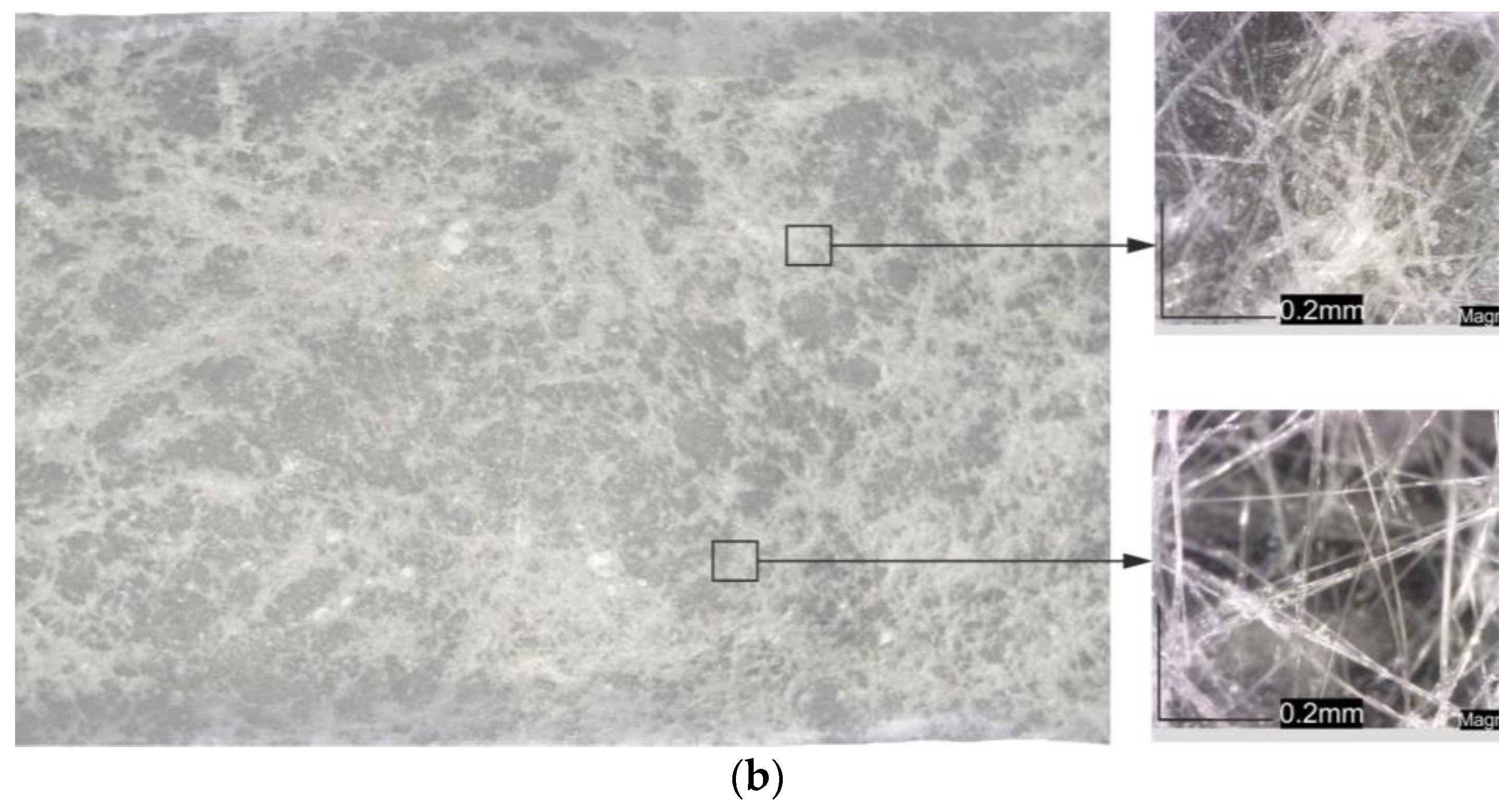

2.2.1. Preparation of Starch-Based Skins

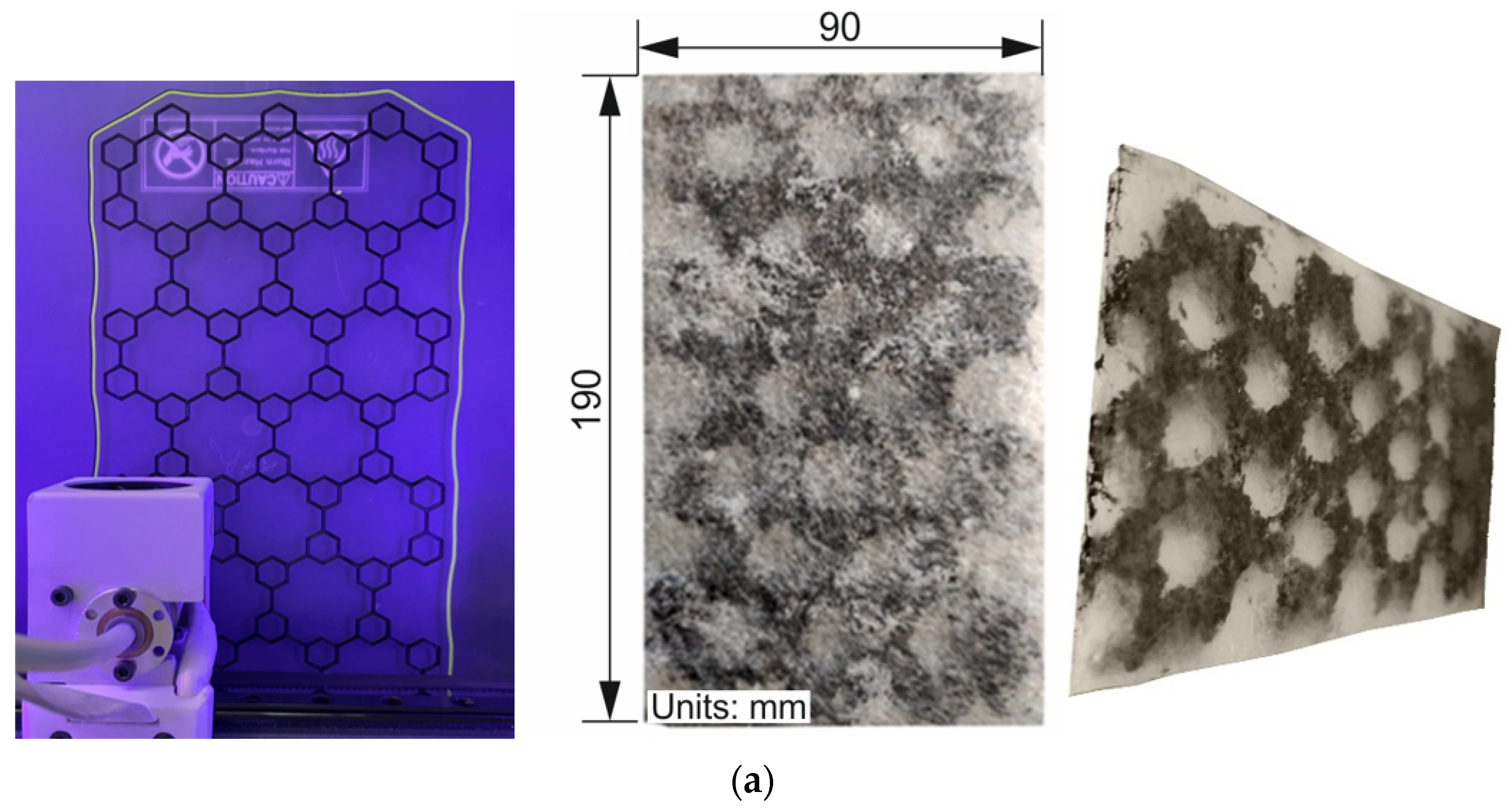

2.2.2. Design and Fabrication of FFF-Printed Honeycomb Structures

2.2.3. Tensile Testing

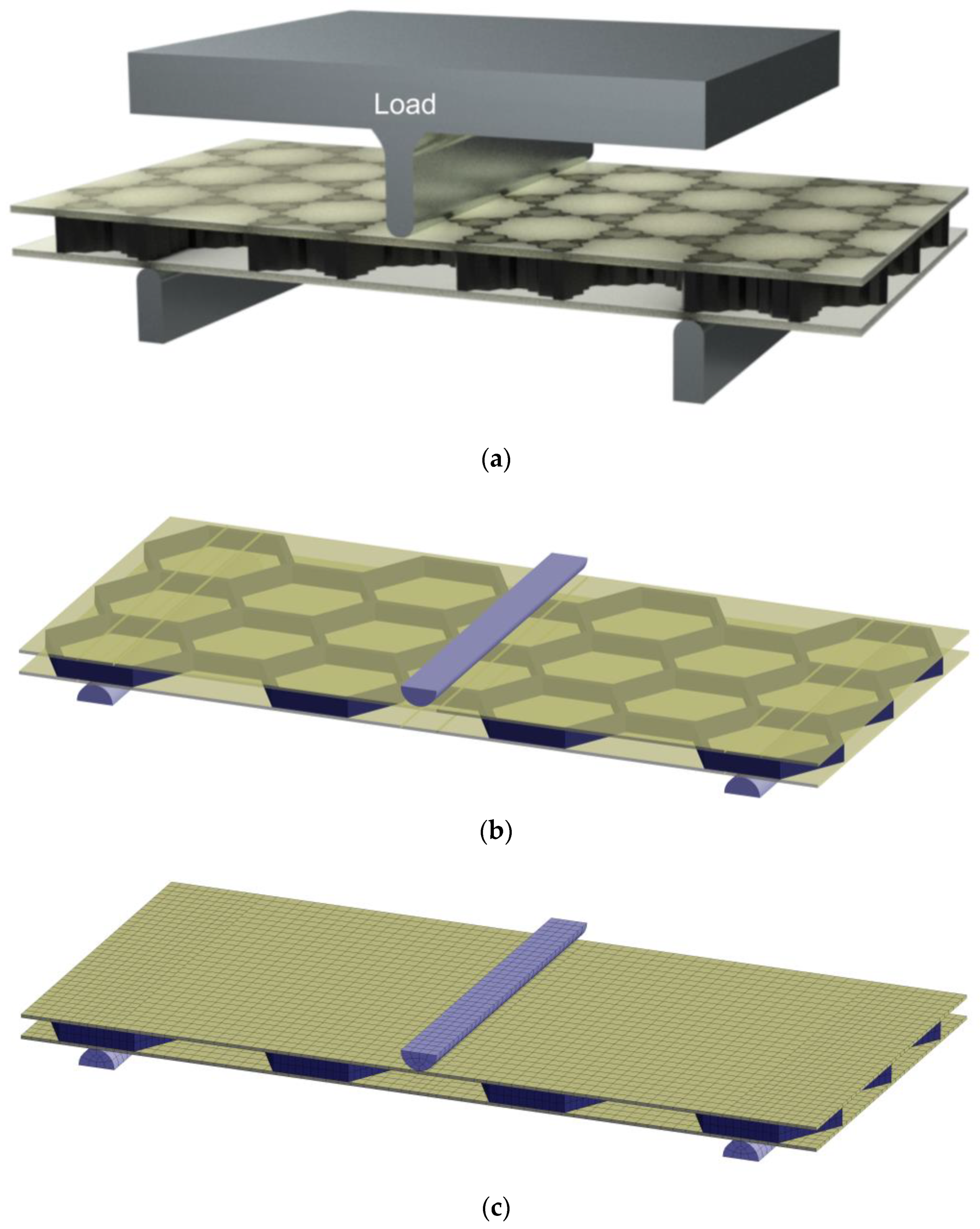

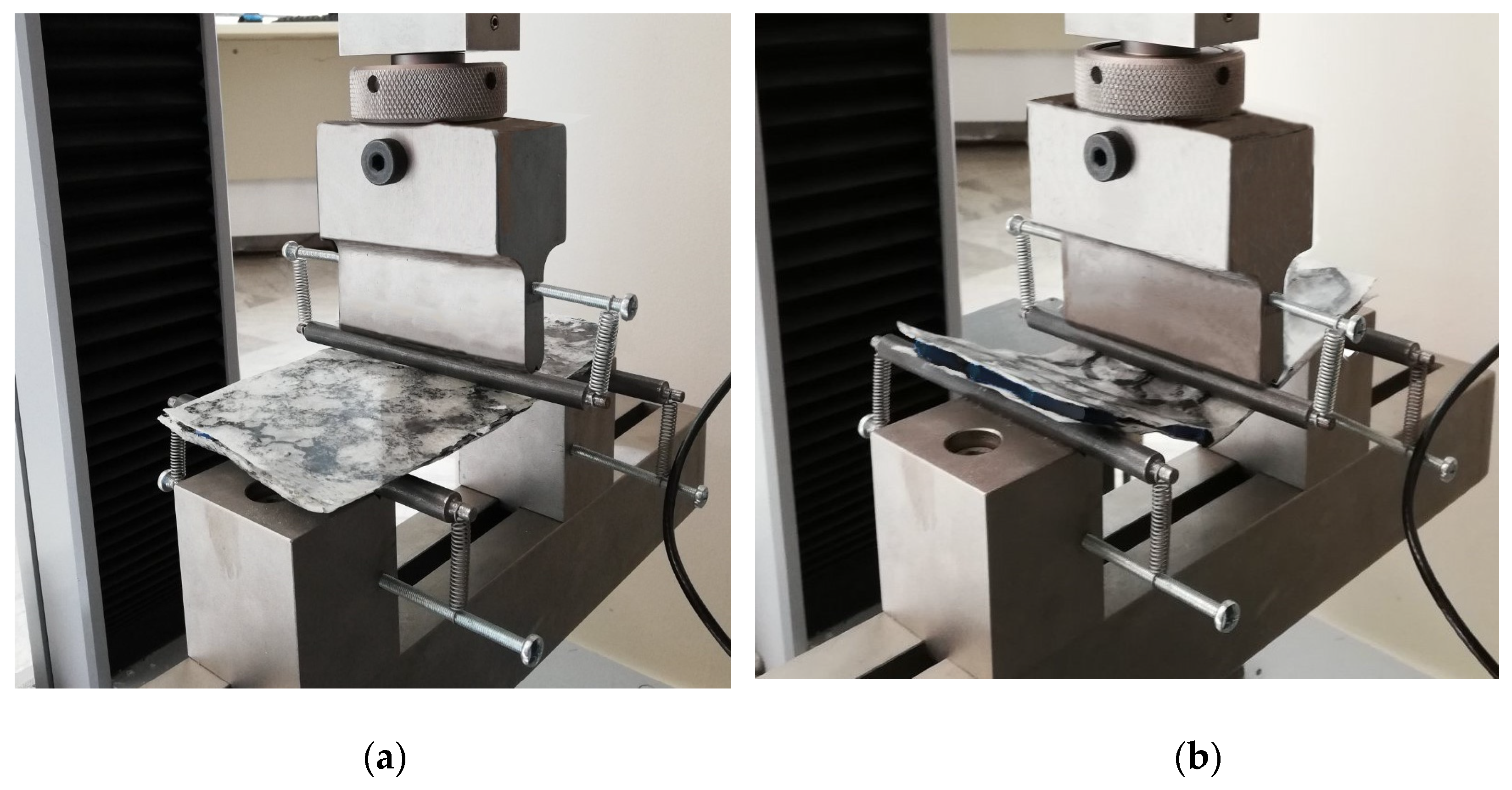

2.2.4. Bending Experiments Assisted by FEA

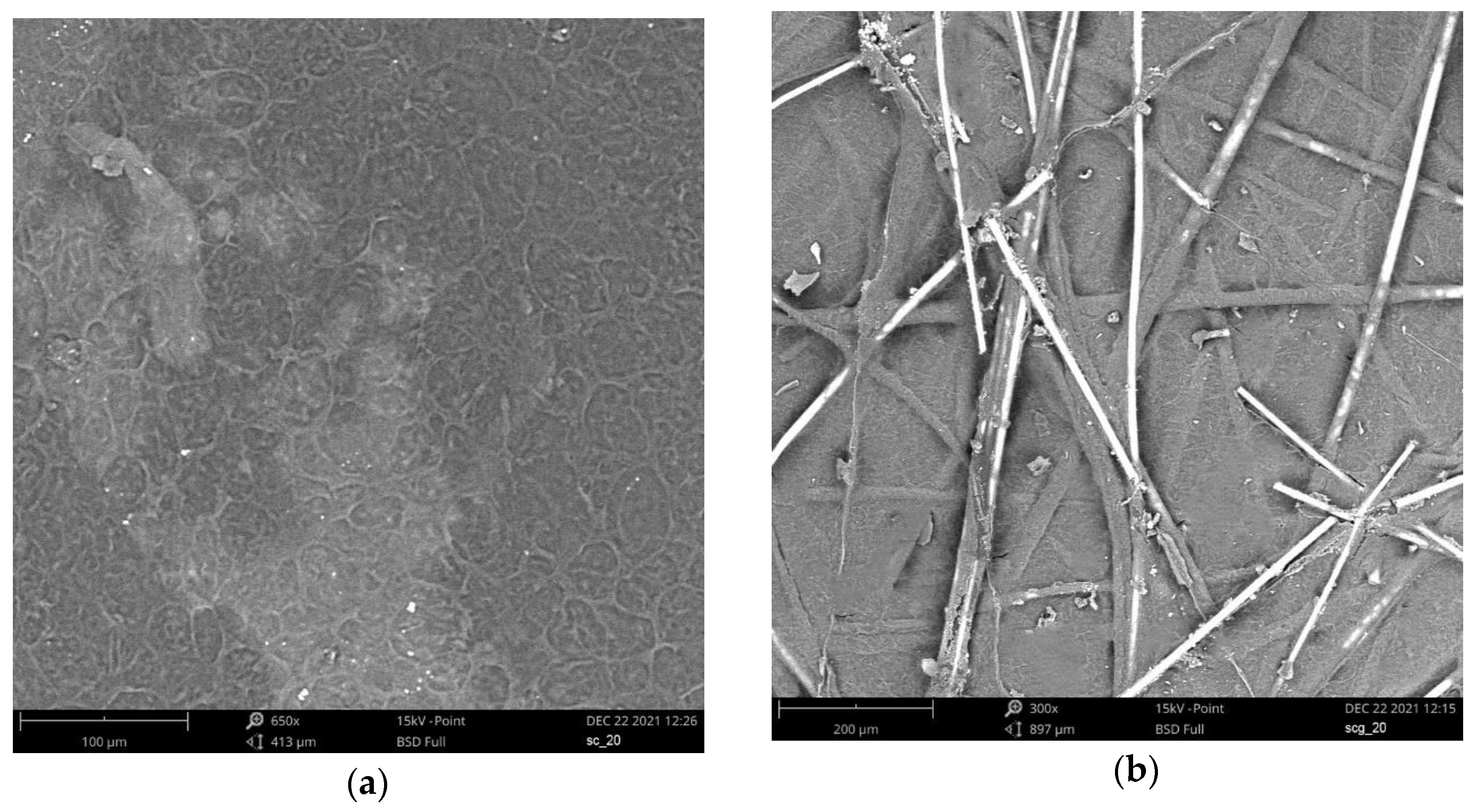

2.2.5. Scanning Electron Microscopy (SEM)

3. Results and Discussion

3.1. Mechanical Properties of Starch-Based Films in Structural Composite Sandwich Panels

3.2. SEM Analysis of the Starch-Based Skins

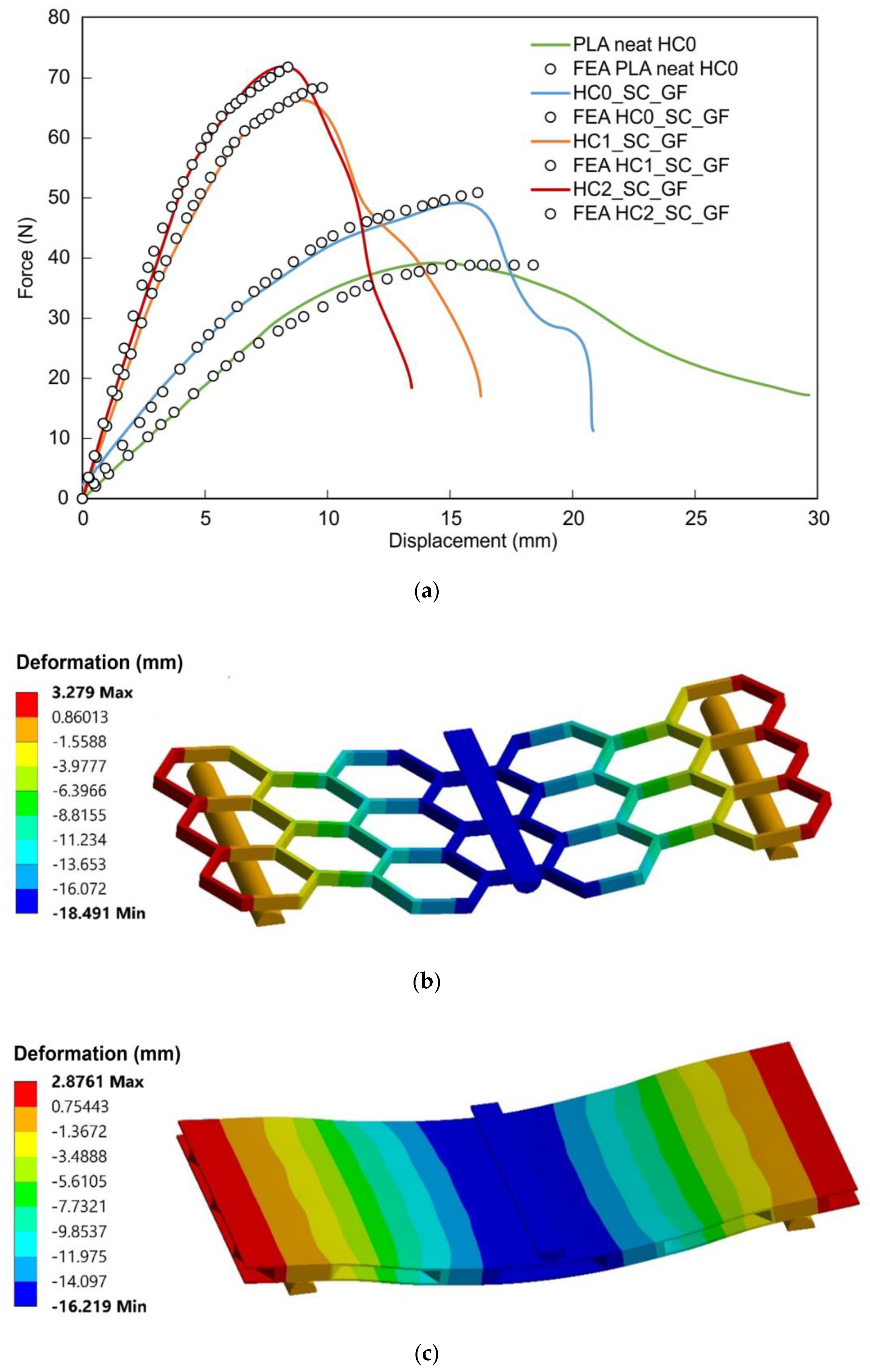

3.3. Bending Behavior and FE Analyses

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Mouritz, A.P.; Gellert, E.; Burchill, P.; Challis, K. Review of advanced composite structures for naval ships and submarines. Compos. Struct. 2001, 53, 21–42. [Google Scholar] [CrossRef]

- Gardner, N.; Wang, E.; Shukla, A. Performance of functionally graded sandwich composite beams under shock wave loading. Compos. Struct. 2012, 94, 1755–1770. [Google Scholar] [CrossRef]

- Gupta, S.; Shukla, A. Blast performance of marine foam core sandwich composites at extreme temperatures. Exp. Mech. 2012, 52, 1521–1534. [Google Scholar] [CrossRef]

- Wijker, J. Chapter: Sandwich Construction. In Spacecraft Structures, 1st ed.; Springer: Berlin/Heidelberg, Germany, 2008; pp. 157–173. [Google Scholar]

- Singha, A.S.; Thakur, V.K. Mechanical properties of natural fiber reinforced polymer composites. Bull. Mater. Sci. 2008, 31, 791–799. [Google Scholar] [CrossRef]

- Singha, A.S.; Thakur, V.K. Chemical resistance, mechanical and physical properties of biofibers-based polymer composites. Polym. Plast. Technol. Eng. 2009, 48, 736–744. [Google Scholar] [CrossRef]

- Pinto, M.; Chalivendra, V.B.; Kim, Y.K.; Lewis, A.F. Effect of surface treatment and Z-axis reinforcement on the interlaminar fracture of jute/epoxy laminated composites. Eng. Fract. Mech. 2013, 114, 104–114. [Google Scholar] [CrossRef]

- Pinto, M.; Chalivendra, V.B.; Kim, Y.K.; Lewis, A.F. Evaluation of surface treatment and fabrication methods for jute fiber/epoxy laminar composites. Polym. Compos. 2014, 35, 310–317. [Google Scholar] [CrossRef]

- Bach, M.R.; Chalivendra, V.B.; Alves, C.; Depina, E. Mechanical characterization of natural biodegradable sandwich materials. J. Sandw. Struct. Mater. 2017, 19, 482–496. [Google Scholar] [CrossRef]

- Jiang, L.; Walczyk, D.; McIntyre, G.; Bucinell, R.; Tudryn, G. Manufacturing of biocomposite sandwich structures using mycelium-bound cores and preforms. J. Manuf. Processes 2017, 28, 50–59. [Google Scholar] [CrossRef]

- Mansour, G.; Zoumaki, M.; Tsongas, K.; Tzetzis, D. Starch-sandstone materials in the construction industry. Results Eng. 2020, 8, 100182. [Google Scholar] [CrossRef]

- Dweib, M.A.; Hu, B.; O’Donnell, A.; Shenton, H.W.; Woola, R.P. All natural composite sandwich beams for structural applications. Compos. Struct. 2004, 63, 147–157. [Google Scholar] [CrossRef]

- Chen, Y.; Chiparus, O.; Sun, L.; Negulescu, I.; Parikh, D.V.; Calamari, T.A. Natural fibers for automotive nonwoven composites. J. Ind. Text. 2005, 35, 47–62. [Google Scholar] [CrossRef]

- Martin, O.; Avérous, L. Poly(lactic acid): Plasticization and properties of biodegradable multi phase systems. Polymer 2001, 42, 6209–6219. [Google Scholar] [CrossRef]

- Pramendra, K.B.; Inderdeep, S.; Jitendra, M. Development and characterization of PLA-based green composites: A review. J. Thermoplast. Compos. Mater. 2014, 27, 52–81. [Google Scholar]

- Ramengmawii, S.; Mohammad, J.; Mohammad, A.; Hassan, F.; Sameer, A.; Naheed, S.; Suchart, S. Flexural and Dynamic Mechanical Properties of Alkali-Treated Coir/Pineapple Leaf Fibres Reinforced Polylactic Acid Hybrid Biocomposites. J. Bionic. Eng. 2021, 18, 1430–1438. [Google Scholar]

- Ting-Ting, L.; Heng, Z.; Shih-Yu, H.; Xin, P.; Qi, L.; Shengyu, T.; Zhiwen, M.; Jia-Horng, L. Preparation and property evaluations of PCL/PLA composite films. J. Polym. Res. 2021, 28, 156. [Google Scholar]

- Panjehpour, M.; Ali, A.A.A.; Voo, Y.L. Structural Insulated Panels: Past, Present, and Future. EPPM-J. 2013, 3, 2–8. [Google Scholar] [CrossRef] [Green Version]

- Lee, J.Y.; An, J.; Chua, C.K. Fundamentals and applications of 3D printing for novel materials. Appl. Mater Today 2017, 7, 120–133. [Google Scholar] [CrossRef]

- Haldar, A.K.; Managuli, V.; Munshi, R.; Agarwal, R.S.; Guan, Z.W. Compressive behaviour of 3D printed sandwich structures based on corrugated core design. Mater. Today Commun. 2021, 26, 101725. [Google Scholar] [CrossRef]

- Gohari, S.; Sharifi, S.; Burvill, C.; Mouloodi, S.; Izadifar, M.; Thissen, P. Localized failure analysis of internally pressurized laminated ellipsoidal woven GFRP composite domes: Analytical, numerical, and experimental studies. Arch. Civ. Mech. 2019, 19, 1235–1250. [Google Scholar] [CrossRef]

- Yuguo, W.; Haoji, W.; Jinhua, W.; Bin, L.; Jingyu, X.; Sheng, F. Finite element analysis of grinding process of long fiber reinforced ceramic matrix woven composites: Modeling, experimental verification and material removal mechanism. Ceram. Int. 2019, 45, 15920–15927. [Google Scholar]

- Gohari, S.; Sharifi, S.; Vrcelj, Z. A novel explicit solution for twisting control of smart laminated cantilever composite plates/beams using inclined piezoelectric actuators. Compos. Struct. 2017, 161, 477–504. [Google Scholar] [CrossRef]

- Gohari, S.; Mozafari, F.; Moslemi, N.; Mouloodi, S.; Sharif, S.; Rahmanpanah, H.; Burvill, C. Analytical solution of the electro-mechanical flexural coupling between piezoelectric actuators and flexible-spring boundary structure in smart composite plates. Arch. Civ. Mech. Eng. 2021, 21, 33. [Google Scholar] [CrossRef]

- Raphaelides, S.N.; Georgiadis, N. Effect of fatty acids on the rheological behaviour of maize starch dispersions during heating. Carbohydr. Polym. 2006, 65, 81–92. [Google Scholar] [CrossRef]

- Müller, P.; Kapin, E.; Fekete, E. Effects of preparation methods on the structure and mechanical properties of wet conditioned starch/montmorillonite nanocomposites films. Carbohydr. Polym. 2014, 113, 569–576. [Google Scholar] [CrossRef] [Green Version]

- Mansour, G.; Zoumaki, M.; Marinopoulou, A.; Raphaelides, S.N.; Tzetzis, D.; Zoumakis, N. Investigation on the Effects of Glycerol and Clay Contents on the Structure and Mechanical Properties of Maize Starch Nanocomposite Films. Stärke 2020, 72, 1900166. [Google Scholar] [CrossRef]

- Zoumaki, M.; Tzetzis, D.; Mansour, G. Development and characterization of starch—based nanocomposite materials. IOP Conf. Ser. Mater. Sci. Eng. 2019, 564, 012037. [Google Scholar] [CrossRef]

- Mansour, G.; Zoumaki, M.; Marinopoulou, A.; Tzetzis, D.; Prevezanos, M.; Raphaelides, S. Characterization and properties of non-granular thermoplastic starch—clay biocomposite films. Carbohydr. Polym. 2020, 245, 116629. [Google Scholar] [CrossRef]

- Mansour, G.; Zoumaki, M.; Tsongas, K.; Tzetzis, D. Microstructural and Finite Element Analysis—Assisted Nanomechanical Characterization of Maize Starch Nanocomposite Films. Mater. Res. 2021, 24, e20200409. [Google Scholar] [CrossRef]

- Ghanbarzadeh, B.; Almasi, H.; Entezami, A.A. Physical properties of edible modified starch/carboxymethyl cellulose films. IFSET 2010, 11, 697–702. [Google Scholar] [CrossRef]

- Lakes, R. Materials with structural hierarchy. Nature 1993, 361, 511–515. [Google Scholar] [CrossRef]

- Ajdari, A.; Jahromi, B.H.; Papadopoulos, J.; Nayeb-Hashemi, H.; Vaziri, A. Hierarchical honeycombs with tailorable properties. Int. J. Solids Struct. 2012, 49, 1413–1419. [Google Scholar] [CrossRef] [Green Version]

- Mansour, M.T.; Tsongas, K.; Tzetzis, D. The mechanical performance of 3D printed hierarchical honeycombs using carbon fiber and carbon nanotube reinforced acrylonitrile butadiene styrene filaments. MATEC Web Conf. 2020, 318, 01049. [Google Scholar] [CrossRef]

- Mansour, M.T.; Tsongas, K.; Tzetzis, D. 3D Printed Hierarchical Honeycombs with Carbon Fiber and Carbon Nanotube Reinforced Acrylonitrile Butadiene Styrene. J. Compos. Sci. 2021, 5, 62. [Google Scholar] [CrossRef]

- Mansour, M.T.; Tsongas, K.; Tzetzis, D.; Antoniadis, A. The in-plane compression performance of hierarchical honeycomb additive manufactured structures. IOP Conf. Ser. Mater. Sci. Eng. 2019, 564, 012015. [Google Scholar] [CrossRef]

- ASTM D882–12; Standard Test Method for Tensile Properties of Thin Plastic Sheeting. ASTM International: West Conshohocken, PA, USA, 2012.

- ASTM C393/C393M-20; Standard Test Method for Core Shear Properties of Sandwich Constructions by Beam Flexure. ASTM International: West Conshohocken, PA, USA, 2020.

- Chandrashekhar, A.; Shaik, H.S.; Ranjan Mishra, S.; Srivastava, T.; Pavan Kishore, M.L. Static Structural Analysis of Hybrid Honeycomb Structures Using FEA. In Recent Trends in Mechanical Engineering; Narasimham, G.S.V.L., Babu, A.V., Reddy, S.S., Dhanasekaran, R., Eds.; Springer: Singapore, 2020; pp. 363–375. [Google Scholar]

- Meifeng, H.; Wenbin, H. A study on composite honeycomb sandwich panel structure. Compos. B Eng. 2008, 58, 709–713. [Google Scholar]

- Gutiérrez, T.J.; Ollier, R.; Alvarez, V.A. Surface properties of thermoplastic starch materials reinforced with natural fillers. In Functional Biopolymers; Thakur, V., Thakur, M., Eds.; Springer: Berlin/Heidelberg, Germany, 2018; pp. 131–158. [Google Scholar]

- Hussain, M.; Khan, R.; Abbas, N. Experimental and computational studies on honeycomb sandwich structures under static and fatigue bending load. J. King Saud Univ. Sci. 2019, 31, 222–229. [Google Scholar] [CrossRef]

- Kladovasilakis, N.; Charalampous, P.; Tsongas, K.; Kostavelis, I.; Tzetzis, D.; Tzovaras, D. Experimental and Computational Investigation of Lattice Sandwich Structures Constructed by Additive Manufacturing Technologies. J. Manuf. Mater. Process. 2021, 5, 95. [Google Scholar] [CrossRef]

- Pandey, J.K.; Singh, R.P. Green nanocomposites from renewable resources: Effect of plasticizer on the structure and material properties of clay-filled starch. Starke 2005, 57, 8–15. [Google Scholar] [CrossRef]

| Length (mm) | Span Length (mm) | Width (mm) | Core Thickness (mm) | Height (mm) |

|---|---|---|---|---|

| 190 | 100 | 90 | 6 | 6.8–7 |

| Sample | Tensile Strength (MPa) |

|---|---|

| S_20 | 41.9 ± 1.2 |

| SG_20 | 50.52 ± 2.1 |

| SC_20 | 45.1 ± 1.6 |

| SCG_20 | 55.33 ± 1.9 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zoumaki, M.; Mansour, M.T.; Tsongas, K.; Tzetzis, D.; Mansour, G. Mechanical Characterization and Finite Element Analysis of Hierarchical Sandwich Structures with PLA 3D-Printed Core and Composite Maize Starch Biodegradable Skins. J. Compos. Sci. 2022, 6, 118. https://doi.org/10.3390/jcs6040118

Zoumaki M, Mansour MT, Tsongas K, Tzetzis D, Mansour G. Mechanical Characterization and Finite Element Analysis of Hierarchical Sandwich Structures with PLA 3D-Printed Core and Composite Maize Starch Biodegradable Skins. Journal of Composites Science. 2022; 6(4):118. https://doi.org/10.3390/jcs6040118

Chicago/Turabian StyleZoumaki, Maria, Michel T. Mansour, Konstantinos Tsongas, Dimitrios Tzetzis, and Gabriel Mansour. 2022. "Mechanical Characterization and Finite Element Analysis of Hierarchical Sandwich Structures with PLA 3D-Printed Core and Composite Maize Starch Biodegradable Skins" Journal of Composites Science 6, no. 4: 118. https://doi.org/10.3390/jcs6040118

APA StyleZoumaki, M., Mansour, M. T., Tsongas, K., Tzetzis, D., & Mansour, G. (2022). Mechanical Characterization and Finite Element Analysis of Hierarchical Sandwich Structures with PLA 3D-Printed Core and Composite Maize Starch Biodegradable Skins. Journal of Composites Science, 6(4), 118. https://doi.org/10.3390/jcs6040118