Electrically Conductive Biocomposites Based on Poly(3-hydroxybutyrate-co-3-hydroxyvalerate) and Wood-Derived Carbon Fillers

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Biobased Carbon Fillers

2.3. Carbon Filler Analysis

2.4. Compounding and Specimen Preparation

2.5. Composite Analysis

3. Results and Discussion

3.1. Filler Preparation and Analysis

3.2. Processing and Compound Properties

3.3. Composite Properties

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Arroyo, J.; Ryan, C. Incorporation of Carbon Nanofillers Tunes Mechanical and Electrical Percolation in PHBV:PLA Blends. Polymers 2018, 10, 1371. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mekonnen, T.; Mussone, P.; Khalil, H.; Bressler, D. Progress in bio-based plastics and plasticizing modifications. J. Mater. Chem. A 2013, 1, 13379. [Google Scholar] [CrossRef] [Green Version]

- Sun, J.; Shen, J.; Chen, S.; Cooper, M.A.; Fu, H.; Wu, D.; Yang, Z. Nanofiller Reinforced Biodegradable PLA/PHA Composites: Current Status and Future Trends. Polymers 2018, 10, 505. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Meereboer, K.W.; Misra, M.; Mohanty, A.K. Review of recent advances in the biodegradability of polyhydroxyalkanoate (PHA) bioplastics and their composites. Green Chem. 2020, 22, 5519–5558. [Google Scholar] [CrossRef]

- Bledzki, A.K.; Jaszkiewicz, A. Mechanical performance of biocomposites based on PLA and PHBV reinforced with natural fibres—A comparative study to PP. Compos. Sci. Technol. 2010, 70, 1687–1696. [Google Scholar] [CrossRef] [Green Version]

- Vieira, L.; Montagna, L.S.; Marini, J.; Passador, F.R. Influence of particle size and glassy carbon content on the thermal, mechanical, and electrical properties of PHBV/glassy carbon composites. J. Appl. Polym. Sci. 2021, 138, 49740. [Google Scholar] [CrossRef]

- Srubar, W.V.; Pilla, S.; Wright, Z.C.; Ryan, C.A.; Greene, J.P.; Frank, C.W.; Billington, S.L. Mechanisms and impact of fiber–matrix compatibilization techniques on the material characterization of PHBV/oak wood flour engineered biobased composites. Compos. Sci. Technol. 2012, 72, 708–715. [Google Scholar] [CrossRef]

- Silva, A.P.B.; Montagna, L.S.; Passador, F.R.; Rezende, M.C.; Lemes, A.P. Biodegradable nanocomposites based on PLA/PHBV blend reinforced with carbon nanotubes with potential for electrical and electromagnetic applications. Express Polym. Lett. 2021, 15, 987–1003. [Google Scholar] [CrossRef]

- Snowdon, M.R.; Mohanty, A.K.; Misra, M. Miscibility and Performance Evaluation of Biocomposites Made from Polypropylene/Poly(lactic acid)/Poly(hydroxybutyrate-co-hydroxyvalerate) with a Sustainable Biocarbon Filler. ACS Omega 2017, 2, 6446–6454. [Google Scholar] [CrossRef]

- Montanheiro, T.L.d.A.; Cristóvan, F.H.; Machado, J.P.B.; Tada, D.B.; Durán, N.; Lemes, A.P. Effect of MWCNT functionalization on thermal and electrical properties of PHBV/MWCNT nanocomposites. J. Mater. Res. 2015, 30, 55–65. [Google Scholar] [CrossRef]

- Paşcu, E.I.; Stokes, J.; McGuinness, G.B. Electrospun composites of PHBV, silk fibroin and nano-hydroxyapatite for bone tissue engineering. Mater. Sci. Eng. C Mater. Biol. Appl. 2013, 33, 4905–4916. [Google Scholar] [CrossRef]

- Fernández Armada, D.; González Rodríguez, V.; Costa, P.; Lanceros-Mendez, S.; Arias-Ferreiro, G.; Abad, M.-J.; Ares-Pernas, A. Polyethylene/poly(3-hydroxybutyrate-co-3-hydroxyvalerate/carbon nanotube composites for eco-friendly electronic applications. Polym. Test. 2022, 112, 107642. [Google Scholar] [CrossRef]

- Ambrosio-Martín, J.; Gorrasi, G.; Lopez-Rubio, A.; Fabra, M.J.; Mas, L.C.; López-Manchado, M.A.; Lagaron, J.M. On the use of ball milling to develop poly(3-hydroxybutyrate-co-3-hydroxyvalerate)-graphene nanocomposites (II)-Mechanical, barrier, and electrical properties. J. Appl. Polym. Sci. 2015, 132, 42217. [Google Scholar] [CrossRef] [Green Version]

- Jun, D.; Guomin, Z.; Mingzhu, P.; Leilei, Z.; Dagang, L.; Rui, Z. Crystallization and mechanical properties of reinforced PHBV composites using melt compounding: Effect of CNCs and CNFs. Carbohydr. Polym. 2017, 168, 255–262. [Google Scholar] [CrossRef]

- Kaniuk, Ł.; Stachewicz, U. Development and Advantages of Biodegradable PHA Polymers Based on Electrospun PHBV Fibers for Tissue Engineering and Other Biomedical Applications. ACS Biomater. Sci. Eng. 2021, 7, 5339–5362. [Google Scholar] [CrossRef]

- Wu, Q.; Wang, Y.; Chen, G.-Q. Medical application of microbial biopolyesters polyhydroxyalkanoates. Artif. Cells Blood Substit. Immobil. Biotechnol. 2009, 37, 1–12. [Google Scholar] [CrossRef]

- He, Y.; Hu, Z.; Ren, M.; Ding, C.; Chen, P.; Gu, Q.; Wu, Q. Evaluation of PHBHHx and PHBV/PLA fibers used as medical sutures. J. Mater. Sci. Mater. Med. 2014, 25, 561–571. [Google Scholar] [CrossRef]

- Tebaldi, M.L.; Maia, A.L.C.; Poletto, F.; de Andrade, F.V.; Soares, D.C.F. Poly(-3-hydroxybutyrate-co-3-hydroxyvalerate) (PHBV): Current advances in synthesis methodologies, antitumor applications and biocompatibility. J. Drug Deliv. Sci. Technol. 2019, 51, 115–126. [Google Scholar] [CrossRef]

- Cava, D.; Giménez, E.; Gavara, R.; Lagaron, J.M. Comparative Performance and Barrier Properties of Biodegradable Thermoplastics and Nanobiocomposites versus PET for Food Packaging Applications. J. Plast. Film. Sheeting 2006, 22, 265–274. [Google Scholar] [CrossRef] [Green Version]

- Rydz, J.; Musiol, M.; Zawidlak-Węgrzyńska, B.; Sikorska, W. Chapter 14—Present and Future of Biodegradable Polymers for Food Packaging Applications. Handb. Food Bioeng. 2018, 20, 431–467. [Google Scholar]

- Modi, S.; Koelling, K.; Vodovotz, Y. Assessment of PHB with varying hydroxyvalerate content for potential packaging applications. Eur. Polym. J. 2011, 47, 179–186. [Google Scholar] [CrossRef]

- Berthet, M.-A.; Angellier-Coussy, H.; Chea, V.; Guillard, V.; Gastaldi, E.; Gontard, N. Sustainable food packaging: Valorising wheat straw fibres for tuning PHBV-based composites properties. Compos. Part A Appl. Sci. Manuf. 2015, 72, 139–147. [Google Scholar] [CrossRef]

- Shayganpour, A.; Nazarizadeh, S.; Grasselli, S.; Malchiodi, A.; Bayer, I.S. Stacked-Cup Carbon Nanotube Flexible Paper Based on Soy Lecithin and Natural Rubber. Nanomaterials 2019, 9, 824. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Dionigi, C.; Posati, T.; Benfenati, V.; Sagnella, A.; Pistone, A.; Bonetti, S.; Ruani, G.; Dinelli, F.; Padeletti, G.; Zamboni, R.; et al. A nanostructured conductive bio-composite of silk fibroin-single walled carbon nanotubes. J. Mater. Chem. B 2014, 2, 1424–1431. [Google Scholar] [CrossRef] [PubMed]

- Tümer, E.H.; Erbil, H.Y. Extrusion-Based 3D Printing Applications of PLA Composites: A Review. Coatings 2021, 11, 390. [Google Scholar] [CrossRef]

- Sathies, T.; Senthil, P.; Prakash, C. Application of 3D printed PLA-carbon black conductive polymer composite in solvent sensing. Mater. Res. Express 2019, 6, 115349. [Google Scholar] [CrossRef]

- Tserpes, K.; Tzatzadakis, V.; Bachmann, J. Electrical Conductivity and Electromagnetic Shielding Effectiveness of Bio-Composites. J. Compos. Sci. 2020, 4, 28. [Google Scholar] [CrossRef] [Green Version]

- Abioye, A.M.; Ani, F.N. Recent development in the production of activated carbon electrodes from agricultural waste biomass for supercapacitors: A review. Renew. Sustain. Energy Rev. 2015, 52, 1282–1293. [Google Scholar] [CrossRef]

- Zheng, T.; Sabet, S.M.; Pilla, S. Polydopamine coating improves electromagnetic interference shielding of delignified wood-derived carbon scaffold. J. Mater. Sci. 2021, 56, 10915–10925. [Google Scholar] [CrossRef]

- Ogale, A.A.; Zhang, M.; Jin, J. Recent advances in carbon fibers derived from biobased precursors. J. Appl. Polym. Sci. 2016, 133, 7. [Google Scholar] [CrossRef] [Green Version]

- Köhnke, J.; Fürst, C.; Unterweger, C.; Rennhofer, H.; Lichtenegger, H.C.; Keckes, J.; Emsenhuber, G.; Mahendran, A.R.; Liebner, F.; Gindl-Altmutter, W. Carbon Microparticles from Organosolv Lignin as Filler for Conducting Poly(Lactic Acid). Polymers 2016, 8, 205. [Google Scholar] [CrossRef] [Green Version]

- Gindl-Altmutter, W.; Czabany, I.; Unterweger, C.; Gierlinger, N.; Xiao, N.; Bodner, S.C.; Keckes, J. Structure and electrical resistivity of individual carbonised natural and man-made cellulose fibres. J. Mater. Sci. 2020, 55, 10271–10280. [Google Scholar] [CrossRef]

- Shao, Y.; Guizani, C.; Grosseau, P.; Chaussy, D.; Beneventi, D. Biocarbons from microfibrillated cellulose/lignosulfonate precursors: A study of electrical conductivity development during slow pyrolysis. Carbon 2018, 129, 357–366. [Google Scholar] [CrossRef]

- Fingolo, A.C.; Bettini, J.; da Silva Cavalcante, M.; Pereira, M.P.; Bufon, C.C.B.; Santhiago, M.; Strauss, M. Boosting Electrical Conductivity of Sugarcane Cellulose and Lignin Biocarbons through Annealing under Isopropanol Vapor. ACS Sustain. Chem. Eng. 2020, 8, 7002–7010. [Google Scholar] [CrossRef]

- Bourke, J.; Manley-Harris, M.; Fushimi, C.; Dowaki, K.; Nunoura, T.; Antal, M.J. Do All Carbonized Charcoals Have the Same Chemical Structure?: 2. A Model of the Chemical Structure of Carbonized Charcoal. Ind. Eng. Chem. Res. 2007, 46, 5954–5967. [Google Scholar] [CrossRef]

- Li, Z.; Reimer, C.; Wang, T.; Mohanty, A.K.; Misra, M. Thermal and Mechanical Properties of the Biocomposites of Miscanthus Biocarbon and Poly(3-Hydroxybutyrate-co-3-Hydroxyvalerate) (PHBV). Polymers 2020, 12, 1300. [Google Scholar] [CrossRef]

- Kalaitzidou, K.; Fukushima, H.; Drzal, L. A Route for Polymer Nanocomposites with Engineered Electrical Conductivity and Percolation Threshold. Materials 2010, 3, 1089–1103. [Google Scholar] [CrossRef]

- Scholz, R.; Herbig, F.; Beck, D.; Spörl, J.; Hermanutz, F.; Unterweger, C.; Piana, F. Improvements in the carbonisation of viscose fibres. Reinf. Plast. 2019, 63, 146–150. [Google Scholar] [CrossRef]

- Köhnke, J.; Gierlinger, N.; Prats-Mateu, B.; Unterweger, C.; Solt, P.; Mahler, A.K.; Schwaiger, E.; Liebner, F.; Gindl-Altmutter, W. Comparison of four technical lignins as resource for electrically conductive carbon particle. BioResources 2019, 14, 1091–1109. [Google Scholar] [CrossRef]

- Liu, Y.; Kontopoulou, M. The structure and physical properties of polypropylene and thermoplastic olefin nanocomposites containing nanosilica. Polymer 2006, 47, 7731–7739. [Google Scholar] [CrossRef]

- Jost, V.; Kopitzky, R. Blending of Polyhydroxybutyrate-co-valerate with Polylactic Acid for Packaging Applications: Reflections on Miscibility and Effects on the Mechanical and Barrier Properties. Chem. Biochem. Eng. Q. 2015, 29, 221–246. [Google Scholar] [CrossRef]

- Chen, Y.; Chou, I.-N.; Tsai, Y.-H.; Wu, H.-S. Thermal degradation of poly(3-hydroxybutyrate) and poly(3-hydroxybutyrate-co-3-hydroxyvalerate) in drying treatment. J. Appl. Polym. Sci. 2013, 130, 3659–3667. [Google Scholar] [CrossRef]

- Mofokeng, J.P.; Luyt, A.S. Morphology and thermal degradation studies of melt-mixed PLA/PHBV biodegradable polymer blend nanocomposites with TiO2 as filler. J. Appl. Polym. Sci. 2015, 132. [Google Scholar] [CrossRef]

- Liu, Q.-S.; Zhu, M.-F.; Wu, W.-H.; Qin, Z.-Y. Reducing the formation of six-membered ring ester during thermal degradation of biodegradable PHBV to enhance its thermal stability. Polym. Degrad. Stab. 2009, 94, 18–24. [Google Scholar] [CrossRef]

- Weng, Y.-X.; Wang, Y.; Wang, X.-L.; Wang, Y.-Z. Biodegradation behavior of PHBV films in a pilot-scale composting condition. Polym. Test. 2010, 29, 579–587. [Google Scholar] [CrossRef]

- Li, Z.; Lin, H.; Ishii, N.; Chen, G.-Q.; Inoue, Y. Study of enzymatic degradation of microbial copolyesters consisting of 3-hydroxybutyrate and medium-chain-length 3-hydroxyalkanoates. Polym. Degrad. Stab. 2007, 92, 1708–1714. [Google Scholar] [CrossRef]

- Mueller, R.-J. Biological degradation of synthetic polyesters—Enzymes as potential catalysts for polyester recycling. Process Biochem. 2006, 41, 2124–2128. [Google Scholar] [CrossRef]

- Bonartsev, A.P.; Boskhomodgiev, A.P.; Iordanskii, A.L.; Bonartseva, G.A.; Rebrov, A.V.; Makhina, T.K.; Myshkina, V.L.; Yakovlev, S.A.; Filatova, E.A.; Ivanov, E.A.; et al. Hydrolytic Degradation of Poly(3-hydroxybutyrate), Polylactide and their Derivatives: Kinetics, Crystallinity, and Surface Morphology. Mol. Cryst. Liq. Cryst. 2012, 556, 288–300. [Google Scholar] [CrossRef]

- Patel, R.; Monticone, D.; Lu, M.; Grøndahl, L.; Huang, H. Hydrolytic degradation of porous poly(hydroxybutyrate-co-hydroxyvalerate) scaffolds manufactured using selective laser sintering. Polym. Degrad. Stab. 2021, 187, 109545. [Google Scholar] [CrossRef]

- Bordes, P.; Hablot, E.; Pollet, E.; Avérous, L. Effect of clay organomodifiers on degradation of polyhydroxyalkanoates. Polym. Degrad. Stab. 2009, 94, 789–796. [Google Scholar] [CrossRef]

- Johnson, D.J. Structure-property relationships in carbon fibres. J. Phys. D Appl. Phys. 1987, 20, 286–291. [Google Scholar] [CrossRef]

- Fu, S.-Y.; Lauke, B.; Mäder, E.; Yue, C.-Y.; Hu, X. Tensile properties of short-glass-fiber- and short-carbon-fiber-reinforced polypropylene composites. Compos. Part A 2000, 31, 1117–1125. [Google Scholar] [CrossRef]

- Unterweger, C.; Mayrhofer, T.; Piana, F.; Duchoslav, J.; Stifter, D.; Poitzsch, C.; Fürst, C. Impact of fiber length and fiber content on the mechanical properties and electrical conductivity of short carbon fiber reinforced polypropylene composites. Compos. Sci. Technol. 2020, 188, 107998. [Google Scholar] [CrossRef]

- Unterweger, C.; Duchoslav, J.; Stifter, D.; Fürst, C. Characterization of carbon fiber surfaces and their impact on the mechanical properties of short carbon fiber reinforced polypropylene composites. Compos. Sci. Technol. 2015, 108, 41–47. [Google Scholar] [CrossRef]

- Thomason, J.L. The influence of fibre length and concentration on the properties of glass fibre reinforced polypropylene: 5. Injection moulded long and short fibre PP. Compos. Part A 2002, 33, 1641–1652. [Google Scholar] [CrossRef]

- Karsli, N.G.; Aytac, A. Tensile and thermomechanical properties of short carbon fiber reinforced polyamide 6 composites. Compos. Part B Eng. 2013, 51, 270–275. [Google Scholar] [CrossRef]

- Newcomb, B.A. Processing, structure, and properties of carbon fibers. Compos. Part A Appl. Sci. Manuf. 2016, 91, 262–282. [Google Scholar] [CrossRef]

| Sample | Filler Type | Tcarb. (°C) | Filler Content (Vol.%) |

|---|---|---|---|

| PHBV | - | - | 0 |

| PHBV_CF900_10 | carb. cellulose | 900 | 10 |

| PHBV_CF1500_10 | carb. cellulose | 1500 | 10 |

| PHBV_CF2000_10 | carb. cellulose | 2000 | 10 |

| PHBV_CF2300_10 | carb. cellulose | 2300 | 10 |

| PHBV_CF2000_5 | carb. cellulose | 2000 | 5 |

| PHBV_CF2000_15 | carb. cellulose | 2000 | 15 |

| PHBV_CF2000_20 | carb. cellulose | 2000 | 20 |

| PHBV_CW900_10 | carb. wood | 900 | 10 |

| PHBV_CW1500_10 | carb. wood | 1500 | 10 |

| PHBV_CW2000_10 | carb. wood | 2000 | 10 |

| PHBV_CW2300_10 | carb. wood | 2300 | 10 |

| PHBV_CW2000_5 | carb. wood | 2000 | 5 |

| PHBV_CW2000_15 | carb. wood | 2000 | 15 |

| PHBV190 * | - | - | 0 |

| PP_CF2000_5 ** | carb. cellulose | 2000 | 5 |

| PP_CF2000_10 ** | carb. cellulose | 2000 | 10 |

| PP_CF2000_15 ** | carb. cellulose | 2000 | 15 |

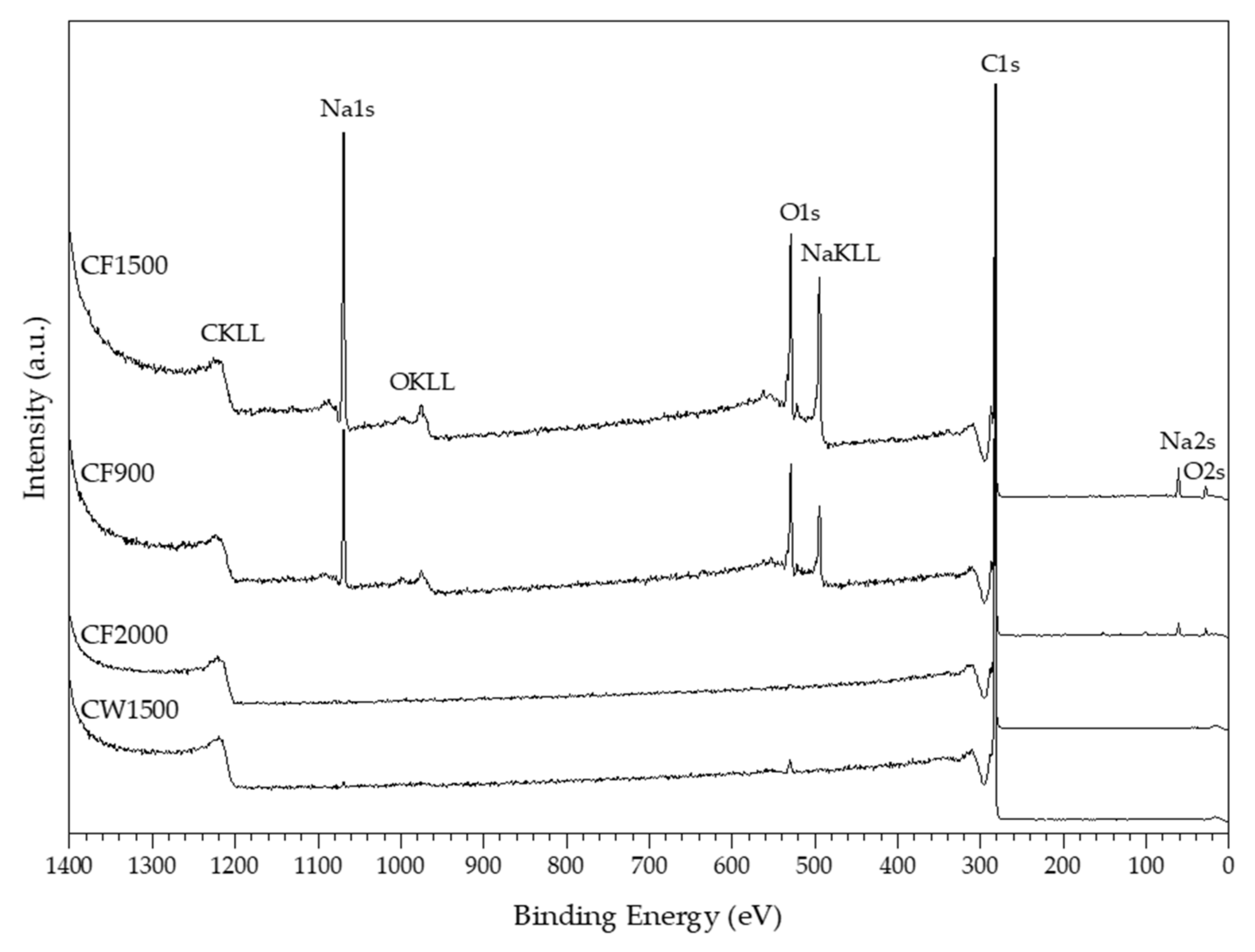

| Sample | d002 | S BET | Moisture | pH | C EDX | O EDX | Na EDX | Ca EDX | C XPS | O XPS | Na XPS |

|---|---|---|---|---|---|---|---|---|---|---|---|

| (nm) | (m2/g) | (g/g %) | (-) | (at.%) | (at.%) | (at.%) | (at.%) | (at.%) | (at.%) | (at.%) | |

| CF900 | 0.375 | 174.0 | 1.09 | 10.8 | 95.69 | 3.95 | 0.25 | 0.00 | 84.5 | 9.6 | 5.9 |

| CF1500 | 0.370 | 2.2 | 0.24 | 11.0 | 97.18 | 2.60 | 0.13 | 0.00 | 76.1 | 12.8 | 11.1 |

| CF2000 | 0.352 | 1.3 | 0.03 | 6.3 | 98.09 | 1.76 | 0.02 | 0.00 | 100.0 | 0.0 | 0.0 |

| CF2300 | 0.344 | 1.8 | 0.02 | 6.0 | 98.60 | 1.30 | 0.02 | 0.00 | - | - | - |

| CW900 | 0.371 | 309.3 | 1.26 | 12.0 | 93.86 | 5.76 | 0.00 | 0.30 | - | - | - |

| CW1500 | 0.359 | 4.7 | 0.19 | 10.3 | 95.98 | 3.68 | 0.00 | 0.20 | 98.9 | 1.1 | 0.0 |

| CW2000 | 0.343 | 3.5 | 0.15 | 6.6 | 97.48 | 1.93 | 0.00 | 0.35 | - | - | - |

| CW2300 | 0.342 | 3.7 | 0.09 | 6.8 | 97.71 | 2.13 | 0.00 | 0.03 | - | - | - |

| Sample | Tmax (°C) | MFI (g/10 min) | Mw (105 g/mol) | PDI | L (µm) | L/D (-) |

|---|---|---|---|---|---|---|

| PHBV (virgin) | - | 19.0 ± 1.3 | 2.07 | 2.48 | - | - |

| PHBV (190 °C) | 195 | 54.3 ± 2.3 | 1.38 | 2.05 | - | - |

| PHBV | 182 | 26.0 ± 1.3 | 1.90 | 1.92 | - | - |

| PHBV_CF900_10 | 184 | 27.6 ± 2.7 | 1.75 | 2.10 | 95 ± 7 | 12.0 ± 0.8 |

| PHBV_CF1500_10 | 175–180 | x | 0.82 | 2.01 | 101 ± 3 | 12.8 ± 0.4 |

| PHBV_CF2000_10 | 183 | 28.5 ± 1.0 | 1.64 | 2.00 | 89 ± 12 | 11.3 ± 0.2 |

| PHBV_CF2300_10 | 184 | 28.2 ± 0.4 | 1.80 | 2.03 | 82 ± 2 | 10.3 ± 0.2 |

| PHBV_CF2000_5 | 185 | 33.5 ± 1.4 | 1.73 | 2.05 | 96 ± 2 | 12.2 ± 0.3 |

| PHBV_CF2000_15 | 188 | 29.0 ± 0.9 | 1.66 | 1.94 | 93 ± 2 | 11.7 ± 0.3 |

| PHBV_CF2000_20 | 192 | 26.3 ± 0.3 | 1.69 | 1.87 | 101 ± 4 | 12.8 ± 0.5 |

| PHBV_CW900_10 | 184 | 28.7 ± 3.7 | 1.92 | 1.95 | 39 ± 5 | 1.23 ± 0.01 |

| PHBV_CW1500_10 | 183 | 31.7 ± 1.2 | 1.52 | 1.97 | 40 ± 4 | 1.21 ± 0.01 |

| PHBV_CW2000_10 | 184 | 32.4 ± 0.4 | 1.79 | 2.10 | 39 ± 2 | 1.21 ± 0.01 |

| PHBV_CW2300_10 | 183 | 34.5 ± 1.3 | 1.79 | 1.97 | 45 ± 1 | 1.24 ± 0.02 |

| PHBV_CW2000_5 | 184 | 36.5 ± 0.6 | 1.63 | 1.85 | 50 ± 3 | 1.27 ± 0.01 |

| PHBV_CW2000_15 | 188 | 30.6 ± 0.8 | 1.74 | 1.77 | 44 ± 2 | 1.24 ± 0.01 |

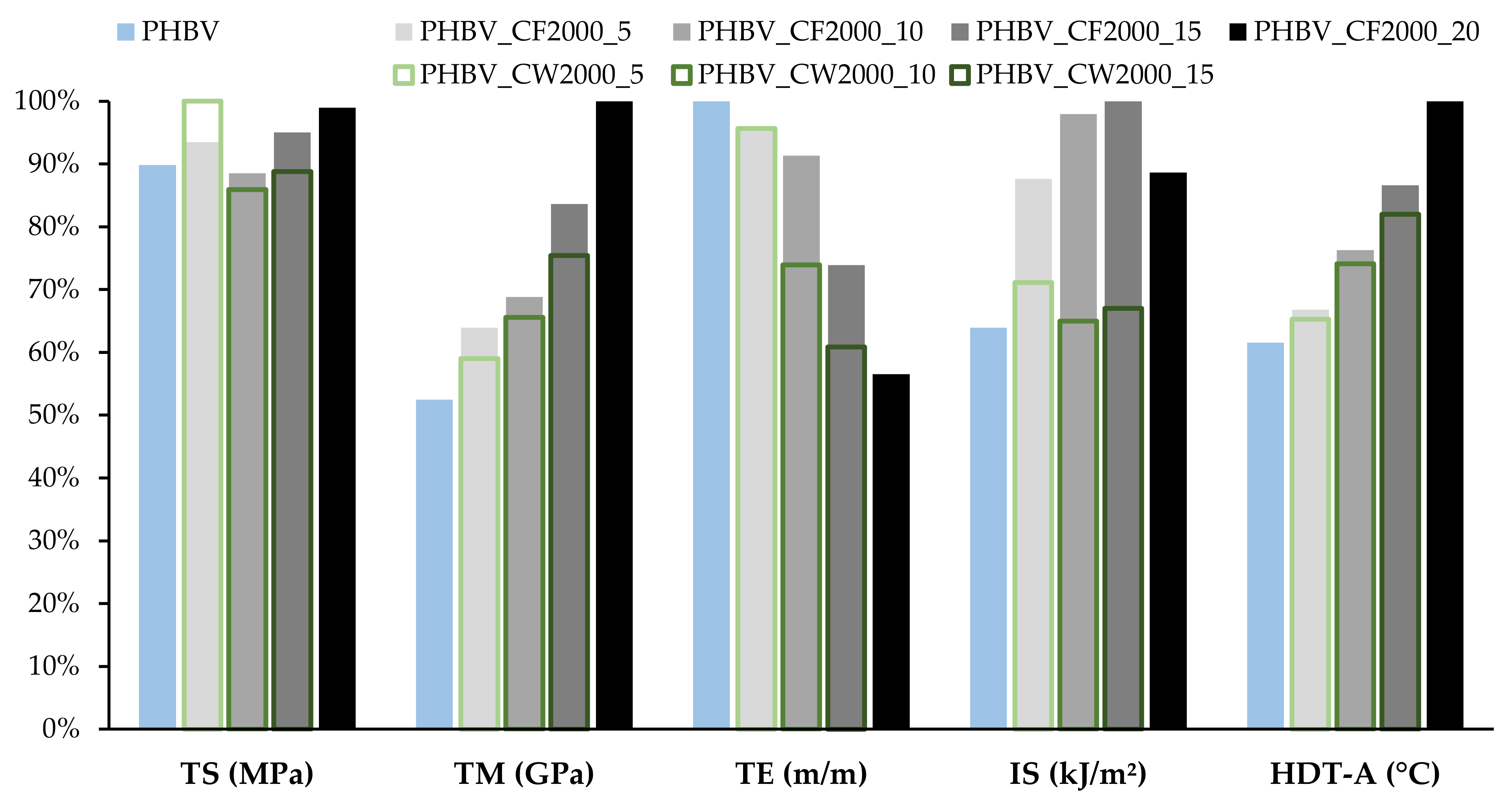

| Sample | TS (MPa) | TM (GPa) | TE (m/m %) | IS (kJ/m2) | NIS (kJ/m2) | HDT-A (°C) | ρ (g/cm3) | σ (S/cm) |

|---|---|---|---|---|---|---|---|---|

| PHBV | 34.5 ± 0.7 | 3.2 ± 0.1 | 2.3 ± 0.2 | 6.2 ± 0.2 | 1.3 ± 0.1 | 78.5 ± 4.6 | 1.246 ± 0.006 | 2.0 × 10−12 |

| PHBV_CF900_10 | 36.1 ± 0.1 | 4.1 ± 0.1 | 2.0 ± 0.2 | 9.9 ± 0.8 | 1.6 ± 0.2 | 100.2 ± 4.9 | 1.265 ± 0.008 | 8.0 × 10−11 |

| PHBV_CF1500_10 * | 23.3 ± 3.8 | 5.1 ± 0.1 | 0.5 ± 0.1 | 3.6 ± 0.5 | 0.9 ± 0.1 | 107.6 ± 3.6 | 1.264 ± 0.005 | 3.0 × 10−10 |

| PHBV_CF2000_10 | 34.0 ± 0.1 | 4.2 ± 0.1 | 2.1 ± 0.1 | 9.5 ± 0.7 | 1.5 ± 0.1 | 97.3 ± 7.8 | 1.264 ± 0.001 | 8.3 × 10−11 |

| PHBV_CF2300_10 | 35.5 ± 0.1 | 4.5 ± 0.1 | 1.7 ± 0.1 | 11.5 ± 0.7 | 1.6 ± 0.2 | 96.8 ± 3.8 | 1.264 ± 0.001 | 1.0 × 10−10 |

| PHBV_CF2000_5 | 35.9 ± 0.1 | 3.9 ± 0.1 | 2.2 ± 0.1 | 8.5 ± 0.6 | 1.9 ± 0.3 | 85.2 ± 1.9 | 1.253 ± 0.003 | 4.0 × 10−12 |

| PHBV_CF2000_10 | 34.0 ± 0.1 | 4.2 ± 0.1 | 2.1 ± 0.1 | 9.5 ± 0.7 | 1.5 ± 0.1 | 97.3 ± 7.8 | 1.264 ± 0.001 | 8.3 × 10−11 |

| PHBV_CF2000_15 | 36.5 ± 0.2 | 5.1 ± 0.1 | 1.7 ± 0.1 | 9.7 ± 0.4 | 1.7 ± 0.3 | 110.4 ± 7.5 | 1.271 ± 0.002 | 6.2 × 10−9 |

| PHBV_CF2000_20 | 38.0 ± 0.2 | 6.1 ± 0.1 | 1.3 ± 0.2 | 8.6 ± 0.9 | 1.6 ± 0.5 | 127.5 ± 5.4 | 1.287 ± 0.002 | 6.9 × 10−1 |

| PHBV_CW900_10 | 34.7 ± 0.1 | 4.1 ± 0.1 | 1.6 ± 0.1 | 6.1 ± 0.1 | 1.4 ± 0.1 | 91.4 ± 4.2 | 1.265 ± 0.001 | 4.5 × 10−12 |

| PHBV_CW1500_10 | 34.0 ± 0.4 | 4.2 ± 0.1 | 1.6 ± 0.1 | 6.0 ± 0.3 | 1.4 ± 0.1 | 93.9 ± 4.4 | 1.264 ± 0.001 | 7.2 × 10−12 |

| PHBV_CW2000_10 | 33.0 ± 0.1 | 4.0 ± 0.1 | 1.7 ± 0.1 | 6.3 ± 0.2 | 1.6 ± 0.2 | 94.5 ± 3.6 | 1.265 ± 0.006 | 3.7 × 10−12 |

| PHBV_CW2300_10 | 32.7 ± 0.2 | 3.9 ± 0.1 | 1.7 ± 0.1 | 6.4 ± 0.3 | 1.9 ± 0.3 | 92.4 ± 3.8 | 1.269 ± 0.001 | 3.6 × 10−12 |

| PHBV_CW2000_5 | 38.4 ± 0.3 | 3.6 ± 0.1 | 2.2 ± 0.1 | 6.9 ± 0.4 | 1.6 ± 0.2 | 83.2 ± 2.4 | 1.255 ± 0.002 | 5.0 × 10−12 |

| PHBV_CW2000_10 | 33.0 ± 0.1 | 4.0 ± 0.1 | 1.7 ± 0.1 | 6.3 ± 0.2 | 1.6 ± 0.2 | 94.5 ± 3.6 | 1.265 ± 0.006 | 3.7 × 10−12 |

| PHBV_CW2000_15 | 34.1 ± 0.2 | 4.6 ± 0.1 | 1.4 ± 0.1 | 6.5 ± 0.4 | 1.6 ± 0.3 | 104.5 ± 4.2 | 1.273 ± 0.004 | 8.7 × 10−12 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Unterweger, C.; Ranzinger, M.; Duchoslav, J.; Piana, F.; Pasti, I.; Zeppetzauer, F.; Breitenbach, S.; Stifter, D.; Fürst, C. Electrically Conductive Biocomposites Based on Poly(3-hydroxybutyrate-co-3-hydroxyvalerate) and Wood-Derived Carbon Fillers. J. Compos. Sci. 2022, 6, 228. https://doi.org/10.3390/jcs6080228

Unterweger C, Ranzinger M, Duchoslav J, Piana F, Pasti I, Zeppetzauer F, Breitenbach S, Stifter D, Fürst C. Electrically Conductive Biocomposites Based on Poly(3-hydroxybutyrate-co-3-hydroxyvalerate) and Wood-Derived Carbon Fillers. Journal of Composites Science. 2022; 6(8):228. https://doi.org/10.3390/jcs6080228

Chicago/Turabian StyleUnterweger, Christoph, Matija Ranzinger, Jiri Duchoslav, Francesco Piana, Igor Pasti, Franz Zeppetzauer, Stefan Breitenbach, David Stifter, and Christian Fürst. 2022. "Electrically Conductive Biocomposites Based on Poly(3-hydroxybutyrate-co-3-hydroxyvalerate) and Wood-Derived Carbon Fillers" Journal of Composites Science 6, no. 8: 228. https://doi.org/10.3390/jcs6080228

APA StyleUnterweger, C., Ranzinger, M., Duchoslav, J., Piana, F., Pasti, I., Zeppetzauer, F., Breitenbach, S., Stifter, D., & Fürst, C. (2022). Electrically Conductive Biocomposites Based on Poly(3-hydroxybutyrate-co-3-hydroxyvalerate) and Wood-Derived Carbon Fillers. Journal of Composites Science, 6(8), 228. https://doi.org/10.3390/jcs6080228